Patents

Literature

47results about How to "Reduce external surface temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous contamination resistant heat reflection phase change insulating paint and its preparing process

InactiveCN101481583AReliable heat and heat insulation effectStrengthen heat protection effectFireproof paintsReflecting/signal paintsCoating systemReflectivity

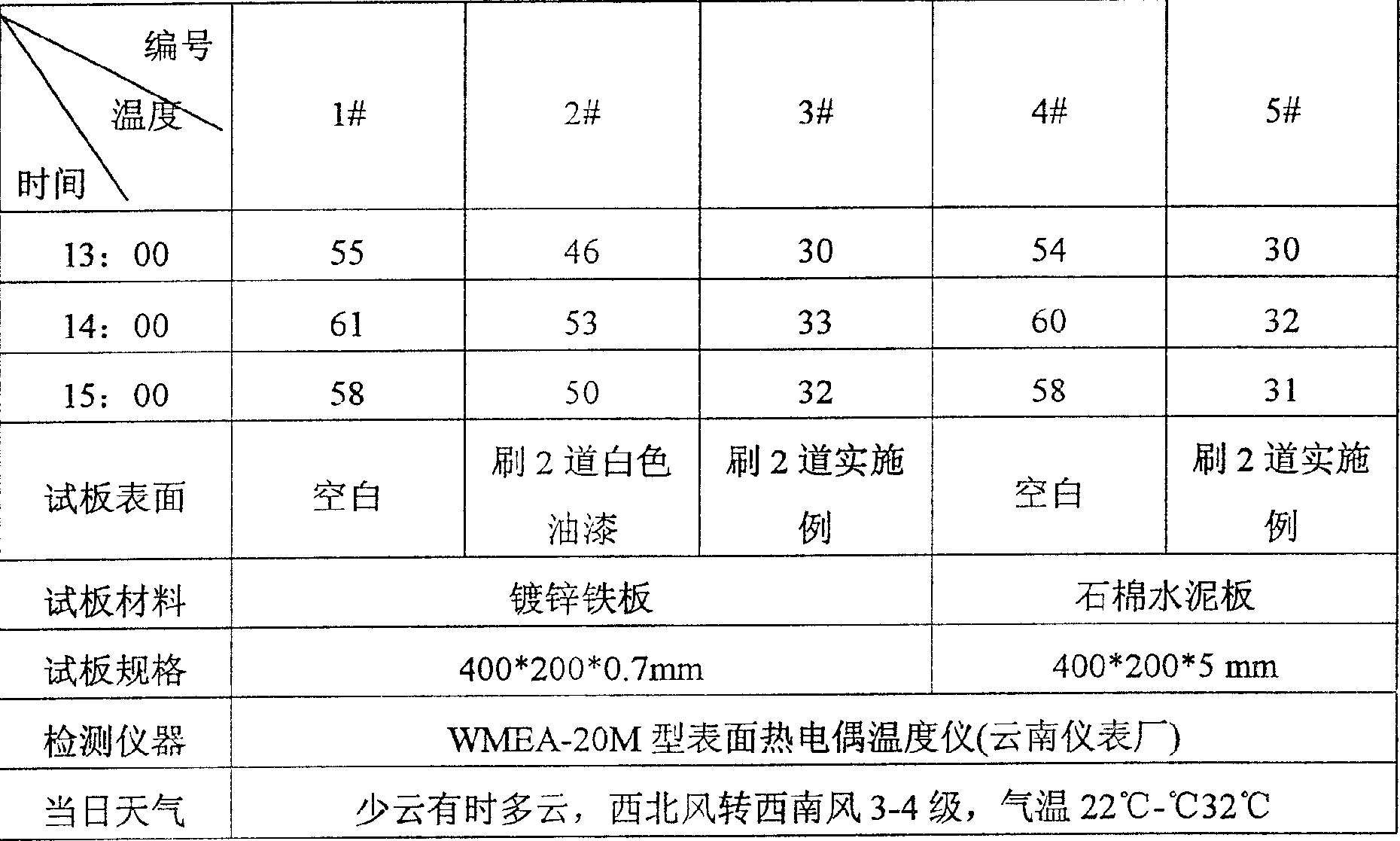

The invention relates to a water-base soil resistant heat-reflecting phase-changing thermal insulating coating system and a preparation method thereof. The coating system is composed of a reflected radiation top coat and a phase-changing thermal insulating primary coat. The top coat mainly comprises a film forming matter, a heat-reflecting paint, an infrared-emitting padding and hollow glass microballoons. The visible light reflectivity is 95%, the all-band reflectivity is 87%, the reflectivity of 3 to 5 microns is 0.92, and the reflectivity of 8 to 13.5 microns is 0.93%. In five times of cycle, the soil resistance is 10%. The primary coat is mainly composed of a film forming matter, phase-changing microballoons, hollow glass microballoons and expanded perlite. The primary coat is 3mm+ in thickness, and the top coat is 60 to 80 microns in thickness; when the temperature of the thermal surface reduces 15 to 20 DEG C, the temperature of the back surface reduces 8 to 15 DEG C.

Owner:BEIHANG UNIV

Multifunctional energy-saving coating for building

InactiveCN1706899AReduce the temperatureReduce running timeCoatingsConservation energySynthetic resin

The present invention is multifunctional energy-saving coating for building, and relates to chemical material for building and heat insulating, building protecting, energy saving, environment protection and other technology. The present invention is paint prepared with synthetic resin as filming material, heat insulating material, pigment, stuffing, assistant, pH regulator, water and other components, and through grinding, dispersing, blending, filtering and other steps. The paint has the features of being non-inflammable, non-toxic and pollution-less, and can form film on the outside of building for decoration, protection, heat insulating, saving energy and protecting environment.

Owner:孙成勋

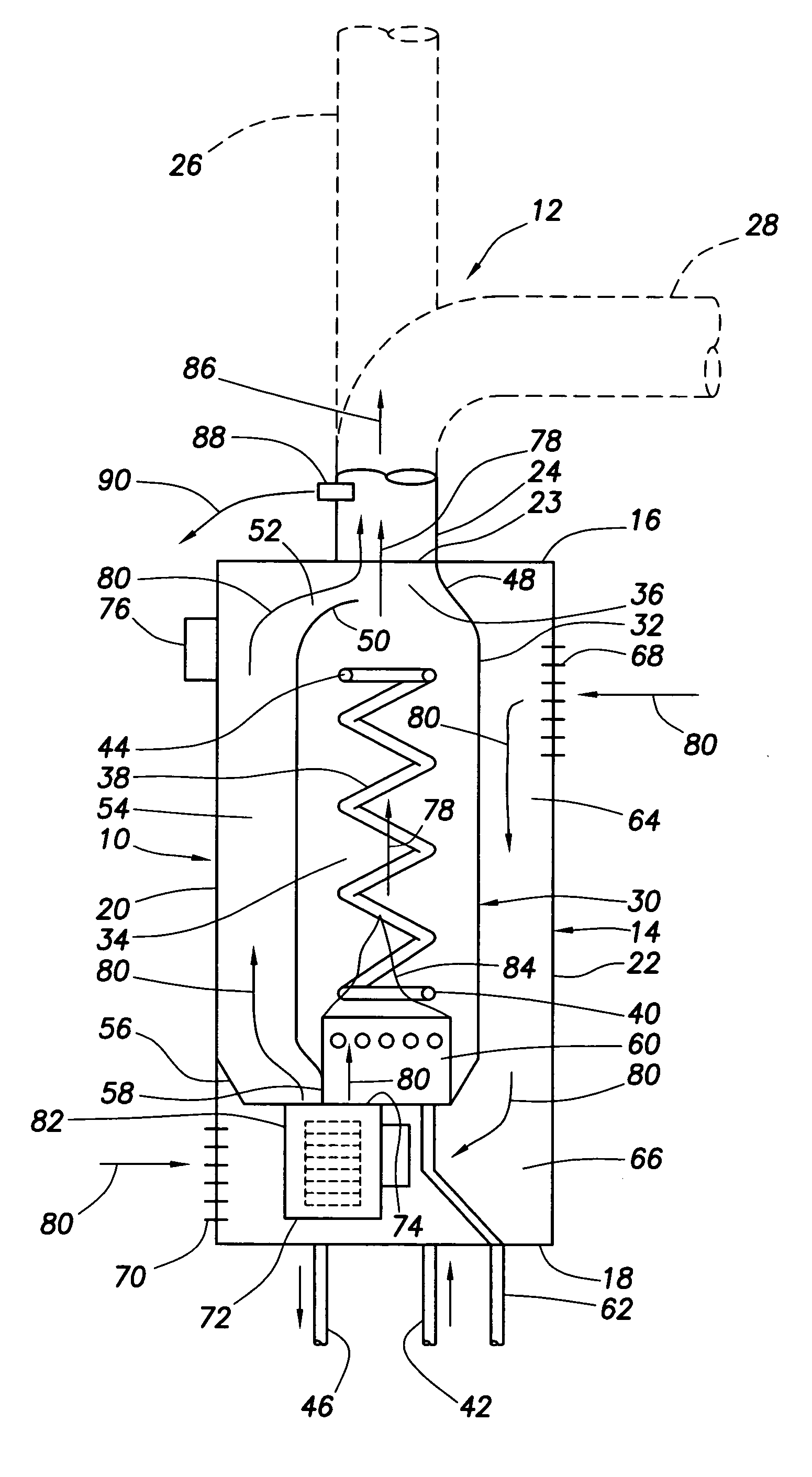

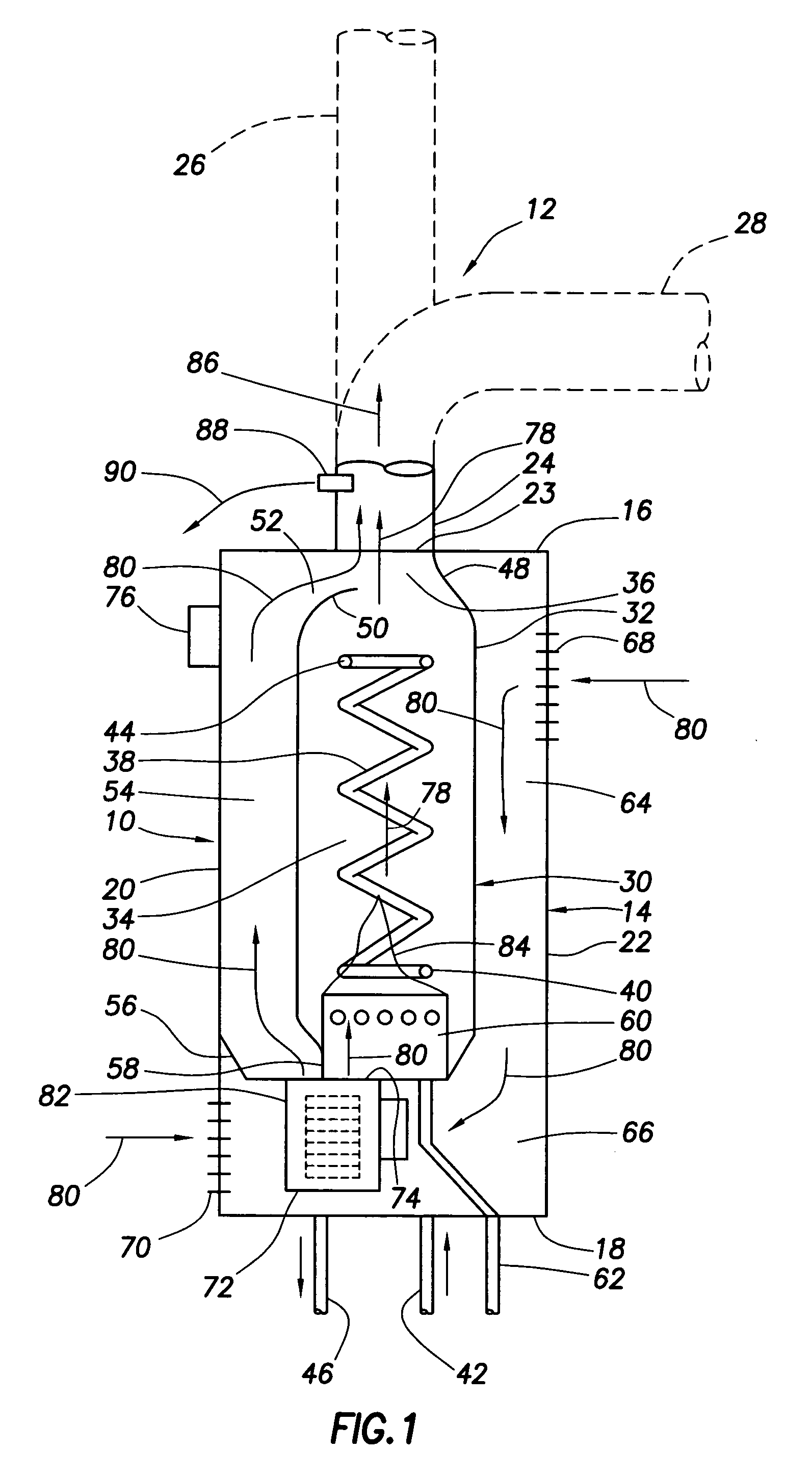

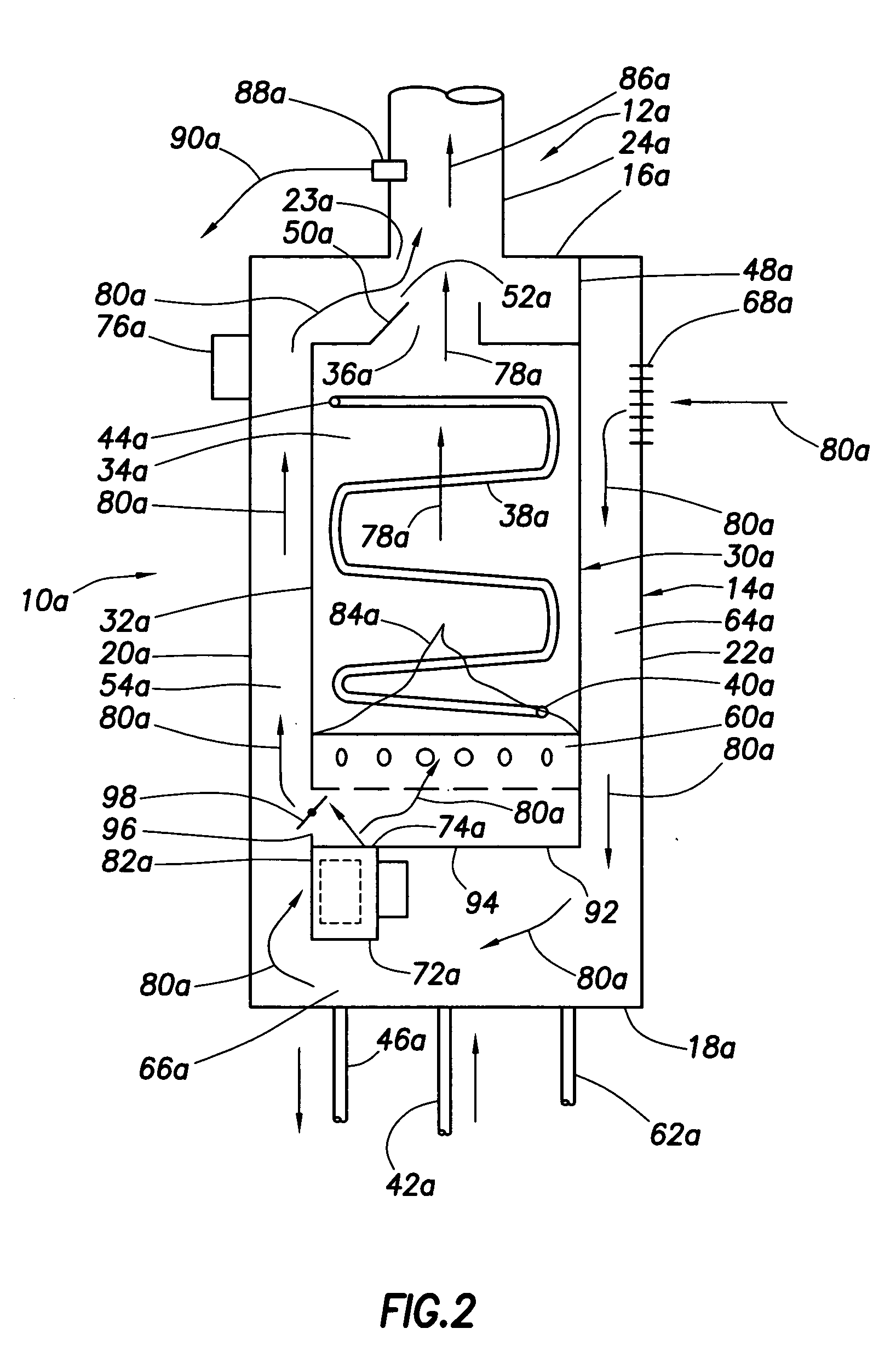

Instantaneous fuel-fired water heater with low temperature plastic vent structure

ActiveUS7337752B2Low costReduce the temperatureSpace heating and ventilation detailsFlash steam boilersCombustorPlastic materials

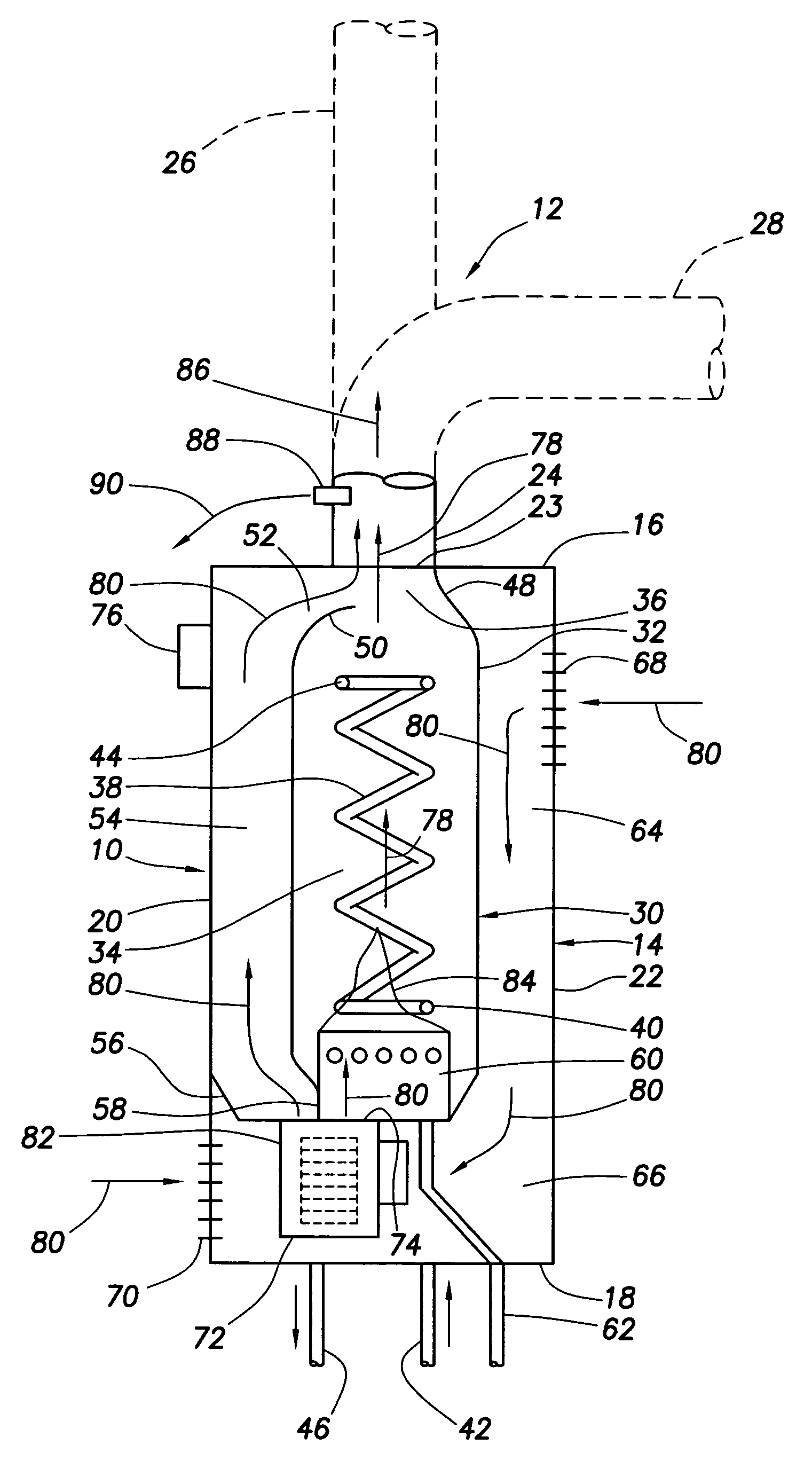

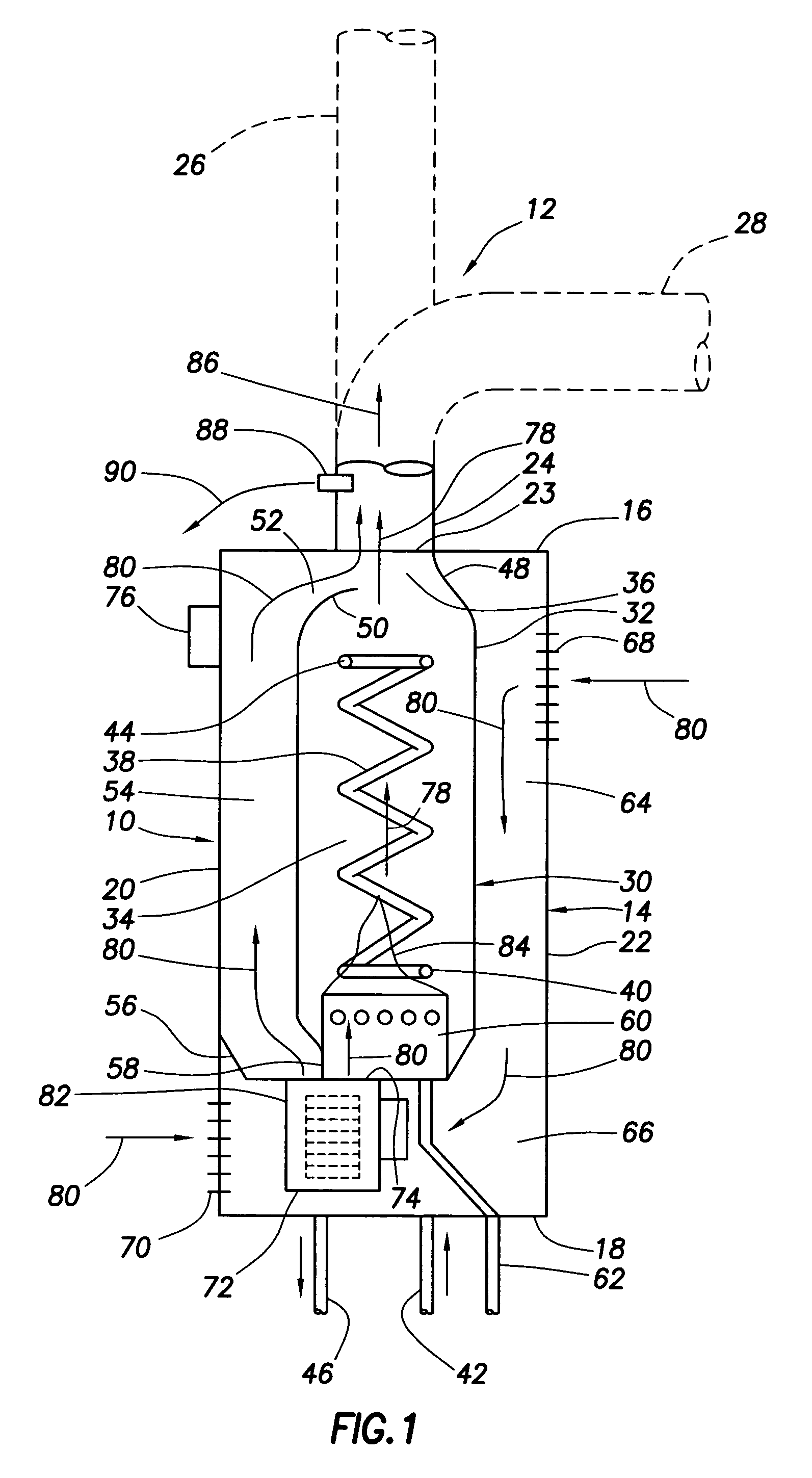

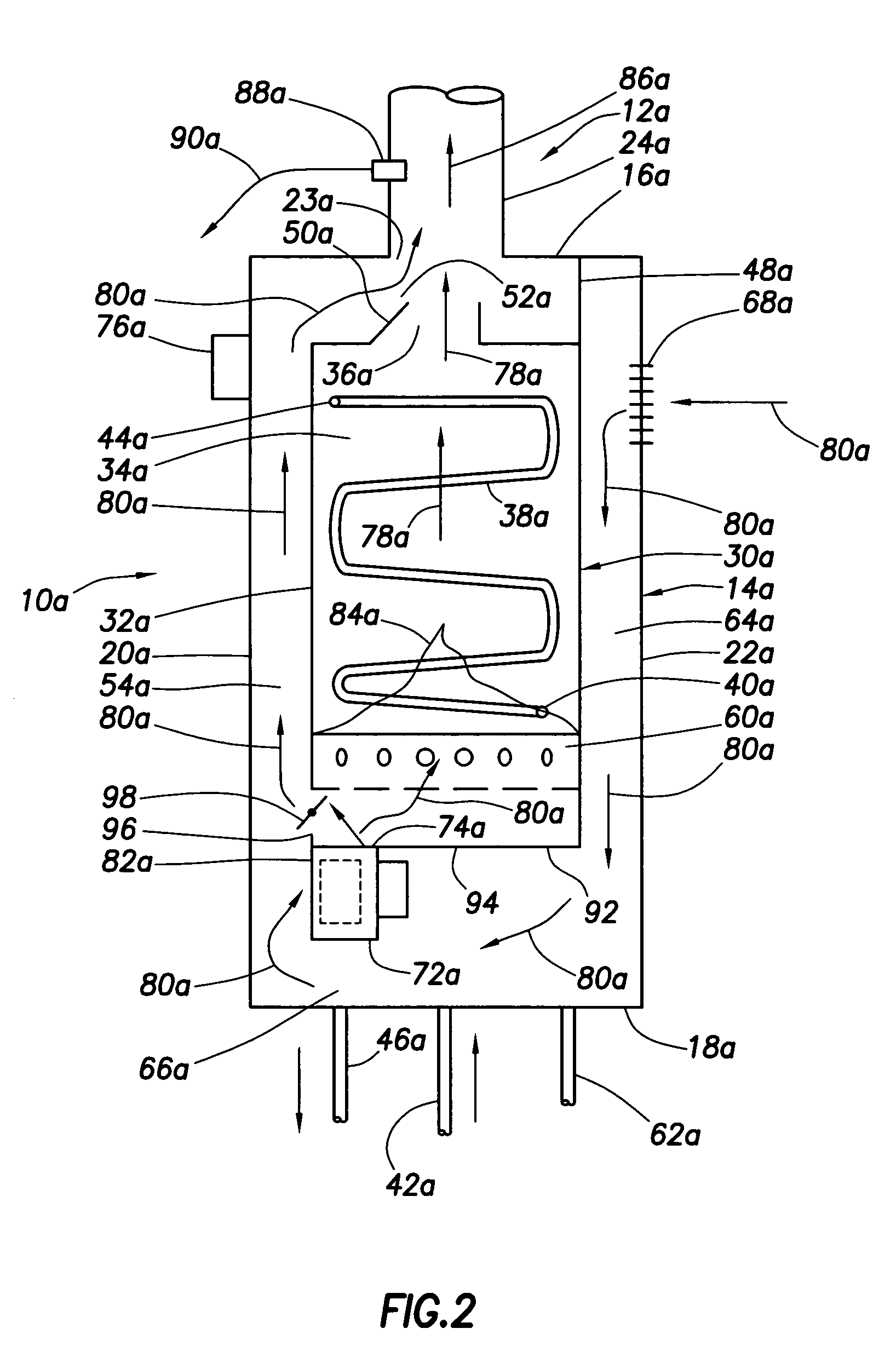

An instantaneous type fuel-fired water heater has a variable speed blower that discharges combustion air into a fuel burner utilized to heat water flowing through a heat exchanger portion of the water heater. A portion of the air discharged from the blower bypasses the burner and associated heat exchanger, flows around the heat exchanger, and then mixes with flue gases being discharged from the heat exchanger portion into the flue portion of the water heater. In this manner, such flue gases are cooled by the bypassing blower discharge air to an extent permitting the flue portion to be formed from a low cost plastic material instead of a high temperature metal material such as stainless steel.

Owner:RHEEM MFG CO

Instantaneous fuel-fired water heater with low temperature plastic vent structure

ActiveUS20070084420A1Low costReduce the temperatureSpace heating and ventilation detailsFlash steam boilersCombustorFlue gas

An instantaneous type fuel-fired water heater has a variable speed blower that discharges combustion air into a fuel burner utilized to heat water flowing through a heat exchanger portion of the water heater. A portion of the air discharged from the blower bypasses the burner and associated heat exchanger, flows around the heat exchanger, and then mixes with flue gases being discharged from the heat exchanger portion into the flue portion of the water heater. In this manner, such flue gases are cooled by the bypassing blower discharge air to an extent permitting the flue portion to be formed from a low cost plastic material instead of a high temperature metal material such as stainless steel.

Owner:RHEEM MFG CO

Production technology for polypropylene tubing containing beta crystal form

ActiveCN102516640AReduce external surface temperaturePrevent freezingRigid pipesWater coolingPolypropylene

The invention provides a production technology for a polypropylene tubing containing a beta crystal form, which comprises the following steps: mixing granulation, fusing plasticization, air precooling, water cooling and annealing. The K beta value of the polypropylene tubing produced by the production technology disclosed by the invention is more than 0.6, and the polypropylene tubing has favorable thermostability.

Owner:WUHAN KINGBULL ECONOMIC DEV

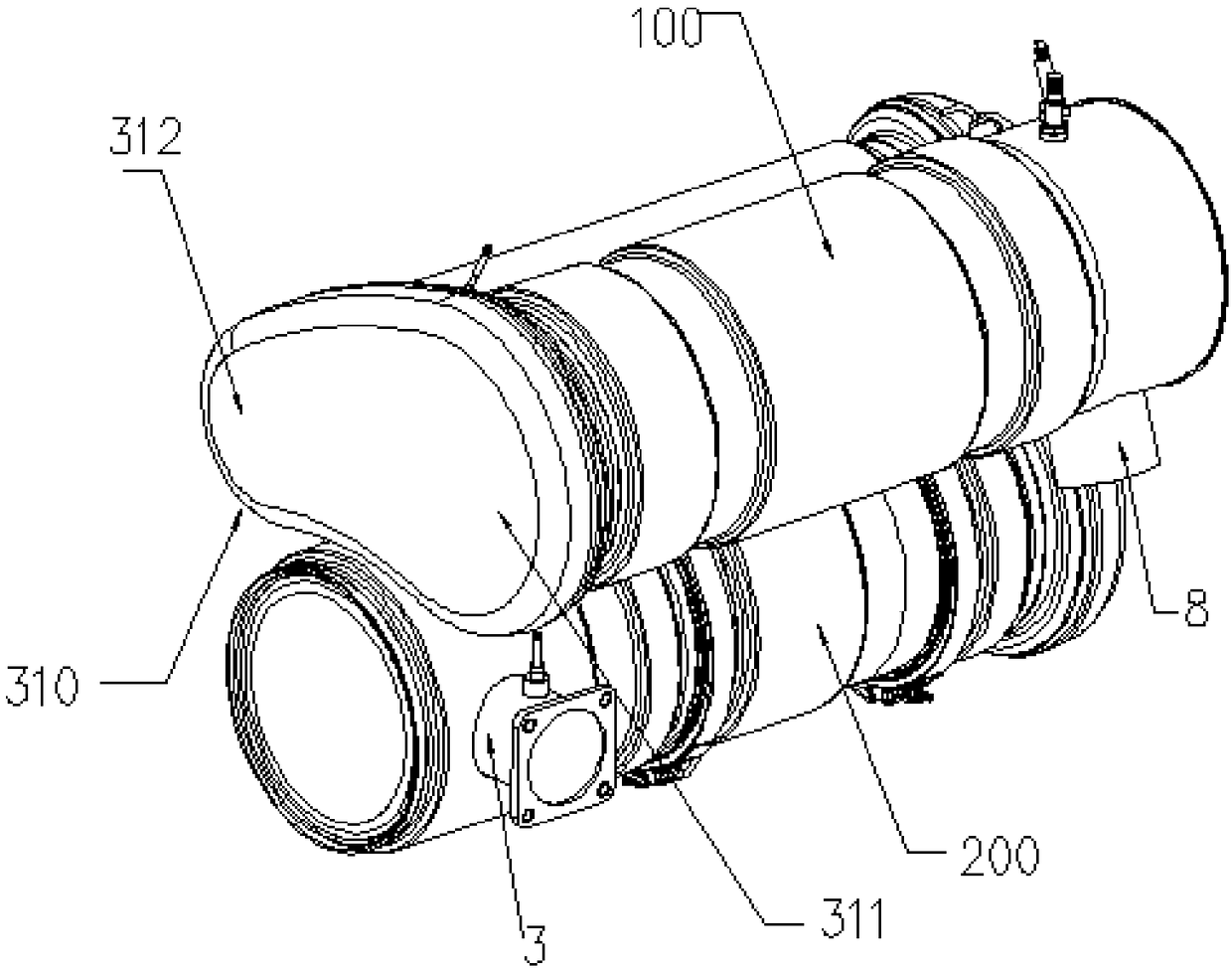

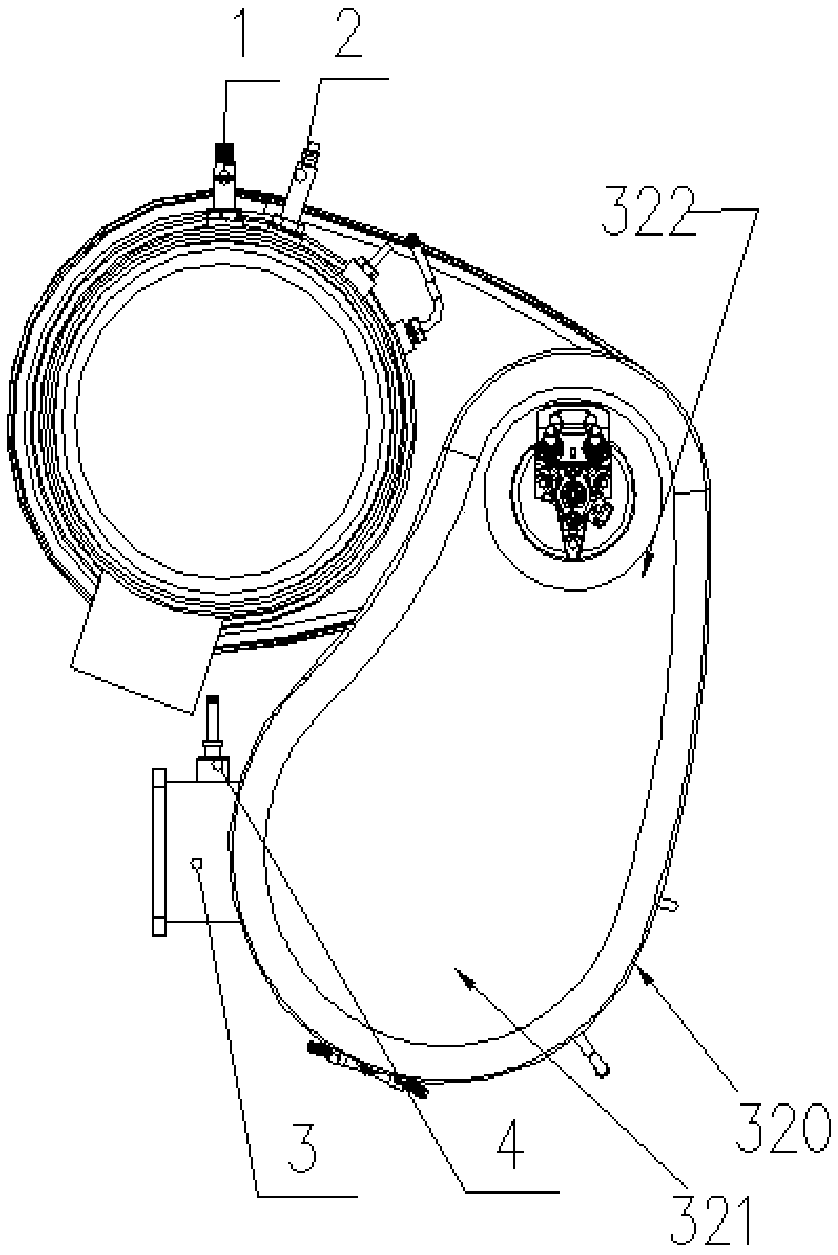

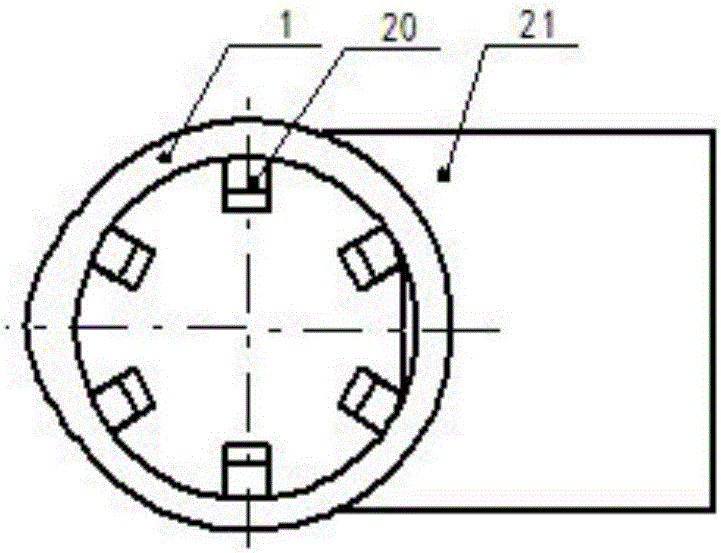

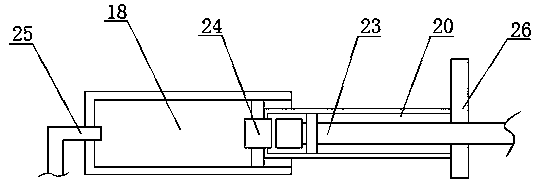

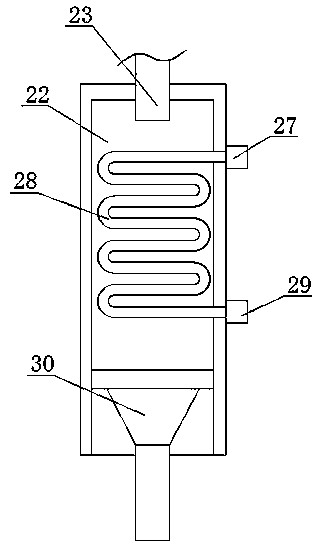

Parallel cylinder type aftertreatment structure assembly

InactiveCN108412593AImprove uniformitySafe Recycling GuaranteeInternal combustion piston enginesExhaust apparatusNitrogenNitrogen oxide

The invention relates to the field of diesel engine tail gas aftertreatment, in particular to a parallel cylinder type aftertreatment structure assembly. The parallel cylinder type aftertreatment structure assembly comprises a first cylinder, a second cylinder, and a connecting pipe for connecting the two cylinders; a first-grade SCR carrier and a second-grade SCR carrier are mounted in the firstcylinder in sequence; a small-head end of a right end cover is welded with the other end of the connecting pipe, and a large-head end is connected with one end of the second cylinder; an intake end cover is arranged at the other end of the second cylinder; the outer wall of the second cylinder is of a segmented structure, and all the sections are connected through hoops; and a DPF carrier and a DOC carrier are arranged between the right end cover and the intake end cover in the second cylinder in sequence. A cyclone mixing pipe is arranged in the connecting pipe. DOC, DPF and SCR are integrated as an aftertreatment circuit; and urea water solution is used as a reducing agent for spraying into an exhaust system to decompose as ammonia in waste gas currents for reaction with nitric oxides under the effect of a catalyst to finally convert to harmless nitrogen and water so as to achieve the effect of purifying vehicle tail gas.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

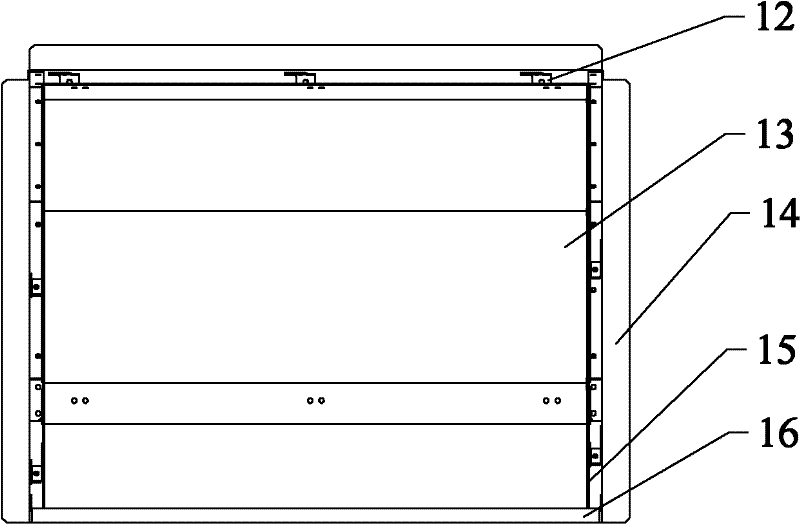

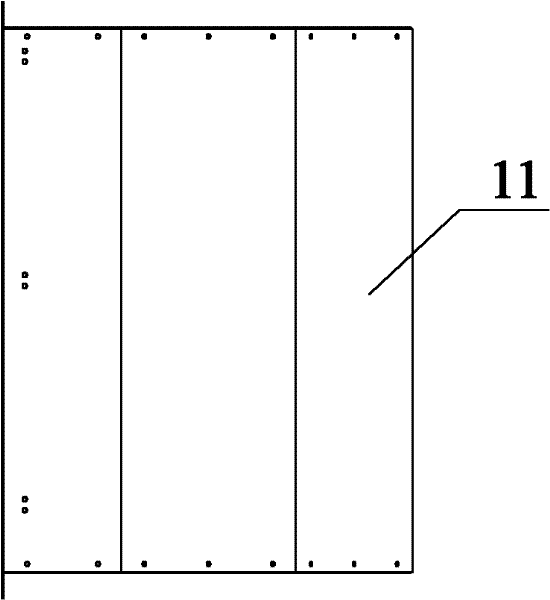

Energy-saving double-skin curtain wall

InactiveCN104963439ASimple structureEasy to useWallsLighting and heating apparatusNatural ventilationDevice form

Provided is an energy-saving double-skin curtain wall, comprising an internal layer glass and an external layer glass, an interlayer space is between the internal layer glass and the external layer glass and air-in-and-out devices are arranged on the upper side and the lower side of the internal layer glass and the external layer glass and are communicated with the interlayer space. The interlayer space and the air-in-and-out devices form airflow exchanging channels. The energy-saving double-skin curtain wall is simple in structure and convenient in use. Through the airflow exchanging channels, natural ventilation is realized and special equipment is not needed. The curtain wall is low in maintenance and operation costs.

Owner:ZHEJIANG JIEFANG DECORATION ENG

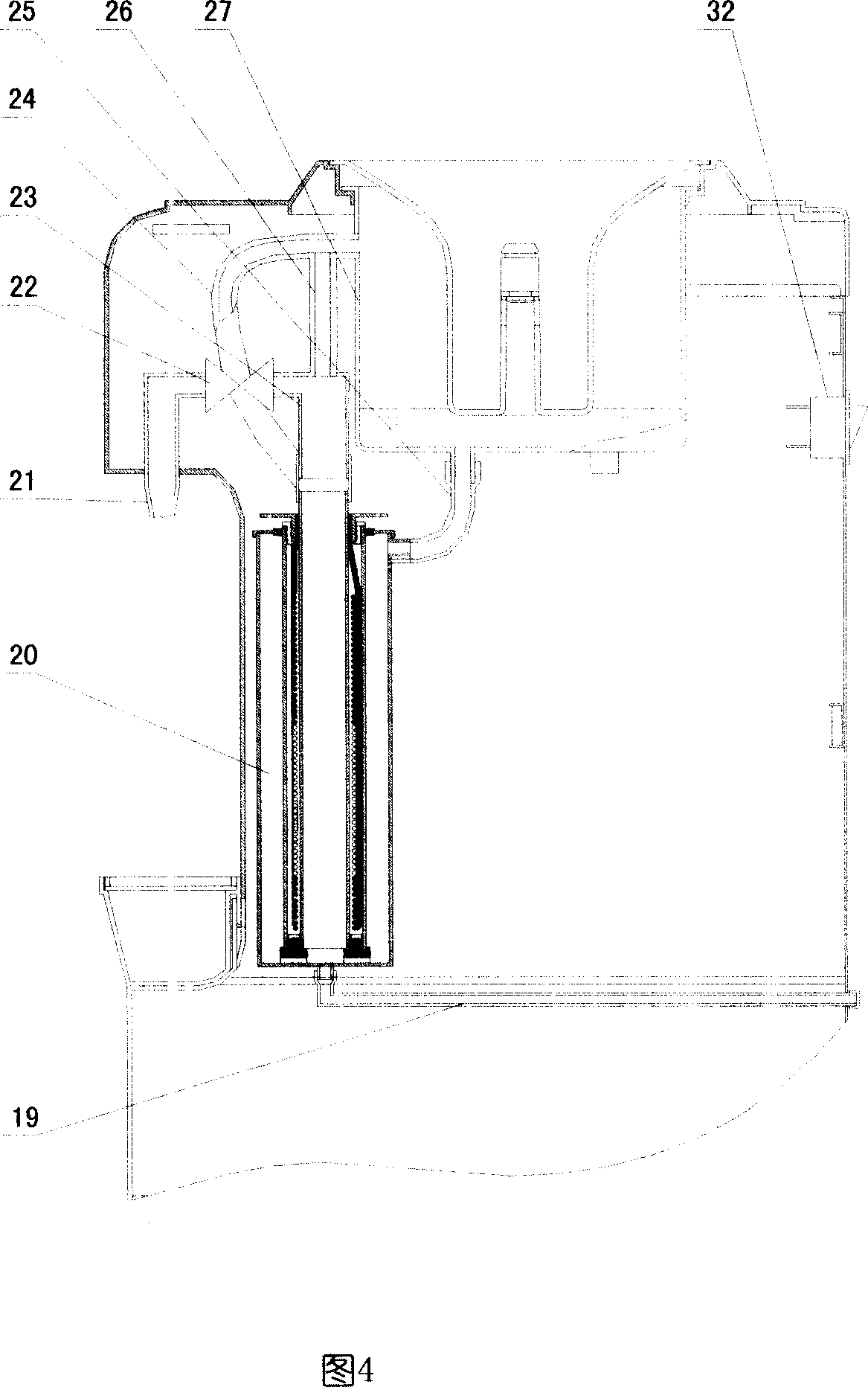

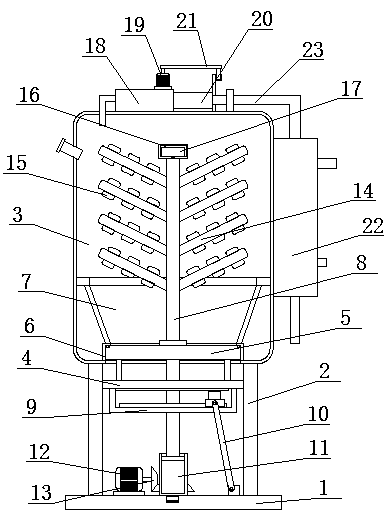

Heat quantity reclaiming type electric heater

An electric heater of heat recovery comprises a nonmetallic water pump, a heating element arranged outside the nonmetallic water pump, a water jacket arranged outside the heating element, the inner drum of the water jacket is sealed and connected with the water pump at lower end, the lower end of the outer drum of the water jacket is equipped with an end plate, a water inlet of a heater is arranged on the upper part of the water jacket, and the water outlet of the heater is the upper end open of the nonmetallic water pump. The electric heater is mainly matched with a water-drinking machine of no hot penetration for heating flowing drinking water, the invention is characterized by high water temperature, low temperature of the outer surface of the heater (about 50 DEG C), non fire threat, energy conservation, scale uneasily producing. The electric heater can be matched with other similar products for heating flowing sanitation liquor.

Owner:黄樟焱

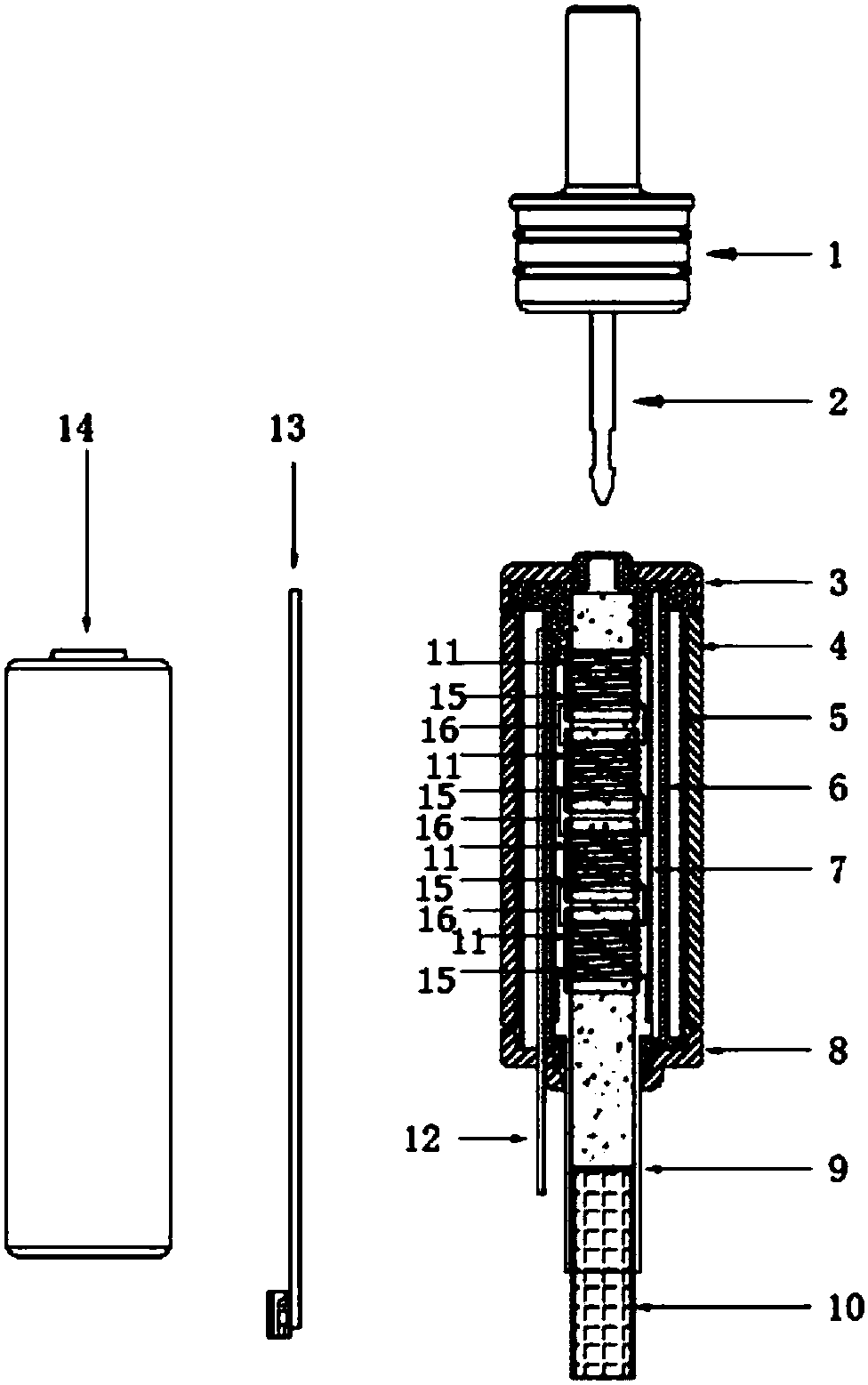

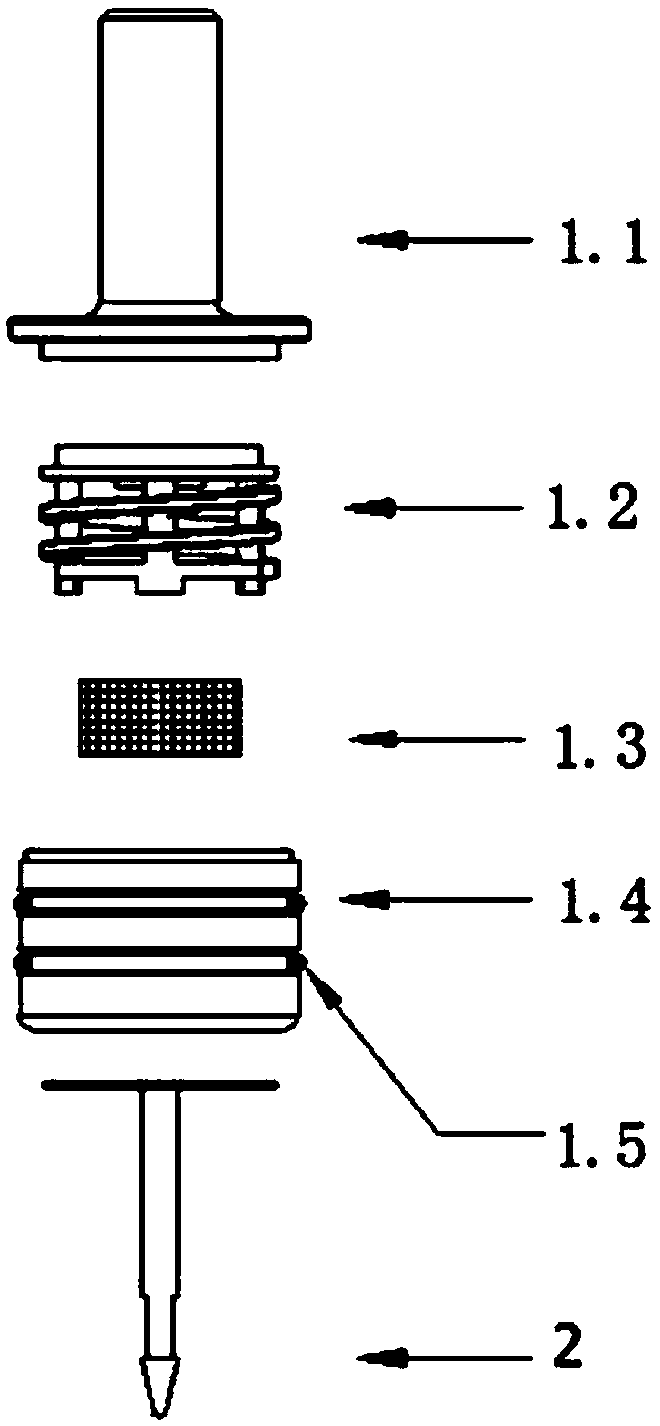

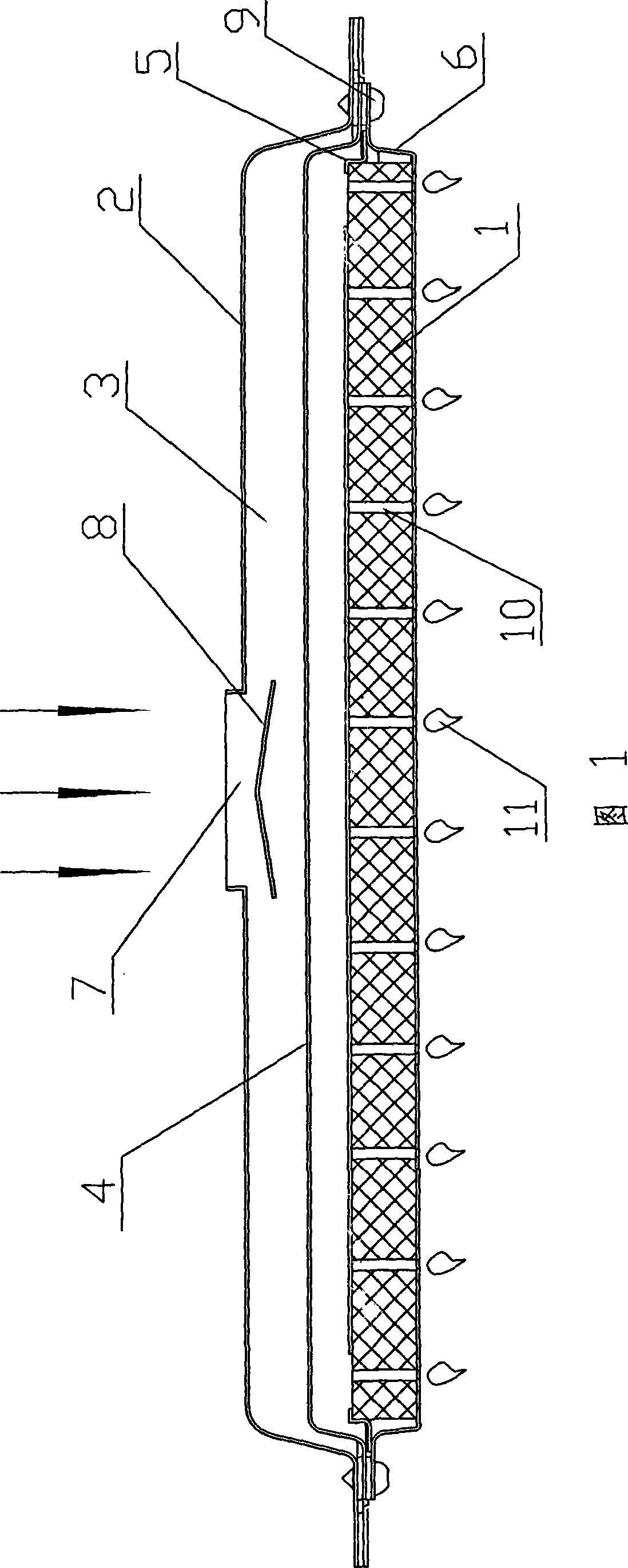

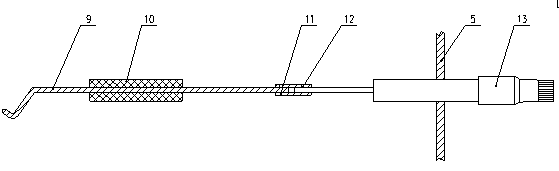

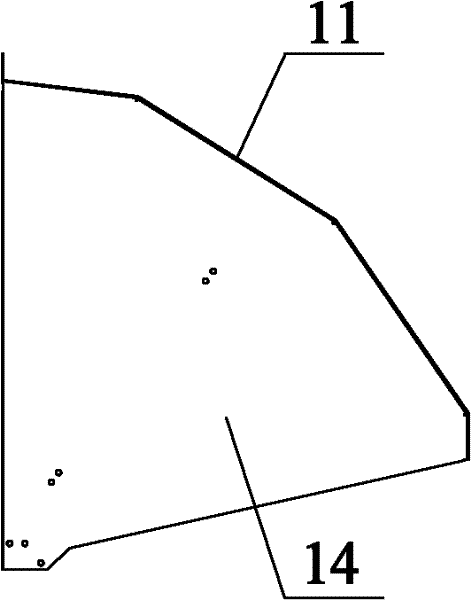

Heating smoking device of heat-not-burn tobaccos

InactiveCN107927911AImprove heating efficiencyReduce external surface temperatureTobacco devicesAlloyHeat not burn

The invention discloses a heating smoking device of heat-not-burn tobaccos. The heating smoking device comprises a heating main unit and a filtering and cooling device, wherein the heating main unit comprises high-temperature-resistant upper cover silicone, an outer aluminum-alloy pipe, a heat-insulation shell, an internal aluminum-alloy pipe, high-temperature-resistant lower cover silicone, a tobacco pipe, one or more heating pipes, a PCBA, a battery and one or more groups of heating wires; each heating pipe is provided with one group of heating wires, one heat-insulation pipe is installed between every two adjacent heating pipes, and each heat-insulation pipe is connected with the heating pipe at the upper end and the heating pipe at the lower end. The tobacco pipe is inserted into one or more heating pipes from the bottom, tobaccos are inserted into the tobacco pipe, and it is achieved that the tobaccos are heated without being burnt through the heating wires outside the heating pipes. In the heating smoking device, multiple groups of anodized aluminum-alloy pipes 11 (A, B, C and D) and multiple groups of PEEK heat-insulation pipes are combined to form a device for stepwise heating and smoking a cigarette, and when the tobaccos are heated stepwise, the heating efficiency is higher, and the temperature on the outer surface is lower.

Owner:SHENZHEN YUKAN TECH CO LTD

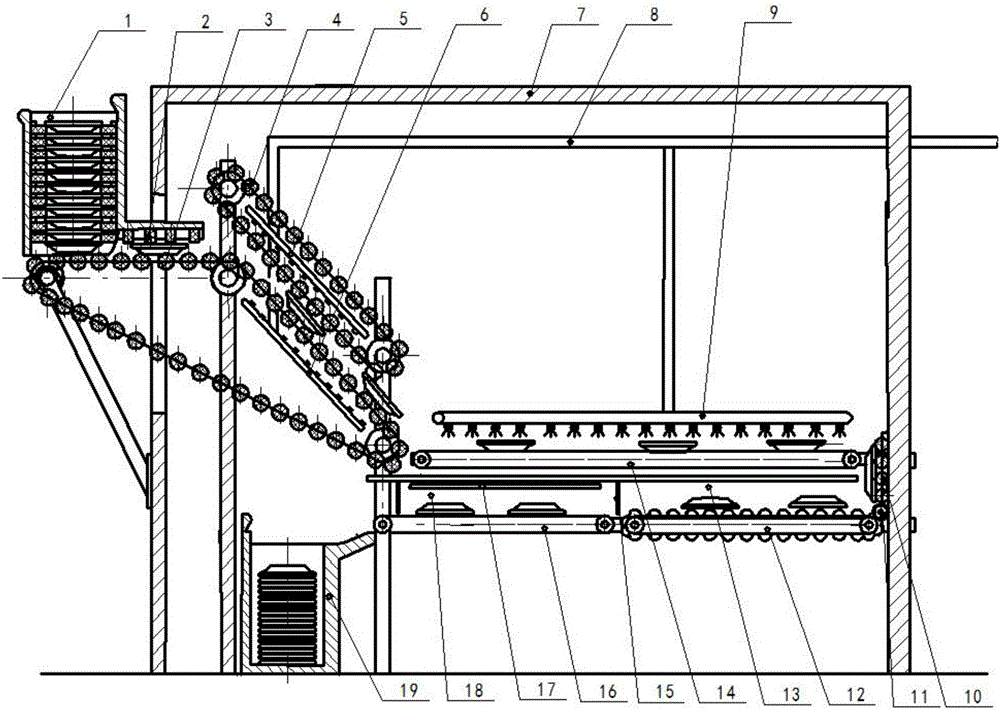

Vegetable sponge embedded intelligent transceiving dish washing system based on afterheat utilization

ActiveCN105078391AAvoid pollutionEliminate pollutionTableware washing/rinsing machine detailsWater resourcesPulp and paper industry

The invention relates to a vegetable sponge embedded intelligent transceiving dish washing system based on afterheat utilization. The vegetable sponge embedded intelligent transceiving dish washing system comprises a dinner plate storing device, an upper washing device, a lower washing device, a flushing device, a water absorbing, a drying and sterilizing device and a dinner plate collecting device all of which are fixedly arranged on a rack; vegetable sponge which is environmentally friendly and degradable, as well as low in price or other biomimetic materials with the cleaning function are adopted as the clean material, the characteristics of efficient oil sticking resistance, and tidiness in cleaning are utilized, the pollution to the environment caused by using dish washing powder existing in the traditional dish washing machine is avoided, and the harm of the residual dish washing powder to the human body is eliminated; meanwhile, clean water needed by flushing the dish washing powder is saved, thus a great deal of water resources is saved; in addition, the afterheat of the drying device is utilized for heating the cleaning water, so that the energy is saved, meanwhile, the washing effect is enhanced, compared with the mechanical scouring principle of the traditional dish washing machine, the vegetable sponge embedded intelligent transceiving dish washing system has the advantage of saving a great deal of water resources, and the pollution to the environment caused by using the dish washing powder is also eliminated.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

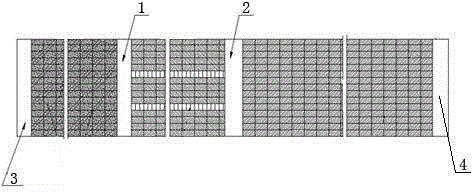

Hot-spinning cogging method based on nonuniform heating of aluminum alloy

InactiveCN105728537AIncrease internal temperatureReduce external surface temperatureShaping toolsMetallic materialsHardness

The invention belongs to the field of machining of metallic materials and particularly relates to a hot-spinning cogging method based on nonuniform heating of aluminum alloy. According to the method, a nonuniform heating way is adopted, so that the temperature of a mandrel and the temperature of a discharging ring are made higher than that of an aluminum alloy billet, and the temperature of the upper end of the aluminum alloy billet is higher than that of the lower end of the aluminum alloy billet. The metal fluidity in the aluminum alloy billet is good, and cracks caused by spinning tensile stress are avoided; the hardness and strength of the outer surface of the aluminum alloy billet are relatively high, the aluminum alloy billet is unlikely to adhere to a spinning roller, the surface quality of the hot-spun billet is good, and the generatrix of the billet is straight; and by the adoption of the method, the temperature of a hot-spinning deformation area can be well controlled, the surface quality of the billet which is hot-spun through the heating method is good, the rate of finished products is high, and the dimensional precision is high.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

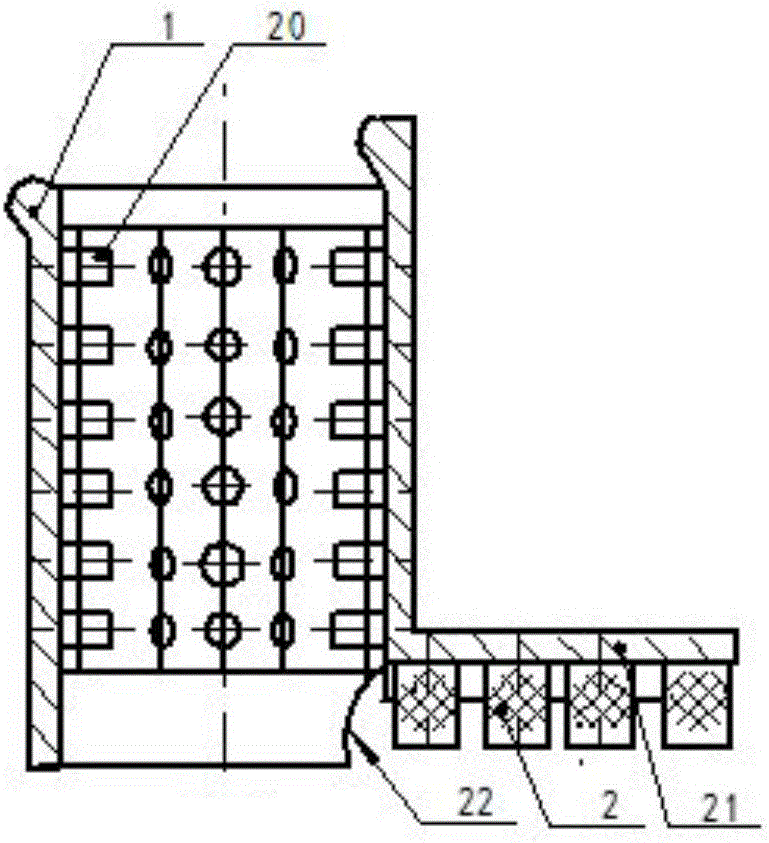

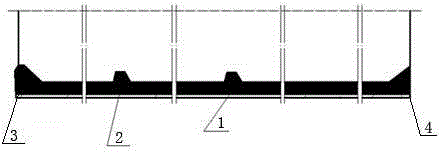

Castable kiln structure of cylindrical heat rotary equipment

Disclosed is a castable kiln structure of cylindrical heat rotary equipment. The castable kiln structure is characterized in that a kiln body is divided into a low-temperature feeding region, a high-temperature heat reaction region and an outlet and flow port. Retaining rings are arranged on regional boundaries of the low-temperature feeding region, the high-temperature heat reaction region and the outlet and flow port. The retaining rings protrude out of a kiln liner, so that the materials are enabled to turn over and change operation orbits through the retaining function of the protrusion height of the retaining rings when materials enter different temperature regions. The shortcomings that the kiln liner shaking during operation of a traditional bricked kiln liner to be separated from a steel casing to produce slip frequency with the same is free of overall strength, the kiln liner can be loosened and disintegrated instantly and cannot be maintained rapidly in a small range, and the like are effectively overcome, so that service life of the cylindrical kiln liner is prolonged by one to several times as compared with that of the bricked kiln liner, working cavities inside the kiln liner can be optionally changed according to technological requirements, damages to certain parts of the kiln liner do not cause affect to the service life of the whole kiln, and rapid maintenance in the small range can be achieved.

Owner:洛阳市洛华粉体工程特种耐火材料有限公司

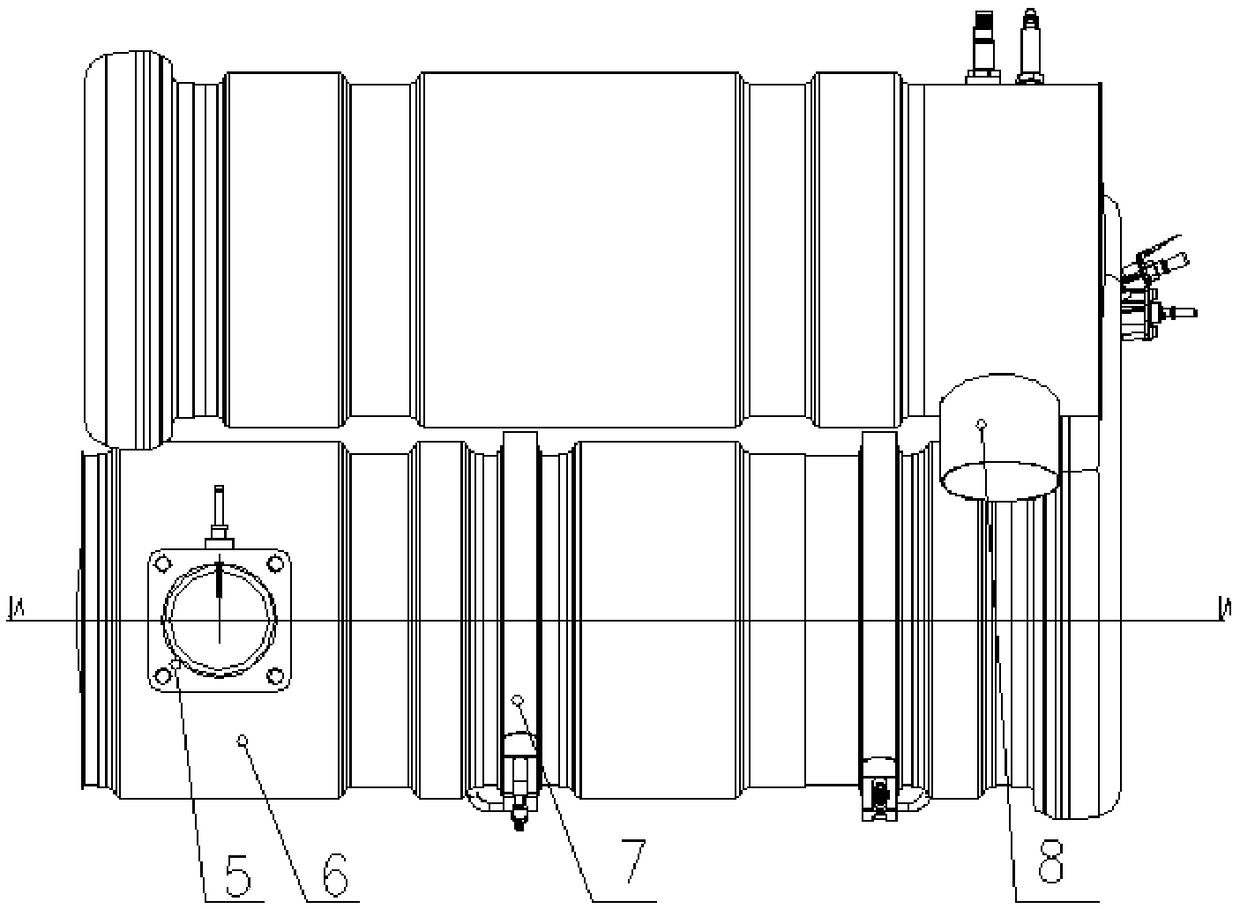

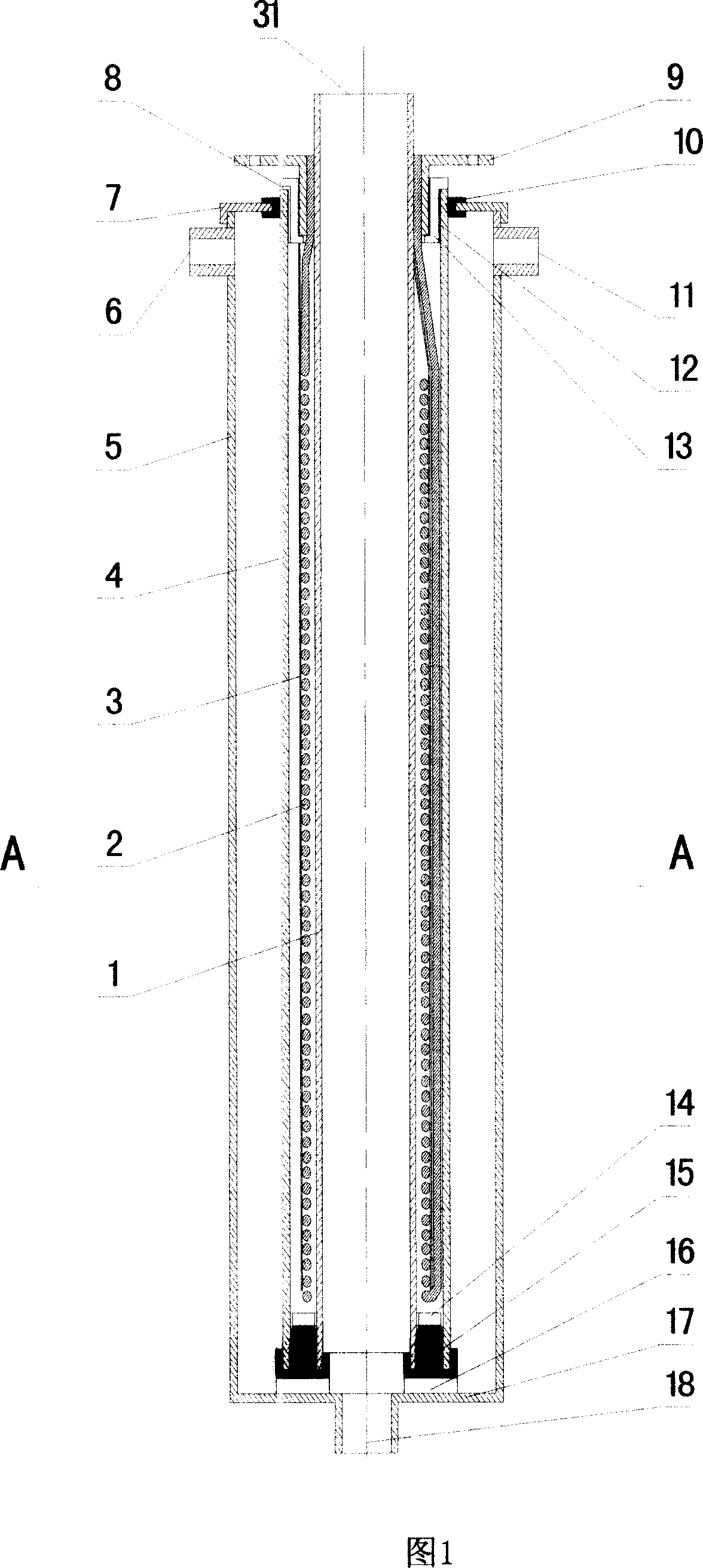

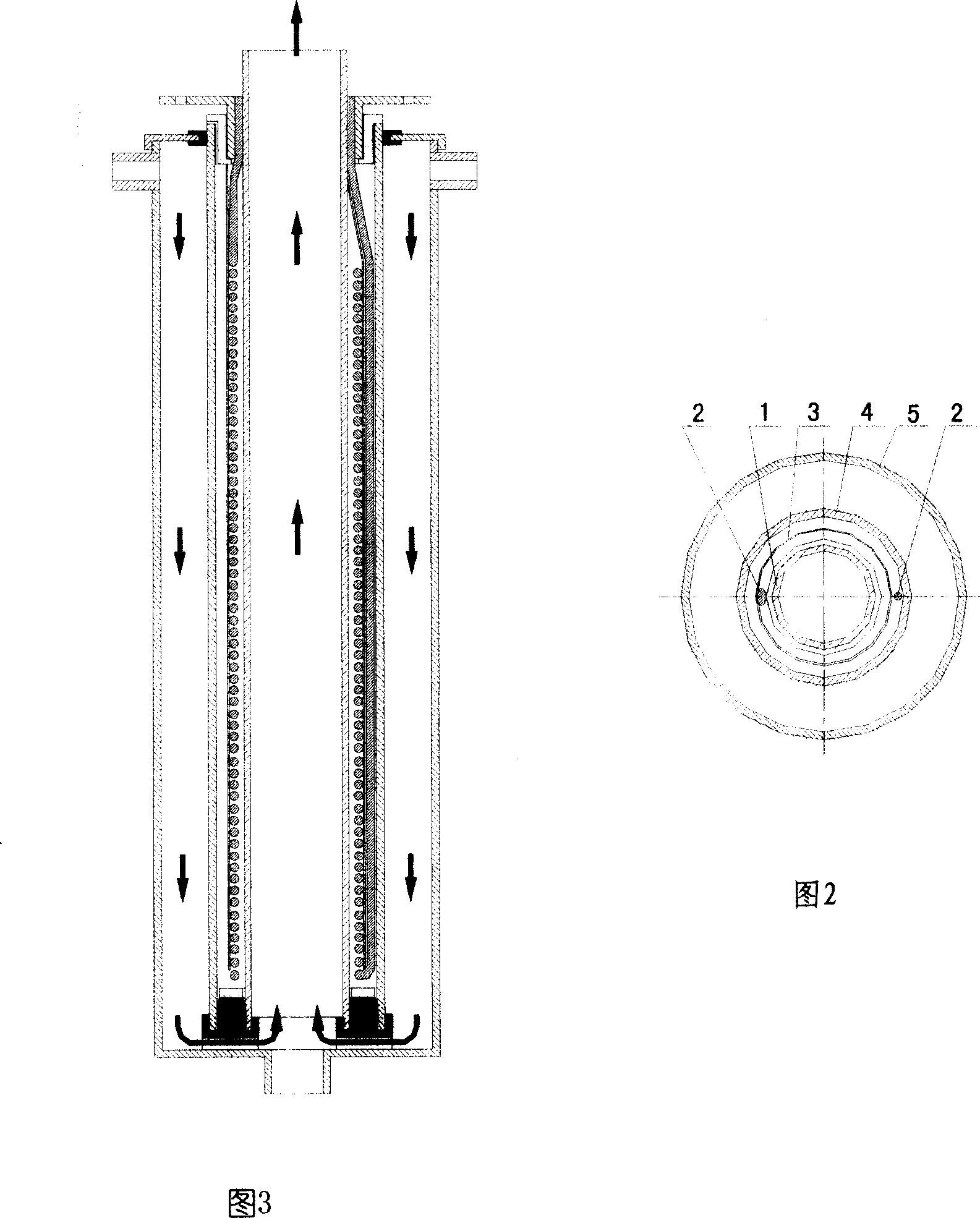

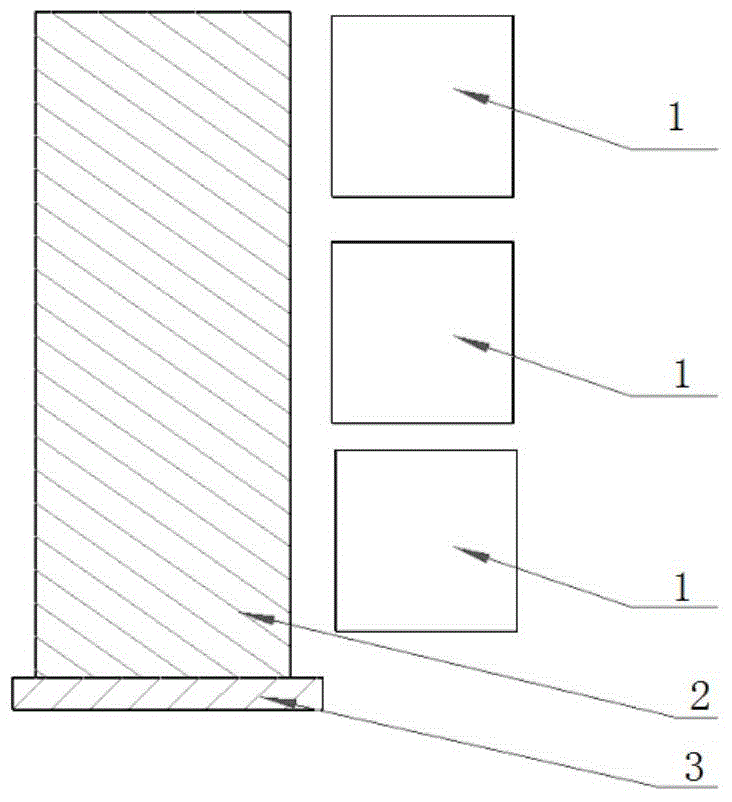

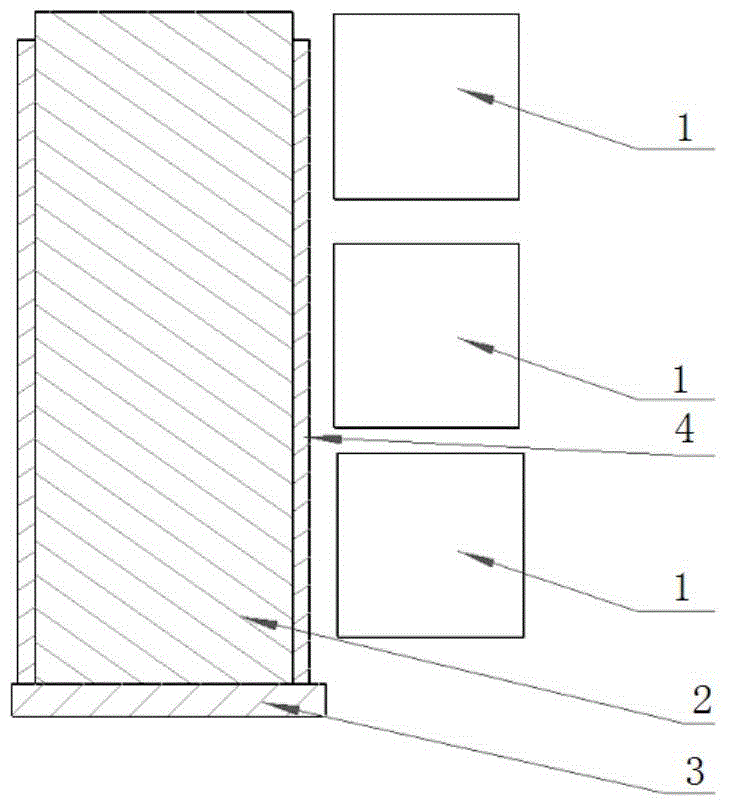

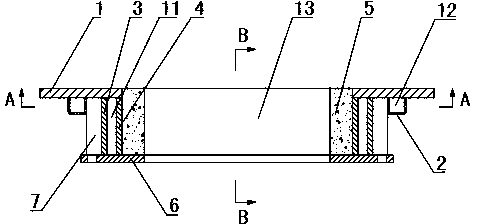

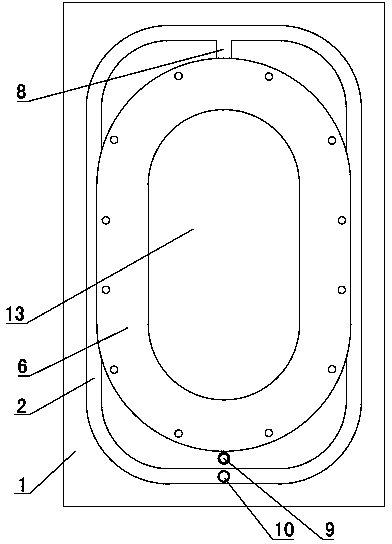

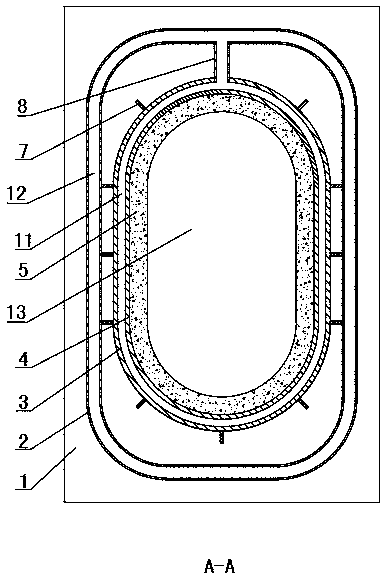

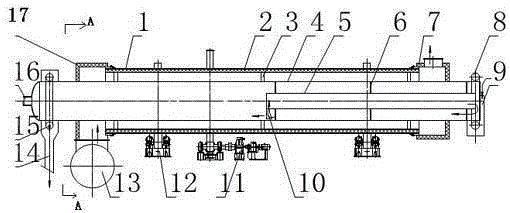

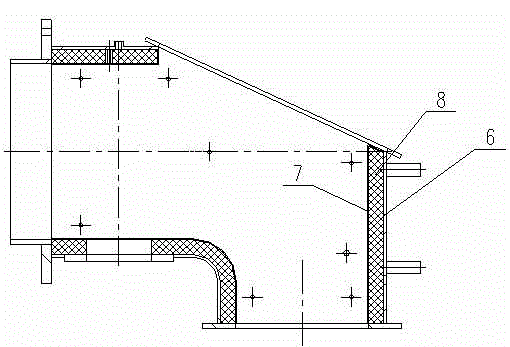

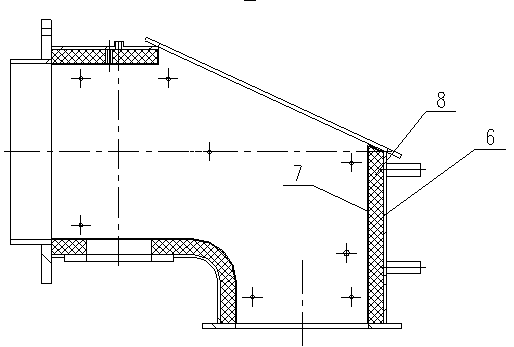

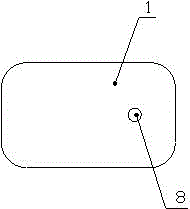

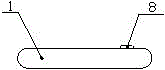

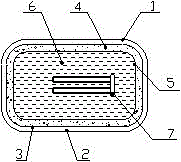

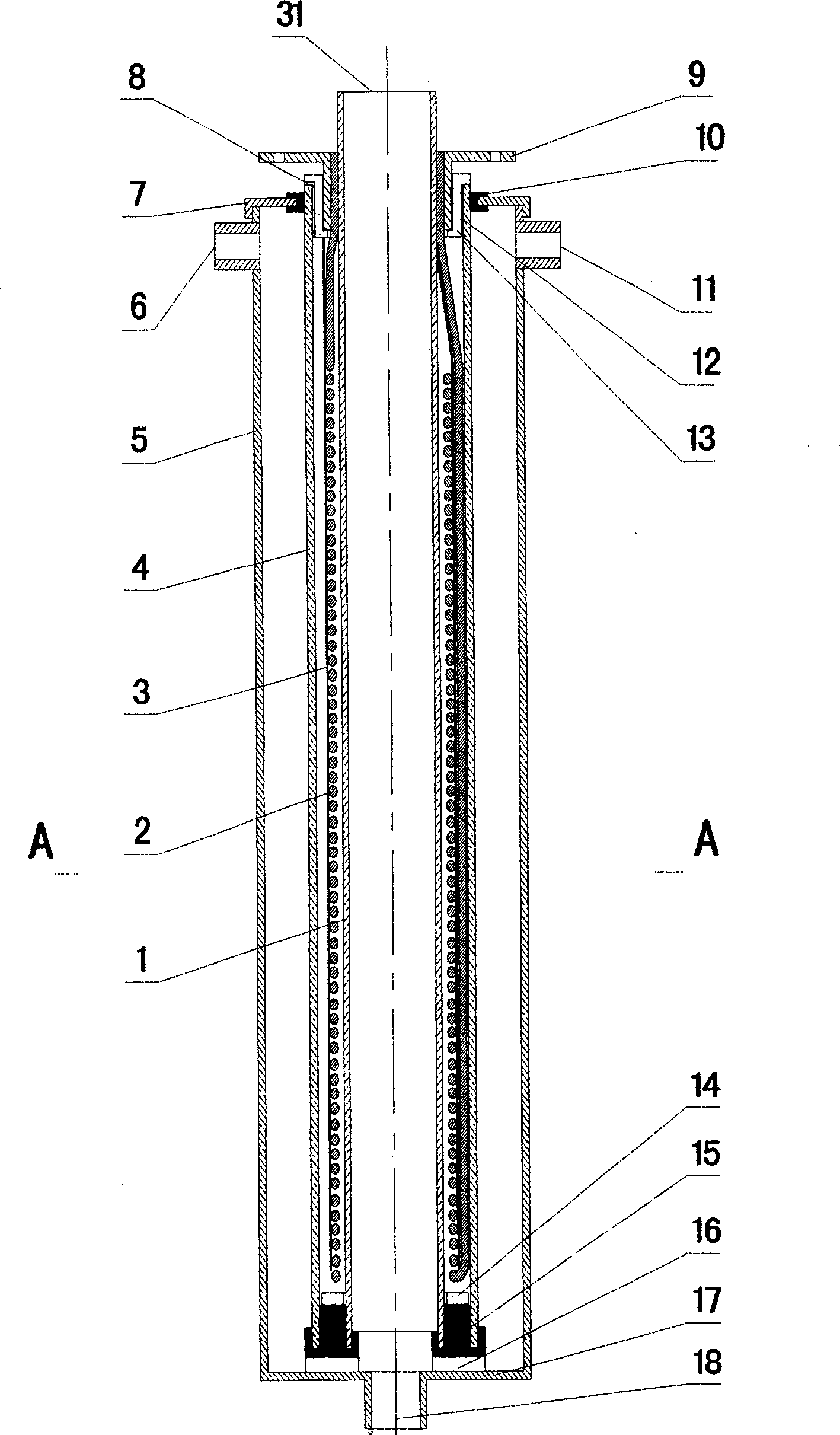

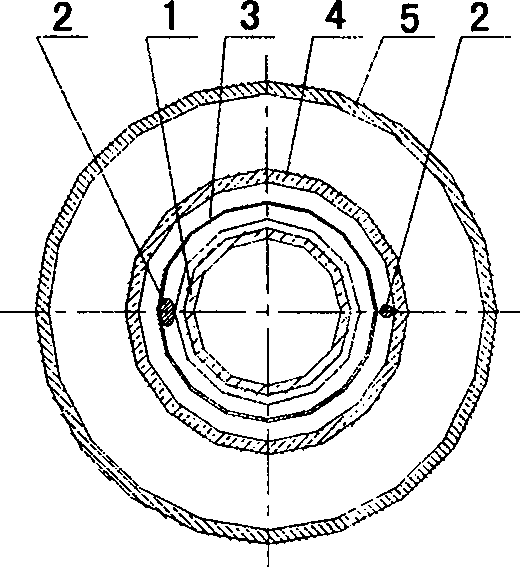

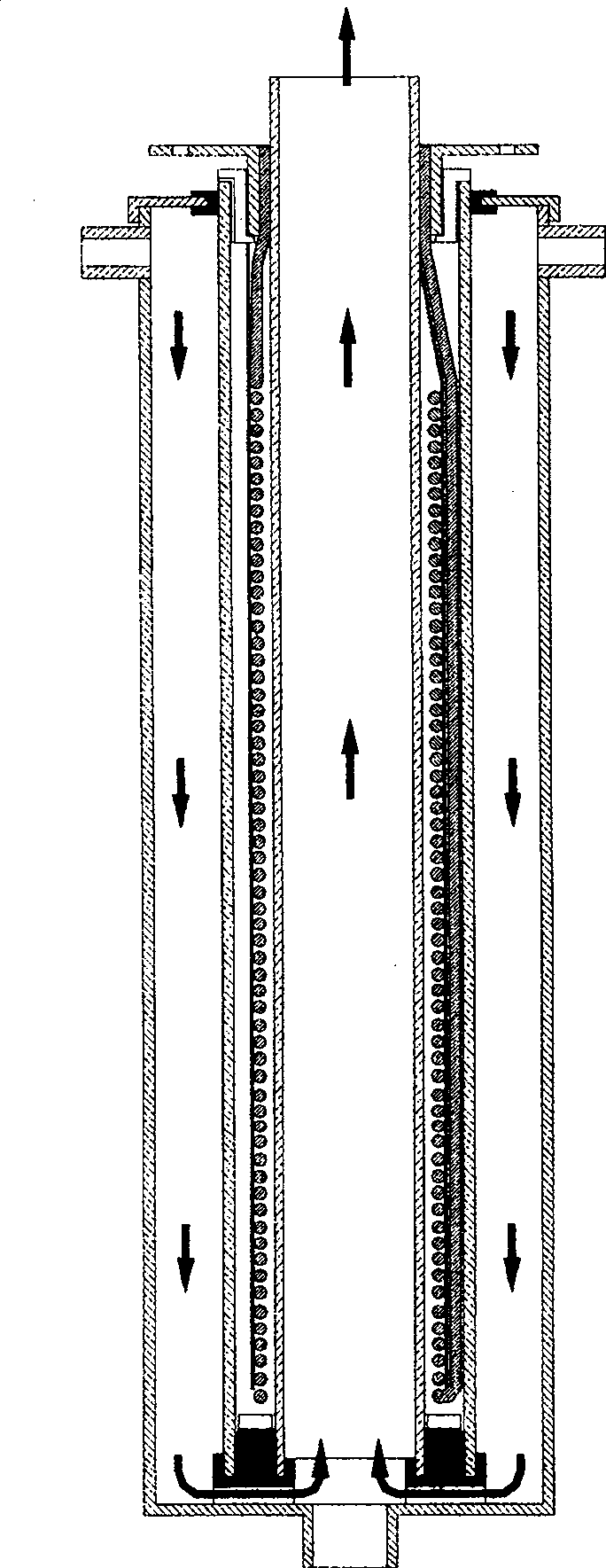

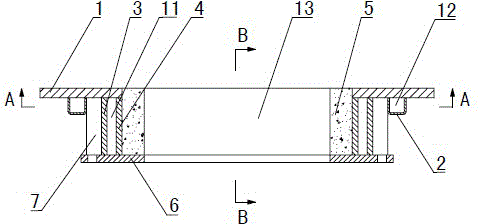

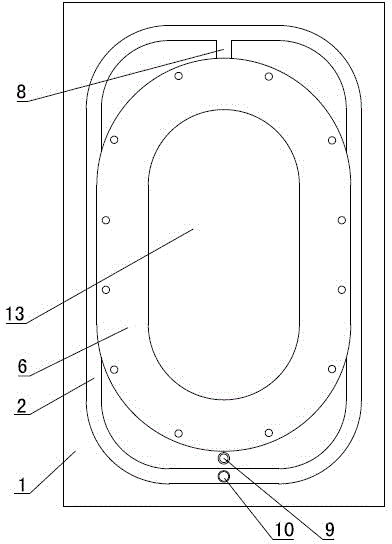

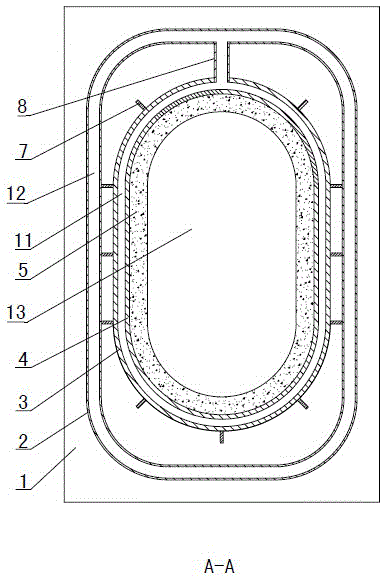

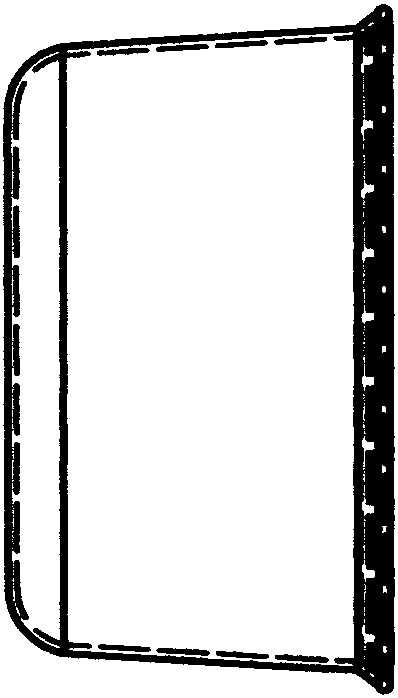

Water-cooling type hearth plate of petroleum coke tank-type calcining furnace

ActiveCN103615902AReduce the temperatureReduce external surface temperatureFurnace coolingHearthPetroleum coke

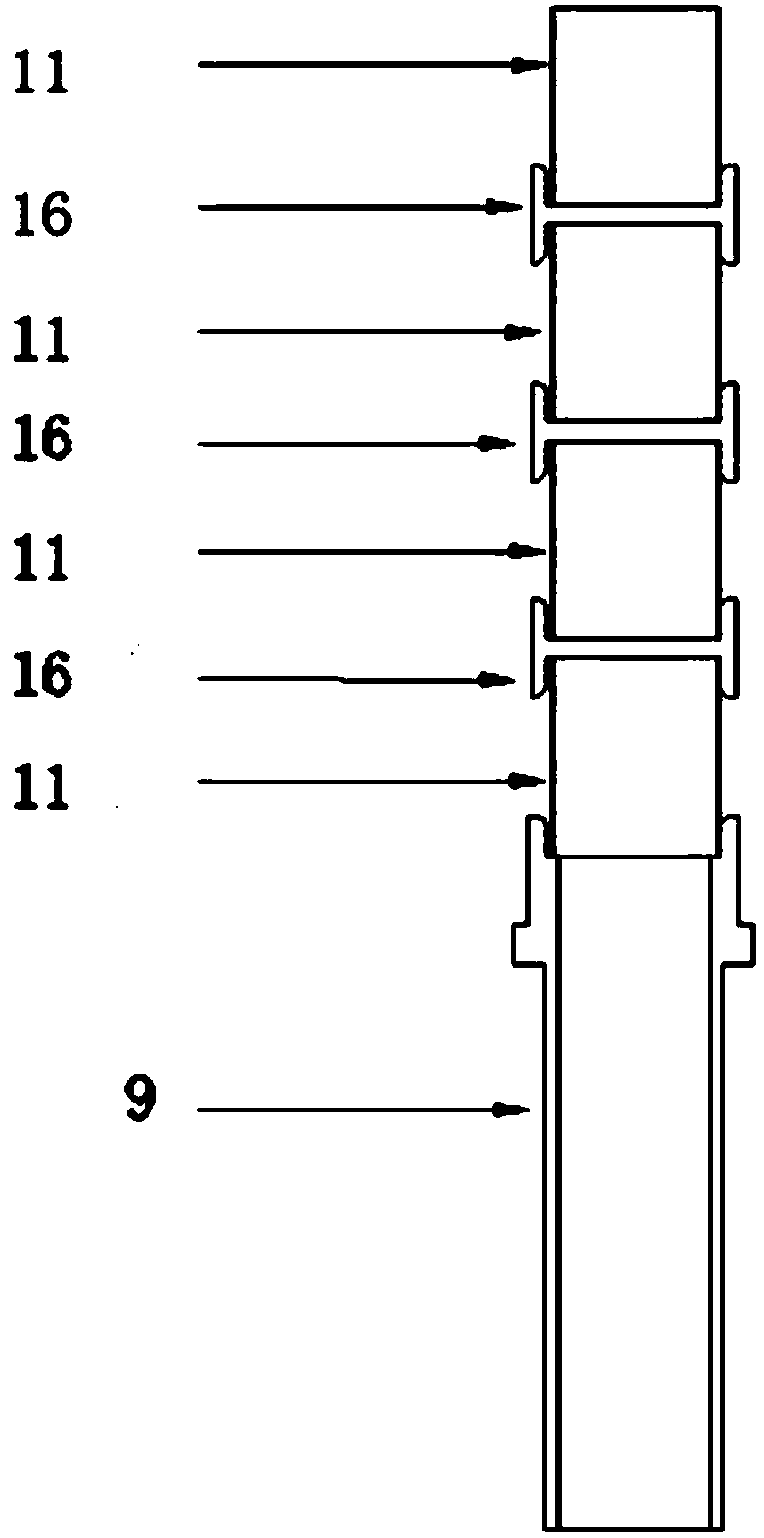

The invention discloses a water-cooling type hearth plate of a petroleum coke tank-type calcining furnace, and belongs to the technical field of petroleum coke tank-type calcining furnaces. An annular water sleeve inner plate (4) and an annular water sleeve outer plate (3) are fixedly connected between an upper flat plate (1) and a lower flange plate (6), the water sleeve inner plate (4), the water sleeve outer plate (3), the upper flat plate (1) and the lower flange plate (6) form a sealed annular cooling sleeve (11) in a surrounding mode, the lower end surface of the upper flat plate (1) is provided with an annular cooling half pipe (2) at the outer side of the water sleeve outer plate (3), the annular cooling half pipe (2) and the upper flat plate (1) form a sealed annular cooling water passage (12), the annular cooling water passage (12) is communicated with the annular cooling sleeve (11) through a connecting half pipe (8), and annular cooling water passage (12) is communicated with a water outlet pipe (10). The water-cooling type hearth plate of the petroleum coke tank-type calcining furnace has the advantages of lowering the temperature of the hearth plate, improving the work reliability of the hearth plate and the like.

Owner:SHANDONG UNIV OF TECH

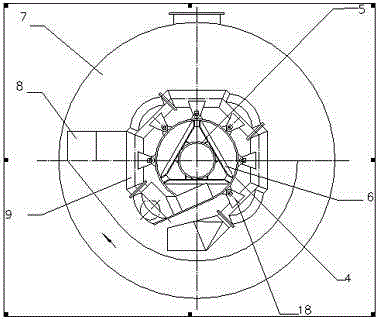

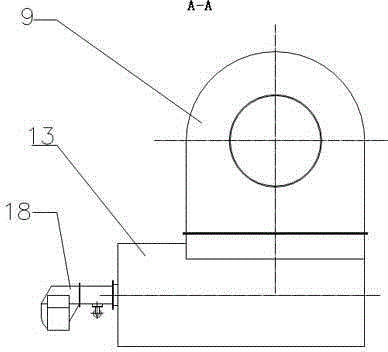

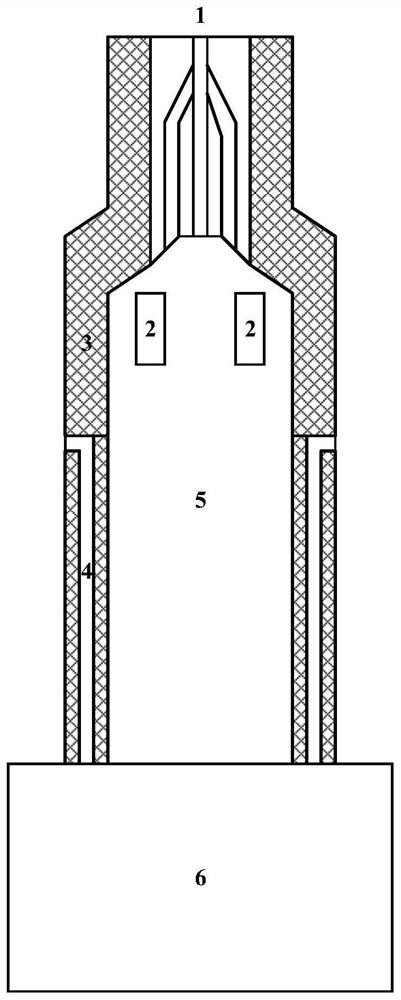

Fully pre-mixing gas combustion burner device

The invention discloses a fully premixed gas burner device which comprises a burner and a fixation device used for fixing the burner, wherein, the periphery of the burner is provided with a gas mixing cavity formed by an encloser; a partial pressure baffle with a hole is arranged between the burner and the encloser; and a clearance is left between the partial pressure baffle and the encloser. Thefully premixed gas burner device has the advantages of not only simple structure and convenient installation and maintenance, but also high combustion efficiency and stable flame, and remarkably reduces the contents of CO and NOx in flue gas.

Owner:GUANGDONG MACRO GAS APPLIANCE

Hybrid heating equipment and application thereof

ActiveCN104694138AReduce lossesHigh thermal efficiencyHorizontal chamber coke ovensSpecial form destructive distillationSlagEngineering

The invention relates to heating equipment, in particular to hybrid heating equipment and application thereof. The hybrid heating equipment comprises a three-layer cylinder structure consisting of an outer cylinder (1), a heating cylinder (4) and a slag return cylinder (5) from outside to inside sequentially, wherein the outer cylinder (1) is supported by a supporting device (12), and driven to rotate by a transmission device (11); a first supporting piece (3) is arranged between an inner wall of the outer cylinder (1) and an outer wall of the heating cylinder (4); a second supporting piece (6) is arranged between an inner wall of the heating cylinder (4) and an outer wall of the slag return cylinder (5); an air inlet cover (17) and an air outlet cover (7) are respectively arranged at the two ends of the outer cylinder (1); the air inlet cover (17) is connected with a heating furnace (13) by a flange; the flange on the heating furnace (13) is connected with a burner (18); one end of the heating cylinder (4) is connected with a feeding airlock (8); and the other end of the heating cylinder (4) is connected with a discharge airlock (15).

Owner:JIANGSU PENGFEI GROUP

Mullite-chromium light weight castable

The invention provides a mullite-chromium light weight castable. The mullite-chromium light weight castable is prepared from the following raw materials in parts by weight: 50 to 65 percent by weight of mullite microporous spheres, 20 to 45 percent by weight of low-iron three-grade high-aluminum clinker powder, 1 to 5 percent by weight of chrome oxide green, 3 to 8 percent by weight of silica micropowder, 4 to 7 percent by weight of pure calcium aluminate cement, and 0.01 to 0.5 percent by weight of a dispersing agent; the mullite microporous spheres are spherical mullite granules formed by secondary granulation sintering of raw ores; the content of Fe2O3 in the low-iron three-grade high-aluminum clinker powder is not greater than 1.5 percent by weight. The mullite-chromium light weight castable has the advantages of higher strength at normal temperature and high temperature, good volume stability and lower heat conduction coefficient; direct reduction of nodules on the surface of an iron furnace lining can be reduced, and the aims of reducing the usage of a furnace lining material, saving energy and prolonging the service life of the furnace lining are achieved.

Owner:JIAOZUO JINXIN HENGTUO REFRACTORIES

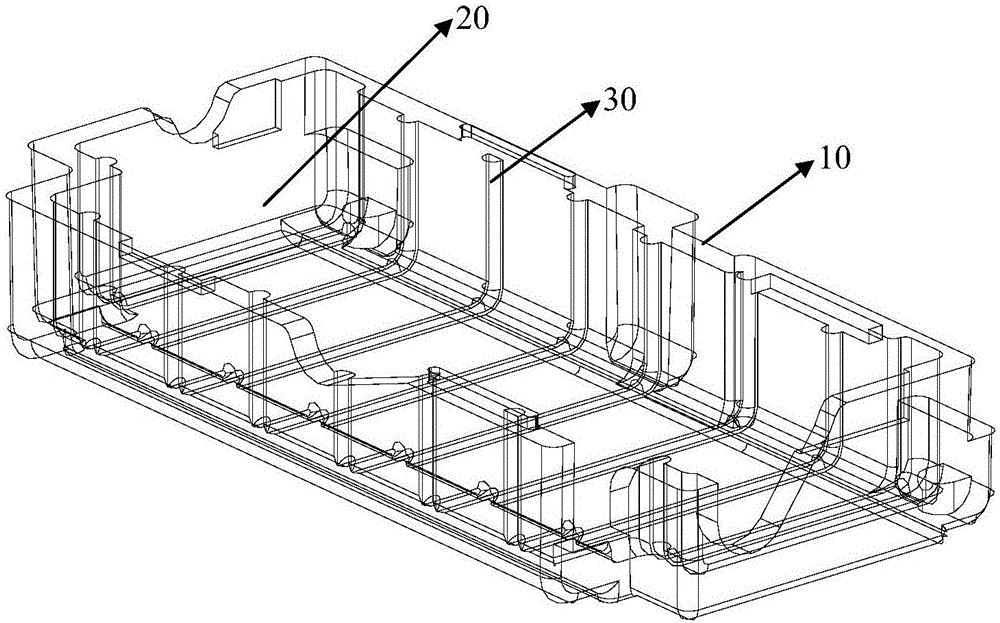

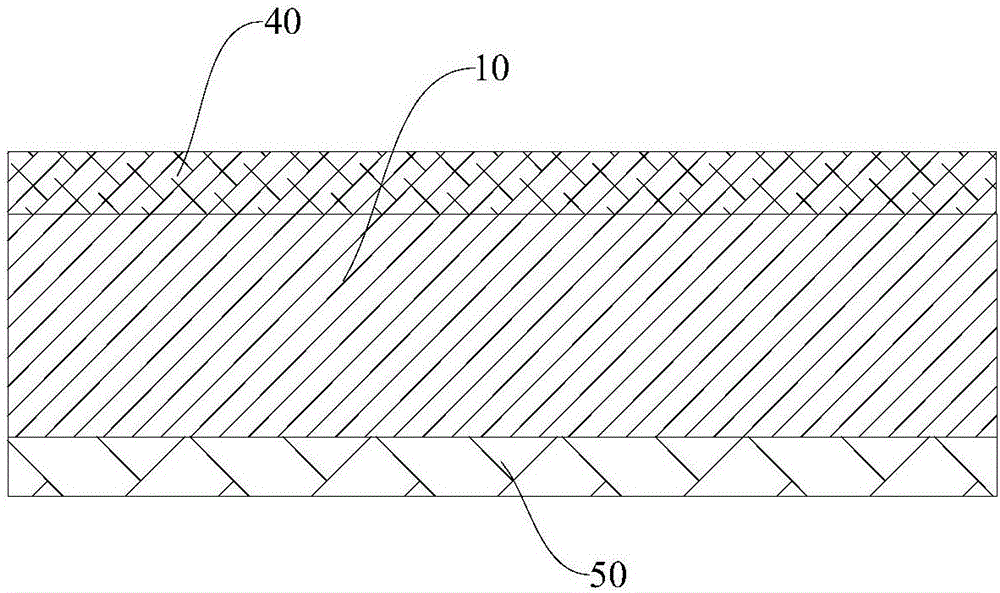

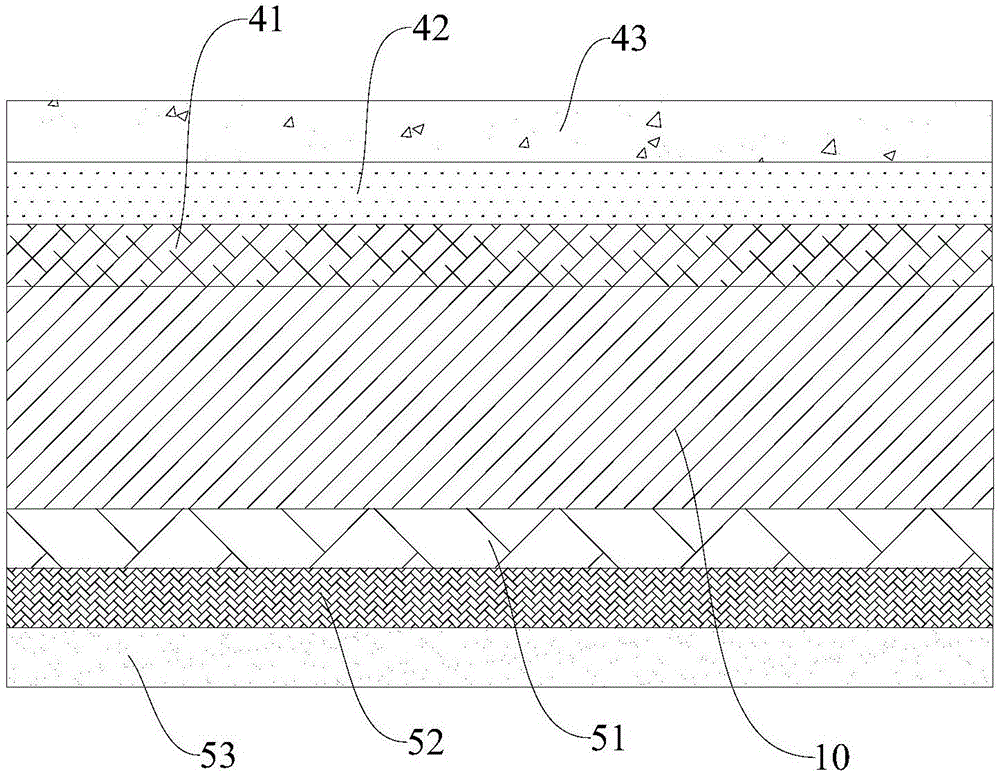

Heat insulation part and heating device comprising same

ActiveCN106341914AImprove insulation effectImprove compactnessElectric heatingThermal insulationEngineering

The invention provides a heat insulation part and a heating device. The heat insulation part comprises a housing and reinforcement ribs, wherein the housing is provided with a chamber for accommodating a heating part, and the reinforcement ribs are arranged on the inner wall of the chamber. It is discovered that through arranging the reinforcement ribs on the inner wall of the chamber of the housing, an air spacing layer can be formed between the housing and the heating part, and since the heat conduction coefficient of the air spacing layer is quite low, the initial temperature of heat transfer can be effectively reduced.

Owner:GUANGDONG MIDEA WHITE HOME APPLIANCE TECH INNOVATION CENT CO LTD +1

Sewage treatment device for environmental engineering

InactiveCN111072085AAchieve clearingSpeed up liquefactionWater/sewage treatment by heatingWater/sewage treatment apparatusLiquid waterSewage treatment

The invention discloses a sewage treatment device for environmental engineering. The sewage treatment device comprises a base. Two stand columns are symmetrically and fixedly mounted at the top of thebase; the same evaporation box is fixedly mounted at the top ends of the two stand columns; the sides, close to each other, of the two stand columns are slidably connected with the same moving plate.A sealing plate is fixedly installed at the top of the moving plate, a sealing ring is fixedly installed on the inner wall of the bottom of the evaporation box, a moving hole is formed in the inner wall of the bottom of the evaporation box, and the top of the sealing plate extends into the sealing ring and is attached to the inner wall of the sealing ring in a sealed mode. The evaporation principle is utilized, water can be heated into gas to be separated from silt, and steam can be quickly cooled to form liquid water under the action of condensation so that existing filtering equipment is not needed for filtering in use, the silt can be thoroughly separated from the water, and the device is very convenient to use.

Owner:南京瑞碧斯生物科技有限公司

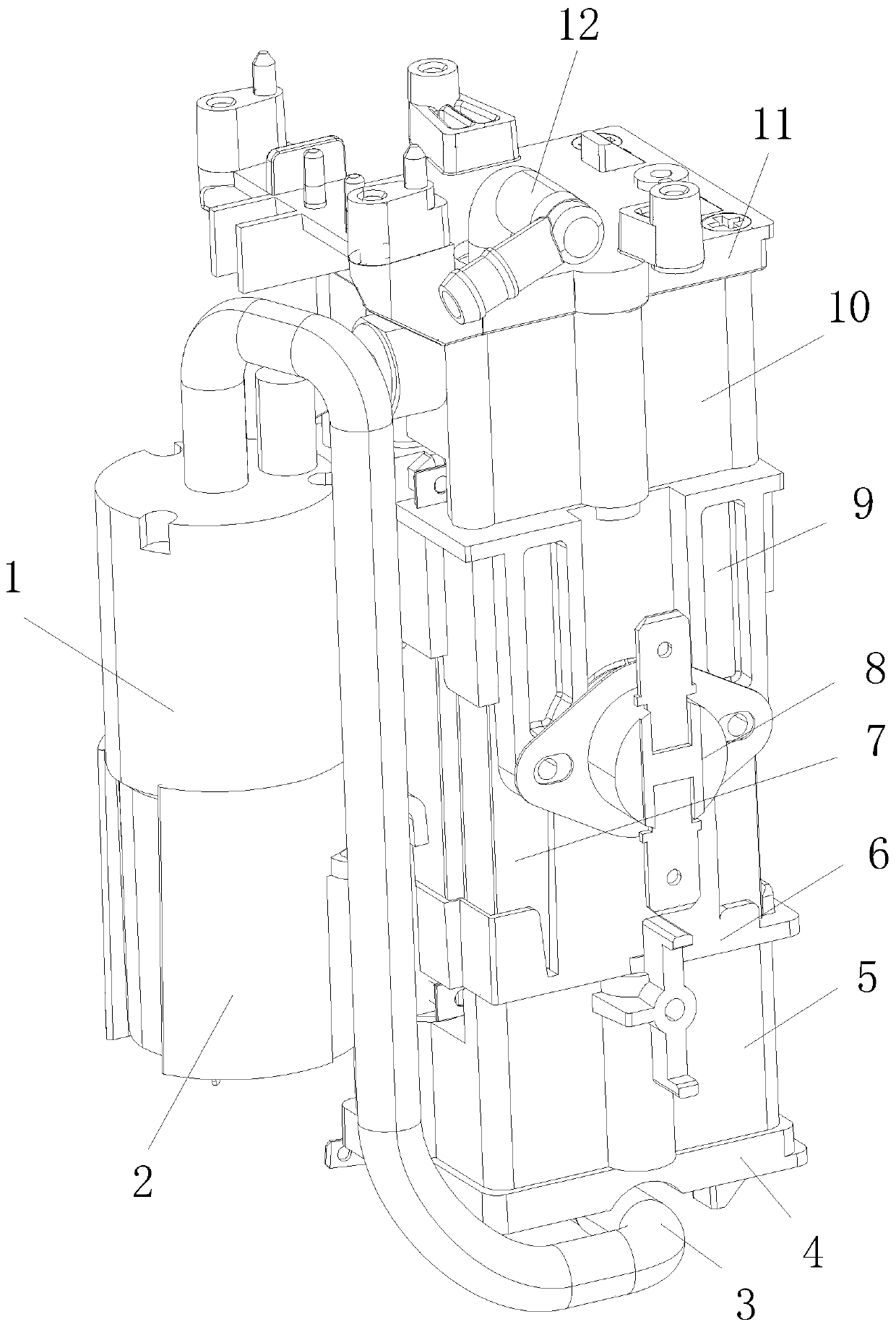

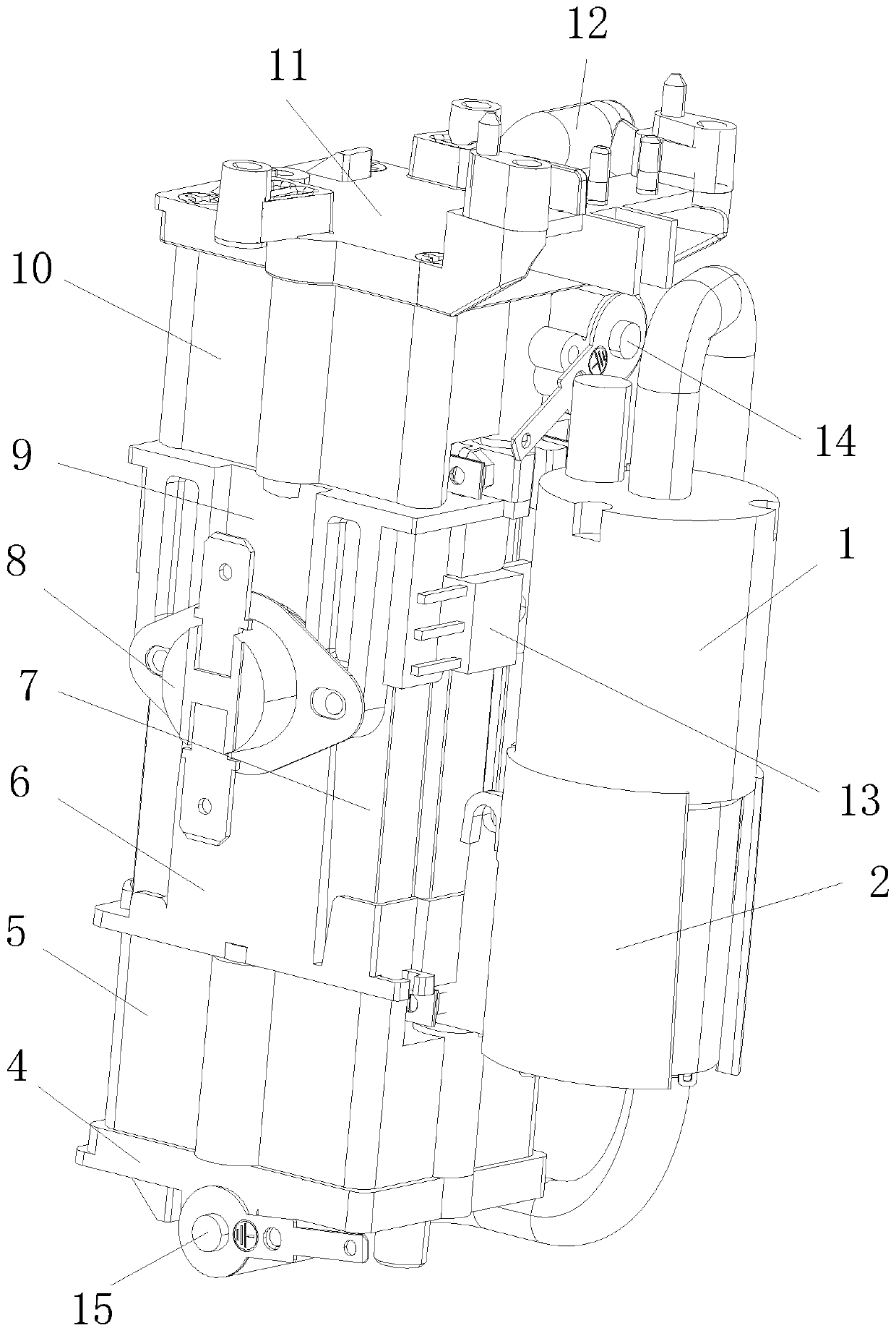

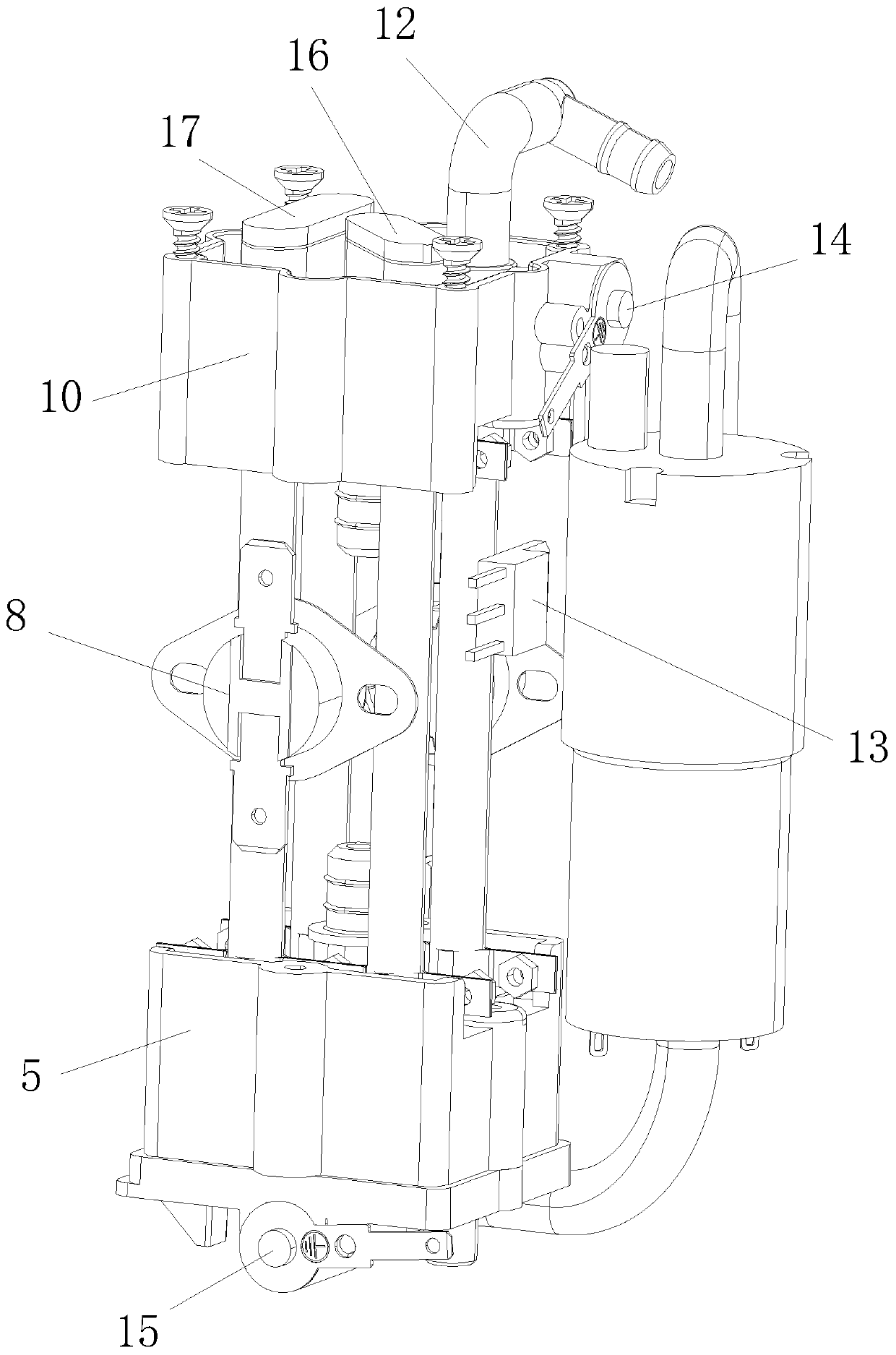

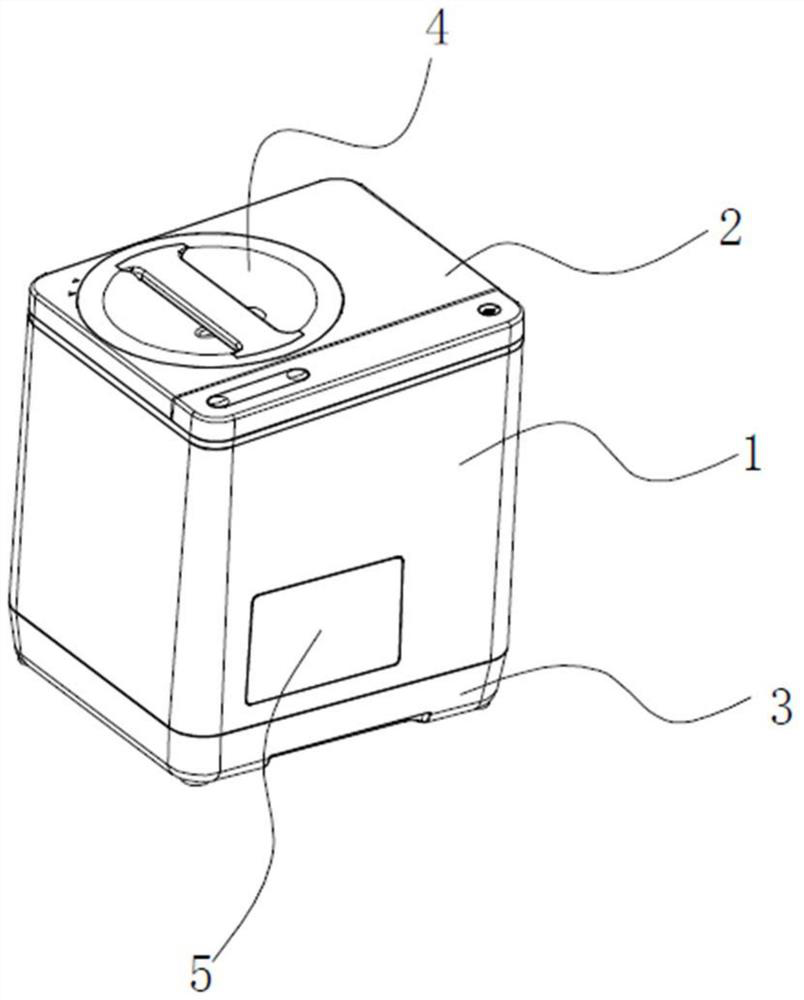

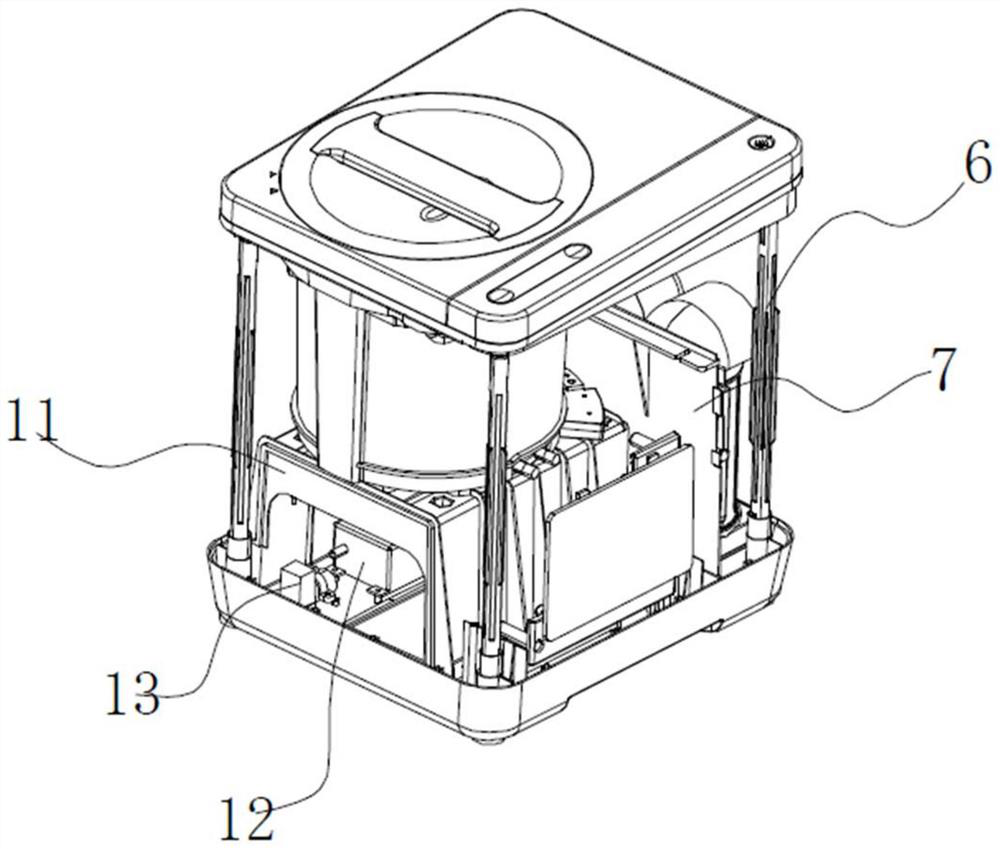

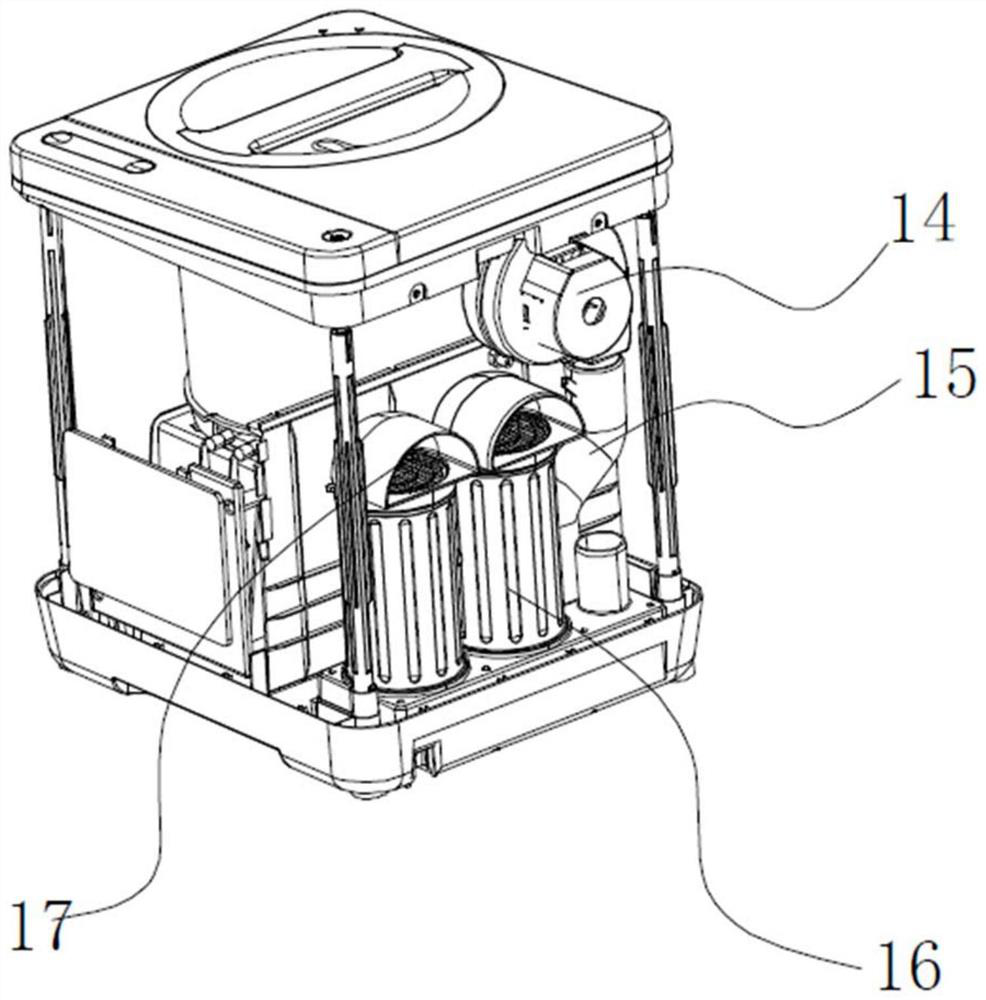

Small liquid heating assembly

PendingCN111076412AHigh electrothermal efficiencySmall structure sizeWater heatersWater sourceEngineering

The invention relates to the technical field of a liquid heating device, in particular to a small liquid heating assembly. The small liquid heating assembly comprises an outer shell, wherein a heatingpipe assembly is arranged in the outer shell, a water pump for providing a water source for the heating pipe assembly is connected to the outer shell through a water pump fixing assembly, the heatingpipe assembly comprises a water inlet pipe communicating with a water outlet of the water pump and a plurality of heating pipes surrounding the peripheral side of the water inlet pipe, a nano electrothermal film is sprayed on the surfaces of the heating pipes, upper ends of the plurality of heating pipes are jointly connected with an upper electrode assembly and lower ends of the plurality of heating pipes are jointly connected with a lower electrode assembly, and a power supply unit is connected between the upper electrode assembly and the lower electrode assembly. The device can not only increase the heating speed, but also recycle heat energy and is more energy-saving. Besides, the device is reasonable in structural design, and all the pipes communicate through an integrally formed structure, so that the device is simple and convenient to assemble, convenient to produce and manufacture and long in service life.

Owner:WUHU ALDOC TECH CO LTD

Kitchen garbage disposer

PendingCN112170464APrevent spillageReduce external surface temperatureGas treatmentSolid waste disposalEngineeringRefuse Disposals

The invention discloses a kitchen garbage disposer. The kitchen garbage disposer comprises a shell, an upper surface cover and a base; a storage barrel is arranged in the shell; a heating disc is mounted at the bottom of the storage barrel; a stirring blade is mounted at the bottom of the inner side of the storage barrel in a rotating mode; the stirring blade is driven by a driving component belowthe storage barrel to rotate; a water tank is mounted on one side of the storage barrel and connected with an exhaust fan through a pipeline; an air inlet of the exhaust fan is located on one side ofthe upper end of the storage barrel; and a detachable barrel cover corresponding to the storage barrel is mounted on the upper face cover. According to the kitchen garbage disposer, odor overflowingcannot be generated, the temperature of the surface of the machine is not high during work, the garbage crushing effect is achieved, and the use requirement is met.

Owner:陈波 +2

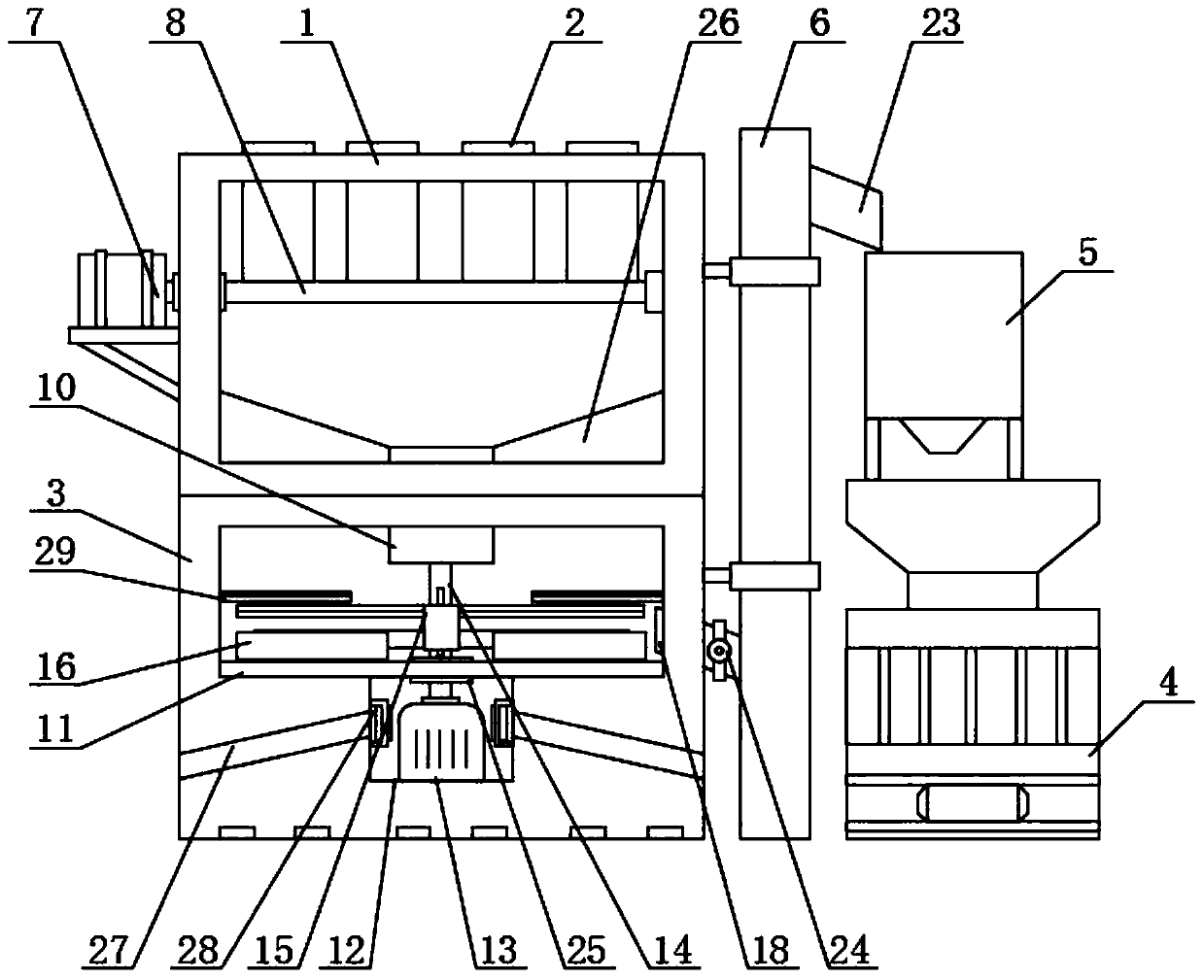

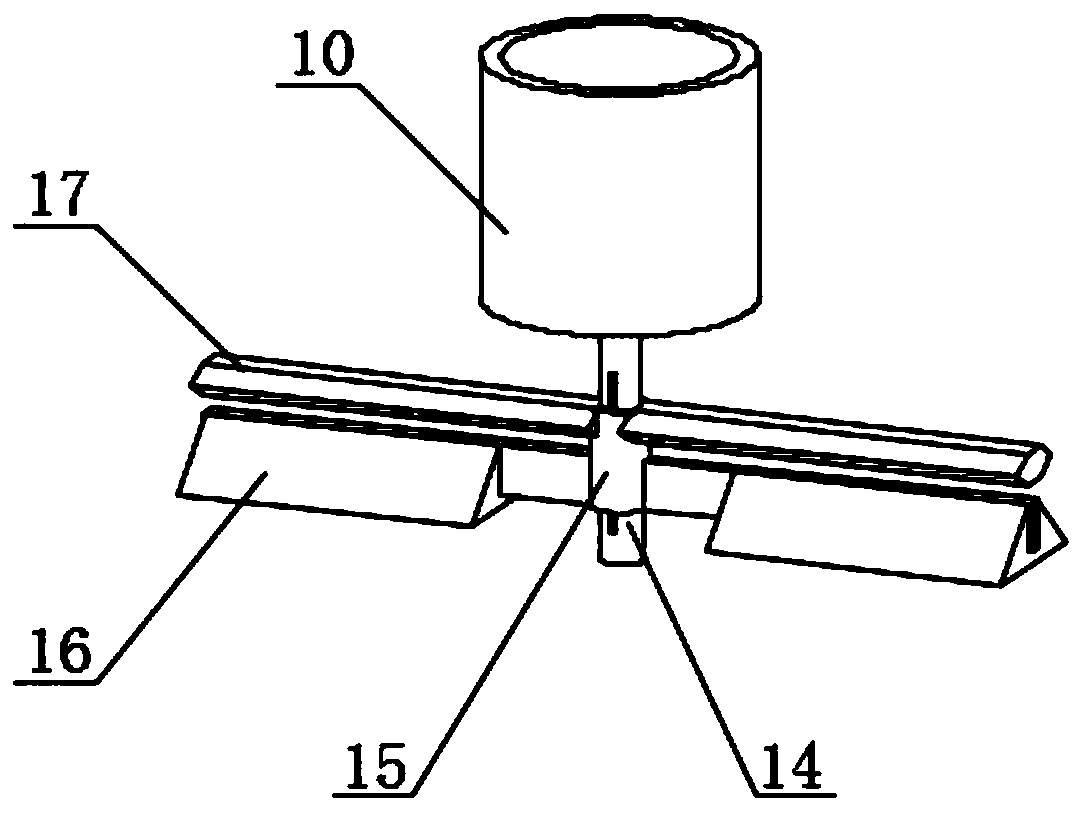

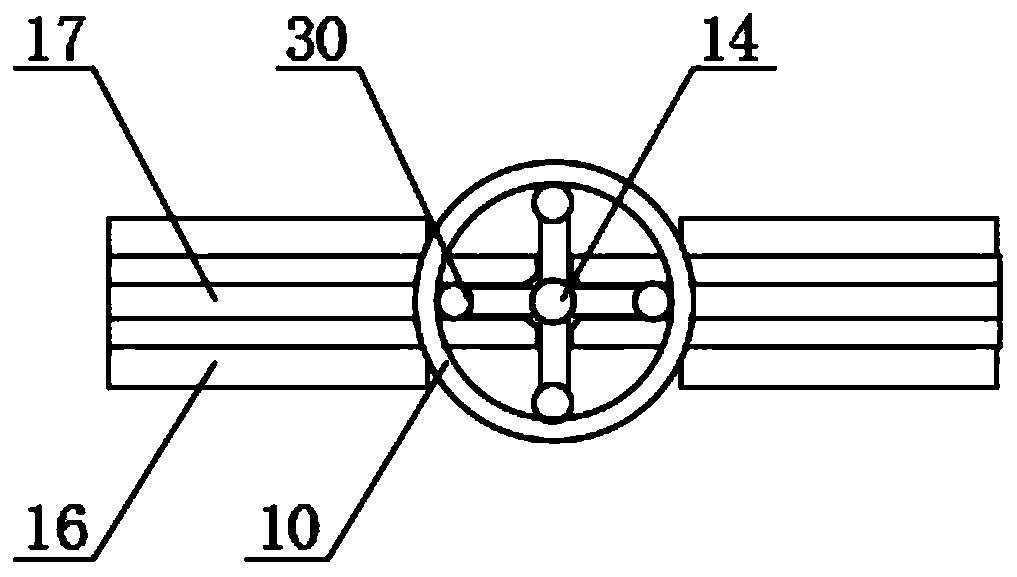

Manufacturing method and tool die of precise concrete briquette

ActiveCN111070398AImprove applicabilityImprove work efficiencyDischarging apparatusMixing operation control apparatusElectric machineryTester device

The invention discloses a manufacturing method and a tool die of a precise concrete briquette, and belongs to the technical field of concrete machining. The tool die comprises a weighing box. The upper surface of the weighing box fixedly communicates with a charging-in barrel, the bottom face of the weighing box is fixedly connected with a stirring box, a block machine is arranged on one side of the stirring box, the top end of the block machine is fixedly connected with a fluidity tester, a feeding barrel is arranged between the block machine and the stirring box, the outer surface of the weighing box is fixedly connected with a first motor, the output end of the first motor is fixedly connected with a first rotary rod, the end, away from the first motor, of the first rotary rod penetrates through the outer surface of the weighing box and stretches into the weighing box, and the outer surface of the first rotary rod is fixedly connected with a blocking plate. The manufacturing methodand the tool die of the precise concrete briquette have the beneficial effects that multiple materials can be weighed and fetched, large particles are broken and cut in the stirring process, and feeding blockage is avoided.

Owner:XINJIANG GUOTONG PIPELINE CO LTD

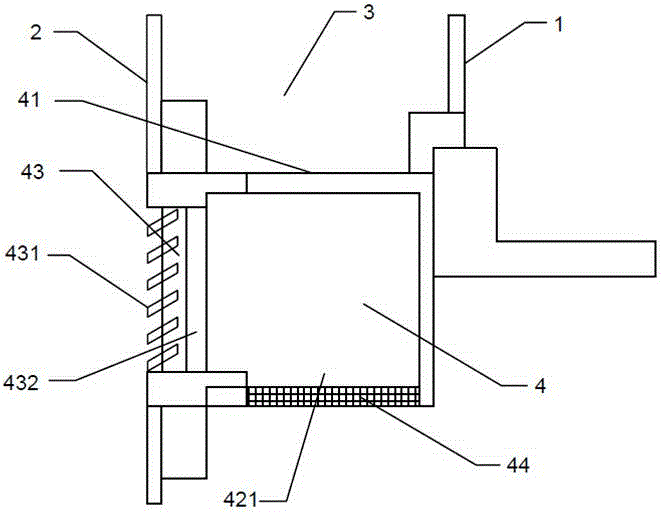

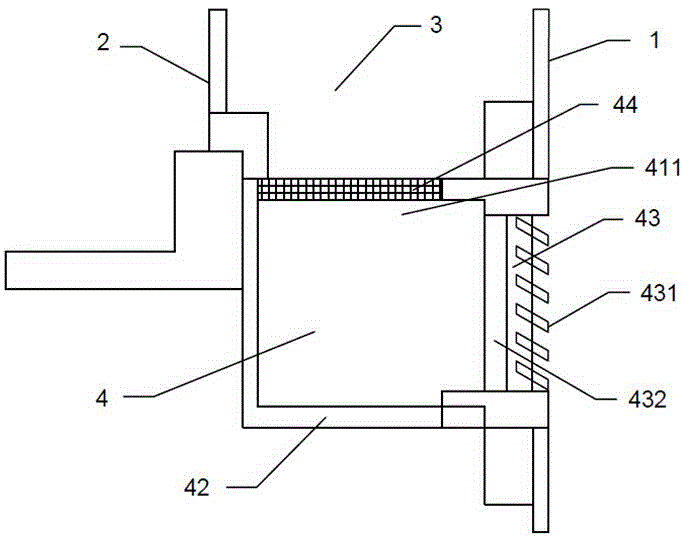

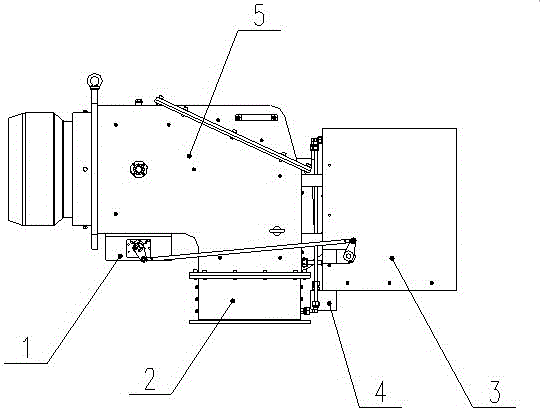

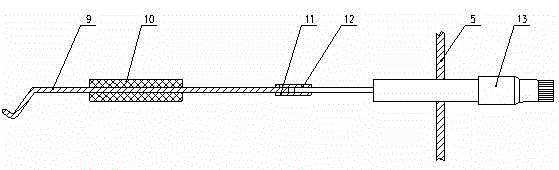

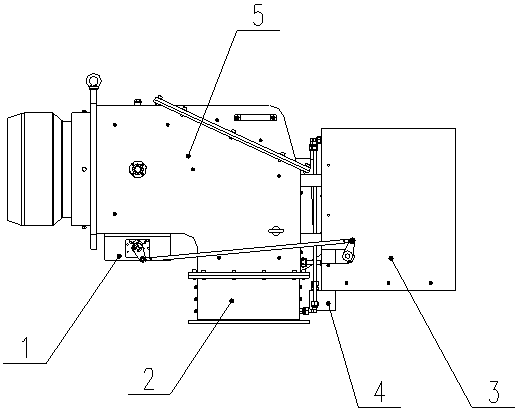

Hot air type combustor

ActiveCN105066125ASolve temperature resistanceReduce external surface temperatureGaseous fuel burnerThermal insulationFire detection

The invention discloses a hot air type combustor. The hot air type combustor comprises a fuel butterfly valve, an air ventilation door, an adjusting mechanism assembly, a cooling air inlet and a combustor shell. The combustor shell comprises an outer shell body, an inner shell body and non-asbestos alumina silicate fiber cotton. An ignition needle device comprises an ignition needle and a ceramic bar installed outside the ignition needle. The bottom of the air ventilation door is connected with a ventilation door assembly. The ventilation door assembly comprises a ventilation door frame, a ventilation door shaft, a temperature sensor and a servo adjusting motor. The combustor shell is further provided with a fire detection thermal insulation sleeve. The fire detection thermal insulation sleeve comprises a flame monitor and a thermal insulation glass cover. A combustion head adjusting barrel assembly is arranged behind the fuel butterfly valve and comprises an air pressure adjusting barrel, an adjusting pull rod and a fuel gas mixing head. The hot air type combustor achieves the aim of temperature resisting of the ignition needle and the flame monitor, the temperature of the outer surface of the combustor is reduced, and pressure adjustment on the ventilation door and the fuel combustion head of the combustor can be automatically carried out along with the temperature change.

Owner:上海凌云瑞升燃烧设备有限公司

A hot air burner

ActiveCN105066125BSolve temperature resistanceReduce external surface temperatureGaseous fuel burnerFiberGlass cover

Owner:SHANGHAI LINGYUN RUISHENG COMBUSTION EQUIP CO LTD

Hot water bottle

ActiveCN104382687AImprove comfortReduce external surface temperatureHeat-exchange elementsTherapeutic coolingThermodynamicsAlcohol

A novel phase-change insulation hot water bag is characterized by comprising three layers, from outside to inside, including an outer layer, an interlayer and an inner layer, a cavity between the outer layer and the interlayer is filled with carbon dioxide, a cavity between the interlayer and the inner layer is filled with alcohol, the inner layer is filled with heat-storing salt solution, an electric heater rod is arranged in the heat-storing salt solution, and the electric heater rod is connected with a power plug through a wire.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Production technology for polypropylene tubing containing beta crystal form

ActiveCN102516640BReduce external surface temperaturePrevent freezingRigid pipesWater coolingPolypropylene

The invention provides a production technology for a polypropylene tubing containing a beta crystal form, which comprises the following steps: mixing granulation, fusing plasticization, air precooling, water cooling and annealing. The K beta value of the polypropylene tubing produced by the production technology disclosed by the invention is more than 0.6, and the polypropylene tubing has favorable thermostability.

Owner:WUHAN KINGBULL ECONOMIC DEV

Double-layer type resistor air-out tube head

InactiveCN102479593AMitigation deliveryReduce external surface temperatureResistor cooling/heating/ventillationEnvironmental resistanceElectrical conductor

The invention relates to a double-layer type resistor air-out tube head, which is provided at one side of a resistor casing and is composed of an external layer component, an internal layer component, a support bar and an interlayer support member. The internal layer component is provided in the external layer component, a gap is provided between the external layer component and the internal layer component, the support bar is connected to the inside wall of the external layer component, and the interlayer support member is provided between the external layer component and the internal layer component. Compared with the prior art, the air-out tube head uses air between the two layers of the air-out tube head for heat insulation, thereby the temperature on the external layer surface can be reduced, hot-air discharged from the resistor is directly contacted and performed heat transfer with the internal layer of the air-out tube head, air is existed between the internal layer and the external layer, air is a poor conductor of heat, heat can be effectively prevented to be transferred to the external layer component, the whole air-out tube head not welding but bolt or riveting, thereby the effect of environmental protection and low carbon can be achieved.

Owner:SHANGHAI GINO TELEMA RESISTORS

Liquid deslagging cyclone burner with interlayer rotational flow secondary air

PendingCN112762439ALow costIncrease swirl intensityFuel feeding arrangementsPulverulent fuel combustion burnersThermodynamicsCombustor

The invention discloses a liquid deslagging cyclone burner with interlayer rotational flow secondary air. The liquid deslagging cyclone burner is characterized by comprising a burner barrel, in-barrel burning space is arranged in the burner barrel, a main secondary air inlet channel and an interlayer secondary air annular channel are arranged on the barrel, one end of the burner barrel is connected with a rotational flow burner, and the other end of the burner barrel is connected with a tail burning chamber; the main secondary air inlet channel communicates to the in-barrel burning space, and the interlayer secondary air annular channel communicates to the tail burning chamber; and the secondary air rotation directions of the main secondary air inlet channel and the interlayer secondary air annular channel are consistent.

Owner:SHANGHAI BOILER WORKS

Heat quantity reclaiming type electric heater

An electric heater of heat recovery comprises a nonmetallic water pump, a heating element arranged outside the nonmetallic water pump, a water jacket arranged outside the heating element, the inner drum of the water jacket is sealed and connected with the water pump at lower end, the lower end of the outer drum of the water jacket is equipped with an end plate, a water inlet of a heater is arranged on the upper part of the water jacket, and the water outlet of the heater is the upper end open of the nonmetallic water pump. The electric heater is mainly matched with a water-drinking machine of no hot penetration for heating flowing drinking water, the invention is characterized by high water temperature, low temperature of the outer surface of the heater (about 50 DEG C), non fire threat, energy conservation, scale uneasily producing. The electric heater can be matched with other similar products for heating flowing sanitation liquor.

Owner:黄樟焱

Water-cooling type hearth plate of petroleum coke tank-type calcining furnace

ActiveCN103615902BReduce the temperatureReduce external surface temperatureFurnace coolingHearthPetroleum coke

The invention discloses a water-cooling type hearth plate of a petroleum coke tank-type calcining furnace, and belongs to the technical field of petroleum coke tank-type calcining furnaces. An annular water sleeve inner plate (4) and an annular water sleeve outer plate (3) are fixedly connected between an upper flat plate (1) and a lower flange plate (6), the water sleeve inner plate (4), the water sleeve outer plate (3), the upper flat plate (1) and the lower flange plate (6) form a sealed annular cooling sleeve (11) in a surrounding mode, the lower end surface of the upper flat plate (1) is provided with an annular cooling half pipe (2) at the outer side of the water sleeve outer plate (3), the annular cooling half pipe (2) and the upper flat plate (1) form a sealed annular cooling water passage (12), the annular cooling water passage (12) is communicated with the annular cooling sleeve (11) through a connecting half pipe (8), and annular cooling water passage (12) is communicated with a water outlet pipe (10). The water-cooling type hearth plate of the petroleum coke tank-type calcining furnace has the advantages of lowering the temperature of the hearth plate, improving the work reliability of the hearth plate and the like.

Owner:SHANDONG UNIV OF TECH

Inner container of electric cooker

InactiveCN105266561AReduce external surface temperatureFast heating and high thermal efficiencyCooking-vessel materialsThermal insulationEngineering

The invention provides an inner container of an electric cooker which belongs to the field of electric appliances. The bottom of the inner container is a heating face, indirect heating faces in the inner container is only used for receiving heat, and the indirect heating faces at the outside of the inner container is made from insulation material to insulation heat. The temperature of the outside surface is low because of heat insulation, the loss of the heat energy of the indirect heating faces during heating can be reduced, the temperature can be quickly raised, the heat availability is high, and the natural insulation time is long.

Owner:陈元庆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com