Manufacturing method and tool die of precise concrete briquette

A concrete test block and tooling technology, which is applied in the direction of manufacturing tools, clay preparation devices, mixing operation control devices, etc., can solve the problems of feeding blockage, inability to weigh and take out multiple materials, etc., to prolong the service life and quickly cut and break effect, the effect of fast stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

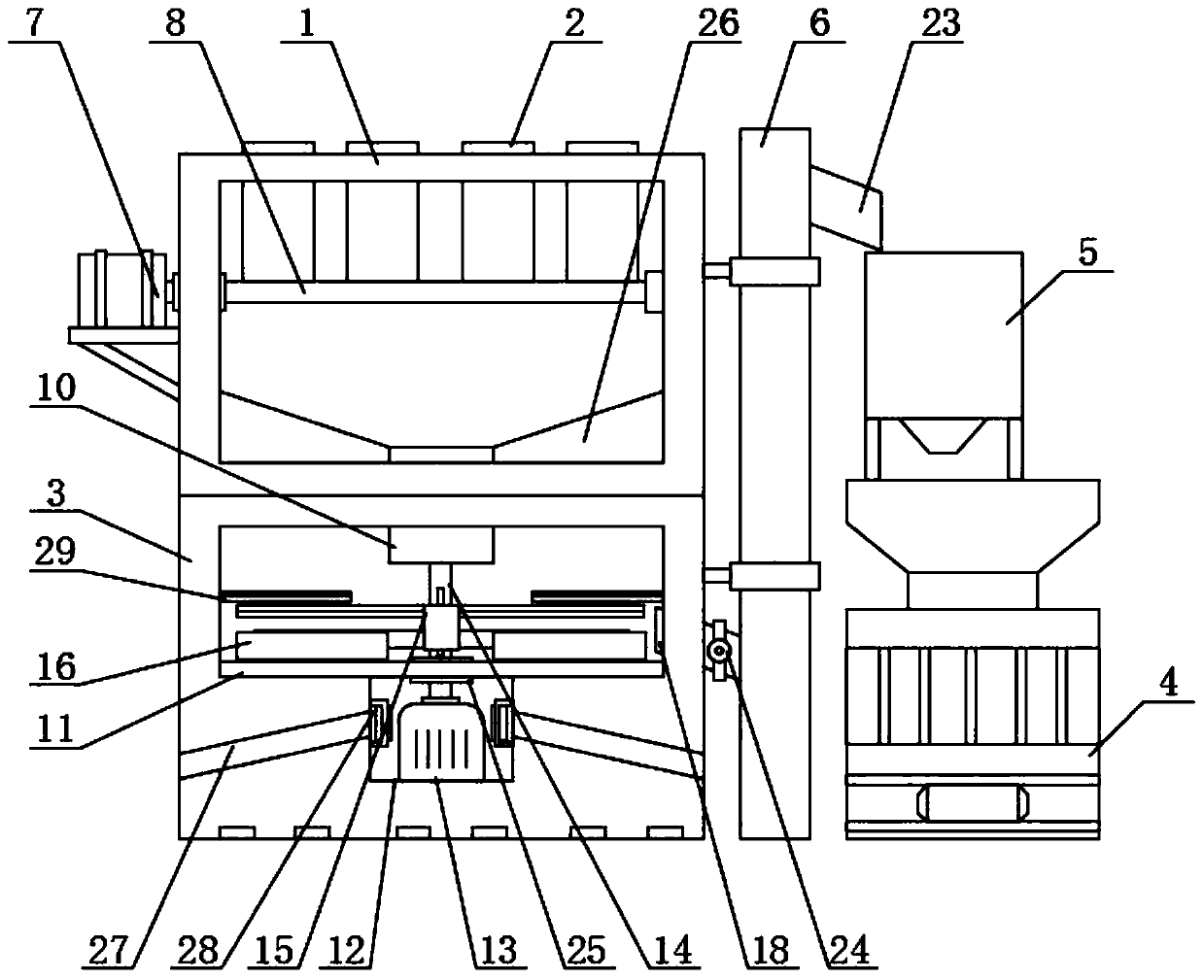

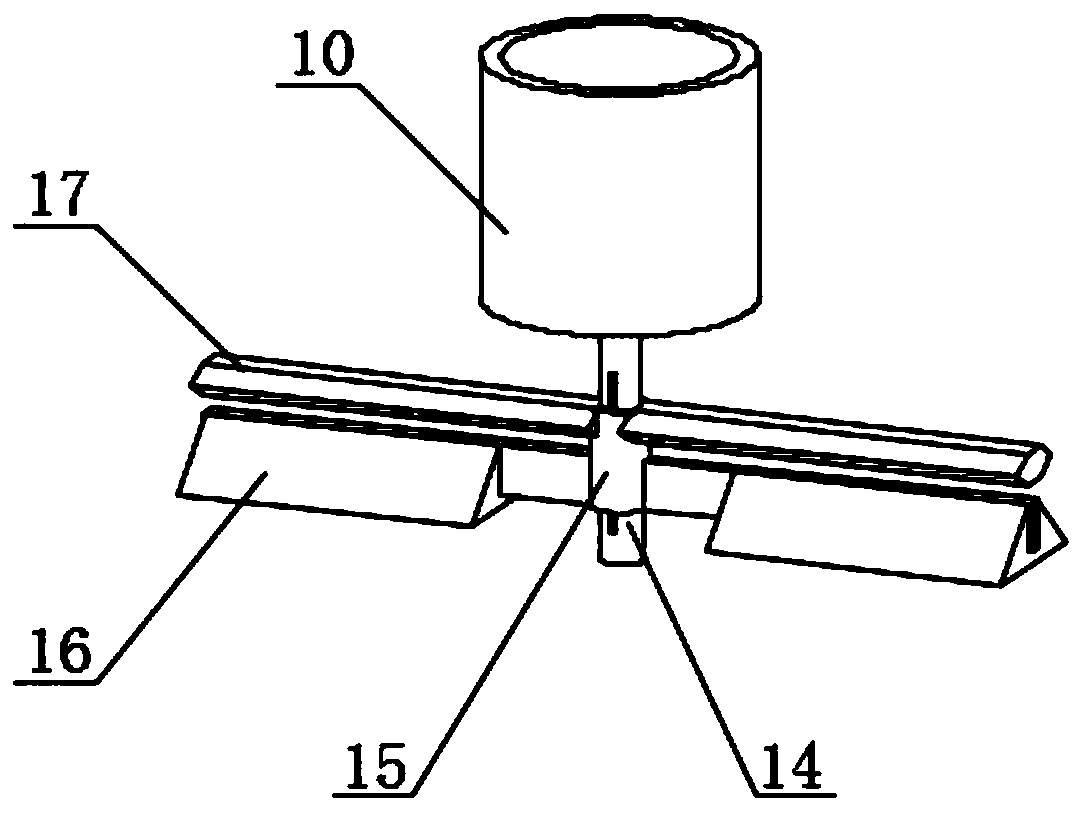

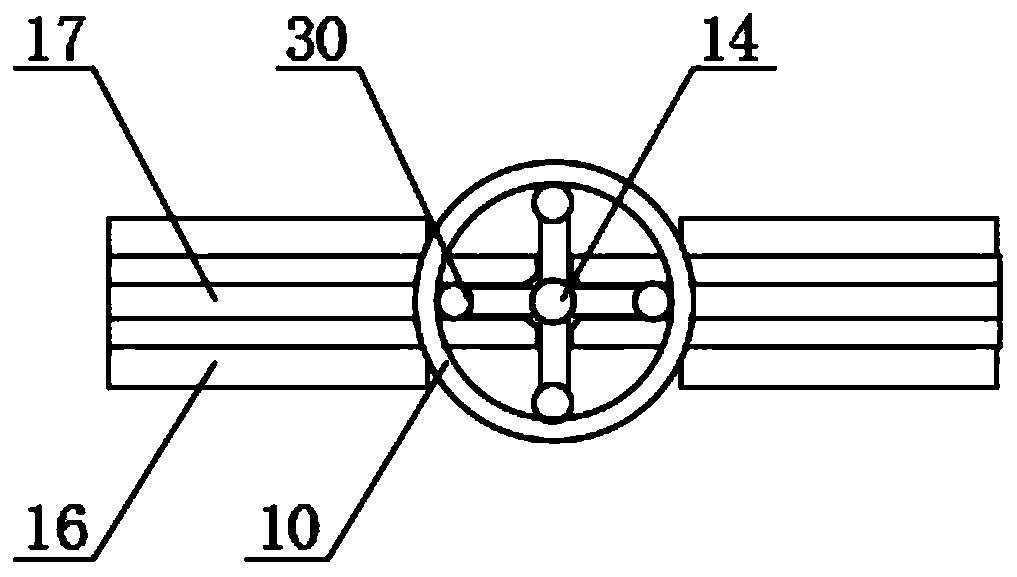

[0024] Such as Figure 1-6 As shown, the present invention provides a technical solution: a precision concrete test block manufacturing method and tooling mold, including a weighing box 1, the inner bottom wall of the weighing box 1 is fixedly connected with a flow guide block 26, and the inclination angle of the flow guide block 26 35 degrees, by setting the guide block 26, it can help the weighing box 1 to discharge more smoothly and avoid material clogging. The upper surface of the weighing box 1 is fixedly connected with the feeding cylinder 2, and the number of feeding cylinders 2 is four , are four pipe bodies with different capacities, respectively put in cement, sand, stones and admixtures, the bottom surface of weighing box 1 is fixedly connected with mixing box 3, and the inner side wall of mixing box 3 is fixedly connected with driven mixing knife 29, driven The bottom surface of the mixing knife 29 is one centimeter apart from the upper surface of the active mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com