Double-layer type resistor air-out tube head

A resistor and air outlet duct technology, applied in the direction of resistor cooling/heating/ventilation devices, etc., can solve the problems of unhealthy operators, long welding work hours, adverse effects, etc., and achieve low external surface temperature, guaranteed strength, The effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

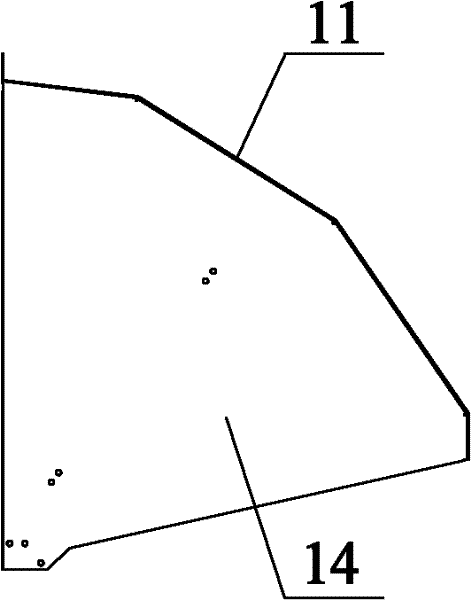

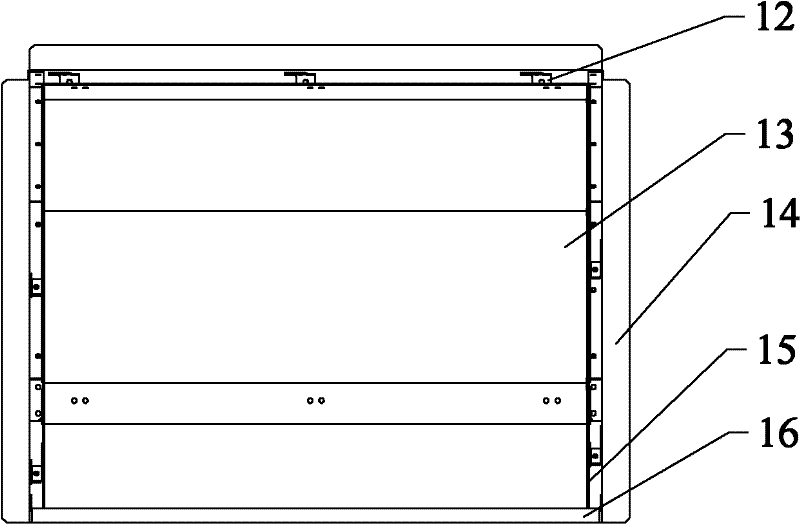

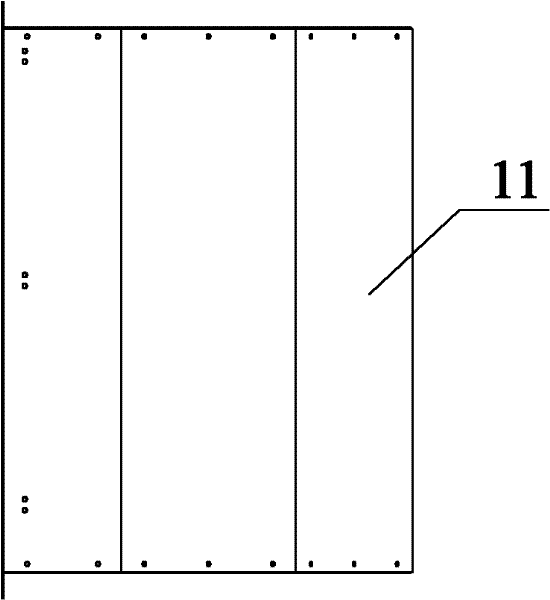

[0023] A double-layer resistor outlet pipe head, its structure is as follows Figure 1~3 As shown, the air outlet pipe head is composed of an outer layer component, an inner layer component, a support rod 16 and an interlayer support member 12, the inner layer component is arranged in the outer layer component, and a gap is provided between the outer layer component and the inner layer component , the outer assembly is composed of the outer layer pipe head bending surface 11 and the outer layer pipe head side wall 14, the outer layer pipe head bending surface 11 is located in the middle of the outer side of the air outlet pipe head 1, and the outer layer pipe head side wall 14 is set On both sides of the outer tube head bending surface 11, the inner layer assembly is composed of the inner layer tube head bending surface 13 and the inner layer tube head side wall 15, and the inner layer tube head side wall 15 is set on the inner layer tube head bending surface 13 sides. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com