Composite Fireproof Cable

A technology for fire-resistant cables and cable core wires, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of cable burning, reduce fire spread, economic losses, etc., achieve the strengthening of the outer protective layer of cables, reasonable structural design, and protection of cable cores line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

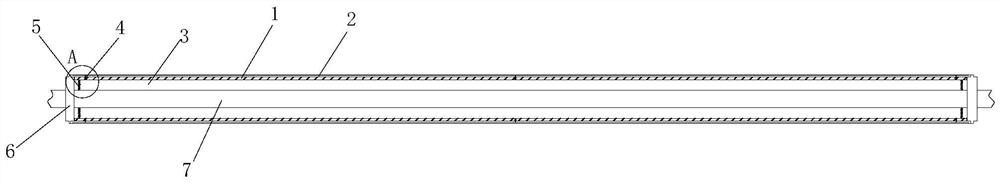

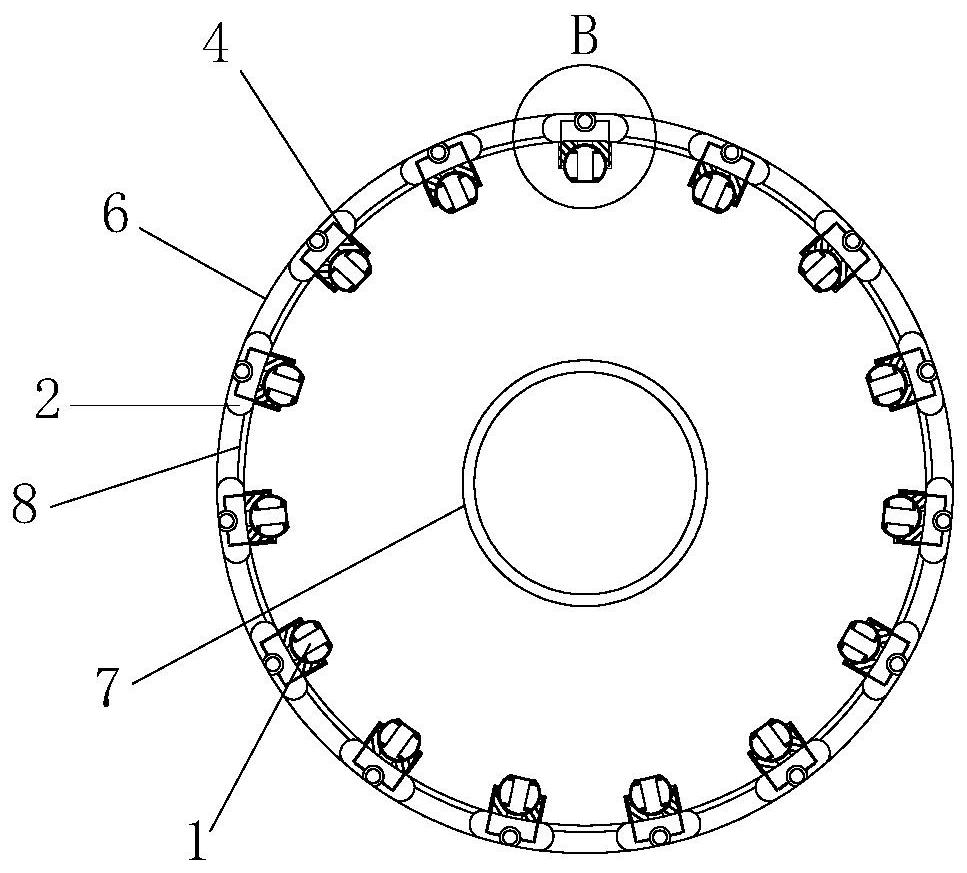

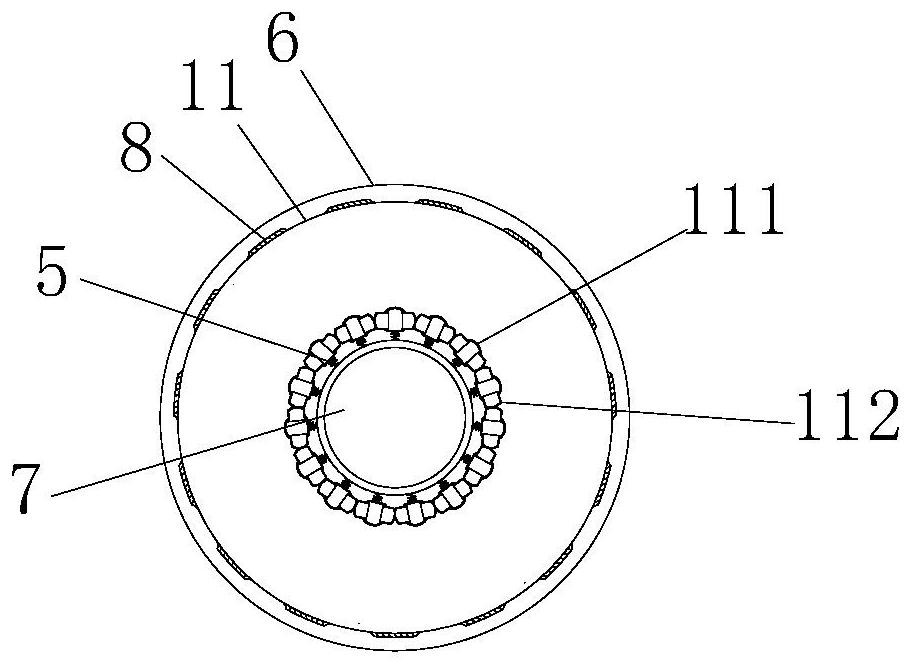

[0021] Such as figure 1 and figure 2 As shown, the composite fireproof cable includes more than one positioning ring 6 equidistantly arranged, and a through hole 3 is opened in the middle of the positioning ring 6, and the cable core wire 7 passes through the through hole on each positioning ring 6, and two adjacent positioning rings 6 An outer protective layer 8 is wrapped between the rings 6, and more than one opening 11 is provided around the outer protective layer 8 on the outer protective layer 8, and assembly steps are arranged on the positioning ring 6 facing the outer protective layer 8. surface 61, the two sides of the outer protective layer 8 are set on the assembly step surface 61, each opening 11 is sealed by a sealing strip 2, and a steel wire device 1 is arranged at the bottom of each sealing strip 2, and the steel wire device 1 They are all fixedly connected to the outer wall surface of the cable core wire 7 through the first spring 5, the first spring 5 is st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com