Circular saw blade with water-drop-shaped inclined hole structure and machining method

A processing method and a drop-shaped technology, applied in metal processing equipment, stone processing tools, stone processing equipment, etc., can solve the problems of reducing the overall strength and wear resistance of the base material, reducing the production efficiency, and increasing the cutting temperature. The effect of improving heat dissipation, reducing friction area, and reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039] Example 1:

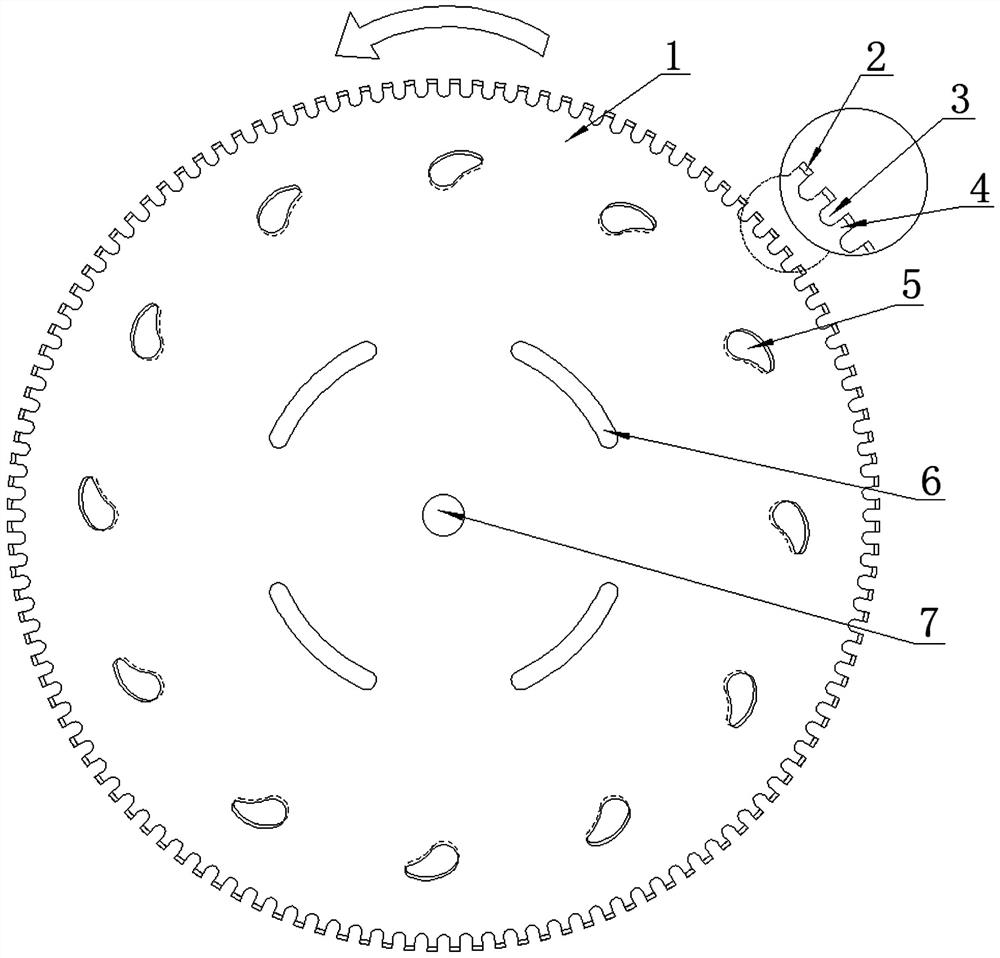

[0040] see Figure 1-6 , a circular saw blade with a drop-shaped oblique hole structure, which includes a saw blade base 1, the center of which is provided with a mounting hole 7; the outer circumference of the saw blade base 1 is processed with evenly distributed saw teeth 4; Chip flutes 3 are formed between adjacent saw teeth 4; blades 2 are arranged on the edge of the saw teeth 4; evenly distributed heat dissipation holes 5 are arranged on the saw blade base 1 and near the chip flutes 3, and the saw blade base 1 is near the installation holes There are evenly distributed heat dissipation grooves 6 near the 7; the inner walls of the heat dissipation holes 5 are all in the form of water droplets with transitional arc inner walls. In the present invention, the above-mentioned circular saw blade can be effectively applied to high-strength rock cutting, the saw blade has good heat dissipation and chip removal effects, high cutting efficiency, simple saw blad...

Example Embodiment

[0050] Example 2:

[0051] The processing method of the circular saw blade with drop-shaped oblique hole structure comprises the following steps:

[0052] Step 1: Select the circular plate of the saw blade base for use;

[0053] Step 2: Put the circular plate blank of the saw blade base on the high-power water jet cutting equipment and fix it;

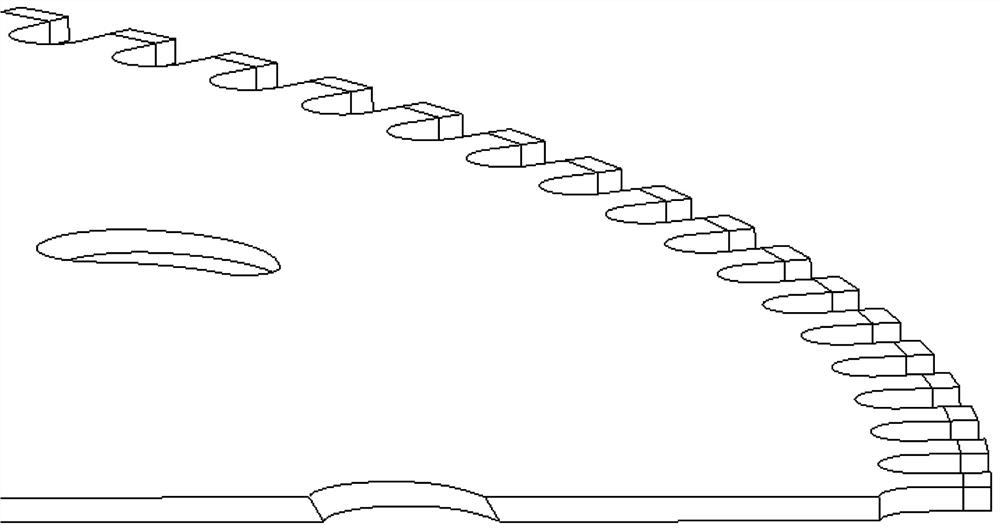

[0054] Step 3: Start the waterjet cutting equipment, first cut the installation hole 7, then cut the heat dissipation groove 6, and then process the chip removal groove 3 on the edge of the saw blade base; finally, when cutting the heat dissipation hole 5, it is necessary to continuously adjust the water jet The angle between the spray head 8 and the saw surface 9 ensures that the inner wall of the processed cooling hole 5 is an inclined inner wall;

[0055] Step 4: Derusting and smoothing the two surfaces of the saw blade substrate processed by the waterjet;

[0056] Step 5: Connect the diamond blade 2 and the sawtooth 4 by brazing...

Example Embodiment

[0061] Example 3:

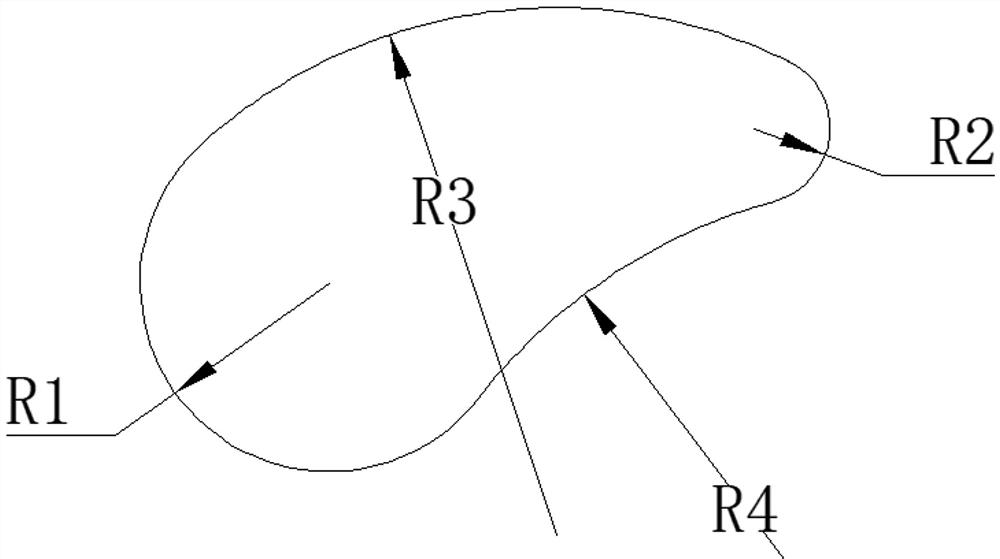

[0062] In this embodiment, in order to ensure that the cooling hole 5 has the best performance and prevent problems such as stress concentration, the values of the four internal arcs are: R1: 25mm, R2: 10mm, R3: 70mm, R4 is: 75mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com