Ultrathin fireproof water-based paint and preparation method thereof

A water-based paint, ultra-thin technology, applied in the direction of fireproof paint, coating, etc., can solve the problems of inconvenient construction, poor decoration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

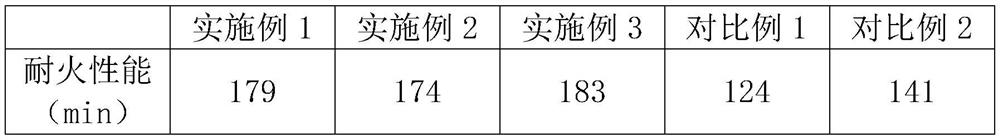

Examples

Embodiment 1

[0025] In Example 1, an ultra-thin fireproof water-based coating is composed of the following components in parts by weight: 40 parts of water, 45 parts of silica sol, 6 parts of butyl acrylate emulsion, 0.5 part of melamine, 15 parts of expansion filler, dodecane 4 parts of dimethyl benzyl ammonium oxide, 0.1 part of defoamer, 0.3 part of thickener and 0.2 part of multifunctional additive.

[0026] Further, the expansion filler is composed of the following components by weight: 20 parts of expandable graphite, 15 parts of perlite, 4 parts of titanium dioxide, 12 parts of vermiculite, 16 parts of diatomaceous earth, 15 parts of sodium sesquicarbonate, polymethyl 25 parts of methyl acrylate and 8 parts of octyl p-dimethylaminobenzoate.

[0027] Further, the preparation method of the expandable filler comprises the following steps: putting expandable graphite, perlite, titanium dioxide, vermiculite, diatomaceous earth and sodium sesquicarbonate into a ball mill and fully mixing,...

Embodiment 2

[0037] In Example 2, an ultra-thin fireproof water-based coating is composed of the following components in parts by weight: 60 parts of water, 65 parts of silica sol, 15 parts of butyl acrylate emulsion, 2 parts of melamine, 25 parts of expansion filler, dodecane 8 parts of dimethyl benzyl ammonium oxide, 0.5 part of defoamer, 0.8 part of thickener and 0.6 part of multifunctional additive.

[0038] Further, the expansion filler is composed of the following components by weight: 30 parts of expandable graphite, 22 parts of perlite, 7 parts of titanium dioxide, 18 parts of vermiculite, 24 parts of diatomaceous earth, 22 parts of sodium sesquicarbonate, polymethyl 25-35 parts of methyl acrylate and 14 parts of octyl p-dimethylaminobenzoate.

[0039] Further, the preparation method of the expandable filler comprises the following steps: fully mix expandable graphite, perlite, titanium dioxide, vermiculite, diatomaceous earth and sodium sesquicarbonate in a ball mill, and mix for ...

Embodiment 3

[0049] In Example 3, an ultra-thin fireproof water-based coating is composed of the following components in parts by weight: 50 parts of water, 55 parts of silica sol, 8 parts of butyl acrylate emulsion, 1 part of melamine, 20 parts of expansion filler, dodecane 6 parts of dimethyl benzyl ammonium oxide, 0.3 part of defoamer, 0.5 part of thickener and 0.4 part of multifunctional additive.

[0050] Further, the expansion filler is composed of the following components by weight: 25 parts of expandable graphite, 20 parts of perlite, 5 parts of titanium dioxide, 15 parts of vermiculite, 20 parts of diatomaceous earth, 18 parts of sodium sesquicarbonate, polymethyl 30 parts of methyl acrylate and 12 parts of octyl p-dimethylaminobenzoate.

[0051] Further, the preparation method of the expandable filler comprises the following steps: fully mix expandable graphite, perlite, titanium dioxide, vermiculite, diatomaceous earth and sodium sesquicarbonate in a ball mill, and mix for 40 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com