A device for coating wax on the surface of electromagnetic wire

A wax coating device and electromagnetic wire technology, applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve the problems of uneven paraffin coating, thick coating, insulation burns, etc., to improve the coating effect and avoid burns , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

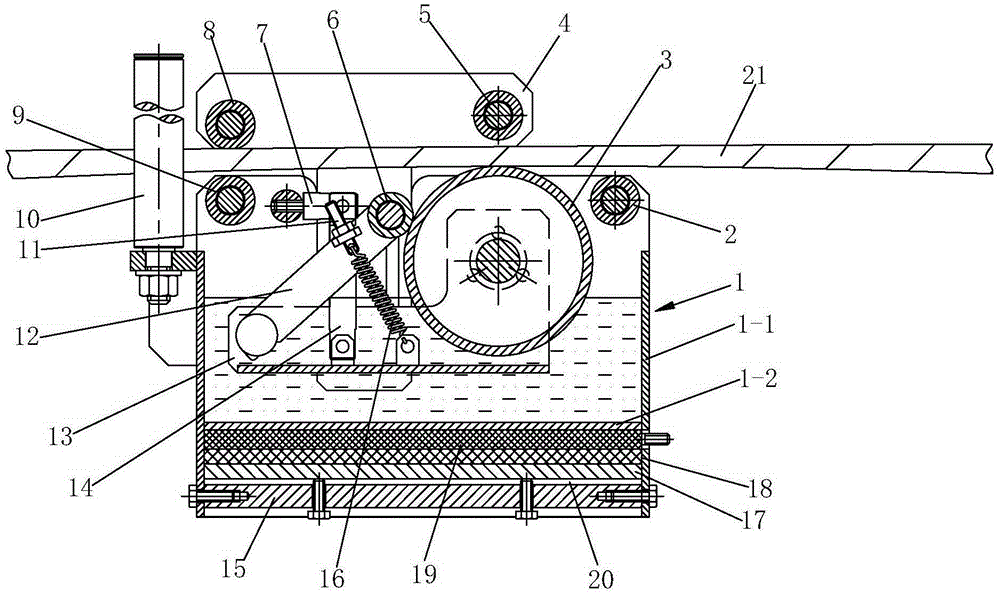

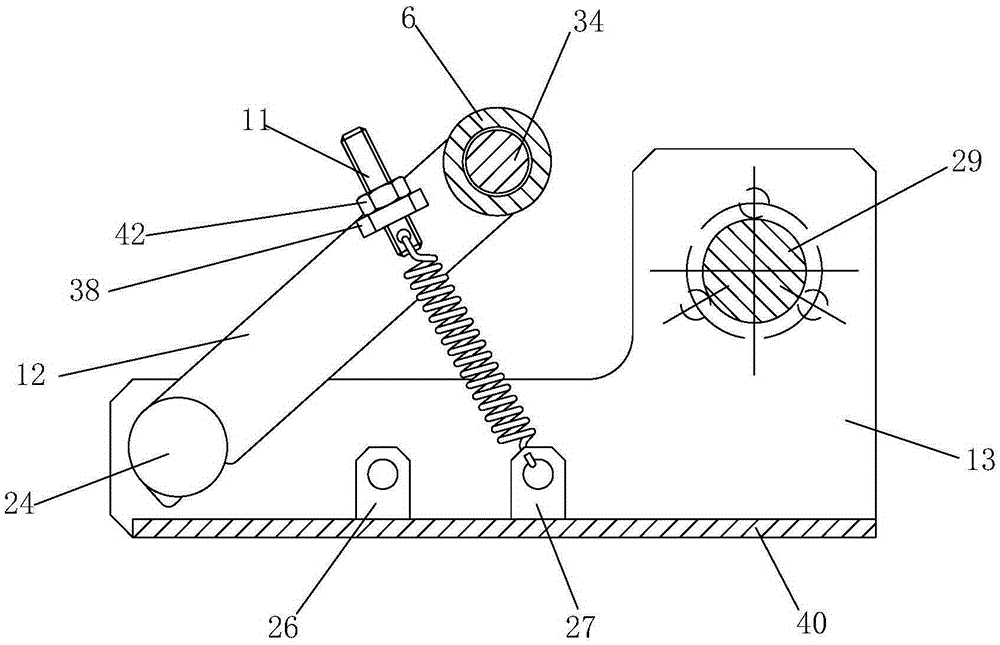

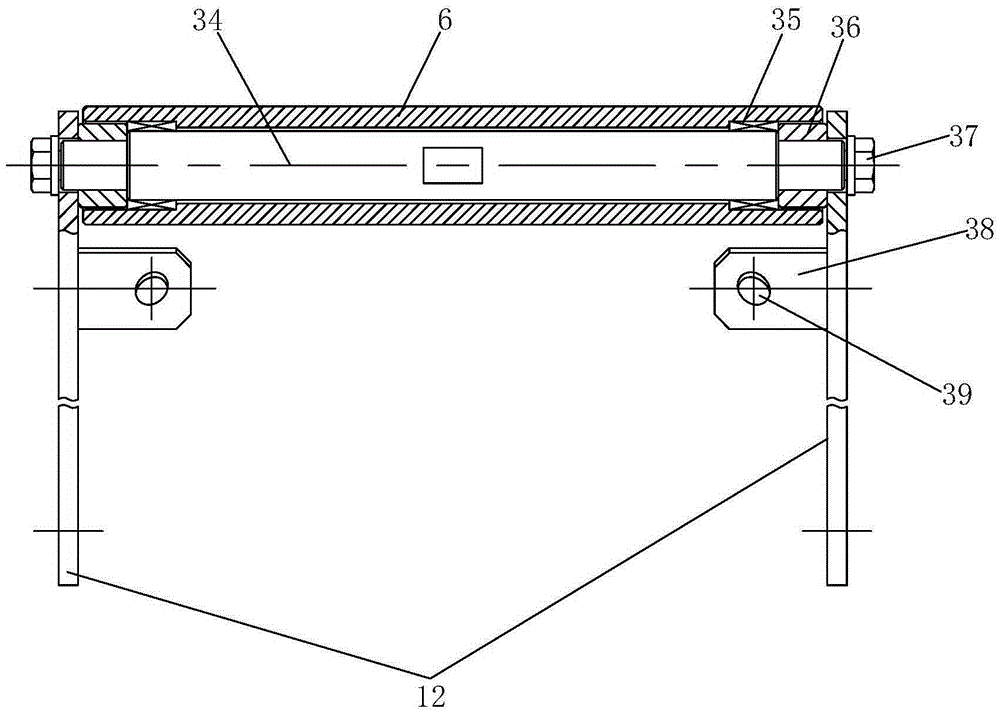

[0056] like figure 1 A kind of electromagnetic wire surface waxing device shown, comprises paraffin box 1, the elevating frame that is arranged in paraffin box 1 and is used for driving described elevating frame rising or lowering lifting mechanism, and described elevating frame is installed with for A waxing roller 3 for applying wax to the electromagnetic wire 21, the paraffin box 1 is provided with a first horizontal guide mechanism 9 and a second horizontal guide mechanism 2 for guiding the electromagnetic wire 21 to pass through the paraffin box 1, the waxing The rollers 3 are arranged between the first horizontal guide 9 and the second horizontal guide 2 .

[0057] In this embodiment, when in use, the electromagnetic wire 21 passes above the paraffin box 1 under the guidance of the first horizontal guide mechanism 9 and the second horizontal guide mechanism 2, and the lifting frame is driven up or down by the lifting mechanism, thereby driving the waxing The roller 3 ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com