Hot air type combustor

A burner, hot air technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of not very good appearance, the burner does not have automatic intelligent functions, etc., to achieve the effect of reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

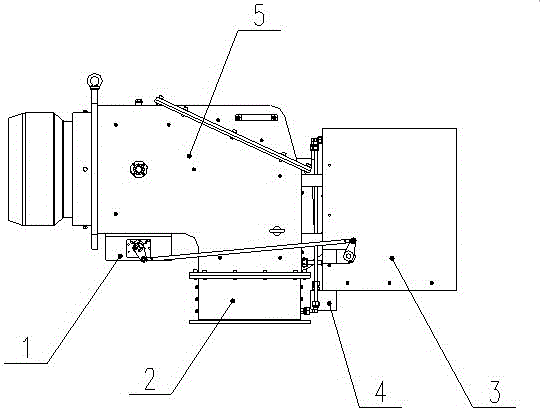

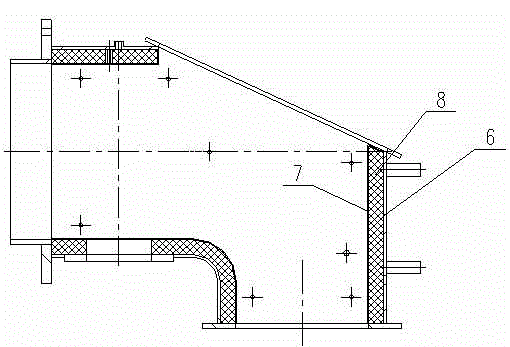

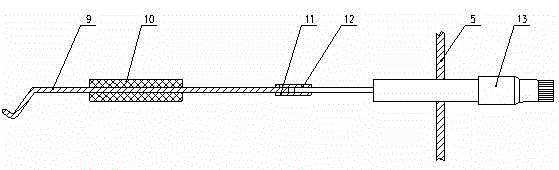

[0019] see Figure 1-6 , a hot air type burner, including a fuel butterfly valve 1, an air damper 2, an adjustment mechanism assembly 3, a cooling air inlet 4 and a burner housing 5, the air damper 2 is installed below the burner housing 5, the The adjustment mechanism assembly 3 is installed on the right side of the burner housing 5, the fuel butterfly valve 1 is installed on the burner housing 5 on the left side of the air damper 2, and the cold air inlet 4 is installed on the adjustment mechanism assembly 3 and the position between the burner housing 5, the burner housing 5 includes an outer shell 6, an inner shell 7 and an asbestos-free aluminum silicate fiber wool 8, the asbestos-free aluminum silicate fiber wool 8 Located between the outer casing 6 and the inner casing 7, the burner casing 5 is provided with an ignition needle device, the ig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com