Pressure-bearing supporting type heat exchanger

A heat exchanger and supporting technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as unstable pressure bearing capacity, leakage, and poor resistance to pressure fluctuations, and achieve improved The effect of pressure-bearing range, expanded application field, and resistance to galvanic corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

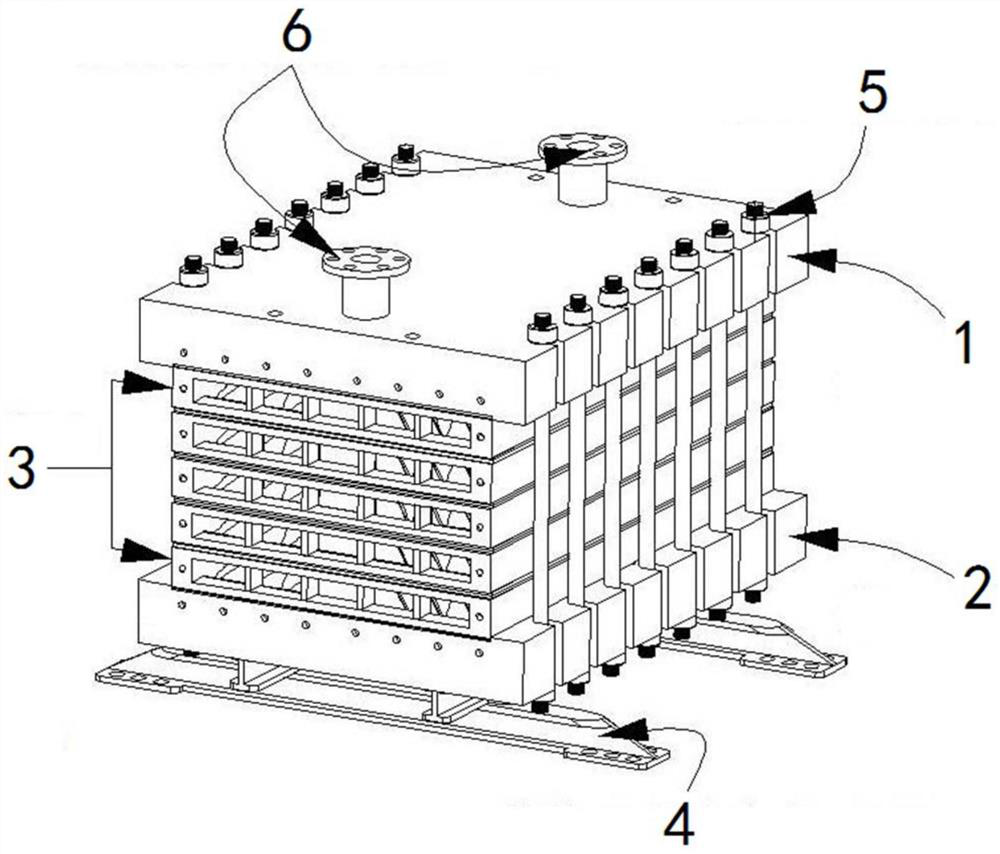

[0041] attached by figure 1 , 5 , 6, 7, and 8 show: a pressure-bearing support type heat exchanger, the heat exchanger includes a heat exchanger body and two ends of the head, the heat exchanger body includes the first clamping plate 1, the second Two clamping plates 2, a heat exchange plate bundle 3 and a main body support 4, the heat exchange plate bundle 3 is fixed between the first clamping plate 1 and the second clamping plate 2 through a plurality of clamping bolts 5, The main body support 4 is arranged below the second clamping plate 2 .

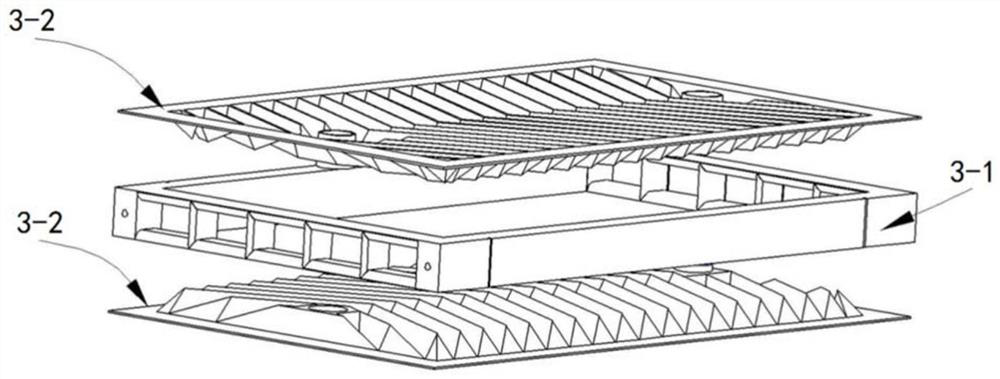

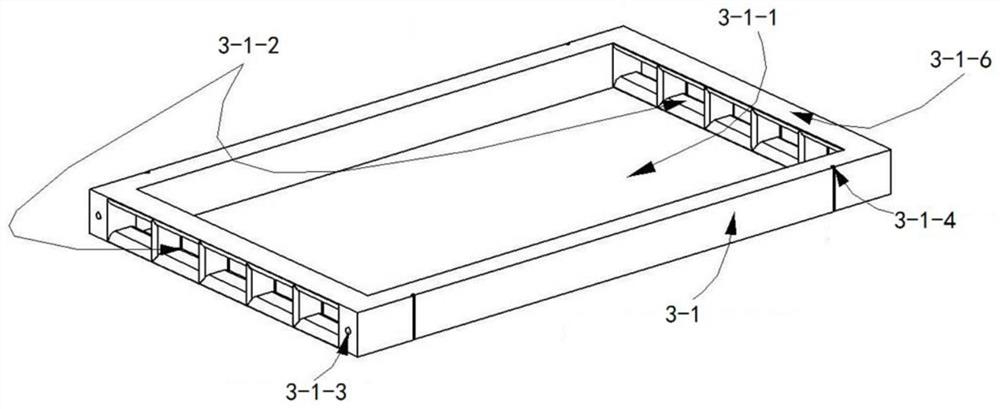

[0042] attached by figure 1 , 2 As shown: the heat exchange plate bundle 3 is composed of a plurality of pressure-bearing support frame combination units, and the pressure-bearing support frame combination unit is composed of a pressure-bearing support frame 3-1 and a pressure-bearing support frame 3-1. The heat exchange plates are assembled by 3-2.

[0043] The structure of the heat exchange plates 3-2 matches the structure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com