Winding device for conductive film production

The technology of a conductive film and a winding device is applied in the direction of winding strips, thin material processing, transportation and packaging, etc. It can solve the problems of single winding range, small holding range, thickness adjustment of conductive film winding, etc. Achieve the effect of expanding the scope of selection and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, purpose and efficacy of the invention easy to understand, the invention is further described in combination with specific embodiments.

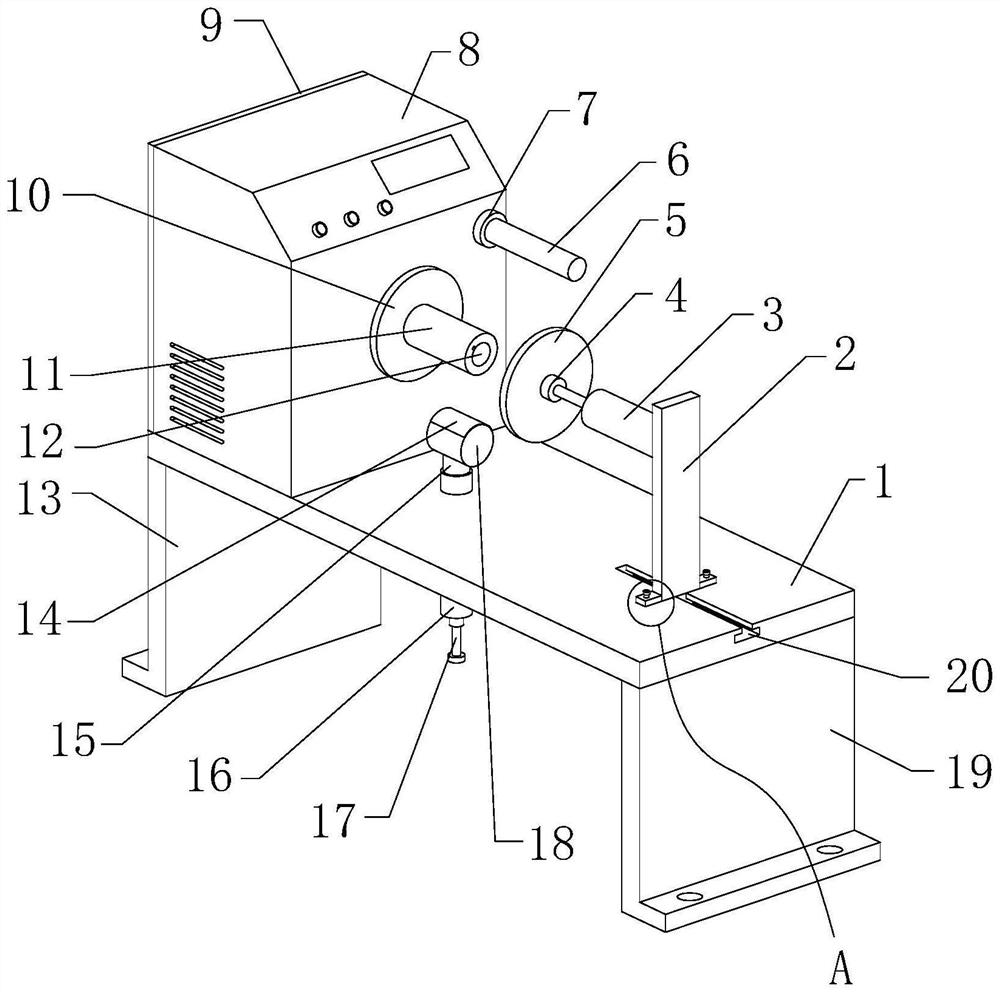

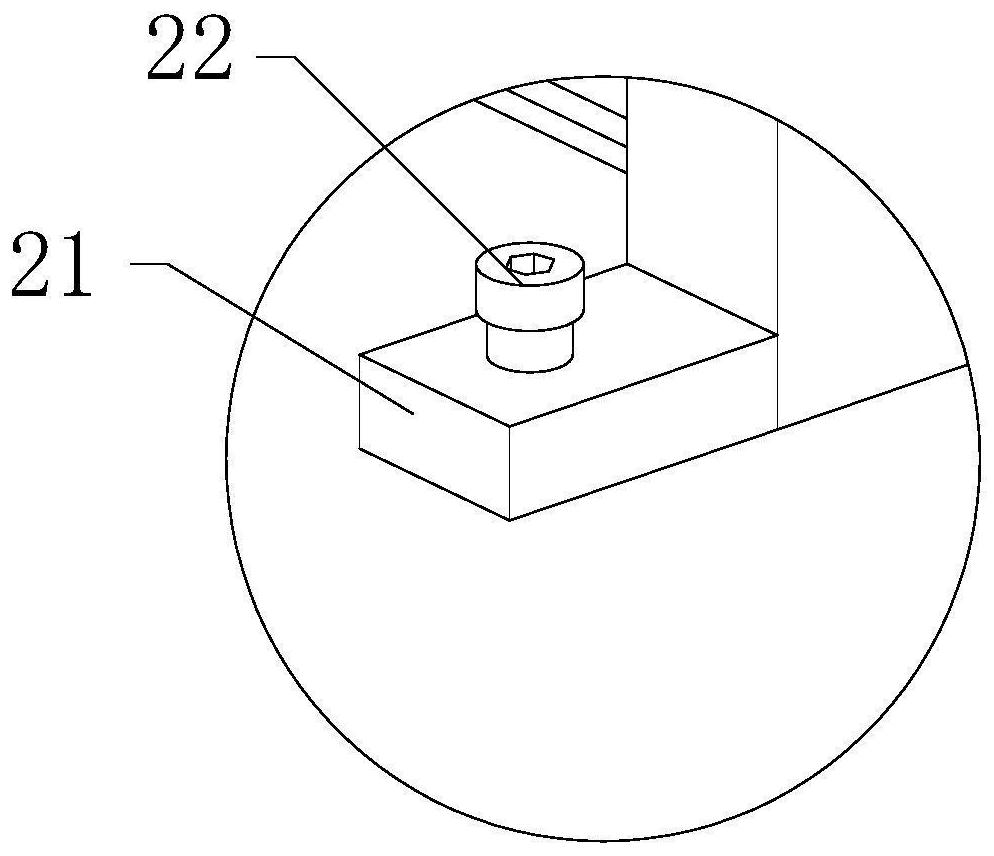

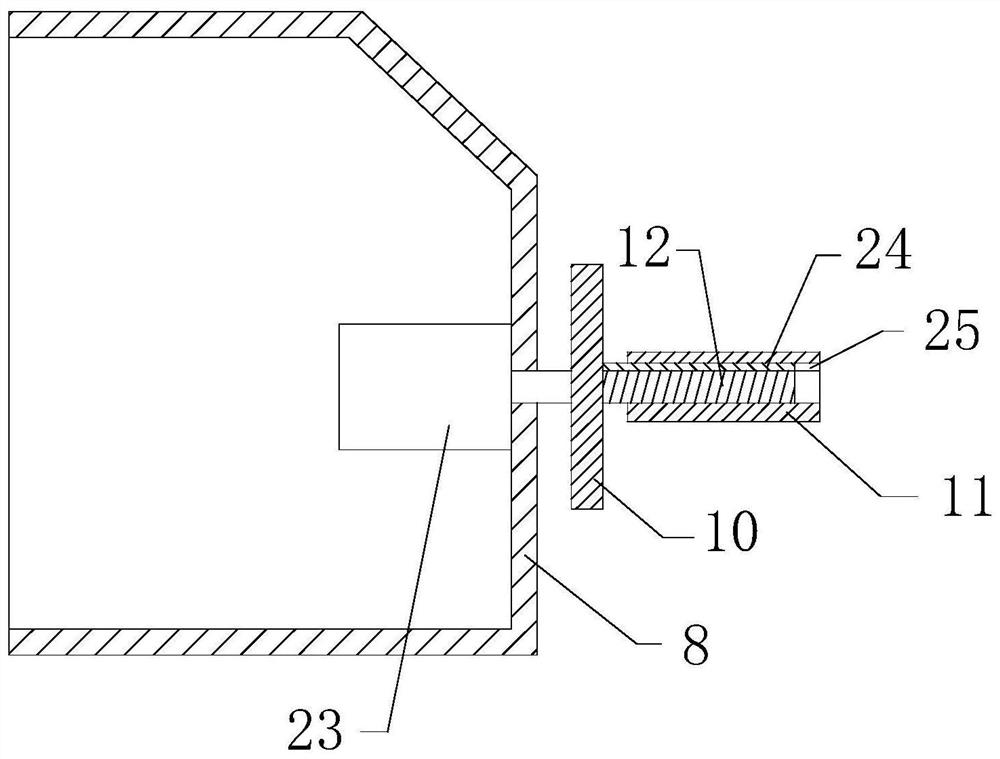

[0023] see also Figures 1 to 5 The invention provides a technical scheme: a winding device for conductive film production, which comprises a platen 1, a support 1 13 and a support 2 19. The support 1 13 is fixed at the left edge of the lower end face of the platen 1, the support 2 19 is fixed at the right edge of the lower end face of the platen 1, a winding assembly is installed on the upper end face of the platen 1, and the winding assembly comprises a support plate 2, an air cylinder 3, a rolling bearing 1 4, a movable chuck 5, a idler 6, a rolling bearing 2 7, an equipment box 8, a box cover 9 The clamping disc 10, the take-up drum 11, the inserting column 12, the T-shaped groove 20, the servo motor 23, the limit strip 24, the limit groove 25 and the T-shaped block 27 are fixed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com