Two-stage water spraying screw mainframe

A host and screw technology, applied in the field of compressors, can solve the problems of poor overall energy efficiency of the host and can not be completely sealed, and achieve the effects of reliable operation, high pressure range and simple sealing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

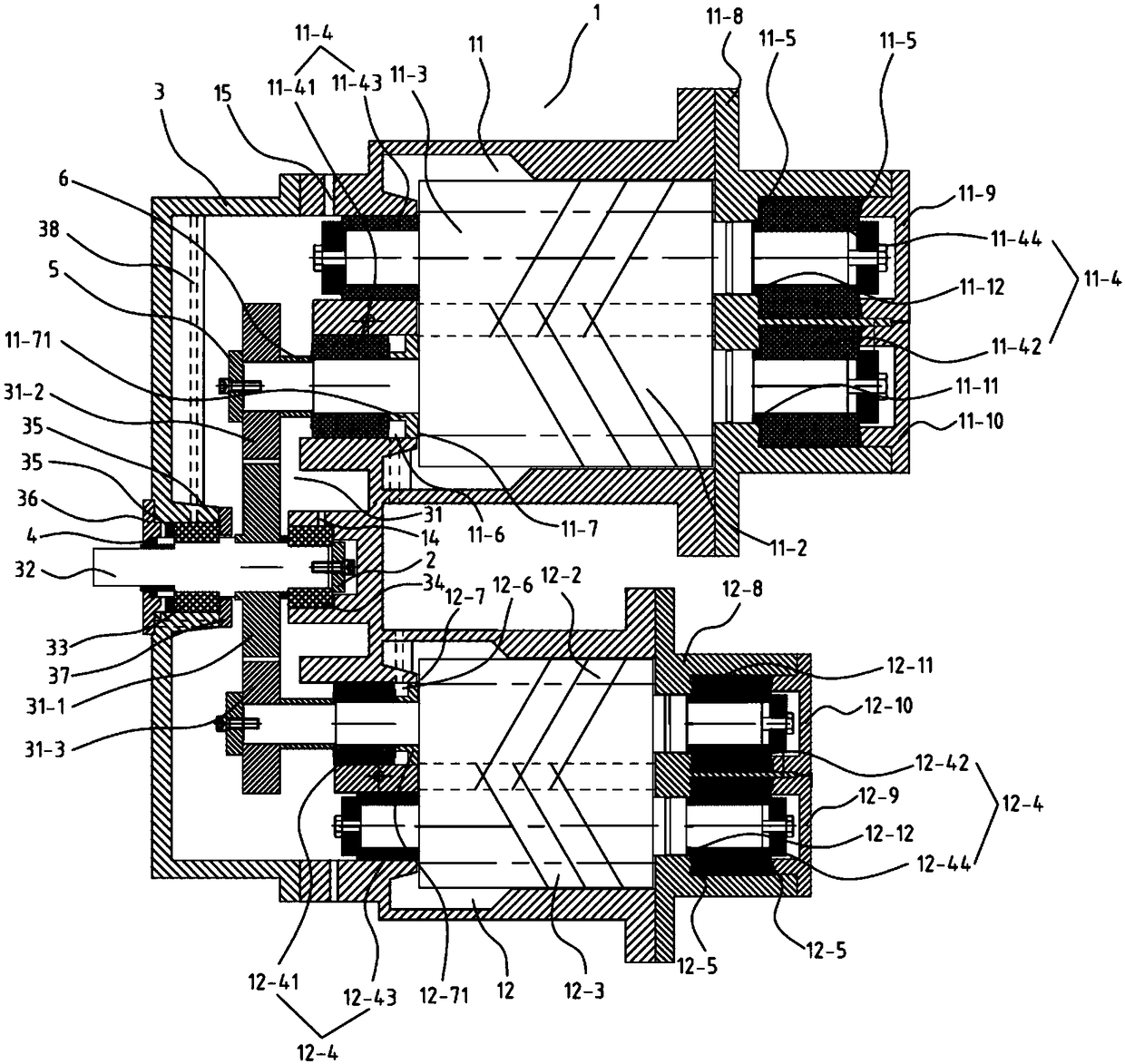

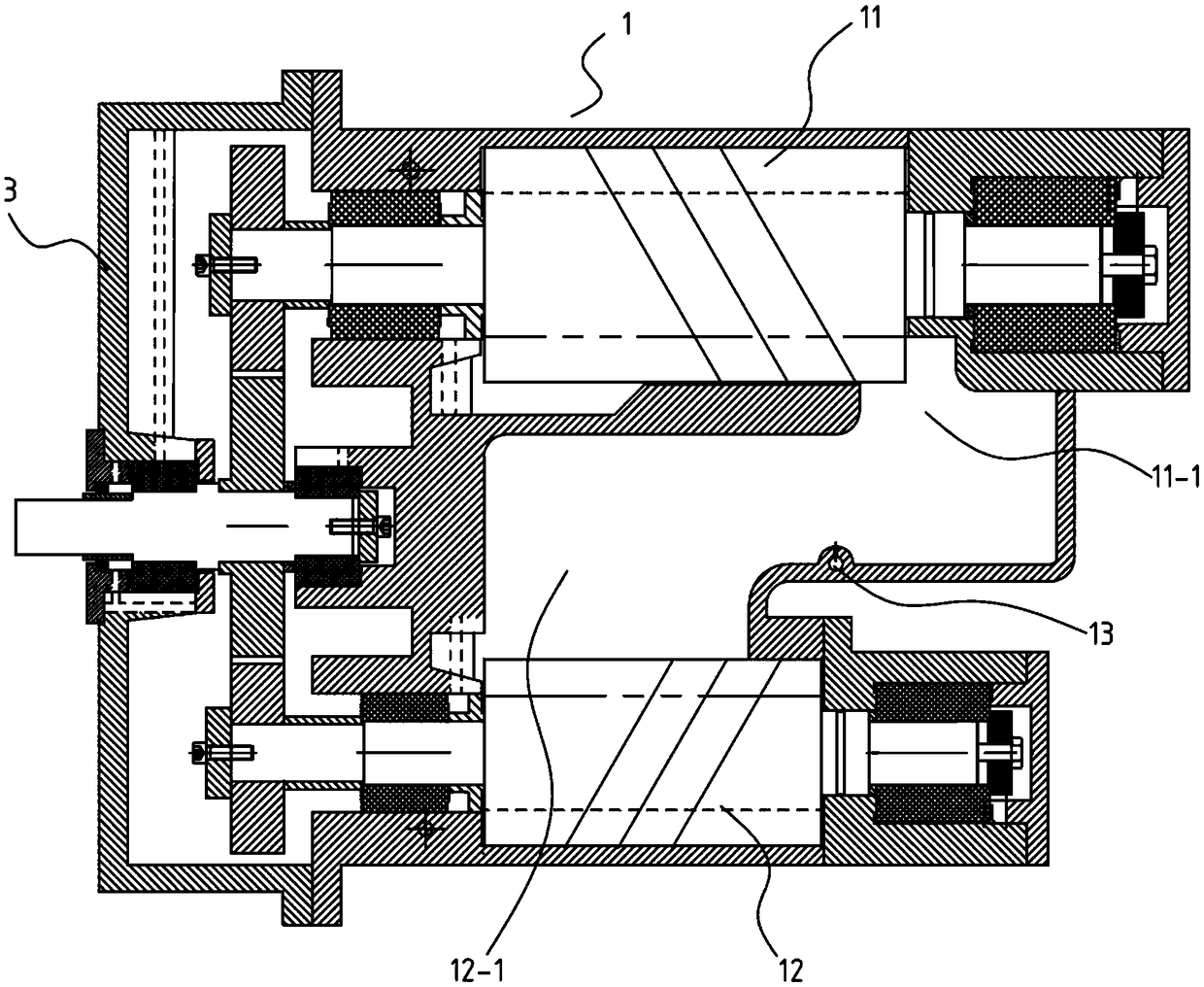

[0025]Embodiment 1: The gear mechanism 31 includes a driving gear 31-1, a primary driven gear 31-2, a secondary driven gear 31-3, a primary driven gear 31-2 and a primary compression chamber 11. The male rotor 11-2 or the first-stage female rotor 11-3 are connected, and a gear washer 6 is sandwiched between the first-stage driven gear 31-2 and the first-stage male rotor 11-2 or the first-stage female rotor 11-3 and passed through The gear pressing block 5 is fastened, and the primary driven gear 31-2 is preferably connected with the primary male rotor 11-2 in the primary compression chamber 11; the secondary driven gear 31-3 is connected with the secondary compression chamber 12 The second-stage male rotor 12-2 or the second-stage female rotor 12-3 are connected, and a gear is interposed between the second-stage driven gear 31-2 and the second-stage male rotor 12-2 or the second-stage female rotor 12-3 The washer 6 is fastened by the gear pressing block 5, and the secondary dr...

Embodiment 2

[0028] Embodiment 2: The two ends of the first-stage male rotor 11-2 in the first-stage compression chamber 11 are respectively installed with a first-stage male front sliding bearing 11-41 and a first-stage male rear sliding bearing 11-42, and are fixed by fasteners; The two ends of the first-stage female rotor 11-3 are respectively equipped with a first-stage female front sliding bearing 11-43 and a first-stage female rear sliding bearing 11-44, and are fixed by fasteners.

[0029] The first-stage positive rear sliding bearing 11-42 and the first-stage female rear sliding bearing 11-44 are respectively provided with first thrust bearings 11-5 along the axial direction, and the first thrust bearing 11-5 on one side is located in a On the first-stage exhaust seat 11-8, the first thrust bearing 11-5 on the other side is located on the first-stage female rear cover 11-9 and the first-stage positive rear cover 11-10; on the first-stage exhaust seat 11-8 The end of the first-stage...

Embodiment 3

[0031] Embodiment 3: The two ends of the two-stage male rotor 12-2 in the two-stage compression chamber 12 are respectively installed with a two-stage male front sliding bearing 12-41 and a second-stage male rear sliding bearing 12-42, and are fixed by fasteners ; The two ends of the secondary female rotor 12-3 are respectively equipped with a secondary female front sliding bearing 12-43 and a secondary female rear sliding bearing 12-44, and are fixed by fasteners.

[0032] Secondary positive rear sliding bearings 12-42 and secondary negative rear sliding bearings 12-44 are respectively provided with second thrust bearings 12-5 along the axial direction, wherein the second thrust bearings 12-5 on one side are located on the second On the first-stage exhaust seat 12-8, the second thrust bearing 12-5 on the other side is located on the second-stage female rear cover 12-9 and the second-stage positive rear cover 12-10; on the second-stage exhaust seat 12-8 The end of the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com