Fully pre-mixing gas combustion burner device

A gas burner and burner technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of unfavorable environmental protection, uneven flame, unreasonable premix chamber structure design, etc., and achieve enhanced efficiency and reduced The effect of outer surface temperature, flame uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

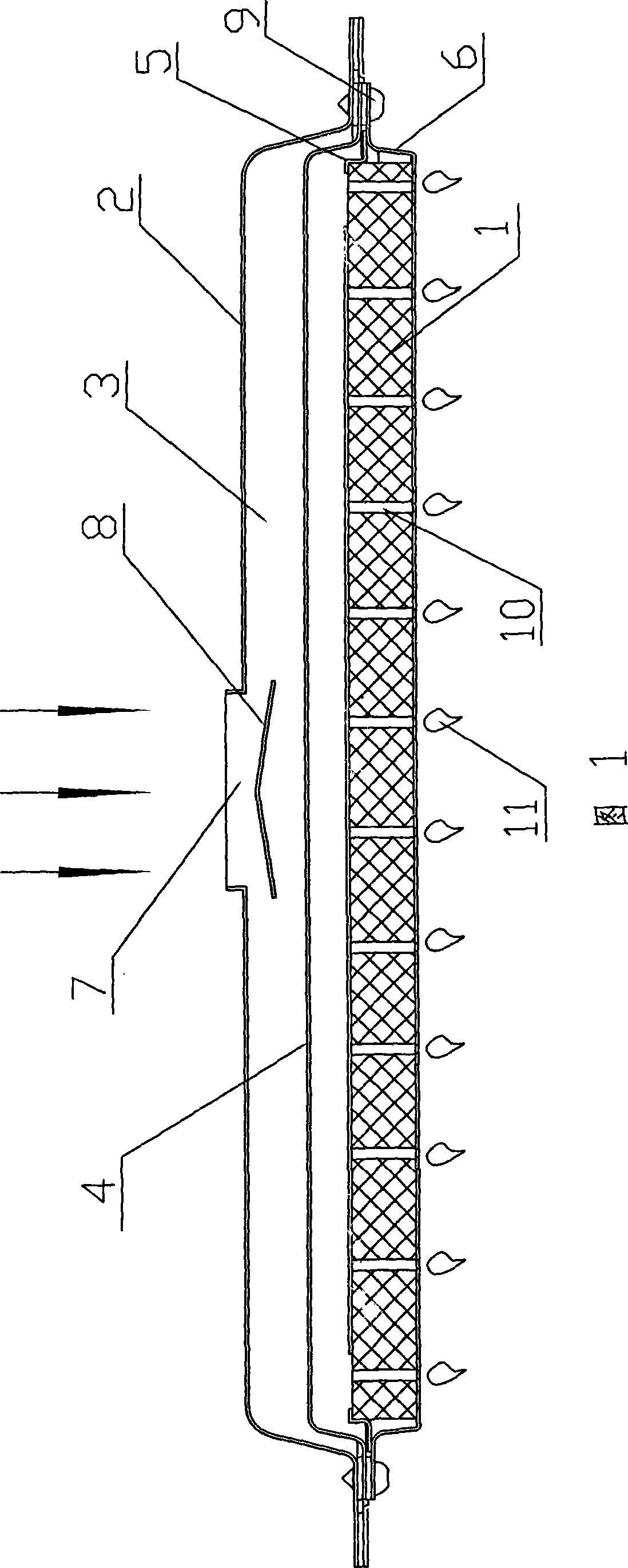

[0020] Specific embodiment one: as figure 1 As shown, this embodiment includes a burner 1 and a fixing device for installing the burner 1. The periphery of the burner 1 is provided with an air-mixing chamber 3 formed by a casing 2, and between the burner 1 and the casing 2 is a The pressure dividing partition 4 has a gap between the pressure dividing partition 4 and the casing 2 . The pressure dividing partition 4 is a plate-shaped structure with a plurality of small holes distributed thereon. The diameter of the small hole away from the air inlet 7 on the pressure dividing partition 4 is equal to the diameter of the small hole close to the air inlet 7 . The fixing device includes a fixed frame 6 and a fixed plate 5, the fixed frame 6 is a frame structure, the fixed plate 5 is a right-angled strip structure, the right-angled side of the fixed plate 5 is lapped on the edge of the burner 1, and the fixed frame 6 is relatively screwed and The burner 1 is fastened on the fixed f...

specific Embodiment 2

[0021] Specific embodiment two: the difference between the present embodiment and embodiment one is that there is no splitter plate 8 under the air inlet 7, and the diameter of the small hole away from the air inlet 7 on the pressure divider 4 is greater than the diameter of the small hole near the air inlet 7 , except for these two differences, other structures and implemented functions are consistent with Embodiment 1.

[0022] In the technical solution of the present invention, the size of the small holes of the pressure dividing partition can be the same, and corresponding changes can also be made according to the wind pressure. Larger holes are opened in places where the wind pressure is small, and holes are opened in places where the wind pressure is high. It will be smaller; if the air inlet is small, a splitter plate will be installed at the air inlet to avoid the wind pressure at this place from being higher than other places. If the air inlet is larger, there is no ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com