Water-cooling type hearth plate of petroleum coke tank-type calcining furnace

A tank-type calcination furnace and petroleum coke technology, applied in the direction of furnace cooling, furnace, furnace components, etc., can solve the problems of uneven thermal expansion, cracking of furnace body, high temperature of furnace bottom plate, etc., achieve uniform temperature distribution and reduce overall temperature difference , reduce the effect of radiation heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

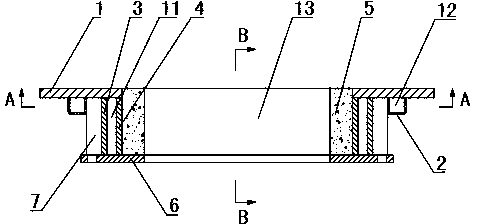

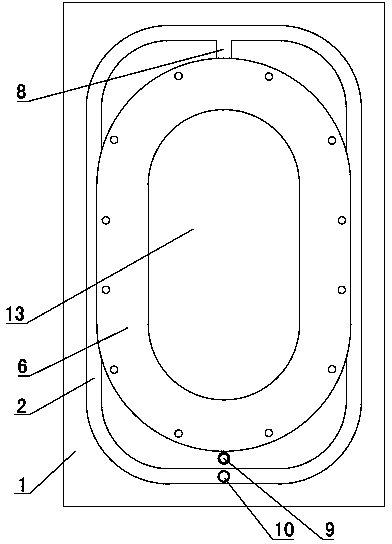

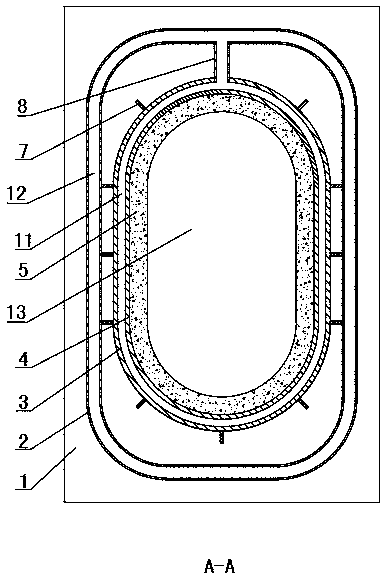

[0022] Figure 1~4 It is the best embodiment of the water-cooled furnace floor of the petroleum coke tank type calciner of the present invention, below in conjunction with the attached Figure 1~4 The present invention will be further described.

[0023] refer to Figure 1~2 , Petroleum coke tank type calciner water-cooled furnace bottom plate, including upper plate 1 and lower flange plate 6, between the upper plate 1 and lower flange plate 6, an annular water jacket inner plate 4 and an annular water jacket are fixedly connected The jacket outer plate 3, the upper plate 1 and the middle of the lower flange plate 6 are all provided with annular through holes, and the annular through holes of the upper plate 1 and the inner wall of the water jacket inner plate 4 are provided with a ring-shaped castable refractory layer 5, The space enclosed by the castable refractory layer 5 is the discharge channel 13 for the high-temperature calcined coke of the tank type calciner. The cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com