Parallel cylinder type aftertreatment structure assembly

A post-processing, cartridge-type technology, which is applied in the direction of exhaust gas treatment, mechanical equipment, engine components, etc., can solve the problems of NH3 uniformity that is not easy to meet the design requirements, poor loading versatility, and large space occupation, etc., to achieve reduction Risk of urea crystallization, convenient regular inspection, and flexible installation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific drawings and embodiments.

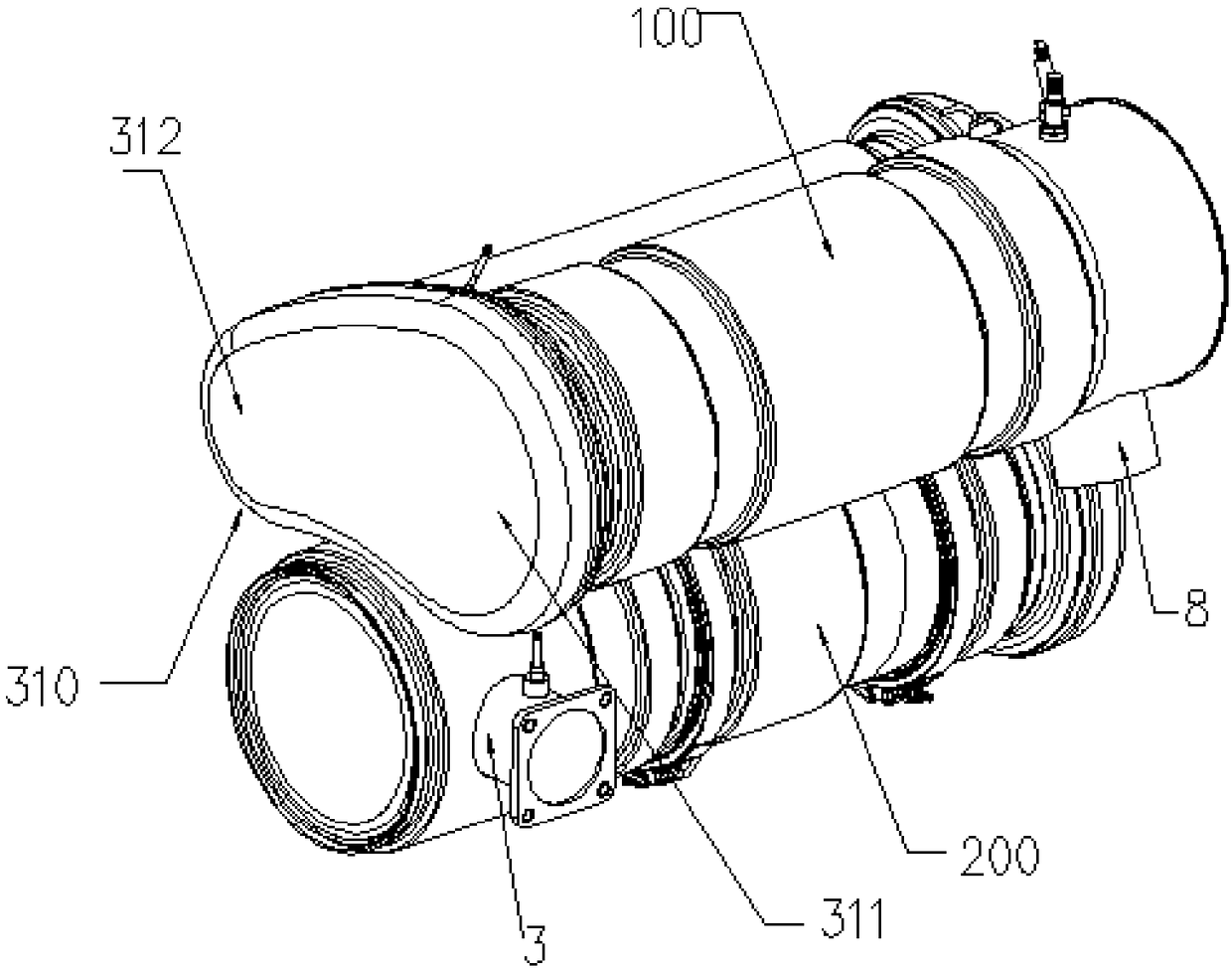

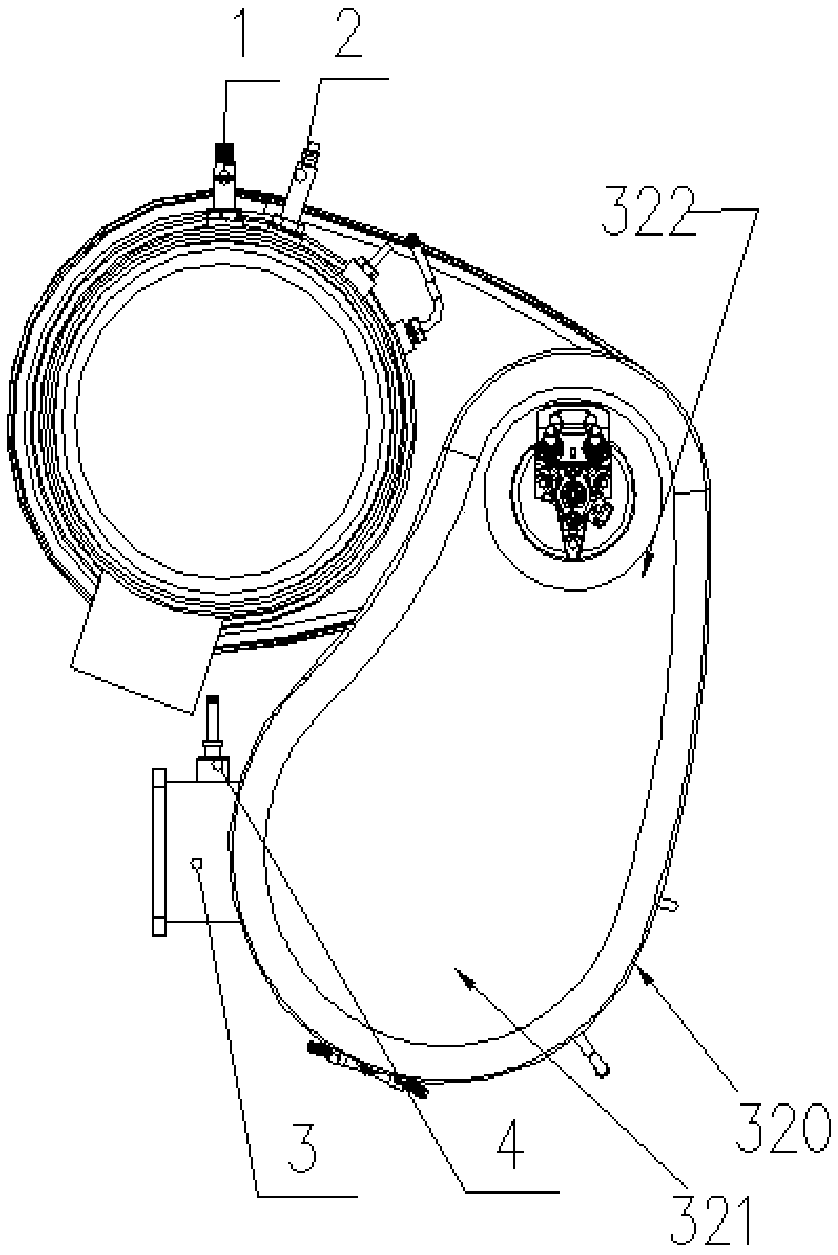

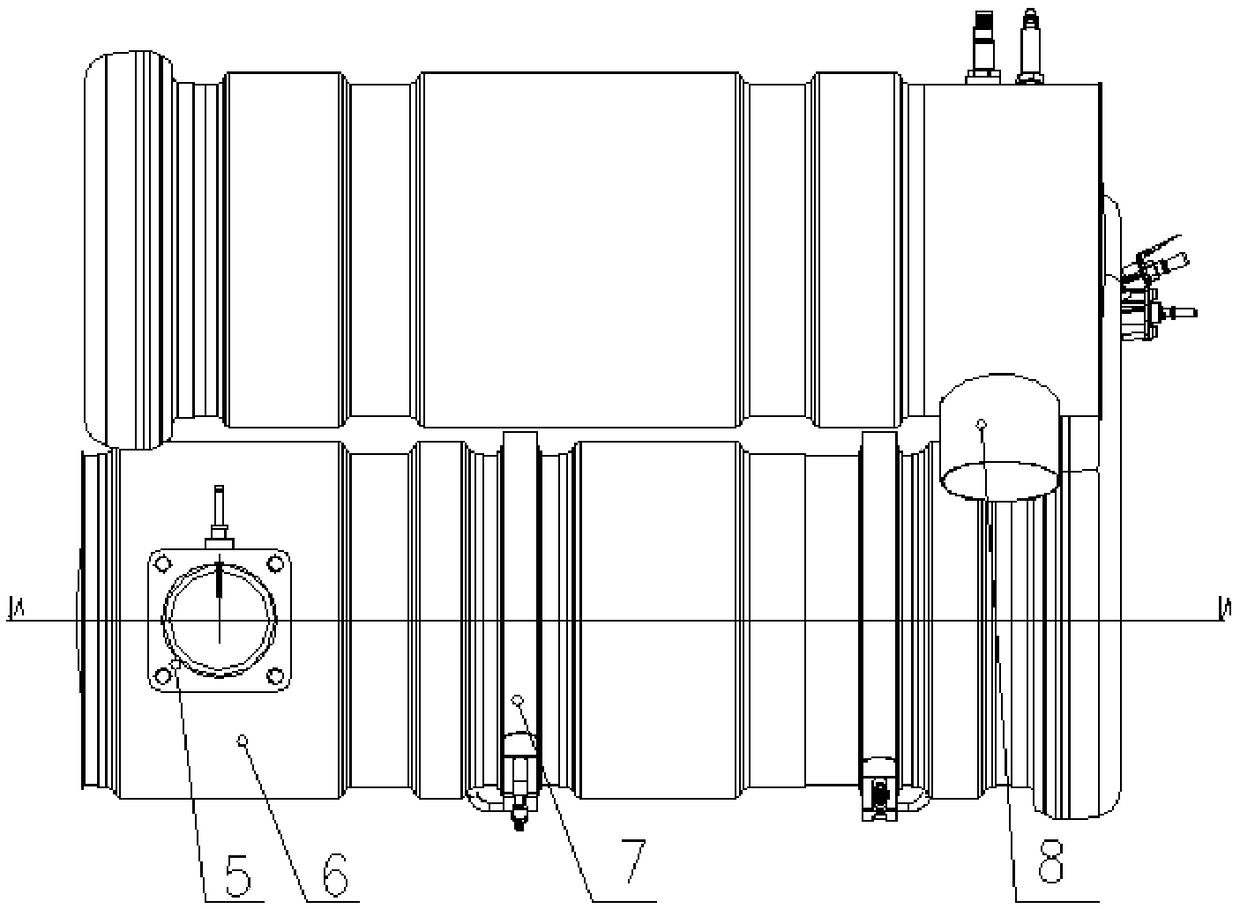

[0039] Such as Figure 1-7 As shown, a parallel cylindrical post-treatment structure assembly is characterized in that it includes:

[0040] The first cylinder 100, the second cylinder 200 and the connecting pipe 16 connecting the two cylinders;

[0041] The two ends of the connecting pipe are respectively connected with a left end cap 310 and a right end cap 320 with the same structure,

[0042] The left end cap and the right end cap have big ends 311, 321 respectively;

[0043] and small ends 312, 322;

[0044] The small end of the left end cap is connected to one end of the connecting pipe, and the large end is connected to one end of the first cylinder; the other end of the first cylinder is provided with an air outlet end cap 330;

[0045] The first cylinder body is provided with an air outlet pipe 8, a nitrogen oxide sensor 1 and a PM sensor 2 near th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com