Heat insulation part and heating device comprising same

A technology for heating parts and components, which is applied to electrical components, electric heating devices, etc., can solve the problems of unfavorable thermal insulation performance, thermal insulation materials and thermal insulation structure design of thermal insulation shell to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

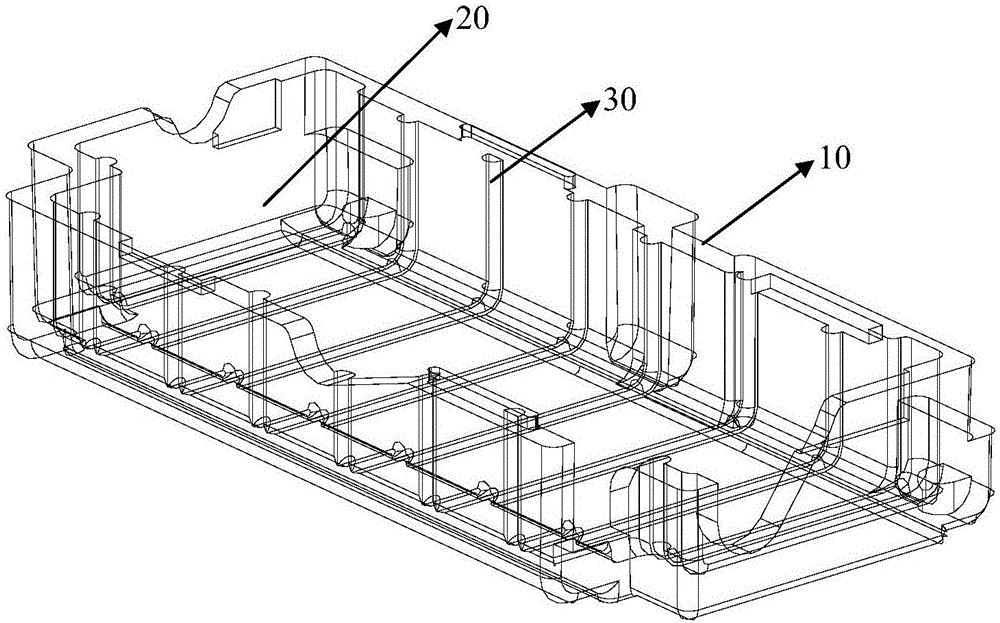

[0062] For the specific structure of the heat insulation components, see figure 1 . Wherein, the housing is formed of the above-mentioned foam-type heat insulating material, and the inner wall of the housing chamber is provided with a plurality of reinforcing ribs evenly distributed on the inner wall surfaces, parallel to each other and evenly distributed.

Embodiment 2

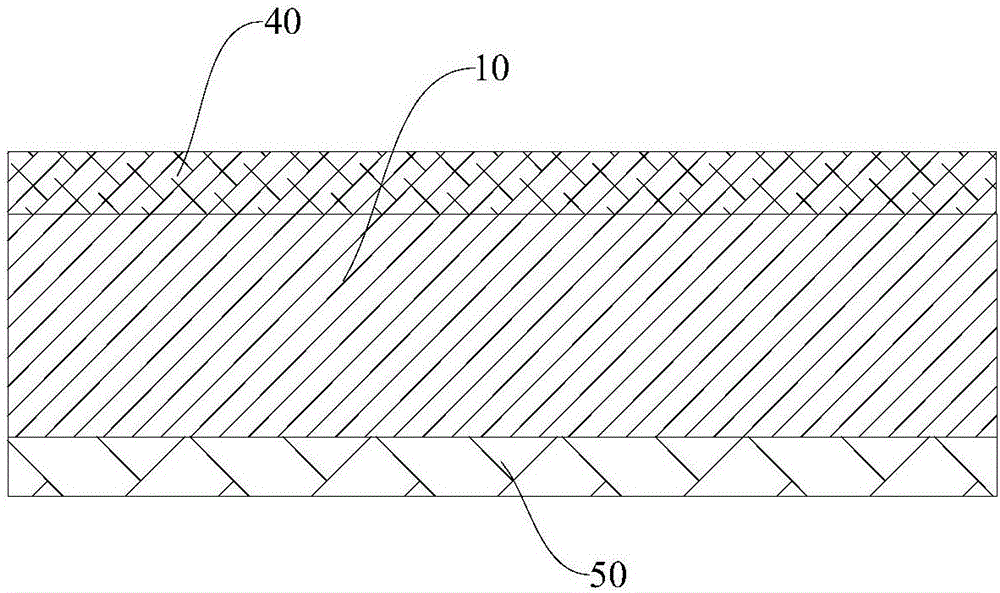

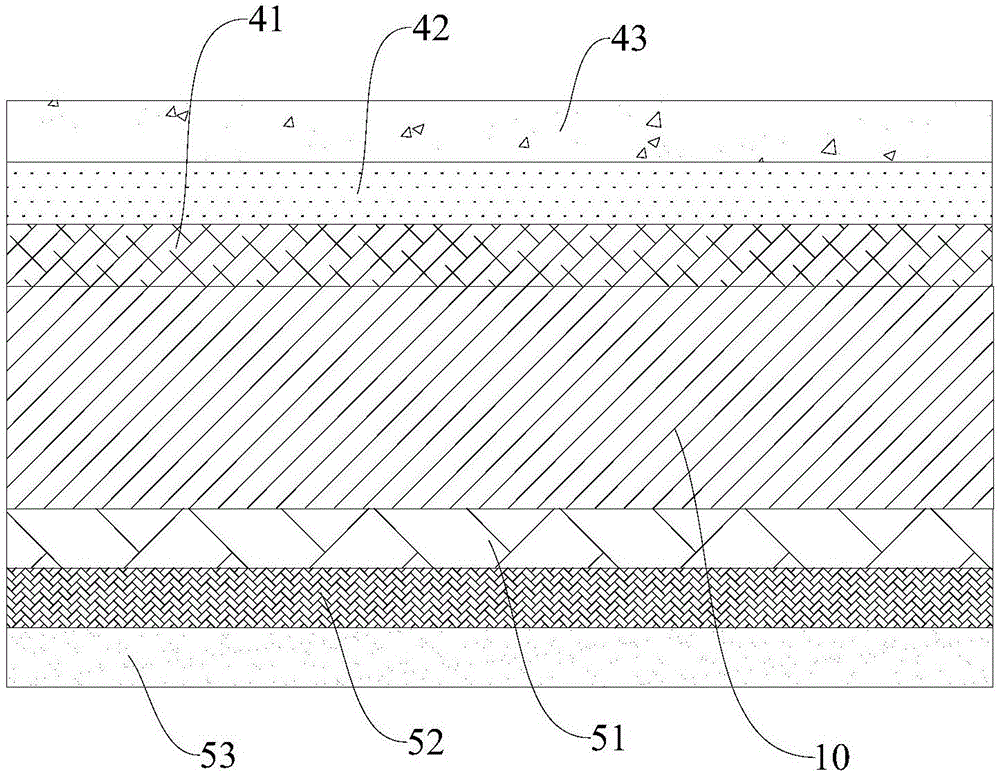

[0064] For the specific structure of the heat insulation components, see figure 1 . Wherein, the specific composition of the housing and the setting of the reinforcing ribs are the same as those in Embodiment 1, the difference is that the inner surface of the housing is provided with a first heat-insulating sublayer, a second heat-insulating sub-layer and a heat-reflecting infrared coating in sequence, and the outer surface of the housing is The surface is sequentially provided with a third heat-insulating sublayer, a fourth heat-insulating sublayer and a heat-conducting coating.

Embodiment 3

[0068] The thermal insulation components of Examples 1-2 and Comparative Example 1 were installed in a steam boiler for heat insulation, heated under the same heating conditions, and the temperature of the outer surface of the steam boiler wall temperature and thermal insulation component was measured as a function of time, and the result See Figure 4 and Table 1, where, Figure 4 is the time-varying curve of the outer surface temperature of the thermal insulation component, (1), (2), and (3) correspond to Comparative Example 1, Example 1, and Example 2, respectively.

[0069] Table 1

[0070]

[0071] Depend on Figure 4 From the results in Table 2, it can be seen that the heat insulation component of the present invention can effectively reduce the heat transfer to the outside, significantly reduce the outer surface temperature and temperature rise rate of the heat insulation component, and increase the temperature of the heating component at the same time.

[0072] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com