Liquid deslagging cyclone burner with interlayer rotational flow secondary air

A technology of liquid slag removal and cyclone combustion, which is applied in the direction of burners, burners, and combustion methods for burning powder fuels, and can solve problems such as the inability to maintain the tail combustion chamber, weaken the effect of slag collection, and high swirl intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

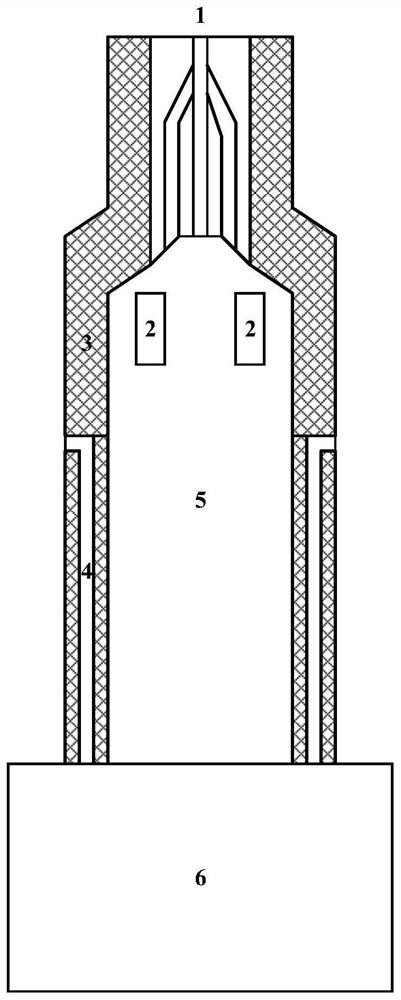

[0022] This example is a liquid slagging cyclone burner with interlayer swirl secondary air, including swirl burner 1, main secondary air inlet channel 2, burner cylinder 3, interlayer secondary air annular channel 4, and combustion in the cylinder space5.

[0023] A swirl burner 1 is arranged on the top of the barrel 3, and the swirl burner 1 uses solid fuel, and the flue gas outlet of the liquid slag discharge cyclone burner is located at the bottom of the burner barrel 3; Wind and solid fuel particles; the secondary air includes the main secondary air and interlayer secondary air, the upper part of the cylinder 3 is arranged with the main secondary air inlet channel 2 along the tangential direction of the cylinder, and the interlayer is arranged at a suitable height of the cylinder 3 The secondary air annular channel 4, the interlayer secondary air keeps rotating at high speed, and the direction of rotation is consistent with the main secondary air. The outlet of the interl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com