Heat recovery system for high temperature flue gas at ammoxidation section

A high-temperature flue gas and heat recovery technology, applied in the chemical industry, inorganic chemistry, climate sustainability, etc., can solve the problems of low ratio of sodium nitrite/sodium nitrate content, high tail gas content, unfavorable environmental protection, etc., to achieve convenient Effects of remote control, improvement of heat energy utilization rate, and increase of boiler steam production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

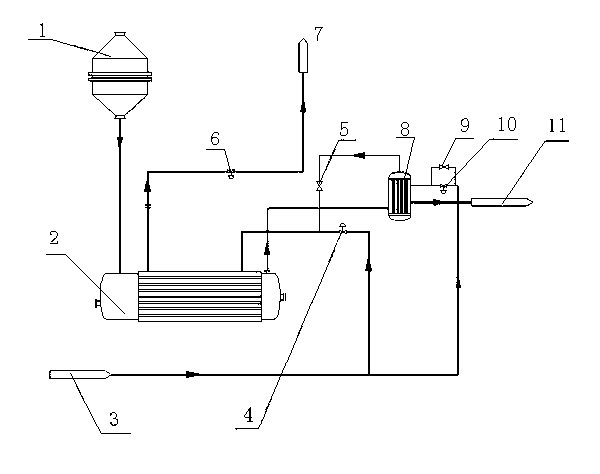

[0011] Such as figure 1 As shown, the ammonia oxidation furnace 1 is connected to the waste heat boiler 2, the waste heat boiler 2 communicates with the outer pipe 7 through the valve three 6, the desalted water tank 3 communicates with the waste heat boiler 2 through the valve one 4, and the waste heat boiler 2 communicates with the alkali absorption section 11 An economizer 8 is added between them, and the economizer 8 communicates with the desalted water tank 3 through the valve 2, and a pneumatic control valve 9 remotely controlled by a decentralized control system and a manual control valve are connected in series between the economizer 8 and the desalted water tank 3 9 is in parallel with the pneumatic control valve 10.

[0012] The desalted water in the waste heat boiler 2 comes from the desalted water tank 3, and the water temperature is about 85°C. The temperature of the process gas from the ammonia oxidation furnace 1 is reduced to about 220°C after heat exchange thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com