Flame pressing type water tube boiler

A technology of water tube boilers and tubes, which is applied in the field of steam generating devices, can solve the problems of large boiler volume, unreasonable flue flow channel design, and insufficient compact furnace body volume, etc., and achieve reasonable design, sufficient heat exchange, and sufficient heat exchange Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

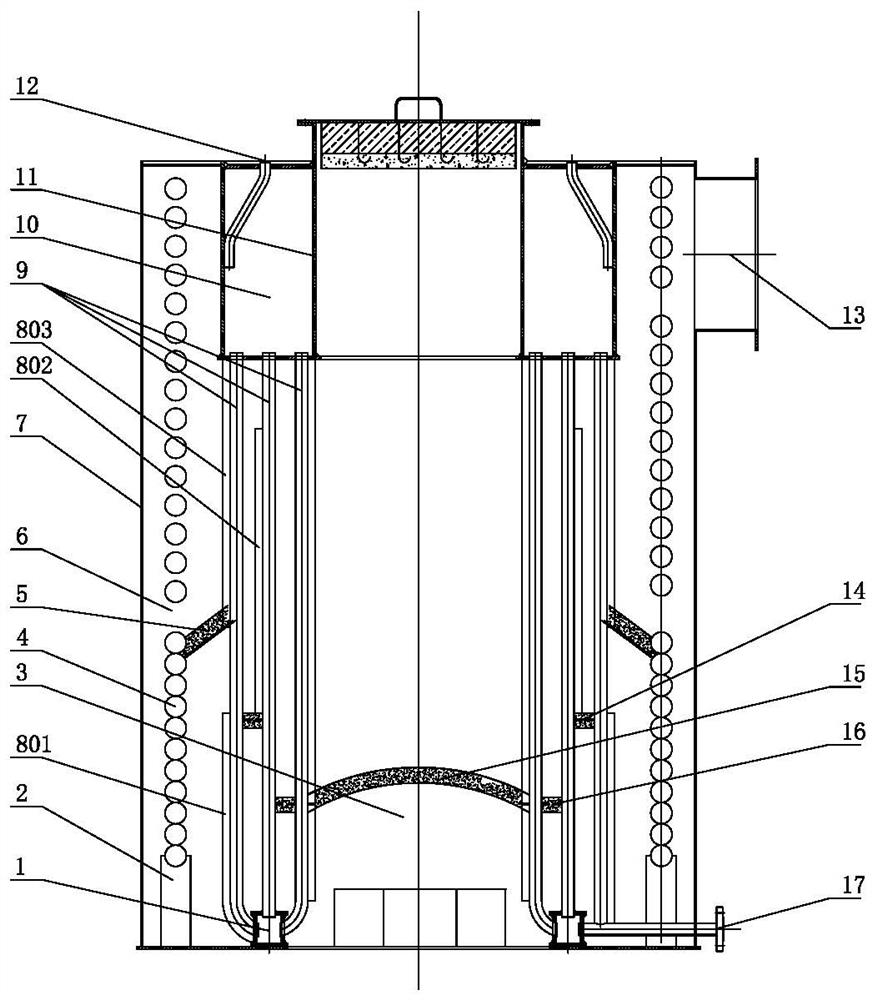

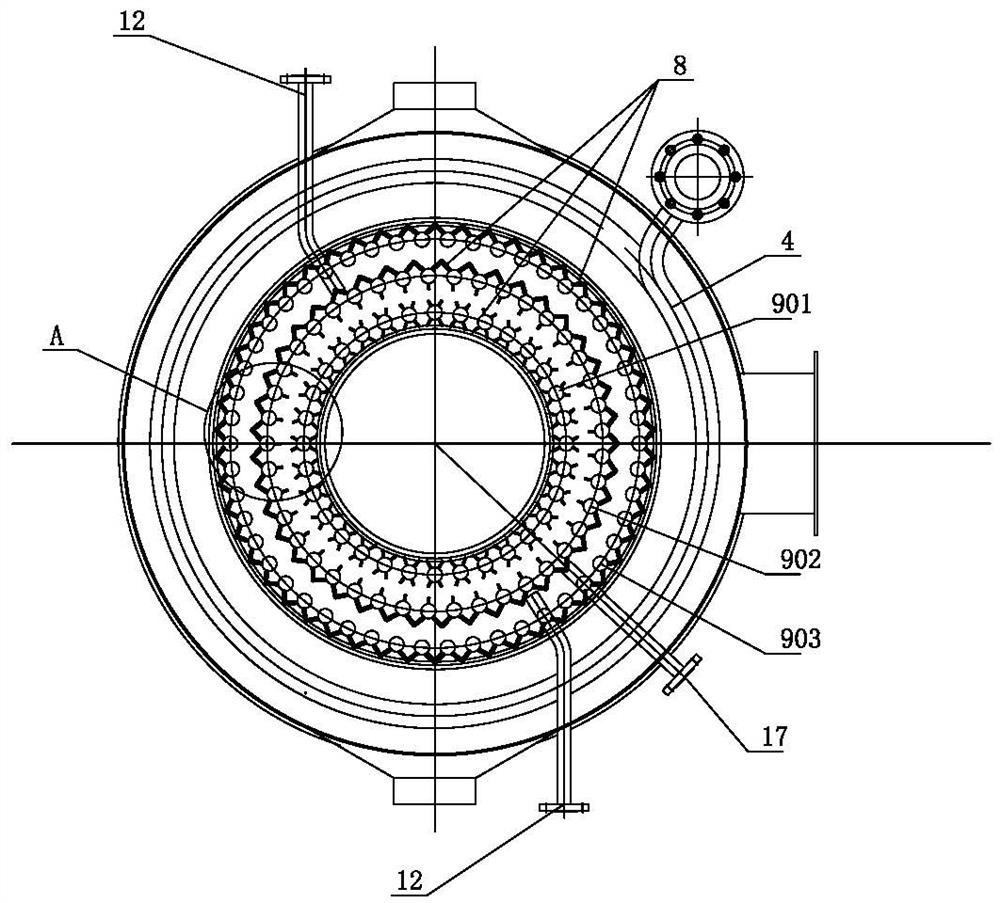

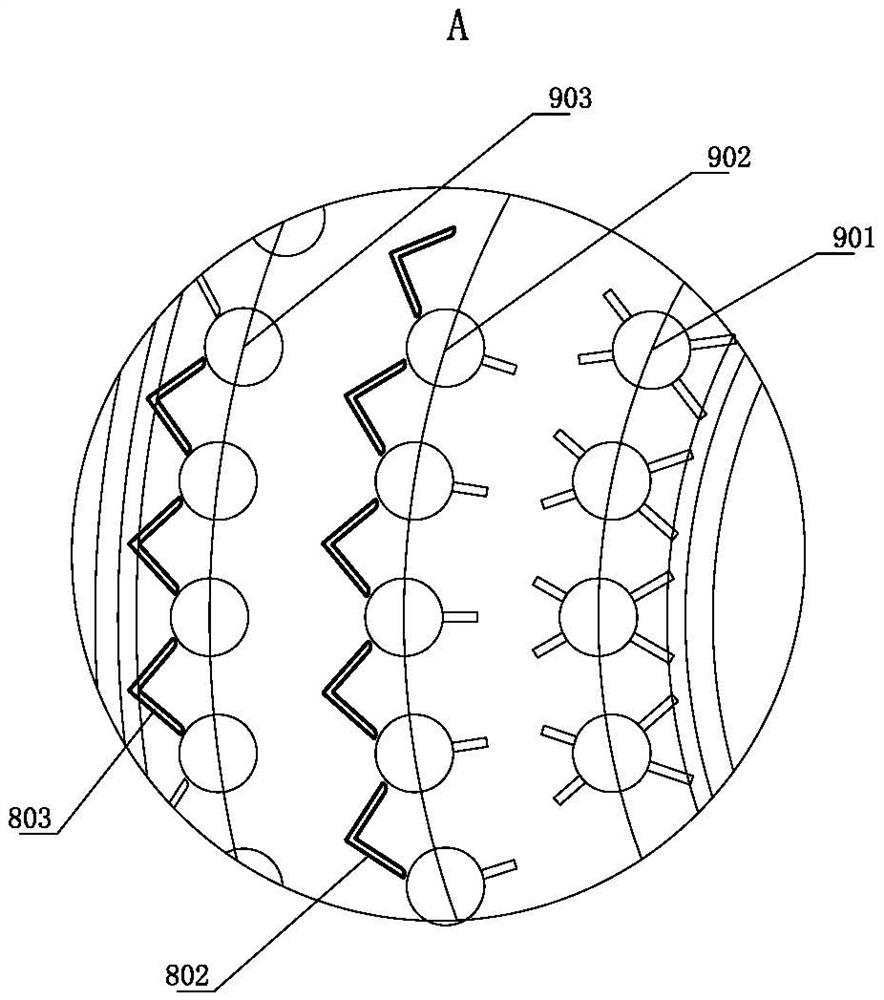

[0018] like Figure 1-4 As shown, a flame pressure water tube boiler, the furnace body 7 is vertically arranged, the furnace body 7 is vertically provided with tubes 9, and the lower end of the tubes 9 is connected to the circular water collecting chamber 1, and the The water chamber 1 is connected to the water inlet pipe 17, and the upper end of the tubes 9 is connected to the steam box 10, and the steam box 10 is provided with a steam outlet 12; in order to reduce the volume of the steam box 10, an inner cylinder 11 is provided in the steam box 10 , the inner cylinder can be used as a maintenance channel, and other heat exchange devices can also be built in it; the tubes 9 are arranged in a concentric circular array, and the tubes 9 are provided with three layers from the inside to the outside, and the circular hollow formed by the inner tubes 901 A flame pressure plate 15 is provided in the cavity, and the furnace chamber 3 is located below the flame pressure plate 15; a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com