System of increasing steam productivity of low-temperature exhaust heat recovery in acid production from sulfur

A technology of low-temperature waste heat and sulfuric acid production, which is applied in the fields of environmental protection, chemical industry, and energy conservation. It can solve the problems of reduced heat release, low-temperature waste heat recovery of sulfuric acid production, low steam production, and reduced water addition, so as to simplify the device structure and improve production. Economic benefits and the effect of increasing steam production in summer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

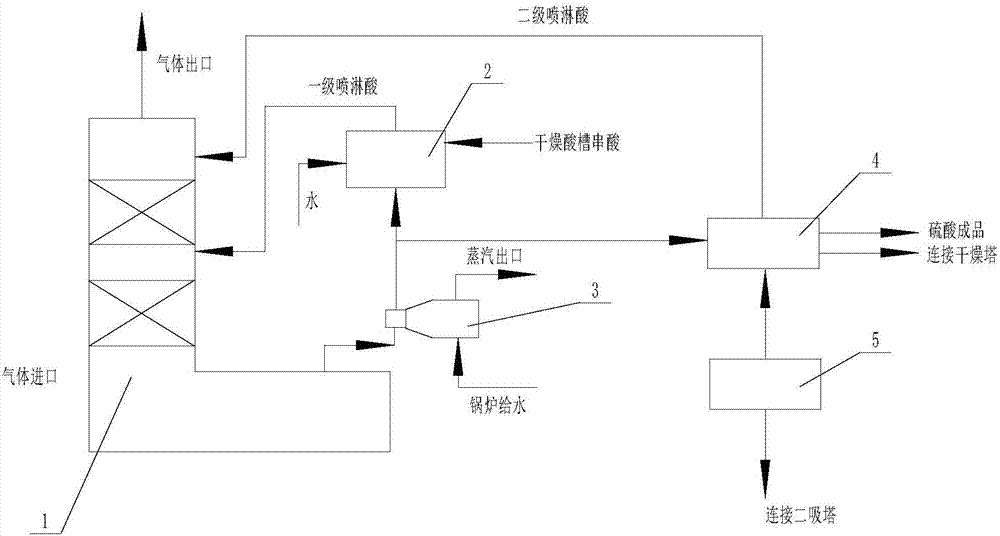

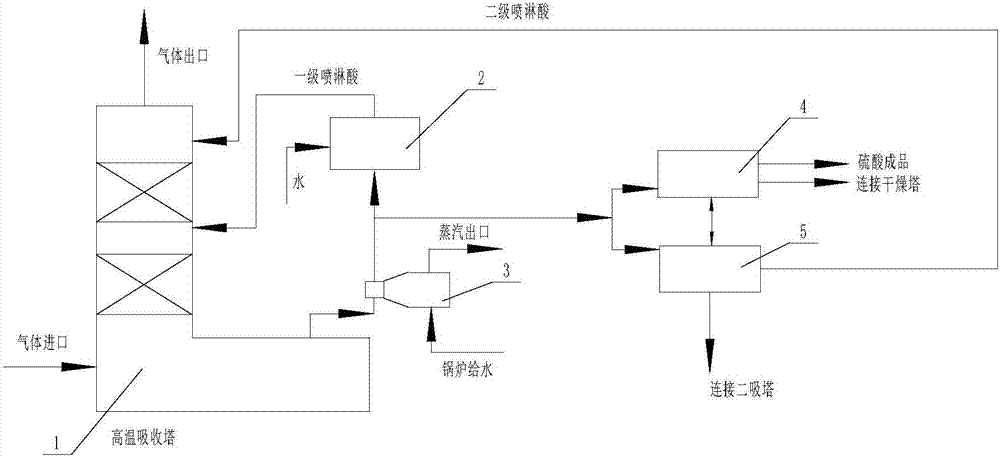

[0027] Aiming at the problems existing in the prior art, the present invention provides a system for improving the steam production rate of low-temperature waste heat recovery in sulfuric acid production, optimizes the existing system for improving the steam production rate of low-temperature waste heat recovery in sulfuric acid production, and simplifies the existing low-temperature waste heat recovery system. The pipeline design of the waste heat recovery system also increases the steam production of the low-temperature waste heat recovery system in summer by 41.6%.

[0028] The technical method of the embodiment of the present invention is to solve the above-mentioned technical problem, and concrete method is as follows:

[0029] like figure 1 and figure 2 Said, a system for improving the steam production of low-temperature waste heat recovery of sulfuric acid, including:

[0030] High temperature absorption tower 1, the high temperature absorption tower 1 is used to abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com