Red coke transporting apparatus and red coke transporting method suitable for quenching coke

A transfer device and technology of red coke, applied in coke cooling, coke oven, petroleum industry, etc., can solve the problems of high investment and operation costs, increased coke burning loss, prolonging the process, etc., to reduce red coke burning loss and Effect of heat loss, reduction of coke burning loss, and reduction of investment amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

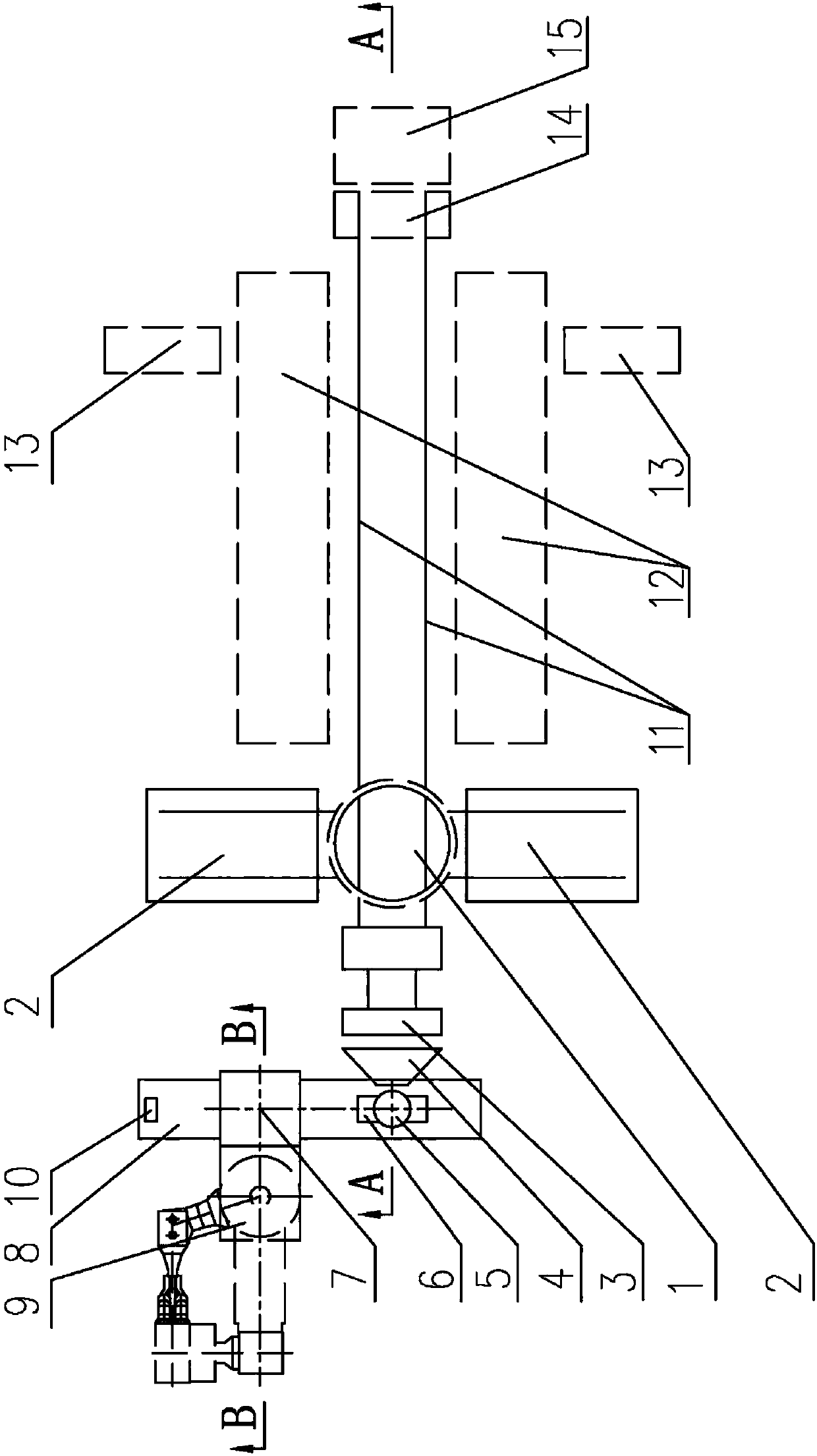

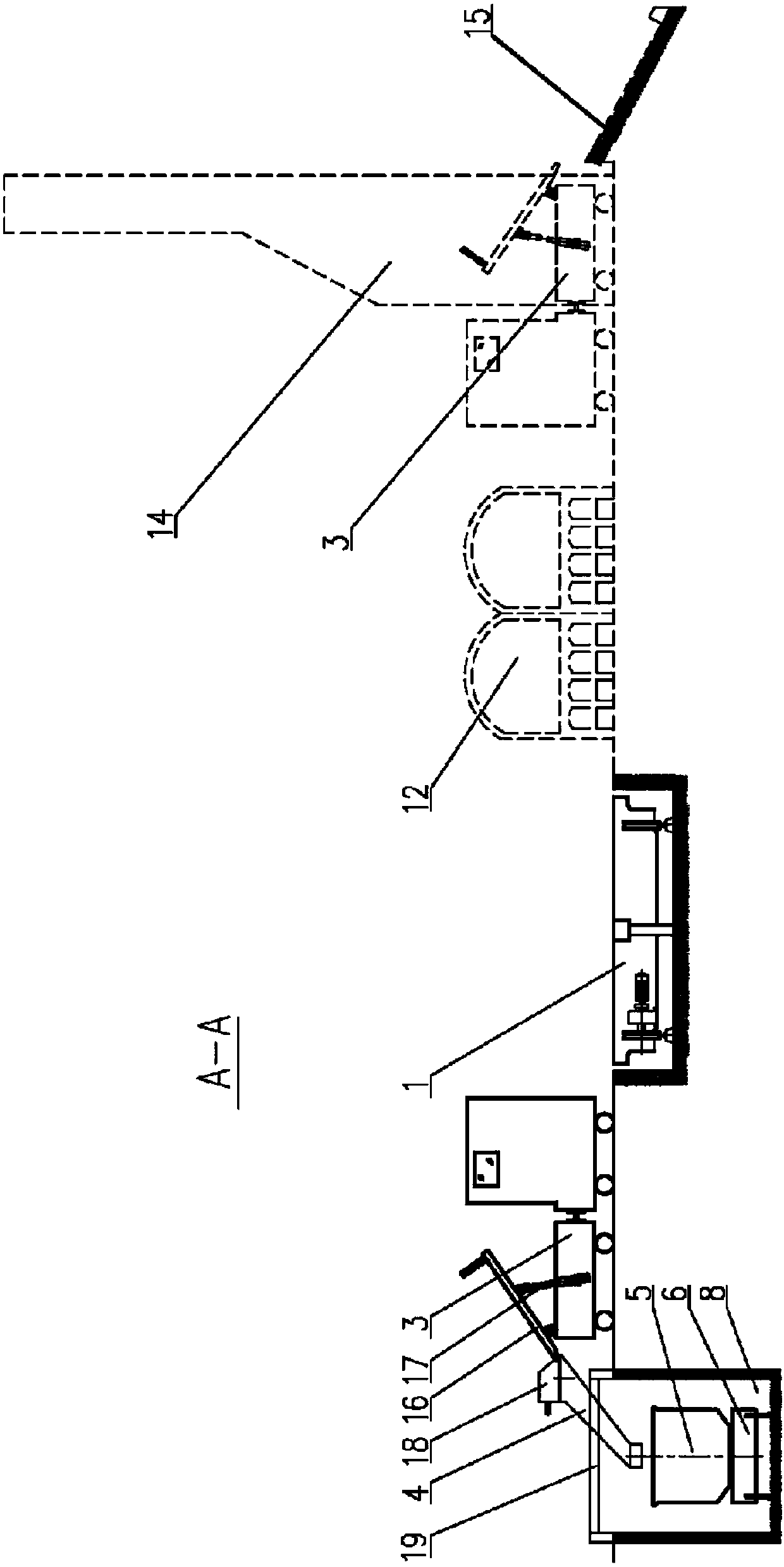

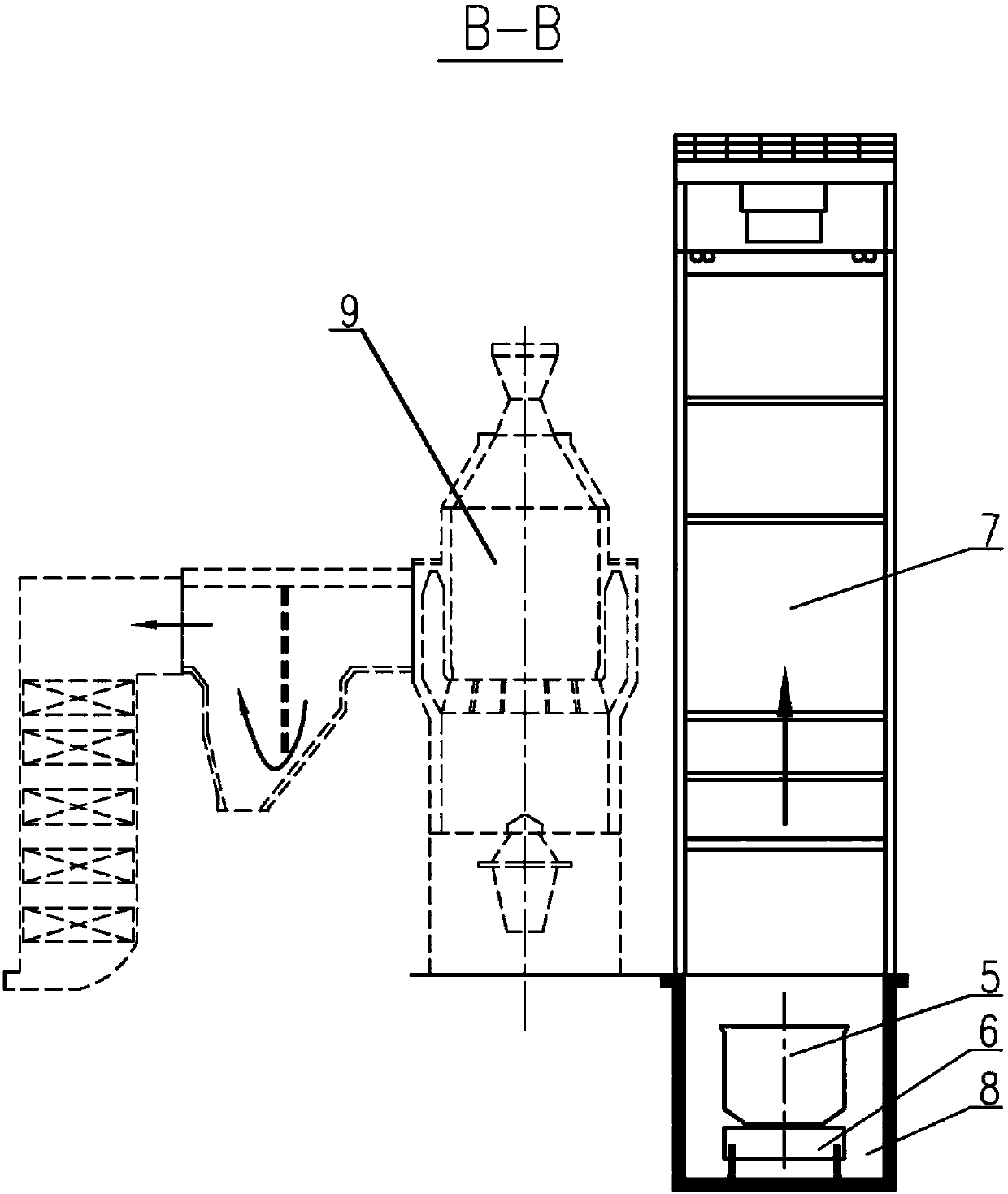

[0061] Example 1, such as Figure 1-Figure 11 shown.

[0062] figure 1 , figure 2 , image 3 Represented is the plane layout and the elevation structure schematic diagram of embodiment 1, in figure 1 , figure 2 , image 3 Among them, 1 coke quenching car rotating platform. 2 There are two parking spaces for quenching vehicles. 3 coke quenching car, which includes components such as 16 coke receiving grooves, 17 tipping mechanisms. 4 focus chute. 5 CDQ coke cans. 6 Carriers. 7 Lift the derrick. 8 pits. 9 CDQ furnace. 10 windlass. 11 coke quenching car track. 12 horizontal heat recovery coke ovens, arranged in two opposite rows, figure 2 Only the elevation structure diagram of the two-hole carbonization chamber is shown in the figure, and the part indicated by the serial number 12 lead is the carbonization chamber. In the actual application process, the number of holes in the carbonization chamber and the number of furnace groups can be increased or decrease...

Embodiment 2

[0072] Example 2, such as Figure 12 shown.

[0073] Compared with Example 1, the difference is that the horizontal heat recovery coke ovens 13 are arranged in a single row, the number of holes in the carbonization chamber and the number of furnace groups can be increased or decreased according to the coke output, and the rest are the same.

Embodiment 3

[0074] Example 3, such as Figure 13 shown.

[0075] Compared with Embodiment 1 and Embodiment 2, the difference lies in that a coke cutting machine 24 is set at the outlet of the coke guide chute 4, and the red coke passes through the coke cutting machine to form the required specification granularity of the process index, and the rest are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com