High-efficiency steam-electricity hybrid power speed regulation unit

A hybrid power and speed regulation technology, applied in electric components, control generators, electrical components, etc., can solve the problems of unsteady combustion of boilers and large efficiency loss, and achieve increased steam extraction, improved thermal cycle efficiency, and payback period. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

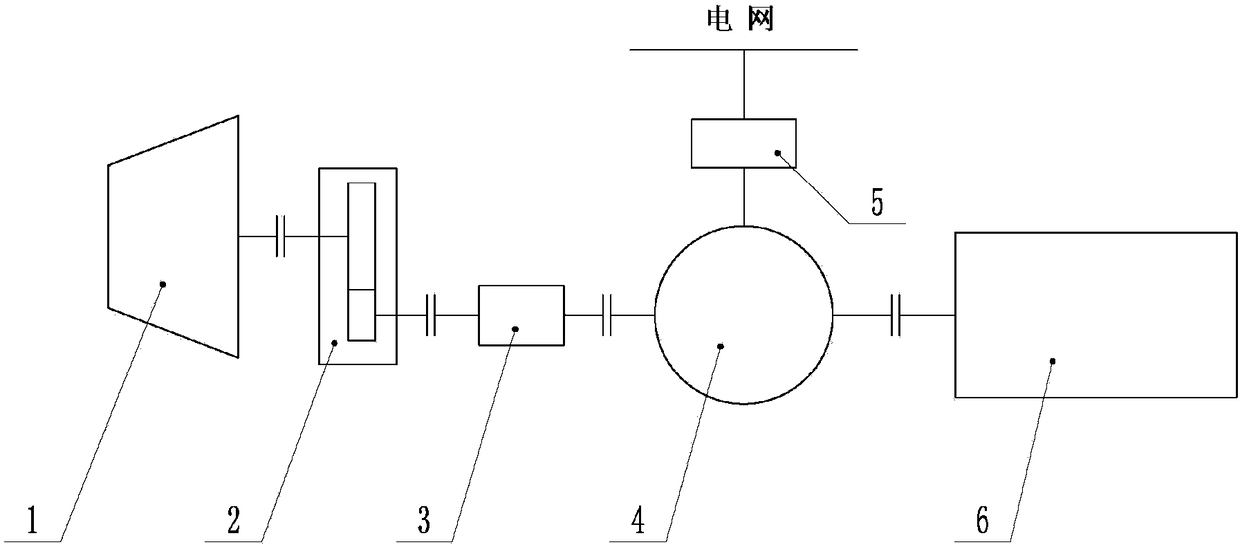

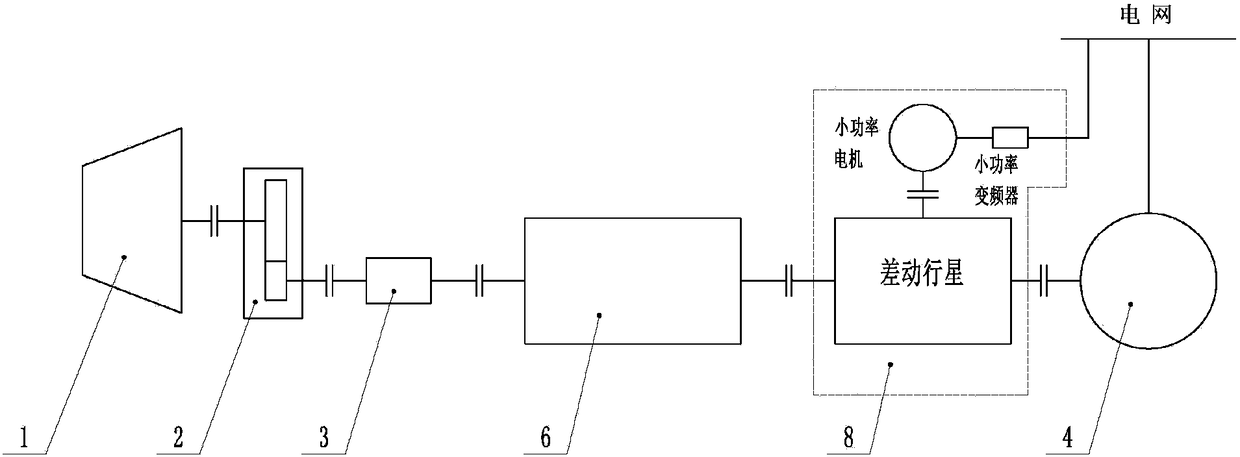

[0031] Example as Figure 1-5 As shown, a high-efficiency steam-electric hybrid speed-regulating unit involved in this embodiment includes a steam turbine 1, a gearbox 2, a synchronous automatic clutch 3, a motor 4, a load 6, a speed-regulating device, the output shaft of the steam turbine 1 and the gearbox 2 input shaft connection, gearbox 2 output shaft and synchronous automatic clutch 3 input shaft connection, synchronous automatic clutch 3 output shaft and motor 4 and load 6 combination assembly, motor 4 and load 6 combination assembly and speed control equipment Matching connection, wherein the motor 4 is connected to the power grid; when the specific unit is started, the motor 4 starts the load 6 through the speed regulating device. At this time, the steam turbine 1 is not started, and is decoupled from the unit through the synchronous automatic clutch 3. When the conditions for rushing are met, and the rotor speed is greater than or equal to the rotor speed of motor 4, ...

Embodiment 2

[0032] Embodiment two, such as figure 1 As shown, the load 6 can be a fan or a water pump, the motor 4 is a double-shaft extension structure, the output shaft of the steam turbine 1 is connected to the input shaft of the gearbox 2, the output shaft of the gearbox 2 is connected to the input shaft of the synchronous automatic clutch 3, and the synchronous automatic clutch 3 is connected. The output shaft of the clutch 3 is connected to the input shaft of the motor 4, the speed regulating device is a full-power frequency converter 5, the motor 4 is connected to the power grid through the full-power frequency converter 5, and the output shaft of the motor 4 is connected to the load 6; specifically, the unit starts At this time, the motor 4 softly starts the load 6 through the full-power frequency converter 5. At this time, the steam turbine 1 is not started, and is decoupled from the unit through the synchronous automatic clutch 3. The unit is equivalent to a conventional variable...

Embodiment 3

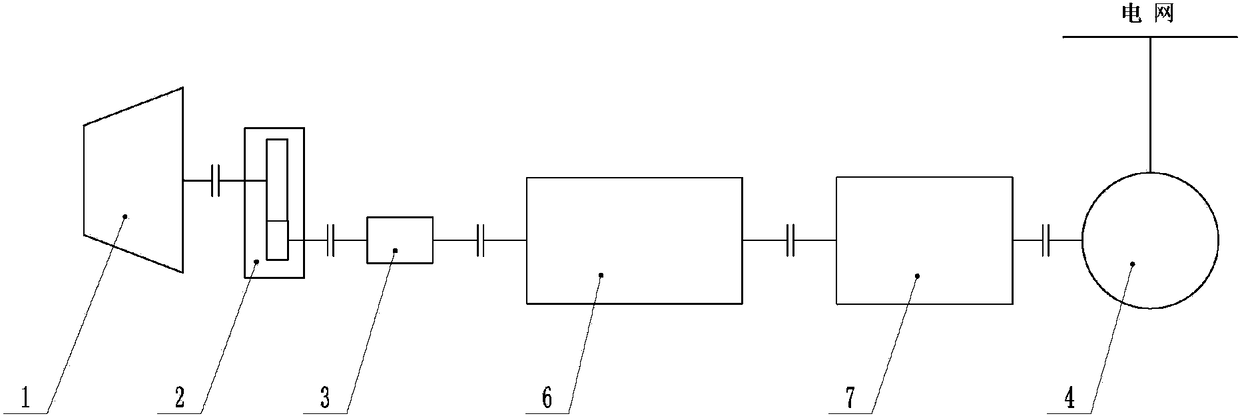

[0034] Embodiment three, such as figure 2As shown, the load 6 is a double shaft extension structure, the output shaft of the steam turbine 1 is connected to the input shaft of the gearbox 2, the output shaft of the gearbox 2 is connected to the input shaft of the synchronous automatic clutch 3, and the output shaft of the synchronous automatic clutch 3 is connected to the left side of the load 6 The side input shaft is connected, the input shaft of the right load 6 is connected to the speed regulating device, the speed regulating device is connected to the motor 4, and the motor 4 is directly connected to the power grid. In this embodiment, the speed regulating device is a planetary hydraulic speed regulating / constant speed device 7 Specifically, when the unit starts, the motor 4 starts the load 6 through the planetary hydraulic speed control / constant speed device 7. At this time, the steam turbine 1 is not started, and is decoupled from the unit through the synchronous automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com