Coke oven raw gas high temperature segment heat high efficient recovering device

A technology of recovery device and waste gas, which is applied to the heating of coke ovens, the discharge device of dry distillation gas, and coke ovens, etc., can solve the problems of large consumption of ammonia water, affecting safe production, affecting the operation of coke ovens, etc., so as to facilitate coordinated production. The effect of progress, guaranteeing stable operation, and a wide range of steam applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

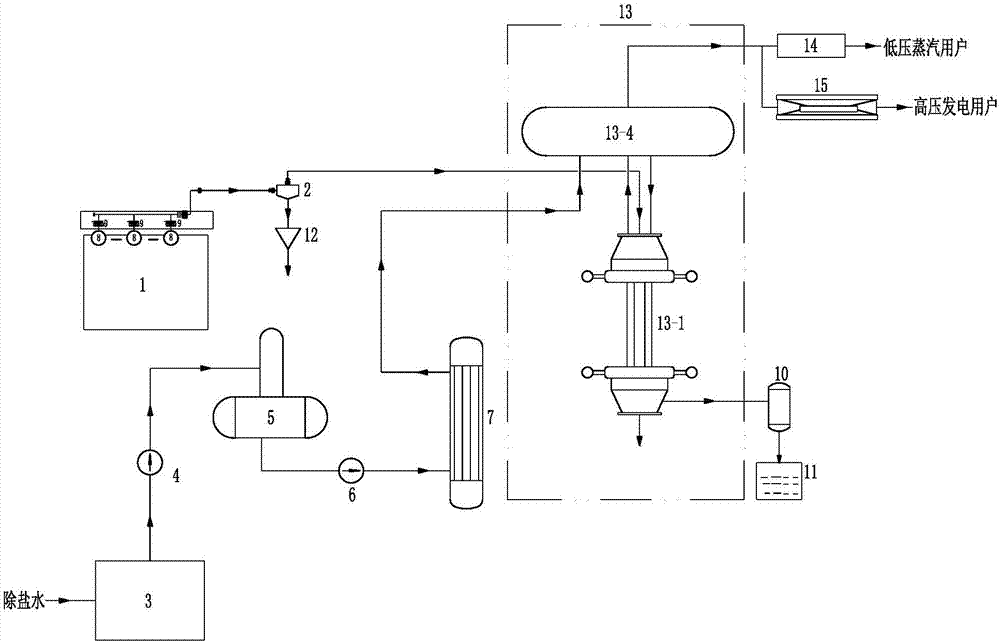

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

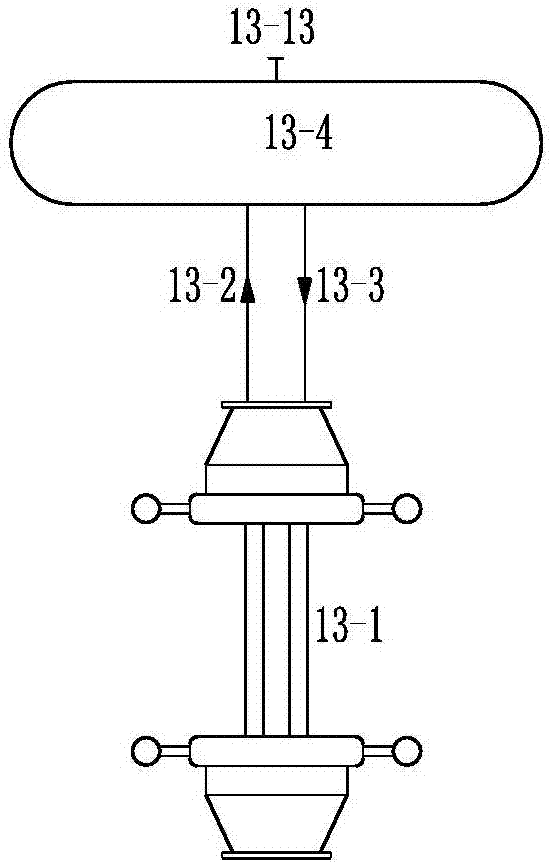

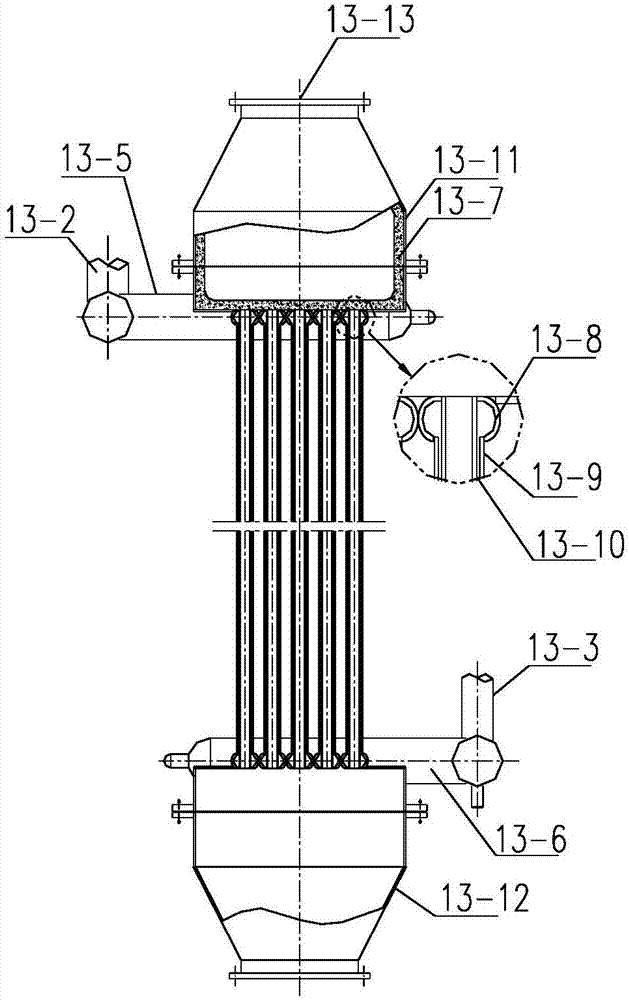

[0023] See Figure 1-Figure 3 As shown, a high-efficiency heat recovery device for coke oven raw gas in the high-temperature section of the present invention includes a high-temperature dust collector 2, a standpipe casing type quenching waste heat boiler 13, a desalinated water tank 3, a deaerator 5, and a low-temperature heat exchanger 7. The standpipe casing type quenching waste heat boiler 13 is composed of a casing type steam heat exchanger 13-1 and a steam drum 13-4, and the gap between the casing type steam heat exchanger 14-1 and the steam drum 13-4 is The riser 13-2 communicates with the downcomer 13-3; the air inlet at the top of the jacketed steam heat exchanger 13-1 is connected to the gas collecting pipe 9 at the top of the coke oven 1 through the high-temperature dust collector 2; the steam drum 13-4 The water inlet is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com