Revolving furnace, electric stove steel-smelting high-temperature gas cooling down heat-recovering steam producing energy conservation system device

A technology of electric furnace steelmaking and high-temperature gas, applied in the direction of steam generation method using heat carrier, etc., can solve the problems of insufficient recovery and utilization, increase of heat dissipation area, large cooling water consumption, etc., to achieve effective use of waste heat, Improve heat transfer efficiency and reduce equipment size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

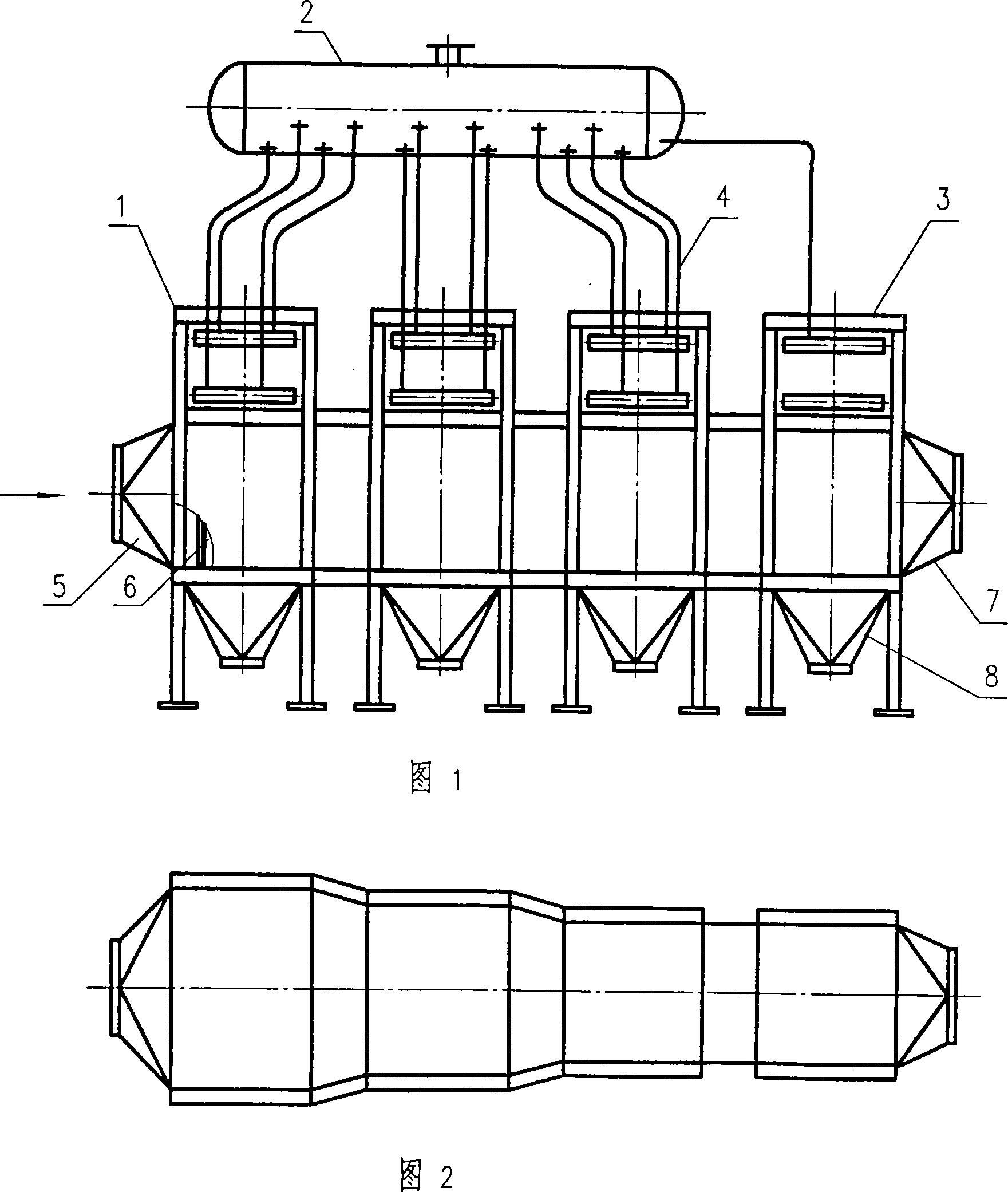

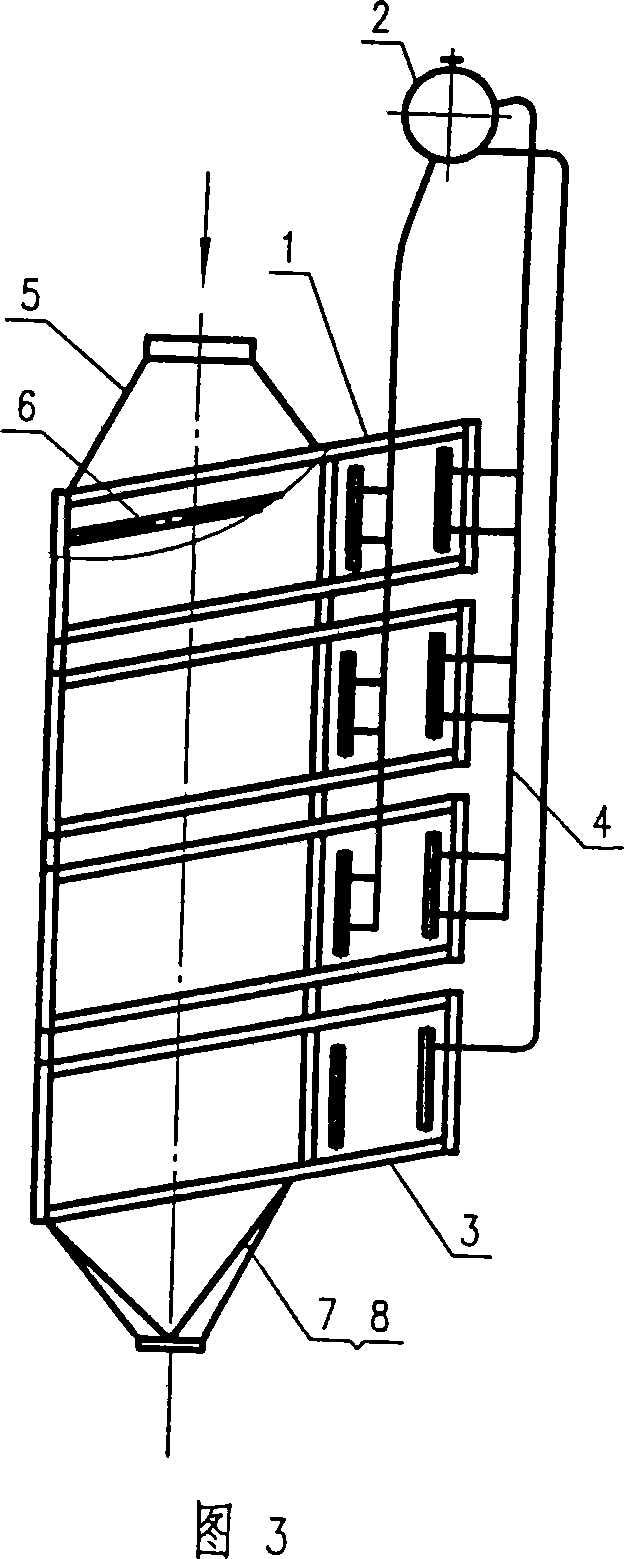

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] Converter, electric furnace steelmaking high-temperature gas cooling waste heat recovery steam production energy-saving system device is mainly composed of steam generator 1, steam drum 2, water preheater 3 and steam-water connecting pipe 4 or consists of steam generator 1, steam drum 2 and steam-water connecting pipe Tube 4 composition. The softened water is sent into the water preheater 3 by a pressurized pump, and sent into the steam drum 2 after preheating, or directly sent into the steam drum 2, connected with the steam generator 1 through the steam-water connecting pipe 4, and the high-temperature gas passes through the inlet port 5 Enter the steam generator 1, exchange heat with the heat transfer element 6 heat pipes or finned tubes in it, and the steam generated is separated by the steam drum 2 and then sent to the pipe network. Depending on the amount of hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com