Heat pump circulating system and method thereof

A circulation system and heat pump technology, applied in heat pumps, compressors with reversible cycles, lighting and heating equipment, etc., can solve the problems of not being able to use tap water as a heat source, and achieve improved primary energy utilization efficiency, low heat source costs, and reduced equipment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

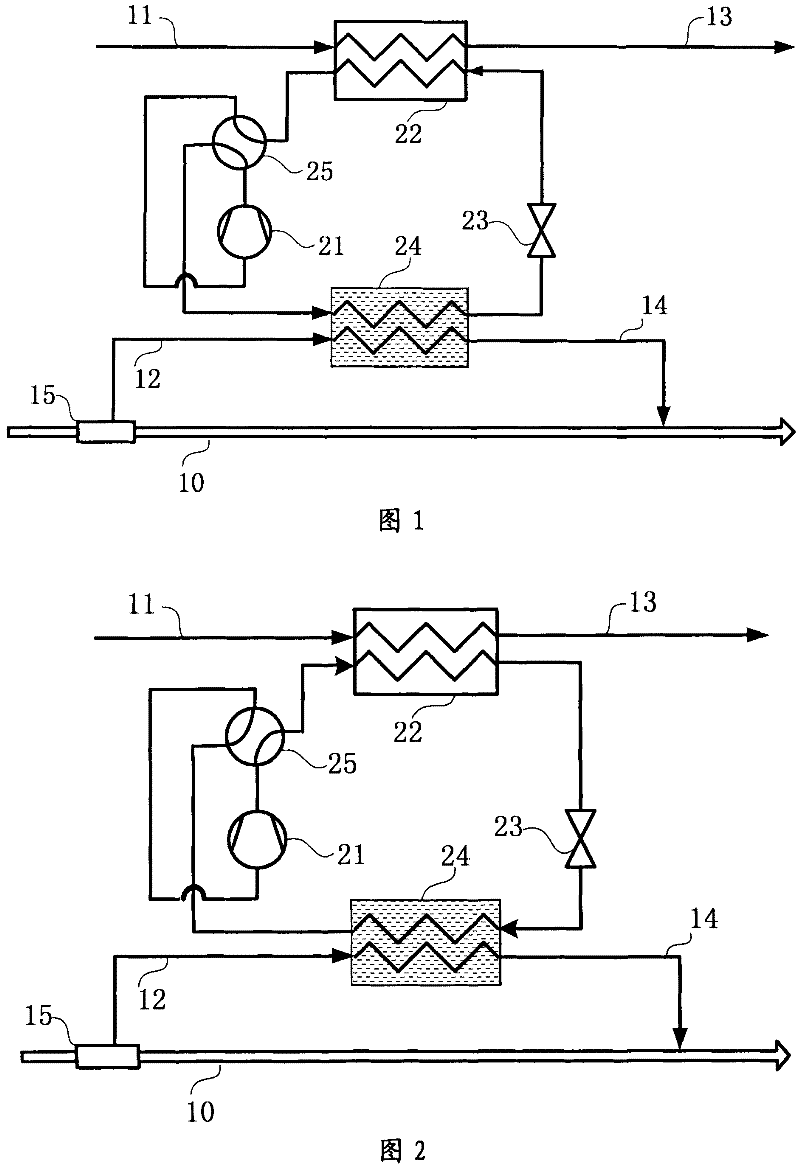

Method used

Image

Examples

example 1

[0078] With commercial electricity as power, adopt the method of embodiment 5 for heating. The inlet temperature of the internal heat exchanger (that is, the condenser) of the external working medium is 37°C, the outlet temperature of the internal heat exchanger is 45°C, the external air temperature is 10°C, and the temperature of the water source (tap water supplied by the city) is 15°C , the evaporation temperature of the refrigerant in the external heat exchanger (that is, the evaporator) is 8°C, and the external heat exchanger is filled with paraffin wax with a carbon number of 15, and its freezing point and solidification heat are about 10°C and 170kJ / kg, respectively. The condensing temperature of the refrigerant in the internal heat exchanger is 50°C, the adiabatic efficiency of the compressor is 0.85, and its heat supply coefficient (COP) is 5.45. Since the power generation efficiency of the utility power at the user end is usually 33%, the primary energy efficiency of...

example 2

[0080] With commercial electricity as power, adopt the method of embodiment 5 to supply cooling. The inlet temperature of the internal heat exchanger (that is, the evaporator) for the external working medium is 15°C, the outlet temperature of the internal heat exchanger is 7°C, the external air temperature is 35°C, and the temperature of the water source (tap water supplied by the city) is 25°C , the evaporation temperature of the refrigerant in the internal heat exchanger is 2°C, the condensation temperature of the refrigerant in the external heat exchanger (ie condenser) is 32°C, and the external heat exchanger is filled with paraffin wax with a carbon number of 18, Its freezing point and freezing heat are about 29°C and 240kJ / kg respectively, the compressor's adiabatic efficiency is 0.85, and its cooling coefficient (COP) is 6.66.

example 3

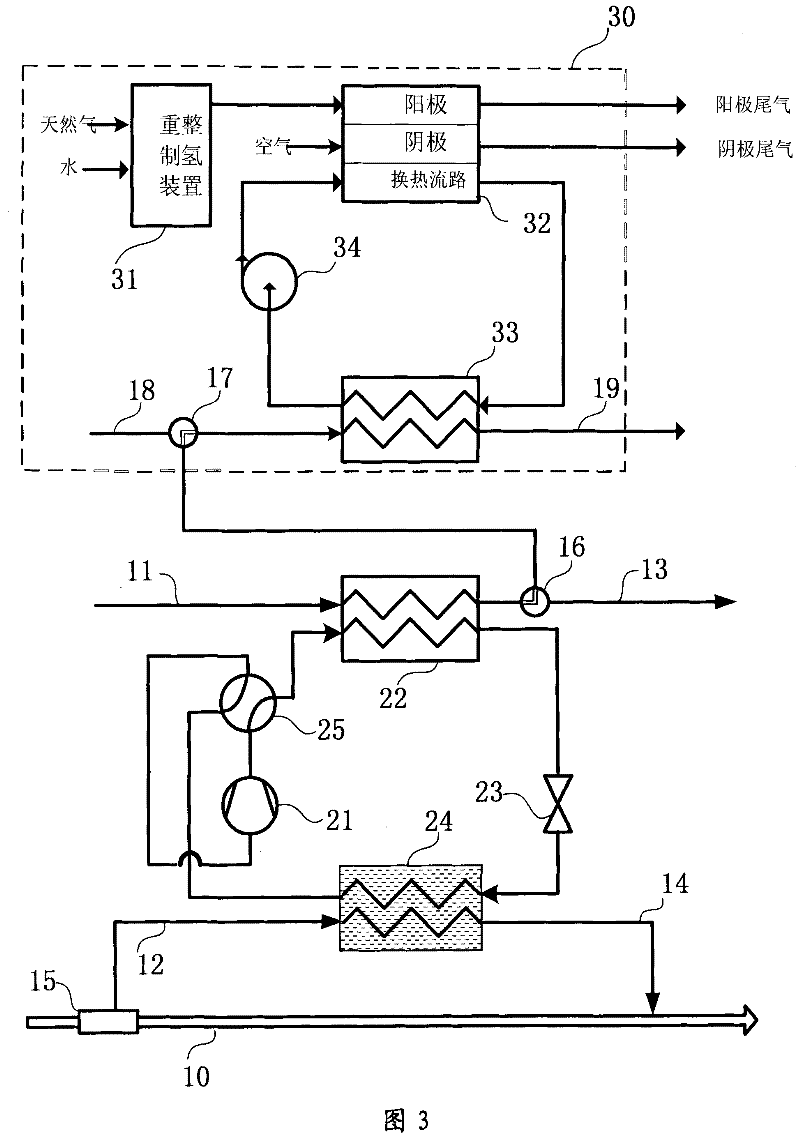

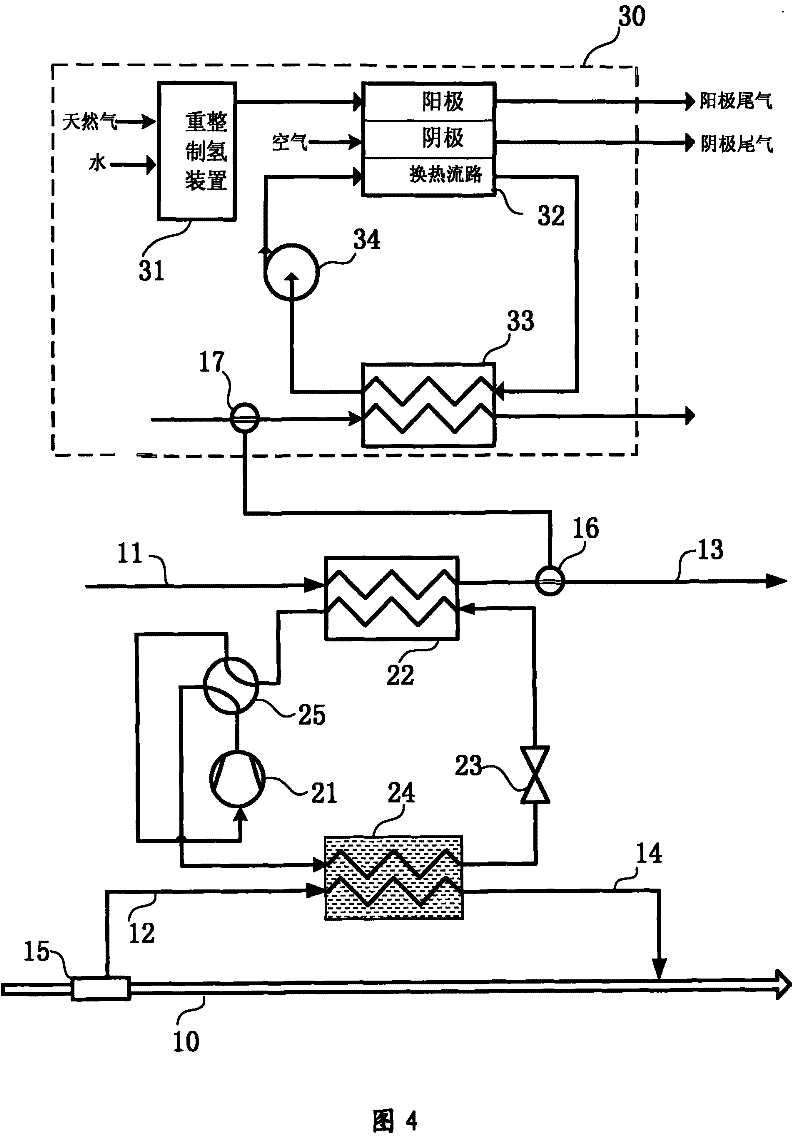

[0082] Adopt the method heating of embodiment 6. The inlet temperature of the internal heat exchanger (i.e. the condenser) of the external working fluid supplied is 37°C, the outlet temperature of the internal heat exchanger is 42°C, the outlet temperature of the heat exchanger 33 is 45°C, the external air temperature is 10°C, and the source water ( The temperature of municipal tap water) is 15°C, the evaporation temperature of the refrigerant in the external heat exchanger is 8°C, and the external heat exchanger is filled with paraffin wax with a carbon number of 15, and its freezing point and solidification heat are about 10°C respectively and 170kJ / kg, the condensing temperature of the refrigerant in the internal heat exchanger is 47°C, the adiabatic efficiency of the compressor is 0.85, the proton exchange membrane fuel cell power generation sub-system uses natural gas as raw material, its power generation efficiency is 37%, and the heat recovery efficiency 40%. The COP o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com