Tail heat utilization and dust removal integrated coil-fired boiler

A coal-fired boiler, an integrated technology, applied in the field of coal-fired boilers, can solve problems such as personnel and equipment safety accidents, strong vibration, etc., and achieve reliable use, high strength, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

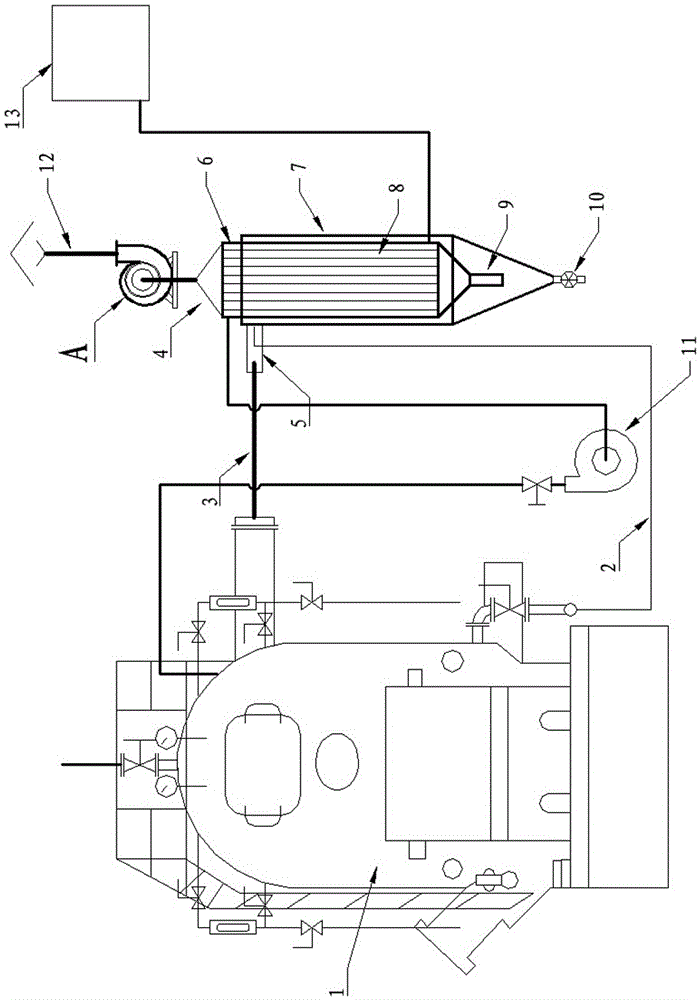

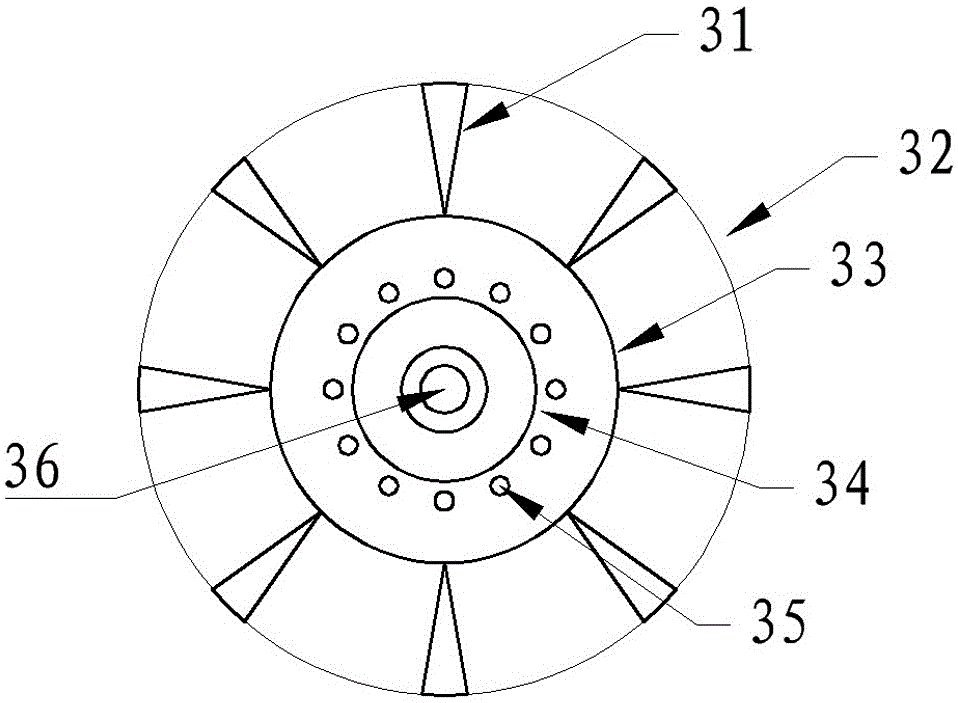

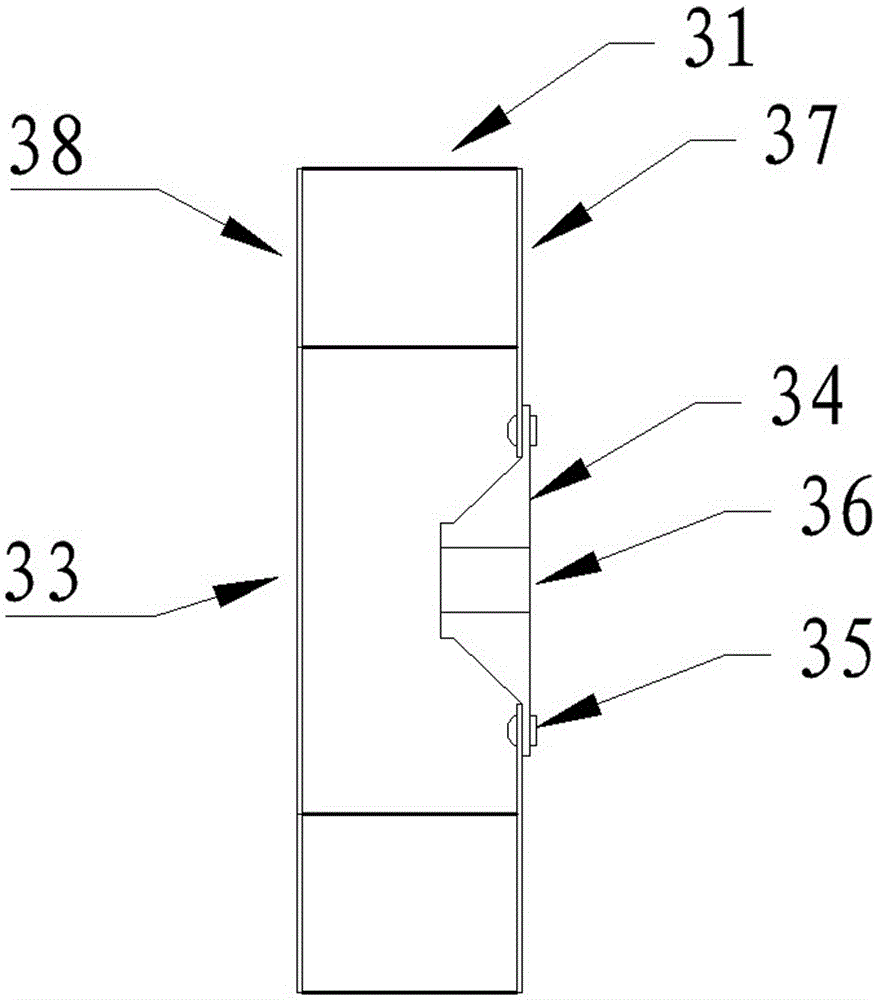

[0030] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0031] Such as figure 1 , figure 2 , image 3 and Figure 4 The exhaust heat utilization and dust removal integrated coal-fired boiler shown in the figure includes boiler main body 1, boiler exhaust pipe 3, boiler sewage pipe 2, cyclone dust removal tail heat efficient utilization device 4 and induced draft fan A, and cyclone dust removal tail heat efficient utilization device 4 consists of columns The tubular heat exchanger 6 and the cyclone dust collector 7 are superimposed. The boiler tail gas pipe 3 is connected to the cyclone dust collector 7 tangentially. Cone, evenly dispersed through the tubes, concentrated by the upper cone bucket and then discharged from the exhaust pipe 12 through the induced draft fan A; the high-level pool 13 is connected to the lower part of the 6 shell side of the tube heat exchanger, and the 6 shell side of the tube heat exchanger T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com