Aconitum brachypodum ventilation type crusher

A pulverizer and air extraction technology, used in mechanical equipment, non-variable-capacity pumps, machines/engines, etc., can solve the problems of personnel and equipment safety accidents, strong vibration, etc., and achieve reliable use, high strength, and lightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail with reference to the accompanying drawings.

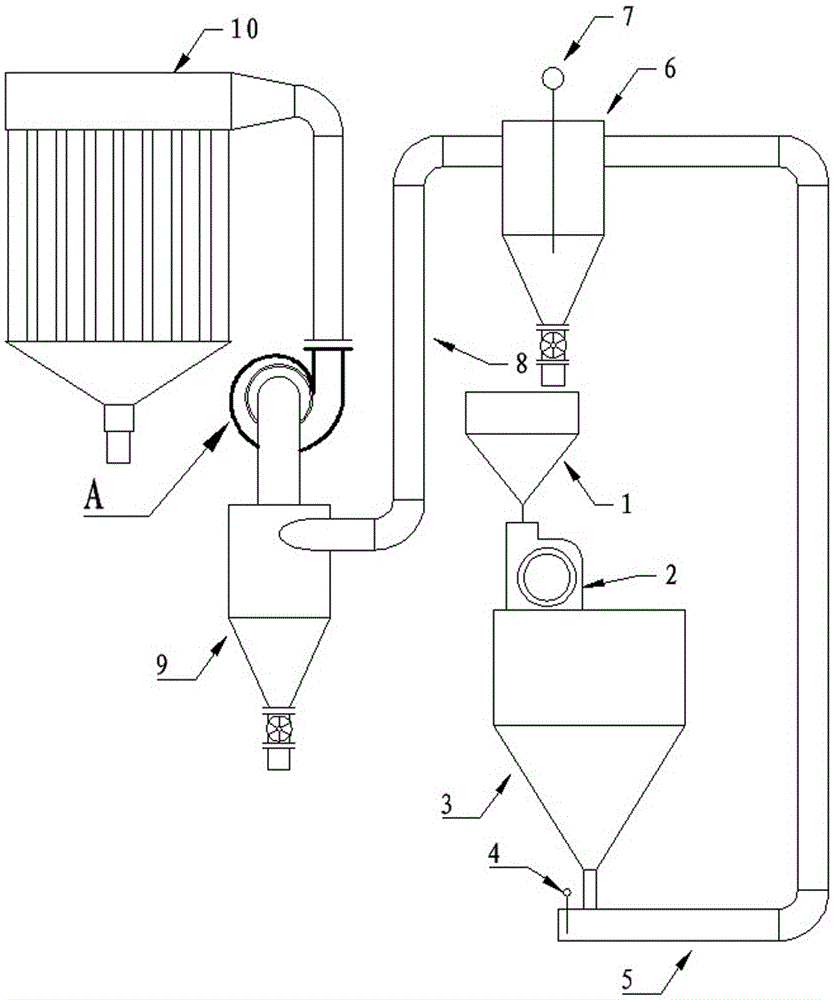

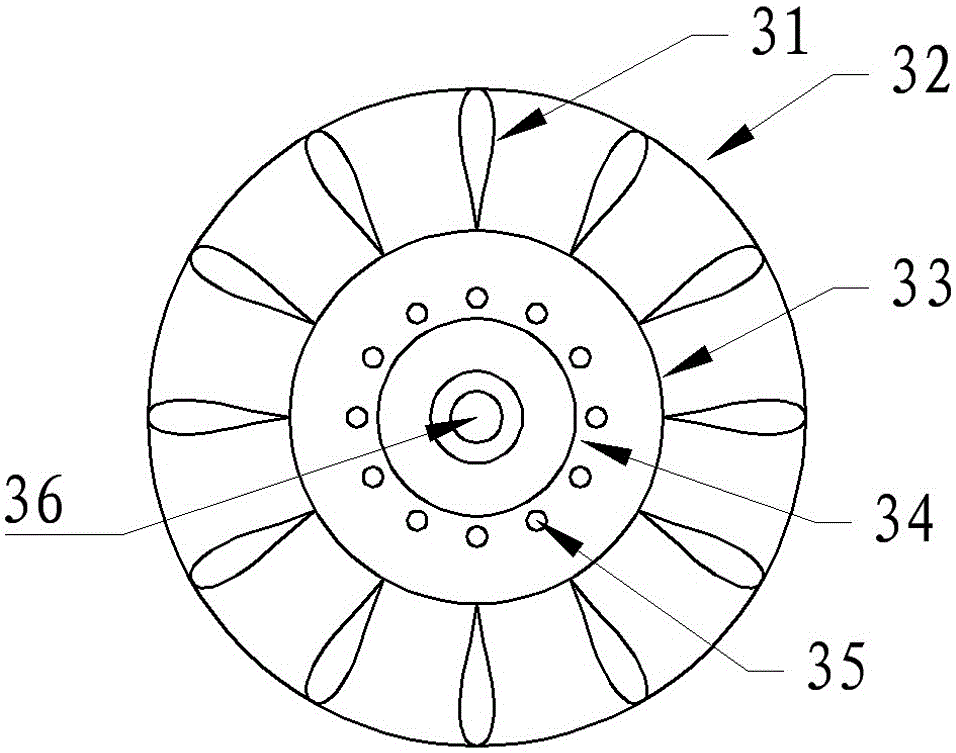

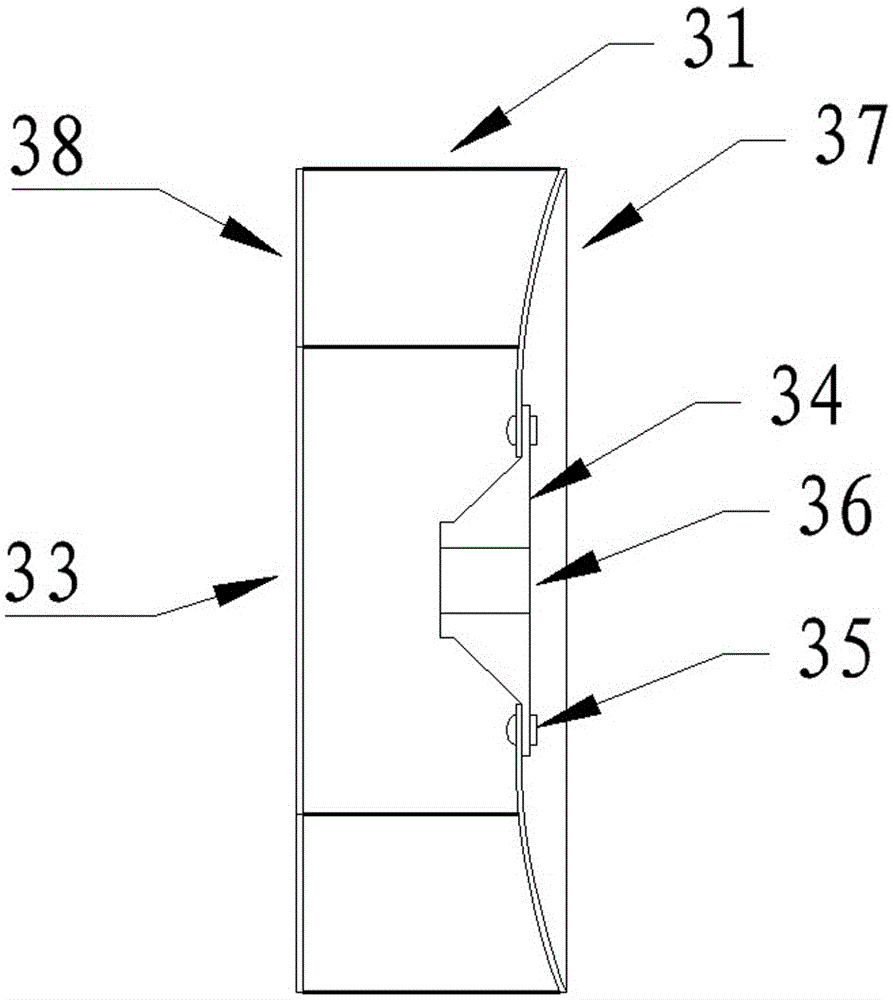

[0031] Such as figure 1 , figure 2 , image 3 with Figure 4 An artemisia suction pulverizer is shown on the snow, including pulverizer 2 and induced draft fan A. The blanking end of pulverizer 2 is connected to induced draft fan A through storage box 3, exhaust pipes 5, 8 and cyclone 9 to extract air. The pipe is provided with a damper 4 for adjusting the air volume; the induced draft fan includes a fan impeller 41 and a casing 45. The fan impeller 41 includes an impeller back plate 37, an impeller panel 38 and blades 31. The blades 31 are arranged radially and symmetrically on the impeller axis. The hollow anti-drop shape, the impeller back plate 37 is dish-shaped; the hollow anti-drop-shaped blades 31 are connected to the impeller panel 38 and welded with the disc-shaped impeller back plate 37 to form the impeller body; the impeller panel 38 is provided with an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com