Tail heat utilization sieve hole flap dryer

A technology of sieve flaps and dryers, applied in progressive dryers, dryers, drying gas arrangement, etc., can solve problems such as difficulty in disassembly, achieve the effects of eliminating fatigue fractures, enhancing axial elasticity, and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will now be further described in detail with reference to the accompanying drawings.

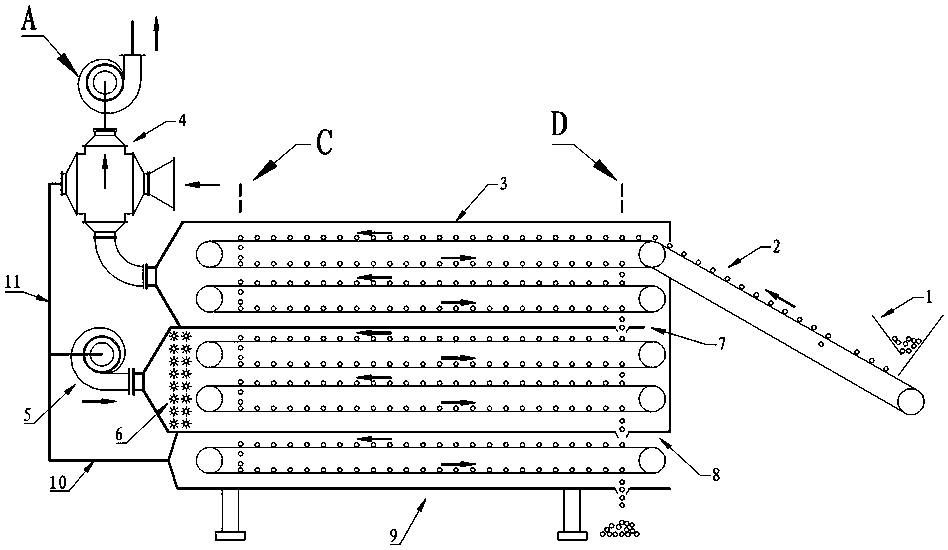

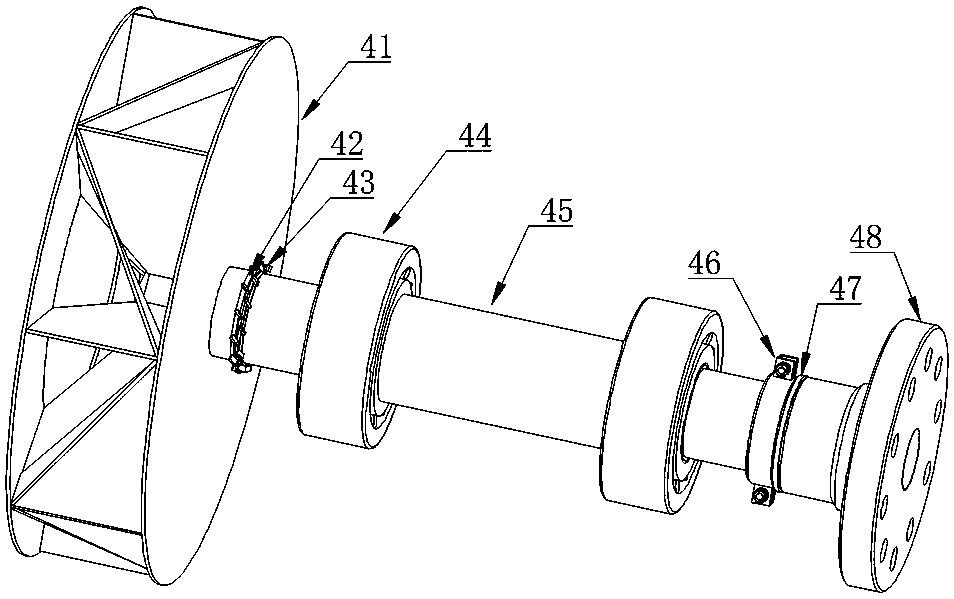

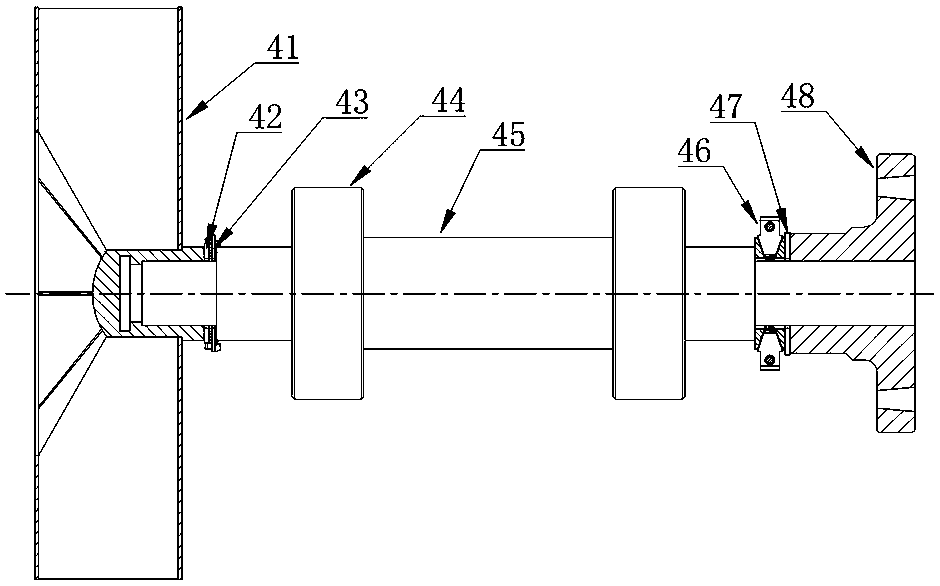

[0034] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 The shown tail heat utilizes a sieve-hole flap-type dryer, including a drying box body 3 and an induced draft fan A. The drying box body 3 is provided with a driving wheel, a passive wheel and a stainless steel sieve plate to form a top-down sieve-hole flap-type conveying 2; The drying cabinet 3 has a middle partition 7 and a lower partition 8 to divide the drying cabinet 3 into three drying areas: upper, middle and lower; The air inlet end of the heat exchanger 4 is connected to the atmosphere, the air outlet end is connected to the air inlet of the blower 5 through the air duct 11, and the air outlet of the blower 5 is connected to the steam fin heater 6 in the middle drying area; the lower drying area is connected back through the air du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com