Patents

Literature

33results about How to "Recycling fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

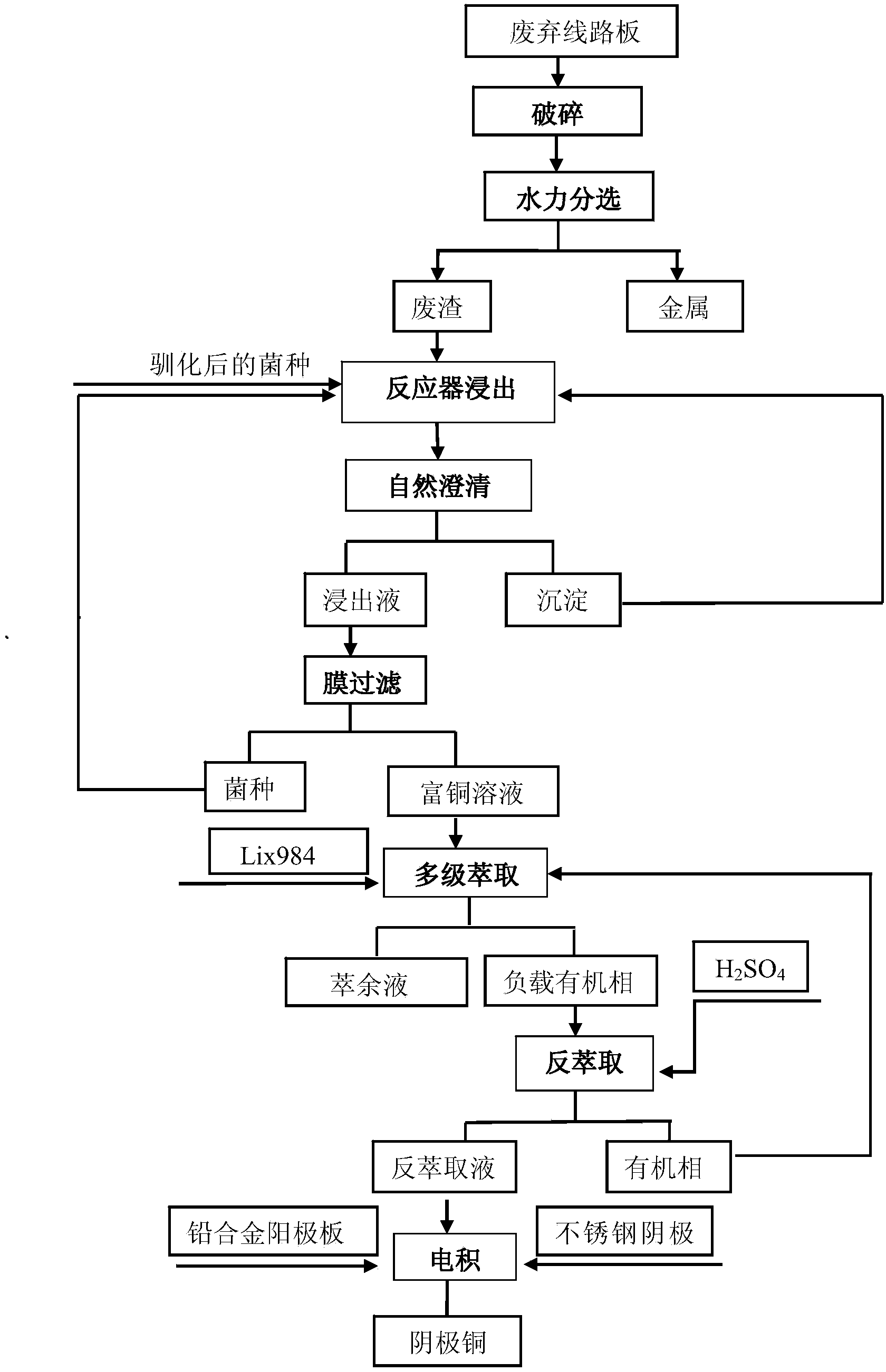

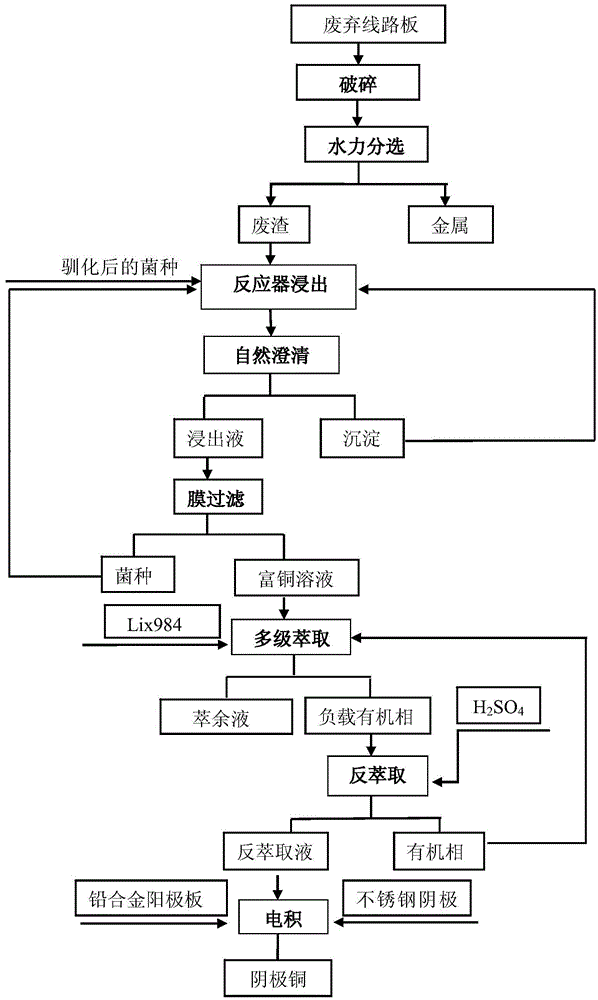

Method for extracting copper in waste printed circuit boards by virtue of moderately thermophilic bacteria

ActiveCN104328283AEfficient separationReduce processingProcess efficiency improvementRaffinateCulture mediums

The invention relates to a method for extracting copper in waste printed circuit boards by virtue of moderately thermophilic bacteria. The method comprises the following steps of carrying out shaker hydraulic sorting on the artificially dismounted and pulverized waste printed circuit boards to obtain metal and waste residues; putting the waste residues into an improved 9K culture medium, adjusting the pH value to 2 and leaching with a mixed strain of leptospirillum ferriphilum, acidithiobacillus caldus, sulfobacillus thermosulfidooxidans and thermoacidiferriphile as a leaching strain to obtain a copper-enriched solution and leaching residues; filtering the copper-enriched solution with a hollow fiber membrane system to obtain the strain and a copper-containing filtrate and putting the strain again into the leaching system for repeatedly using; and extracting the copper-containing filtrate with hydroxy oxime and a hydroxy oxime complex Lix984 as extraction agents to obtain a copper-loaded organic phase and a raffinate, carrying out back extraction on the copper-loaded organic phase with a 10-30% sulfuric acid solution to obtain a back extract and a blank organic phase and carrying out electrodeposition on the back extract to obtain cathode copper and an electrodeposited barren liquid. By the method disclosed by the invention, the environment-friendly, economic and full-value recovery of the waste printed circuit boards is achieved and the method has the advantages of short flow, low investment, high efficiency and low treatment cost and is suitable for the recovery of all types of the waste printed circuit boards.

Owner:CENT SOUTH UNIV

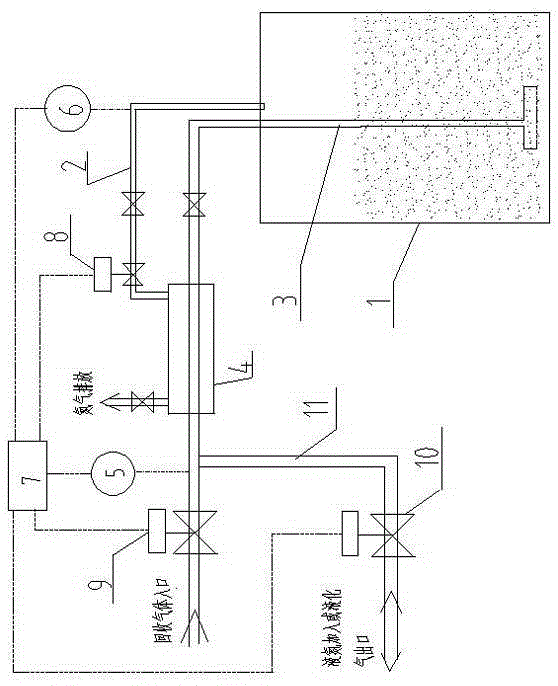

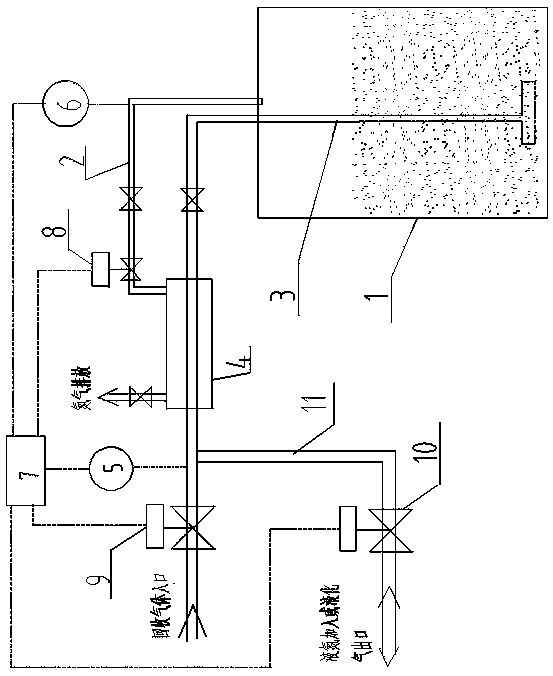

Method and device for efficiently liquefying and recovering natural gas

ActiveCN105387683AEasy to useLow investment costSolidificationLiquefactionBoiling pointLiquid nitrogen

The invention relates to a method and a device for efficiently liquefying and recovering natural gas. The method is characterized in that liquid nitrogen and natural gas are different in boiling point, freezing point, saturation temperature and pressure, and on that basis, natural gas can be directly charged into a cryogenic vessel which is filled with liquid nitrogen; the natural gas and the liquid nitrogen in the same cryogenic vessel are directly mixed, exchange heat and then are liquefied to obtain LNG (Liquefied Natural Gas); the saturation pressure of liquid in the cryogenic vessel is controlled to prevent the natural gas from solidifying and icing as well as effectively separating the LNG and the liquid nitrogen. The method and the device have the main advantages that equipment investment cost is low, and the LNG can be normally used; the method and the device can be widely applied to the liquefaction of a micro gas source, and particularly suitable for BOG recovering during LNG refilling.

Owner:WUXI CHINA RESOURCES GAS

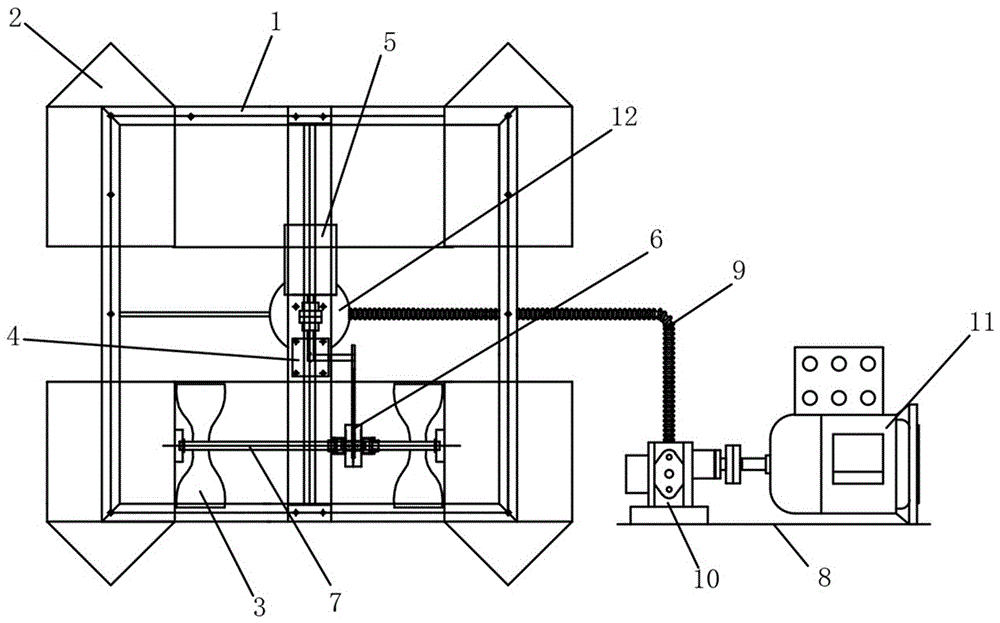

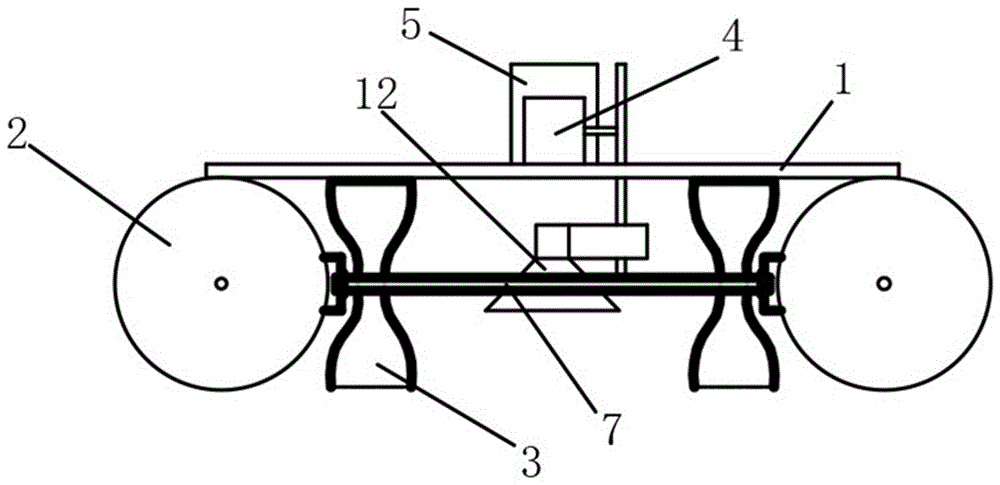

Floating automatic oil recovery device

InactiveCN105951695ASimple structureReasonable designWater cleaningGeneral water supply conservationImpellerMarine engineering

The invention discloses a floating automatic oil recovery device. The floating automatic oil recovery device comprises a fixed rack body, buoyancy tank bodies, at least one impeller, a speed reducer, a first driving unit, a second driving unit, a transmission assembly, an oil sucking assembly and a controller. The multiple buoyancy tank bodies are mounted on the fixed rack body. The impellers are mounted on the fixed rack body through a shaft lever. The floating automatic oil recovery device is simple in structure and reasonable in design; and by issuing a control instruction to the controller, the impellers can rotate, and then displacement of the whole device can be controlled. The overall using efficiency can be greatly improved while the basic function of floating oil recovery is achieved, and the device is quite suitable for recovery of large-area floating oil.

Owner:JIZHOU SAFE EXPLOSION PROOF EQUIP CO LTD

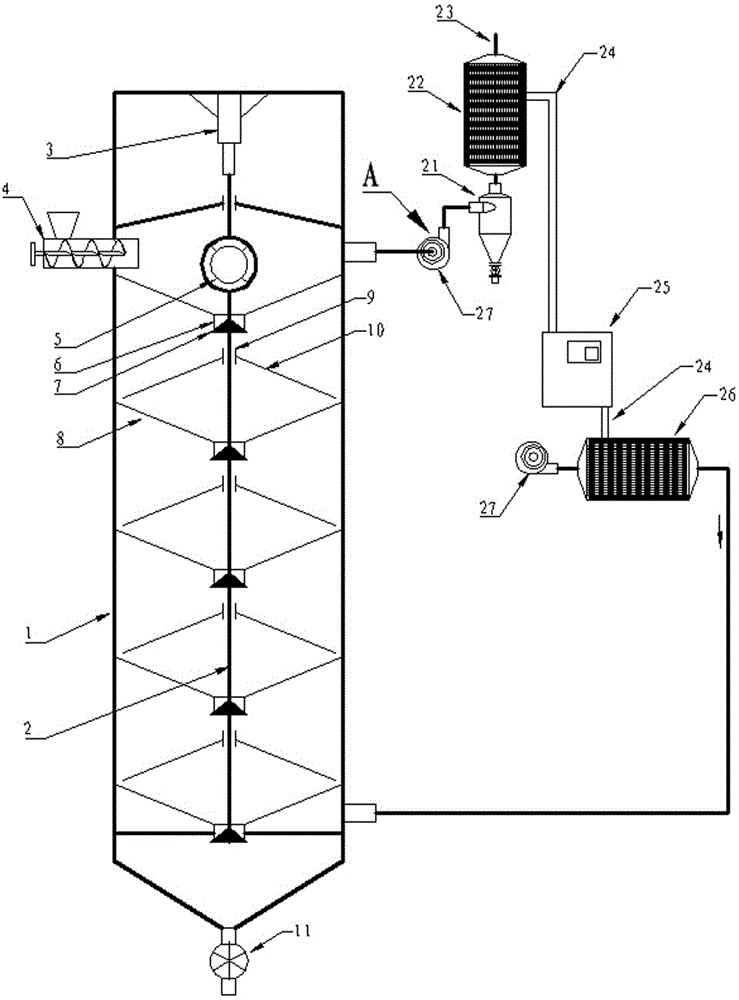

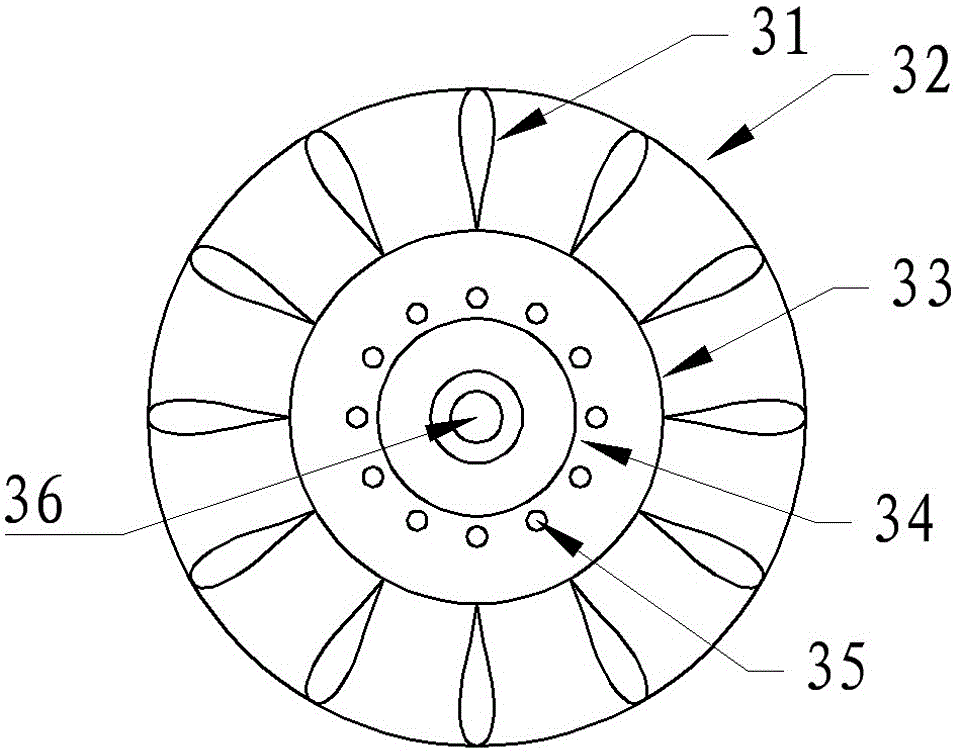

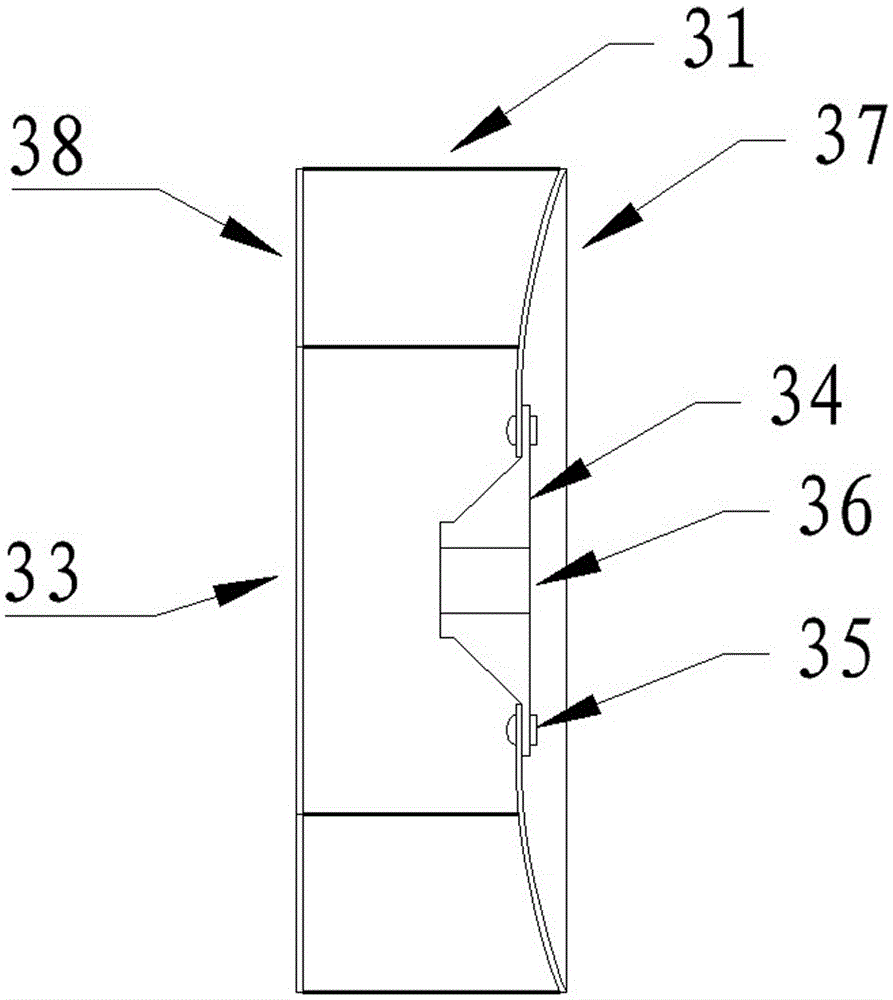

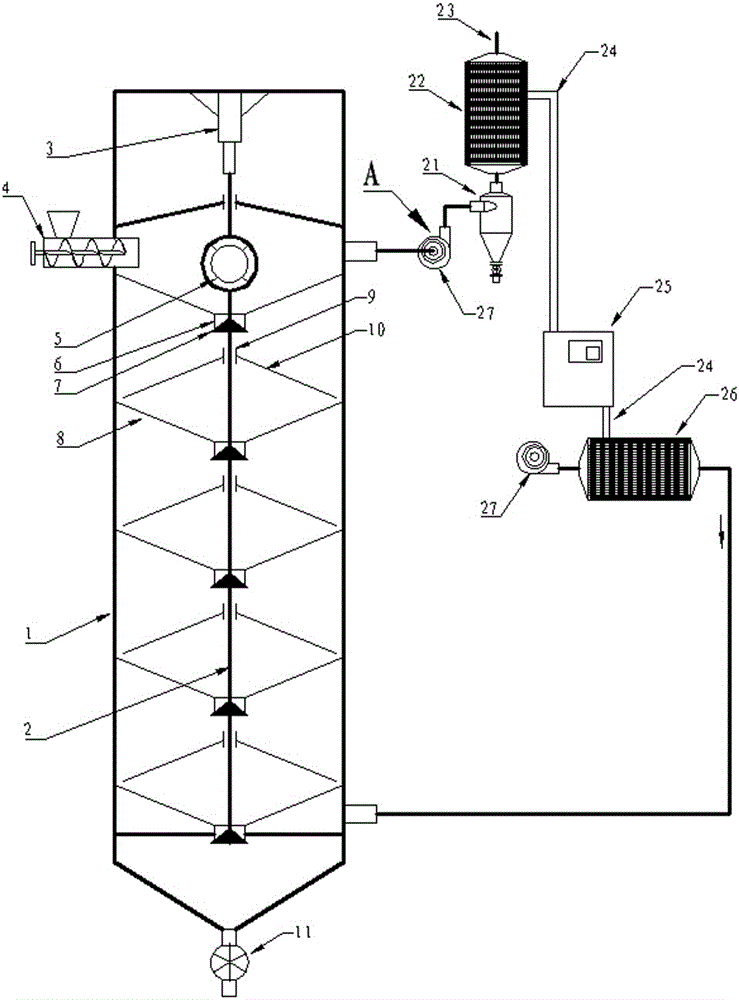

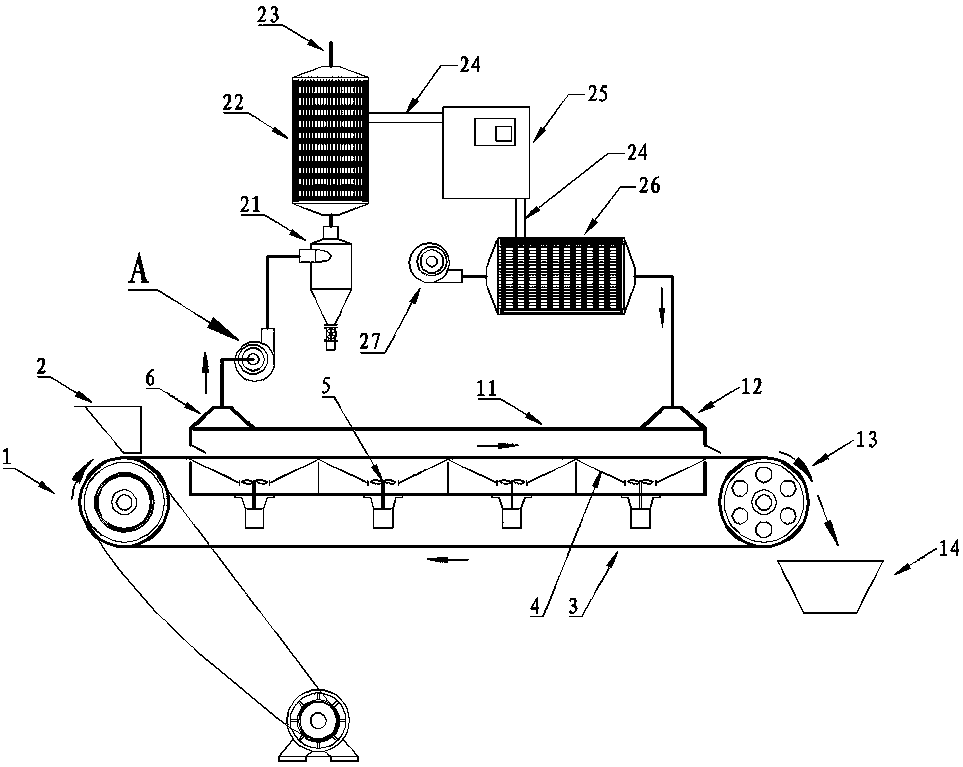

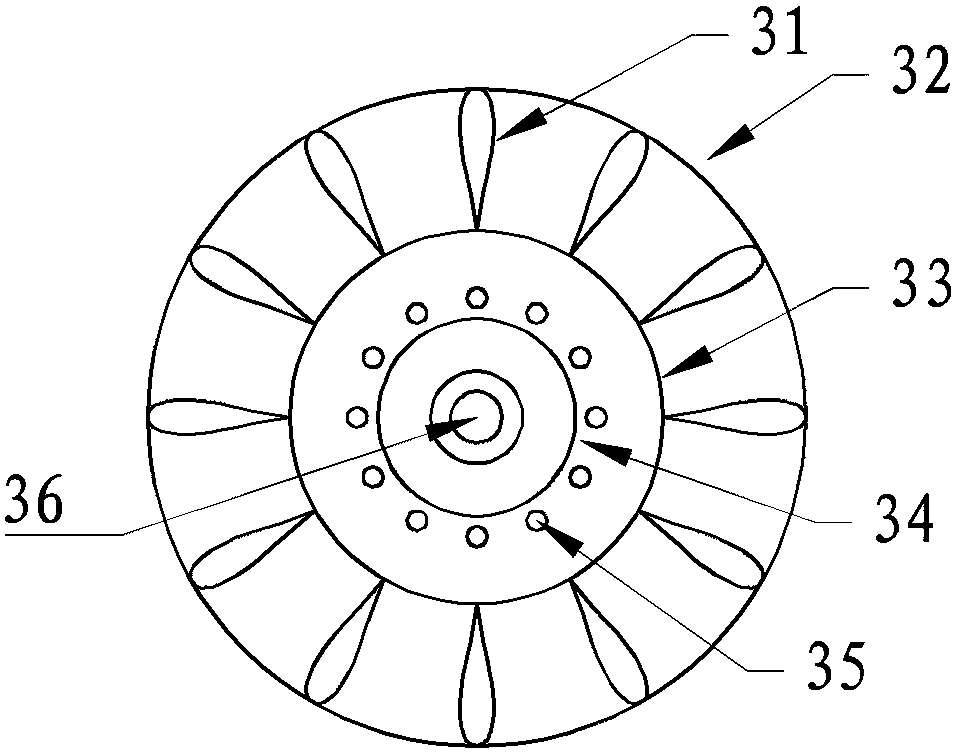

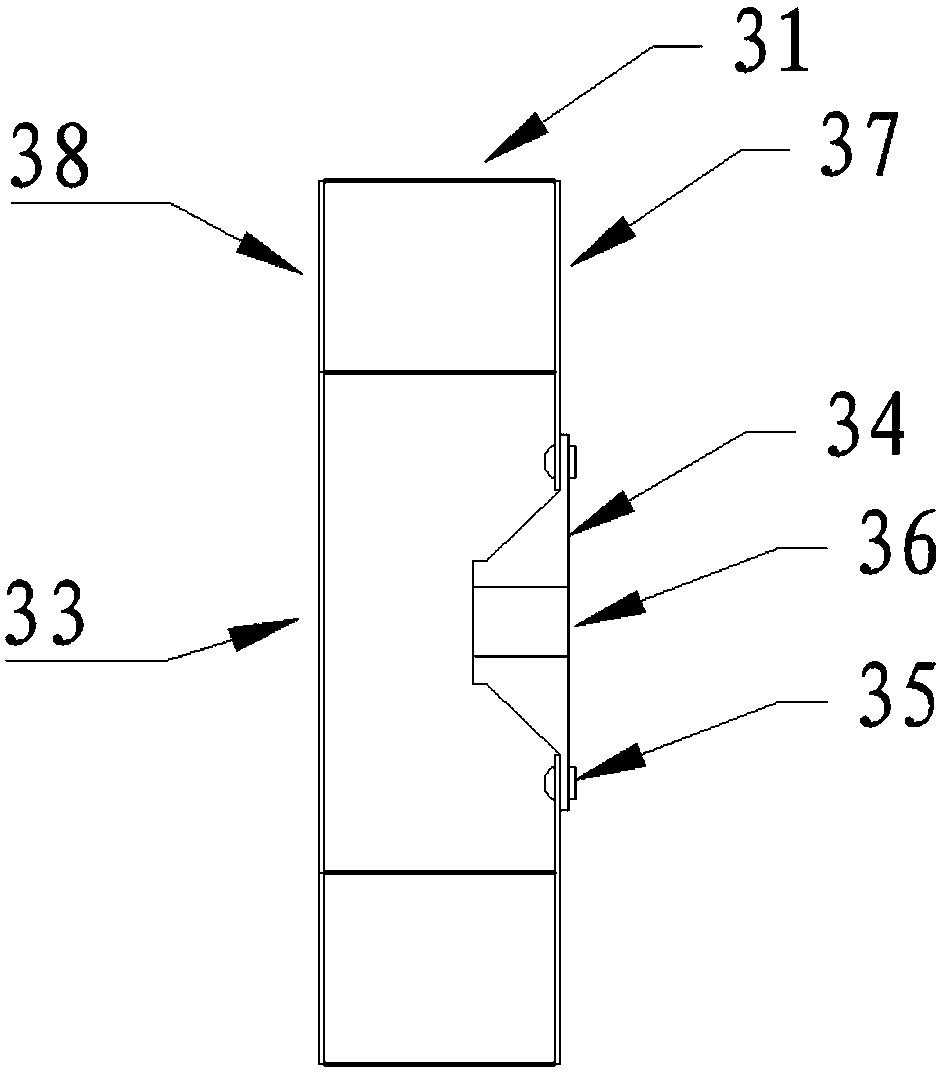

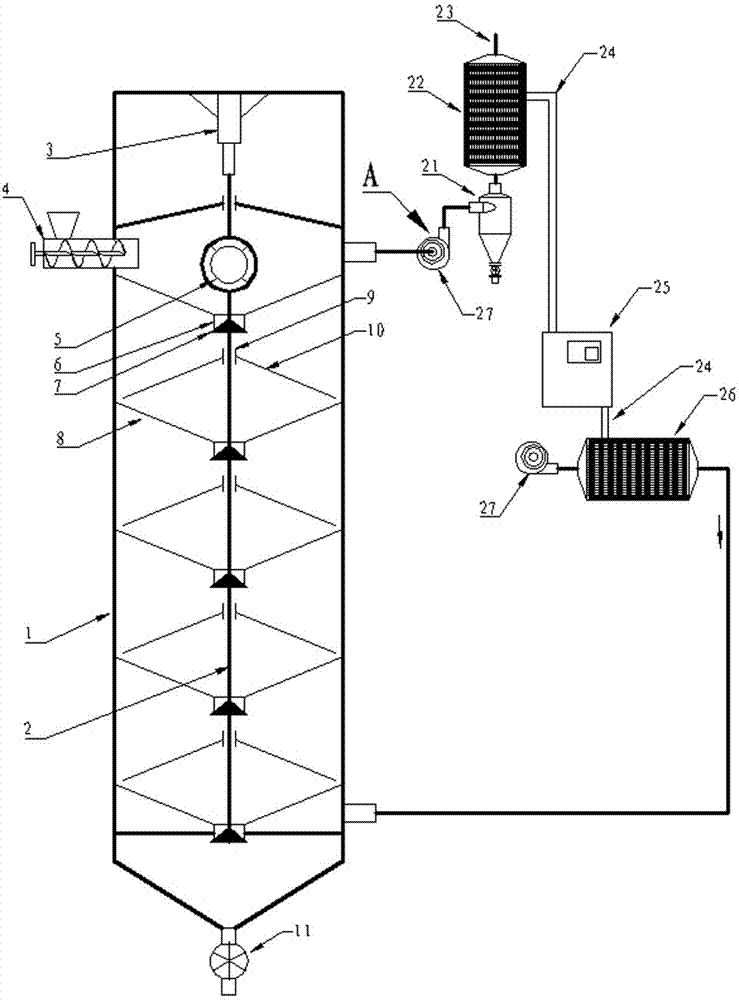

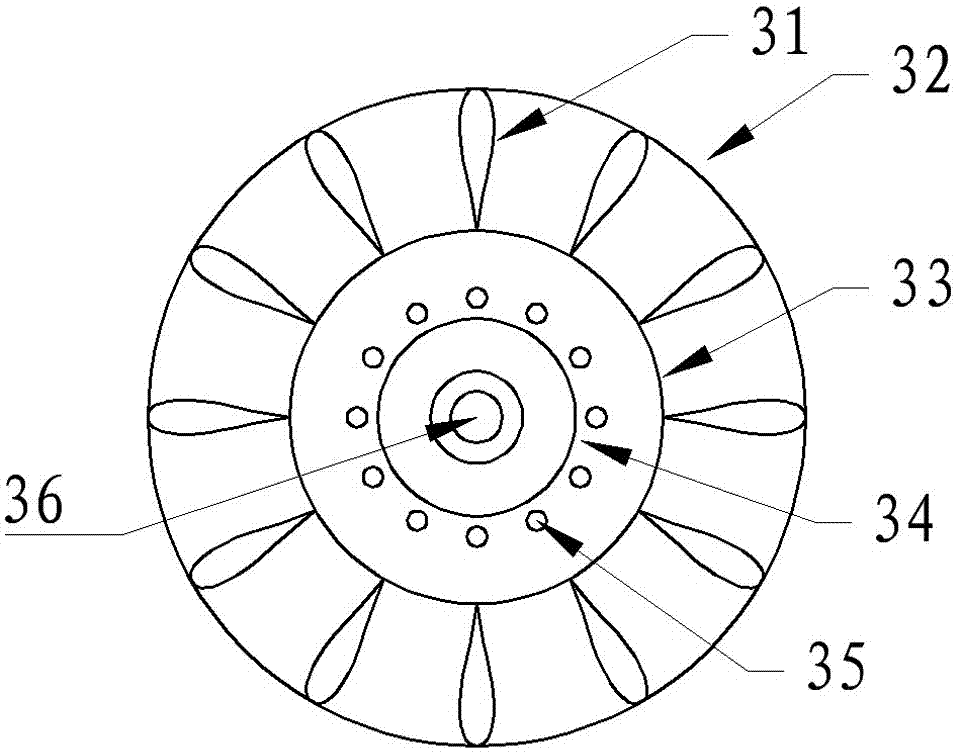

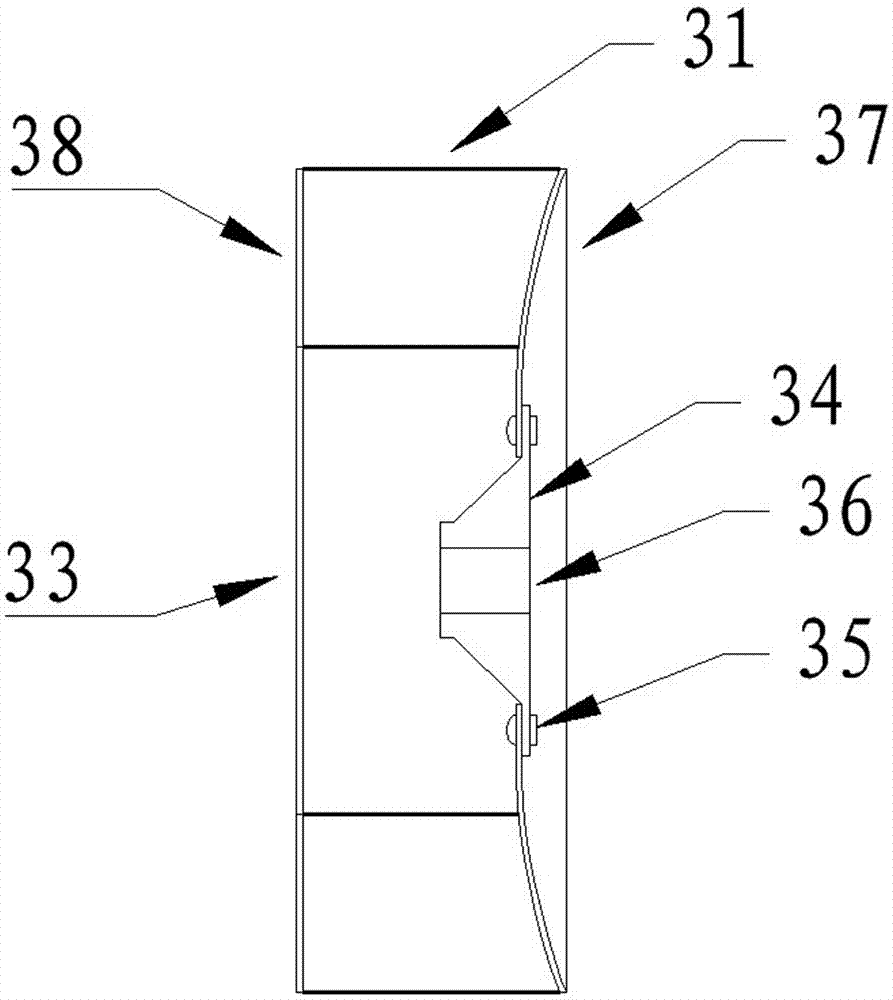

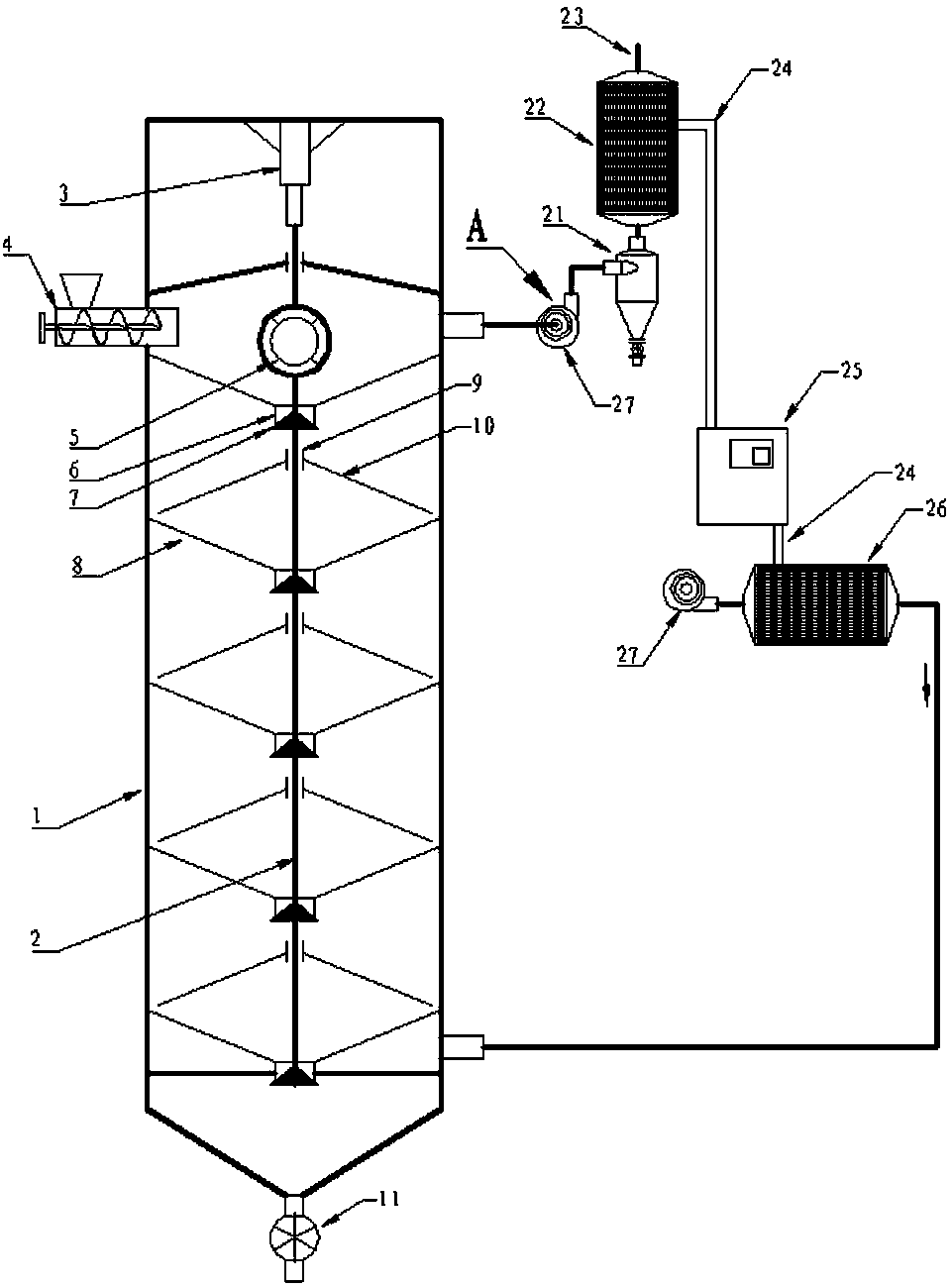

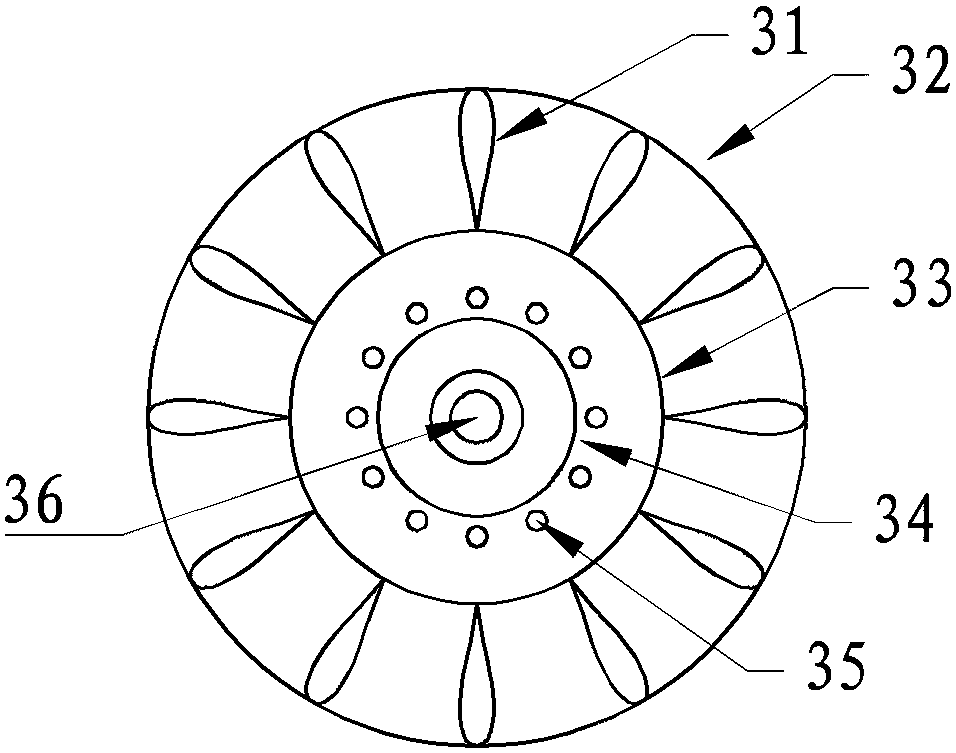

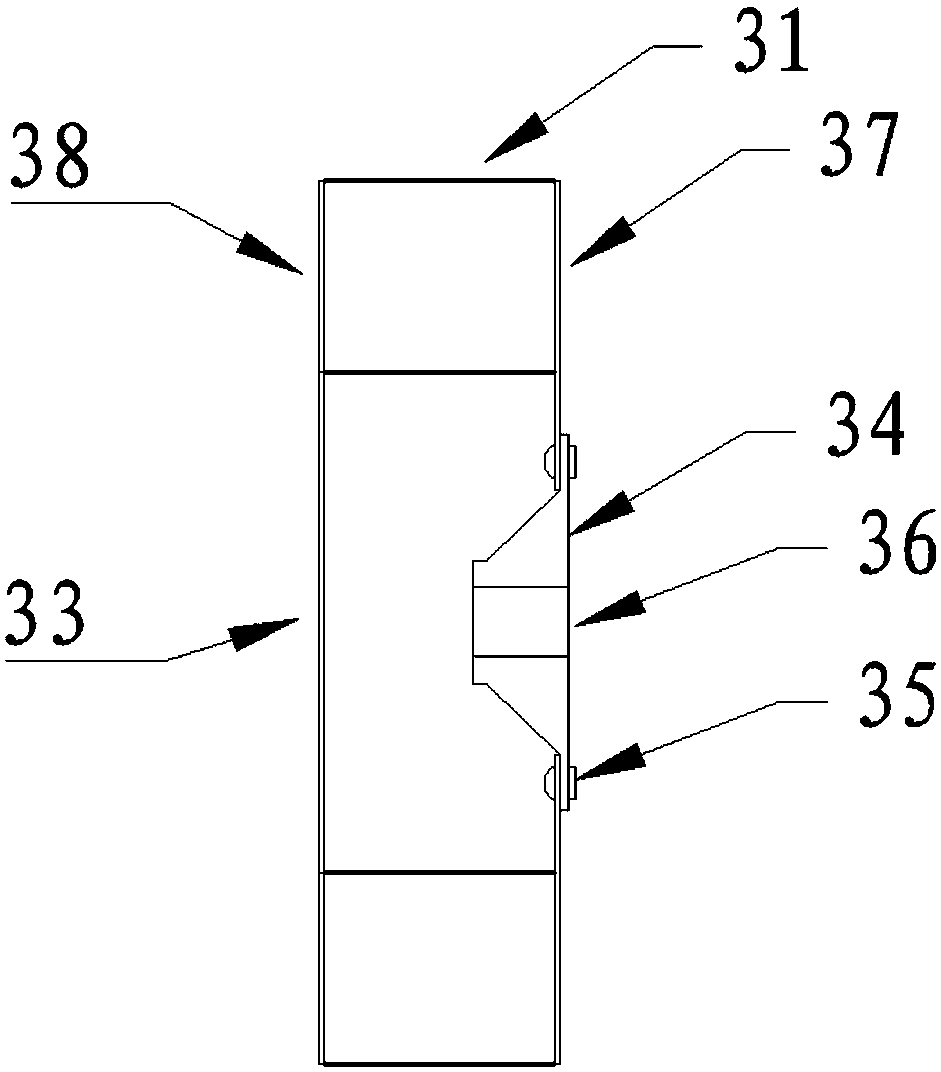

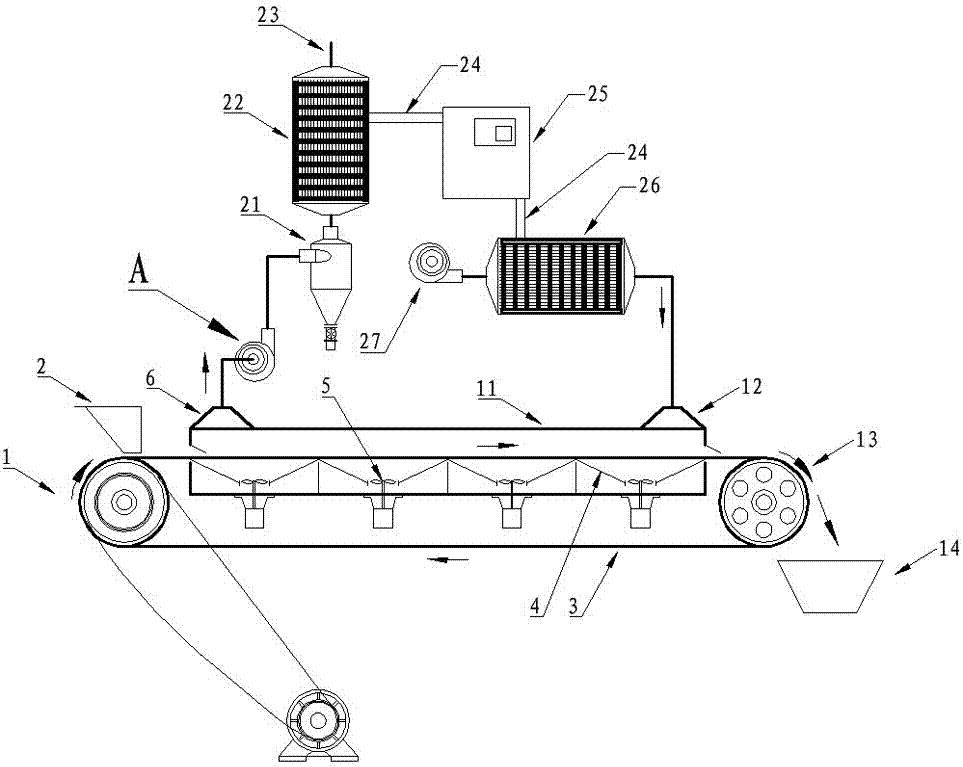

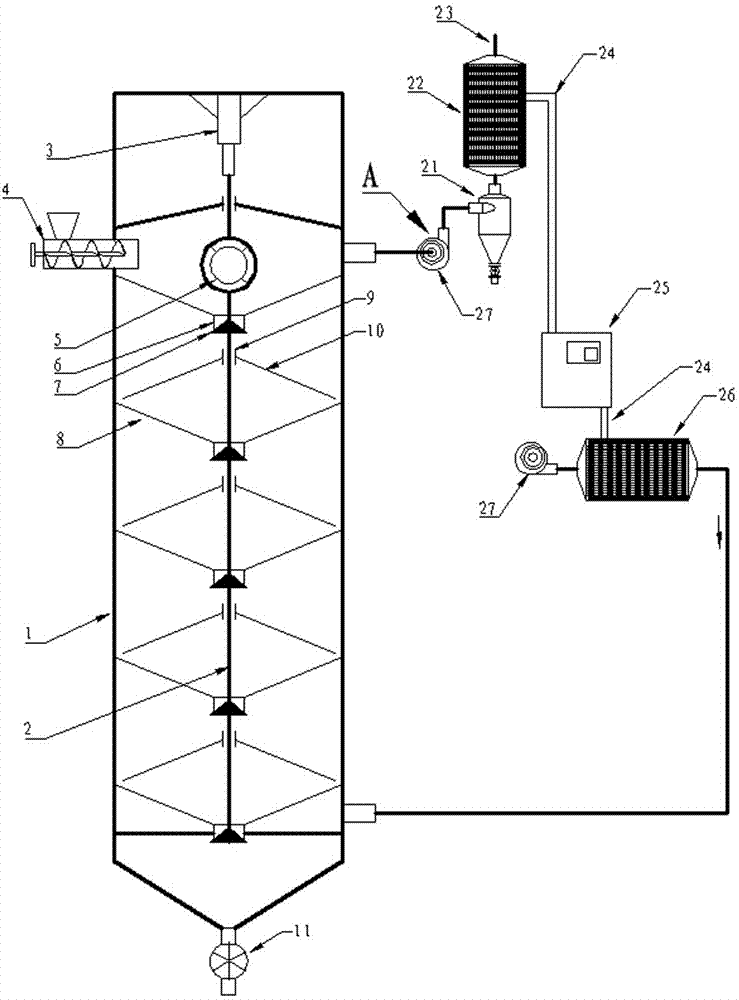

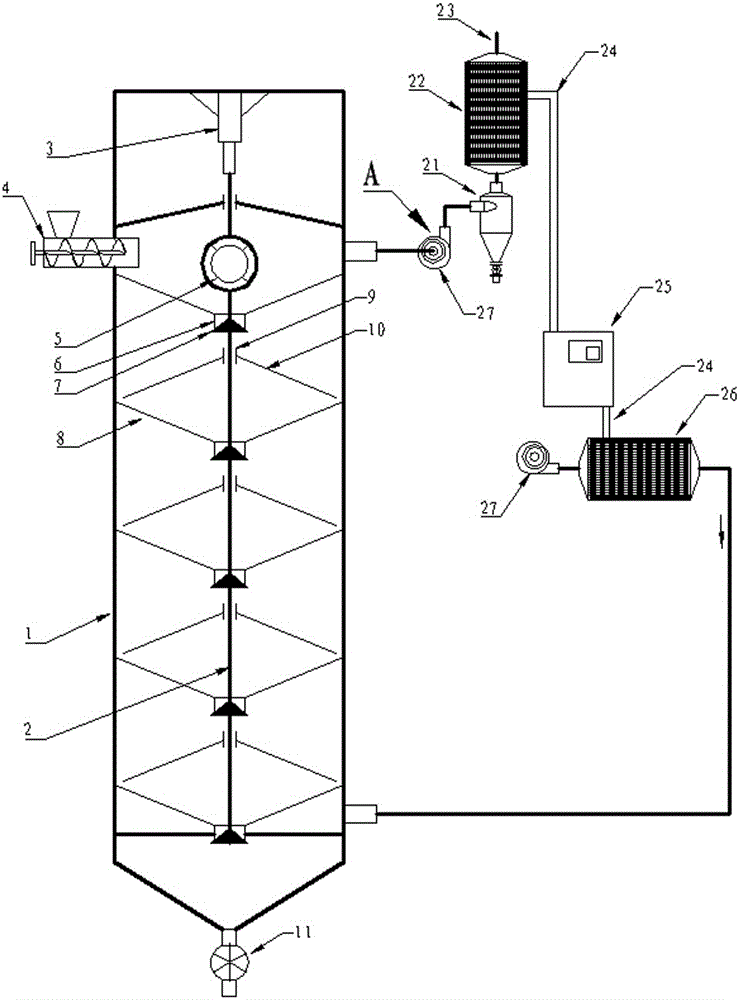

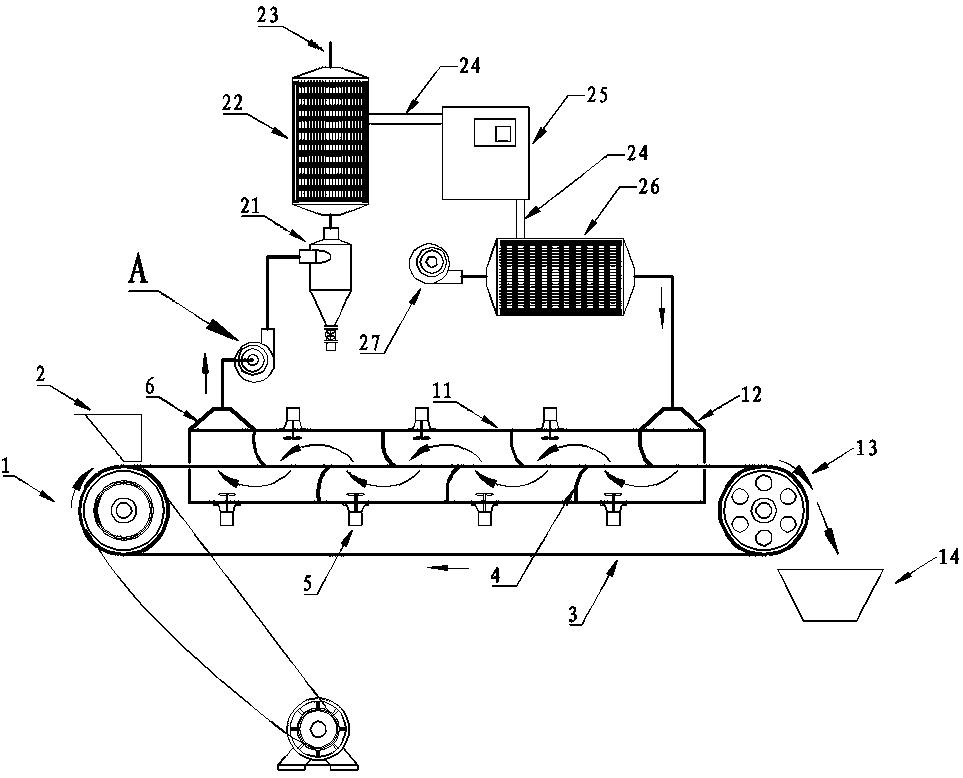

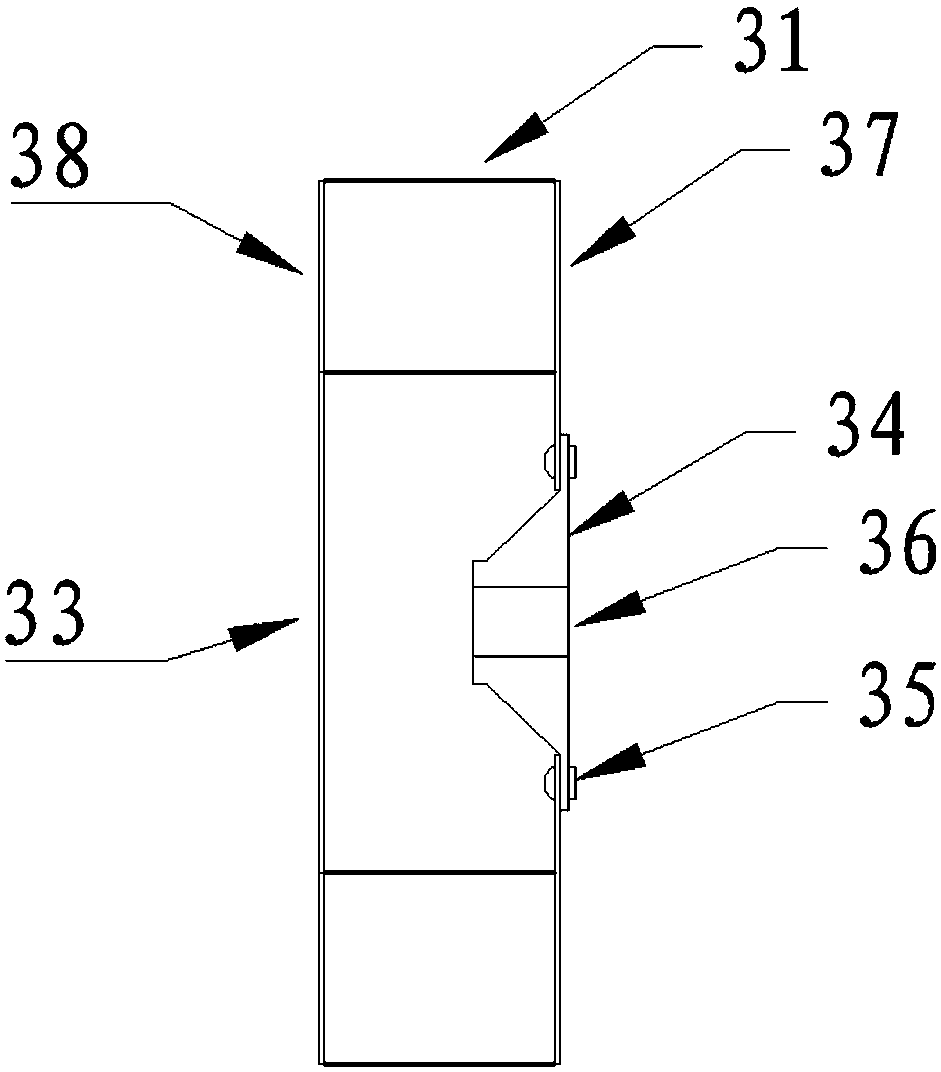

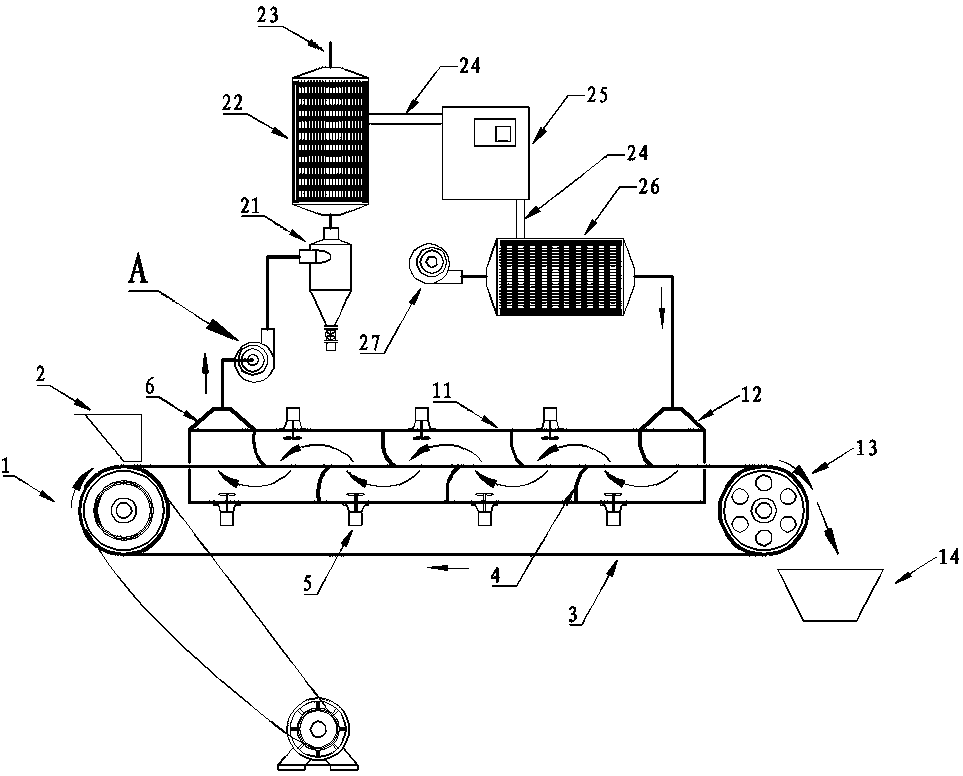

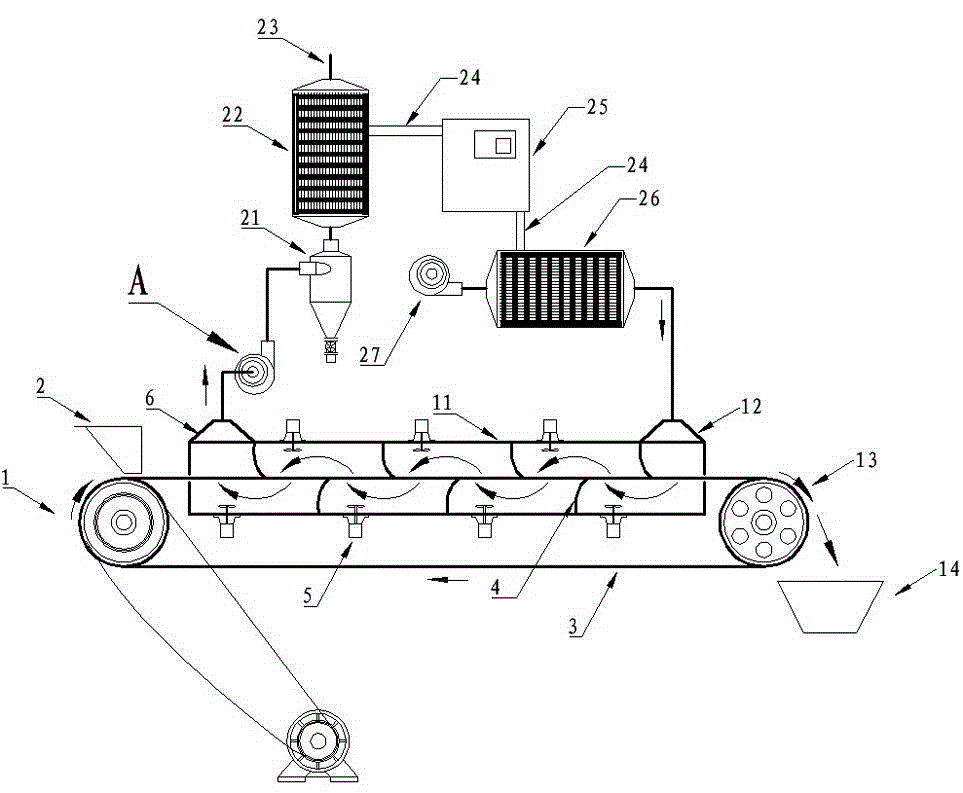

Heat pump type tail heat recovery and penetrating counterflow fluidized drying machine

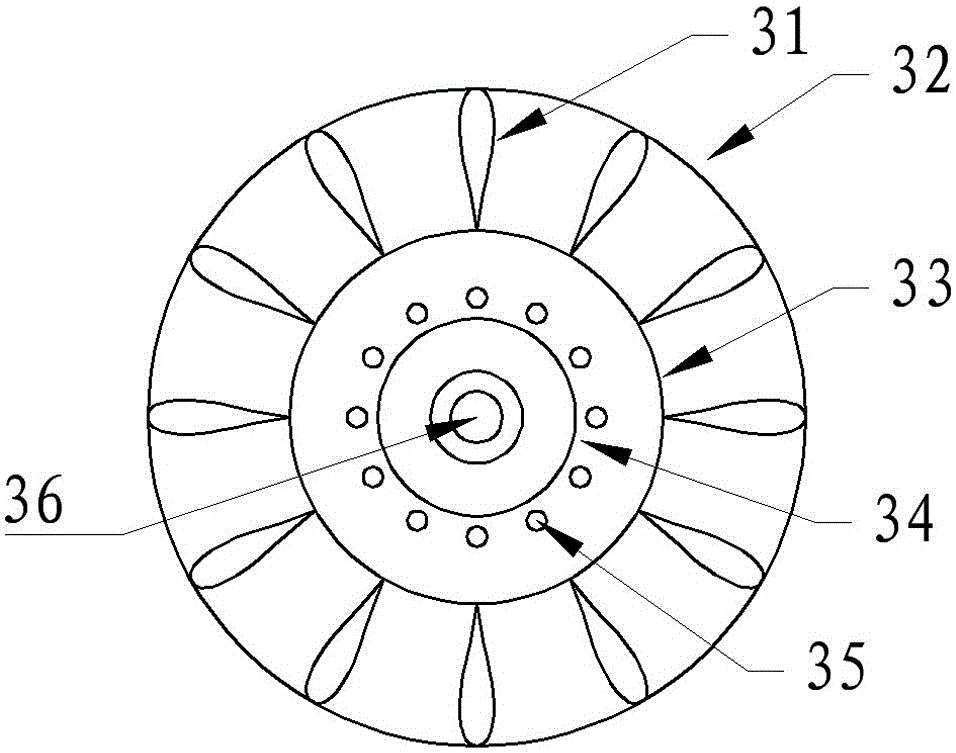

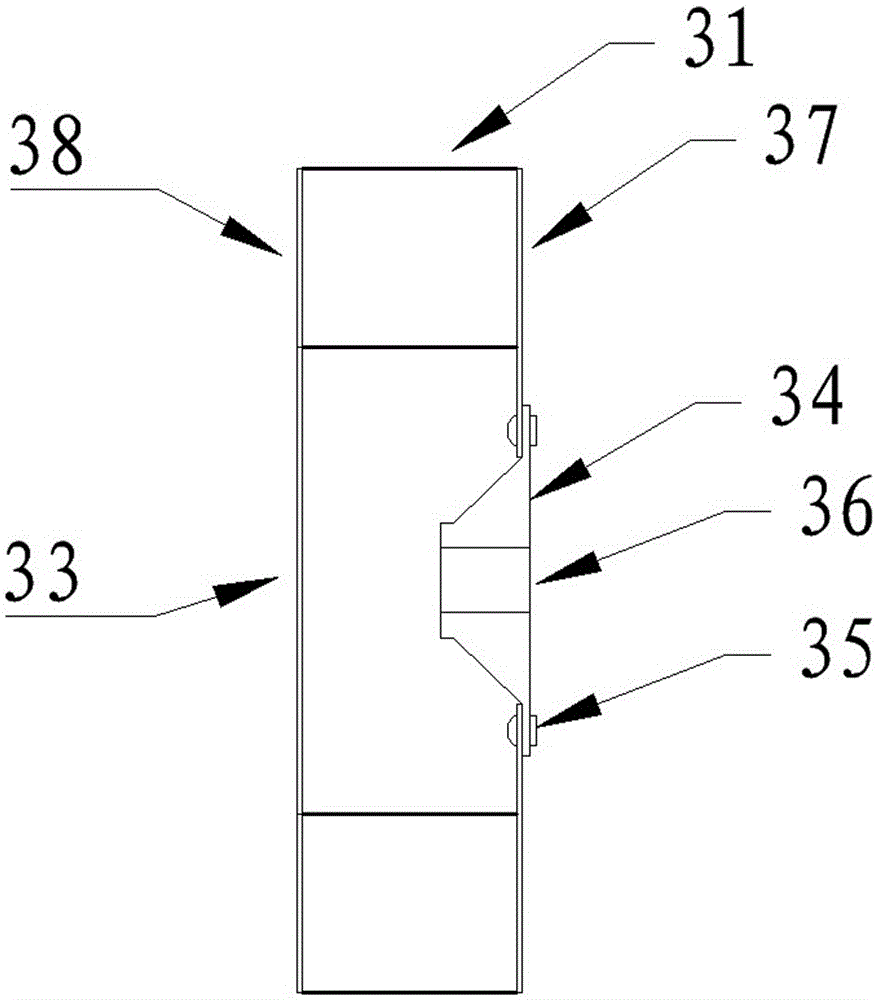

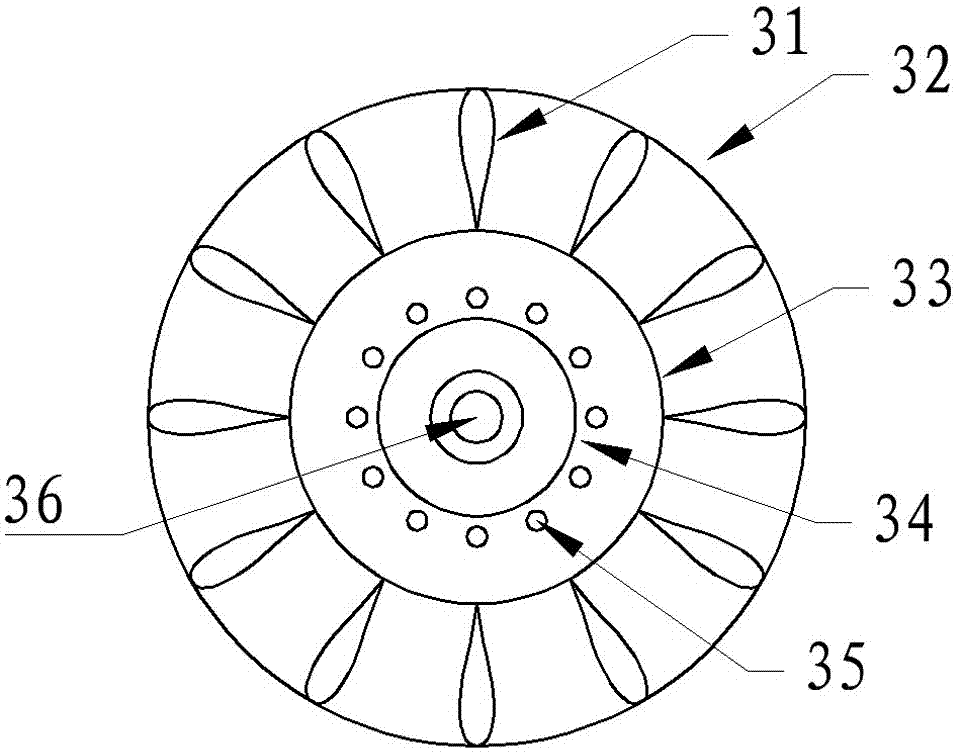

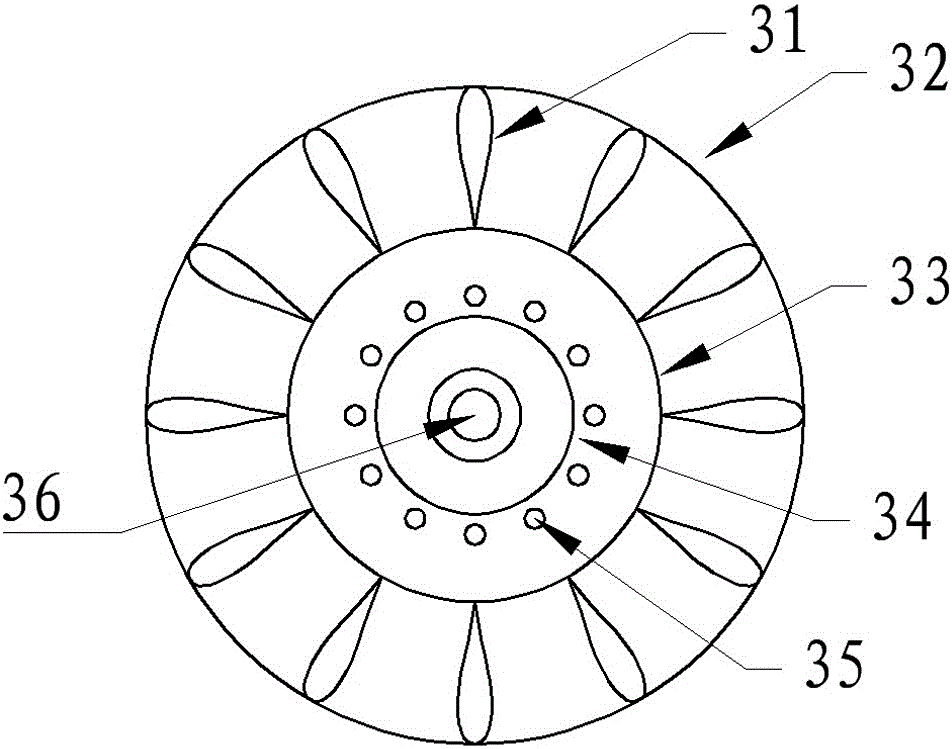

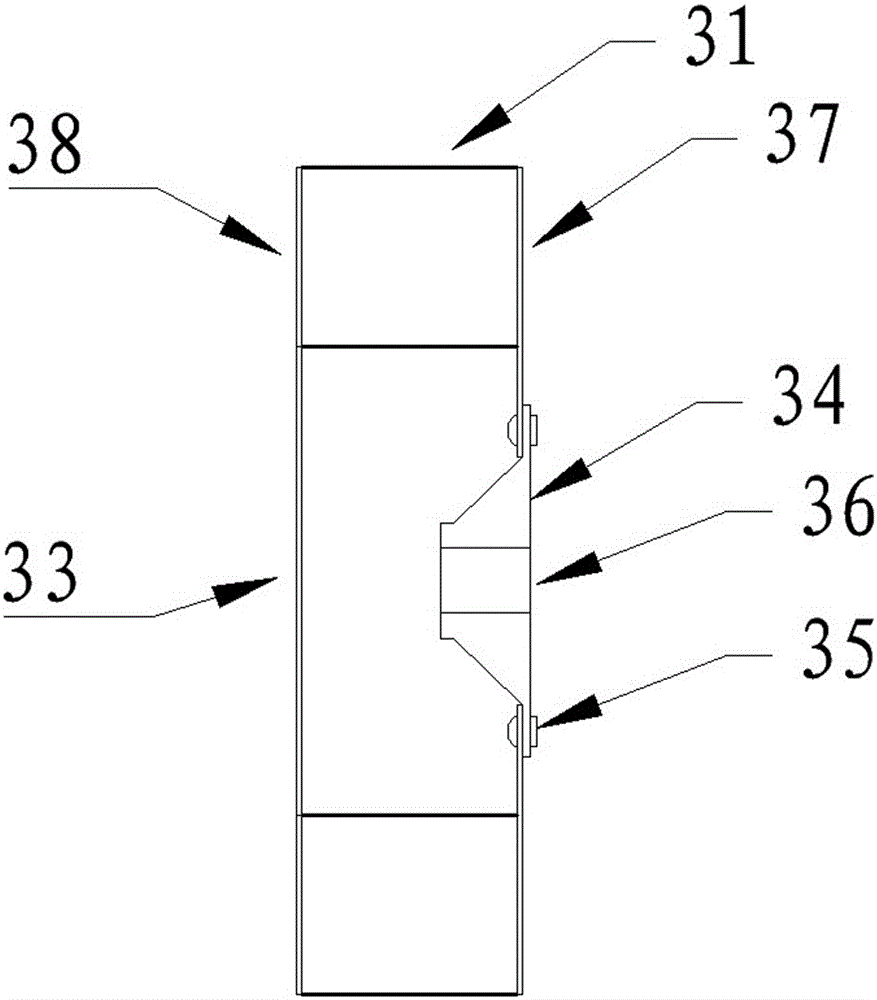

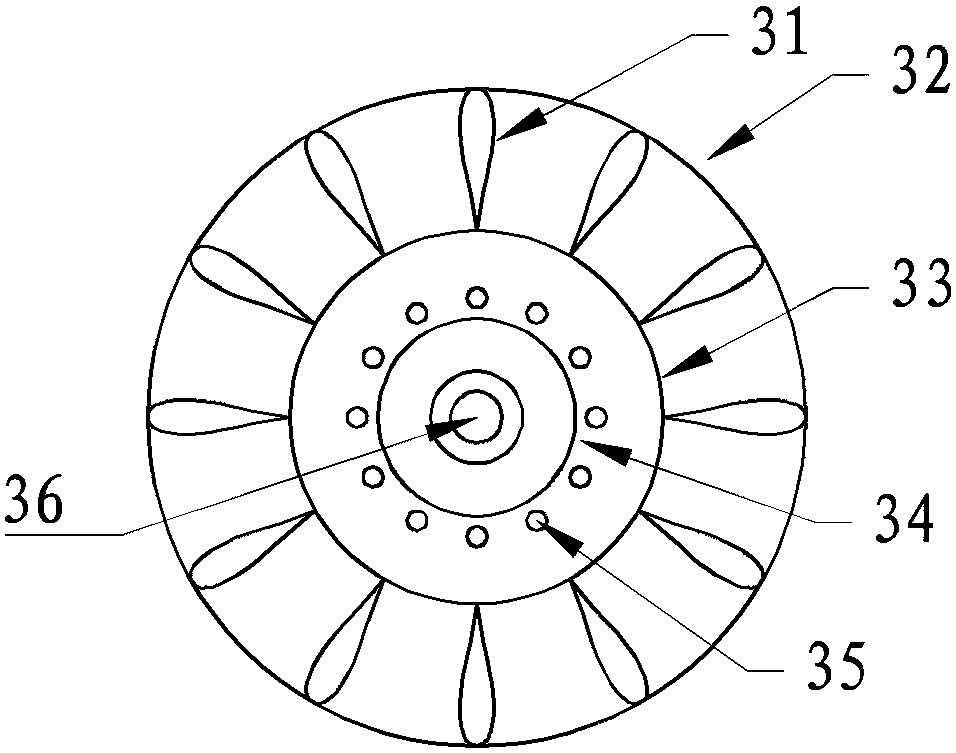

ActiveCN105066653AImprove rigidityImprove carrying capacityDrying solid materials with heatPump componentsDrop-shapedAir blower

The invention discloses a heat pump type tail heat recovery and penetrating counterflow fluidized drying machine. A material seal spiral feeding machine is arranged on the upper portion of a drying tower, and an air-lock valve discharging machine is arranged at the bottom of the drying tower. The upper portion of the drying tower is connected with an inducted draft fan, and the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector, and then evacuation is carried out. The evaporator of the heat pump system is connected with a main engine through a refrigerant pipe, and the main engine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected with the lower portion of the drying tower through the condenser. An impeller of the induced draft fan is provided with a structure with hollow inverted-drop-shaped blades and a dish-shaped back plate. The contour line of the appearance of the induced draft fan is an involute. Screen mesh cone covers, screen mesh cone discs, a blanking tube, a telescopic vibration transmission shaft and a conical plug are arranged, so that penetrating, counterflow, boiling and fluidized drying on materials are achieved ingeniously and perfectly, and a classic boiling counterflow drying mode is thoroughly exceeded; and more energy is achieved, the drying quality is higher, the power consumption of the fan is lower. The heat pump type tail heat recovery and penetrating counterflow fluidized drying machine is especially suitable for recovery of heat of low-temperature tail gas.

Owner:JIANGSU XUEMEI REFRIGERATION EQUIP

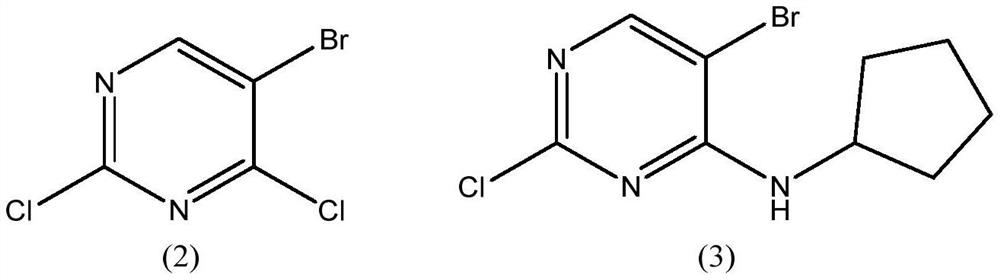

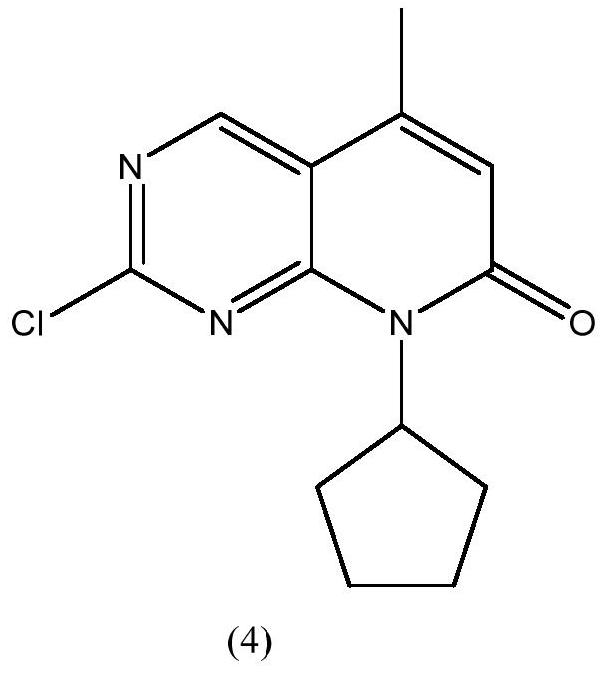

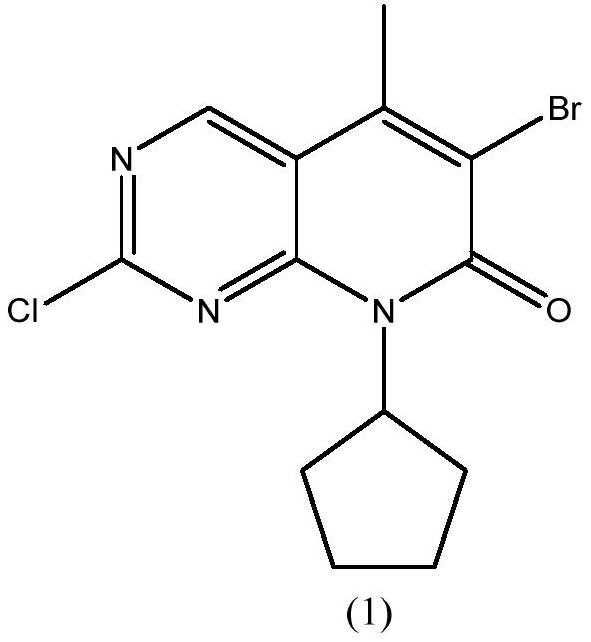

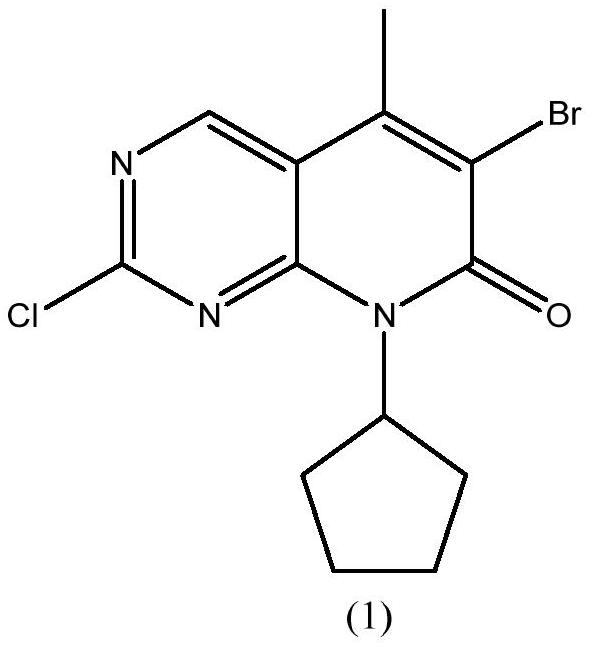

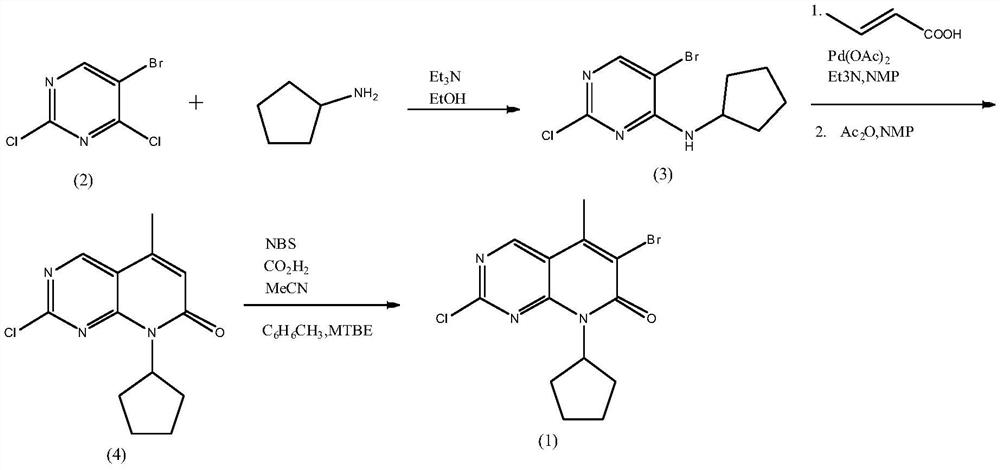

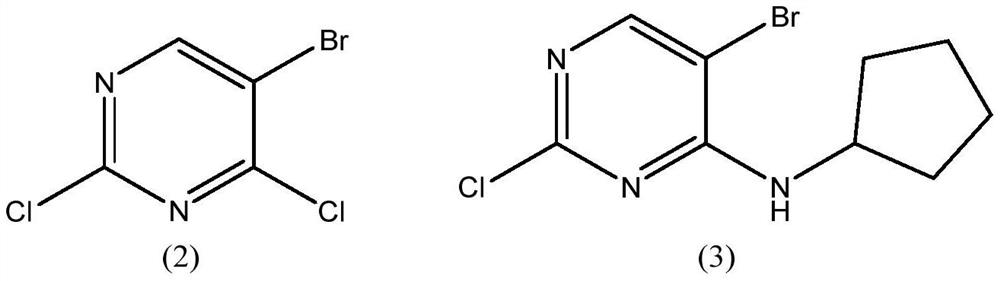

Preparation method of palbociclib intermediate

ActiveCN112898299AMild reaction conditionsSimple post-processingOrganic chemistryAcetic anhydrideKetone

The invention discloses a preparation method of a palbociclib intermediate. The method comprises the following steps: preparing 5-bromine-2-chloro-N-cyclopentylamine pyrimidine-4 amine from 5-bromine-2,4-dichloropyrimidine and cyclopentylamine by taking solvents such as dichloromethane and water as solvents and taking inorganic base as an acid-binding agent; with DIEA as an acid-binding agent, DMF as a solvent and TBAB as a phase transfer catalyst, in the presence of water, catalyzing with a trace amount of palladium, and carrying out normal hexane reflux dehydration; further subjecting the acetic anhydride to dehydration cyclization, such that 2-chloro-8-cyclopentyl-5-methylpyridino[2,3-D]pyrimidine-7-(8H)-ketone is obtained; and reacting the obtained compound with NBS (N-bromosuccinimide) in acetonitrile to obtain the 6-bromo-2-chloro-8-cyclopentyl-5-methylpyridino[2, 3-D]pyrimidine-7(8H)-ketone. The method is mild in reaction, simple and convenient to operate, recyclable in solvent, less in environmental pollution, high in yield, low in cost, high in product quality and suitable for industrial production.

Owner:SHANDONG BOYUAN PHARM CO LTD

Tower type penetrating reverse flow fluidized drier

ActiveCN104990369AAchieve penetrationAchieve countercurrentDrying solid materials with heatHearth type furnacesAir blowerCyclonic spray scrubber

The invention discloses a tower type penetrating reverse flow fluidized direr. A material seal screw feeder is arranged at the upper portion of a drying tower. An air-lock valve discharger is arranged at the bottom of the drying tower. The upper portion of the drying tower is connected with an induced draft fan. The induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector and then is evacuated. The evaporator of the heat pump system is connected with a host through a refrigerant pipe. The host is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected with the lower portion of the drying tower through the condenser. A plurality of layered repeated structures composed of sieve hole conical covers and sieve hole conical discs are arranged inside the drying tower. The sieve hole conical covers, the sieve hole conical discs, a discharging pipe, a stretchable vibration transmission shaft and a conical plug are arranged, so that penetrating, reverse flow, boiling and fluidization drying of materials are ingeniously and perfectly achieved, the classic boiling reverse flow drying mode is completely exceeded, more energy is saved, the drying quality is higher, and electricity consumption of the fans is lower; heat-pump-type tail heat recovery is particularly suitable for heat recovery at the low tail gas temperature.

Owner:泰兴市中全新能源技术有限公司

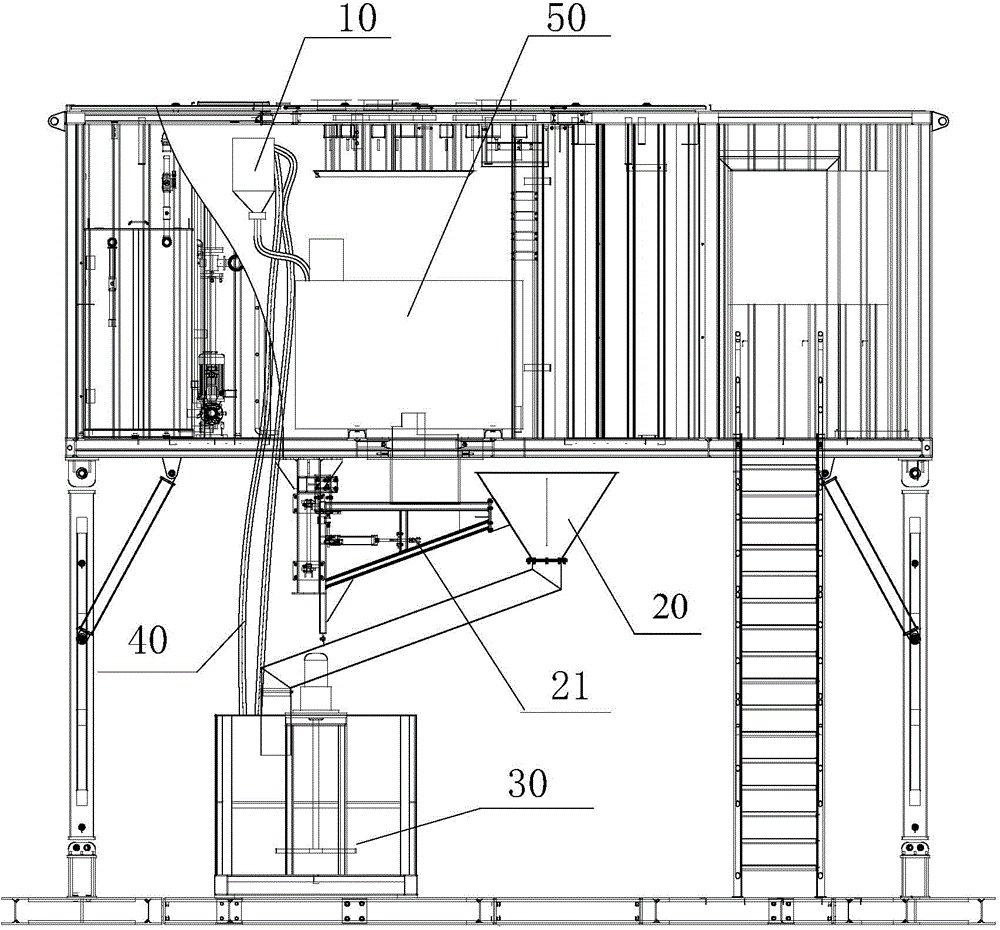

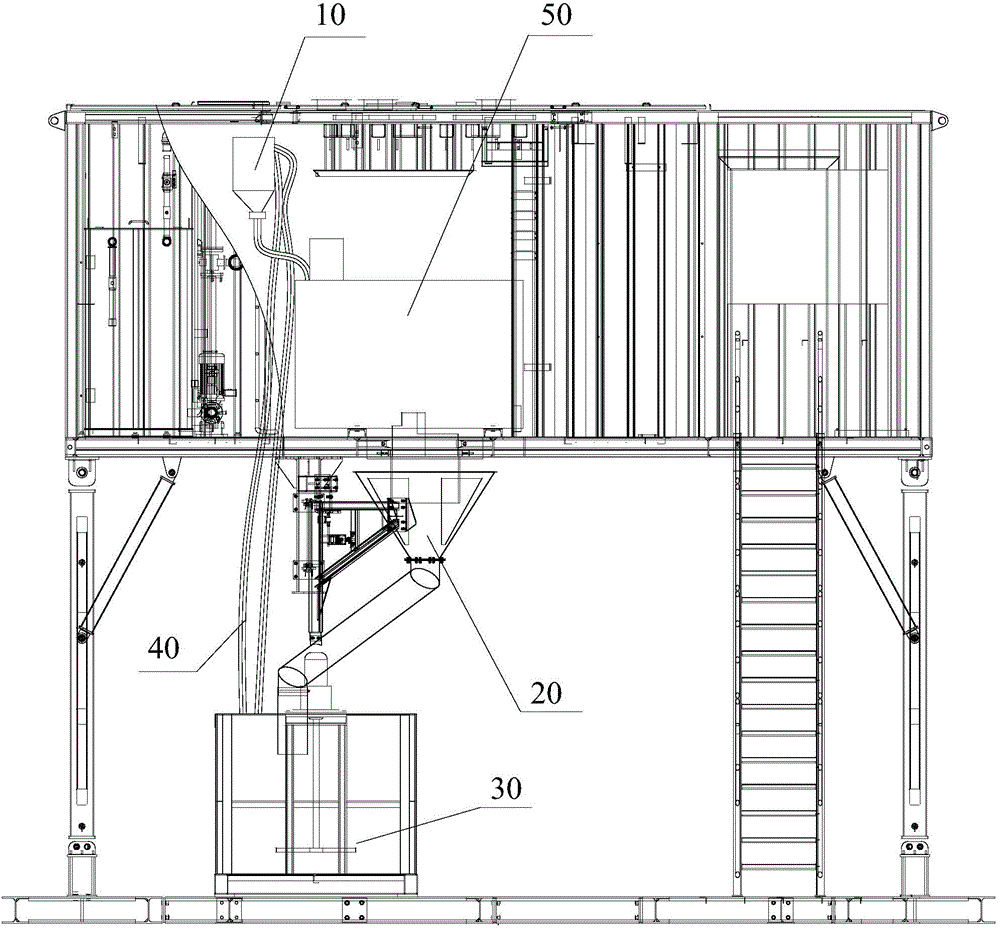

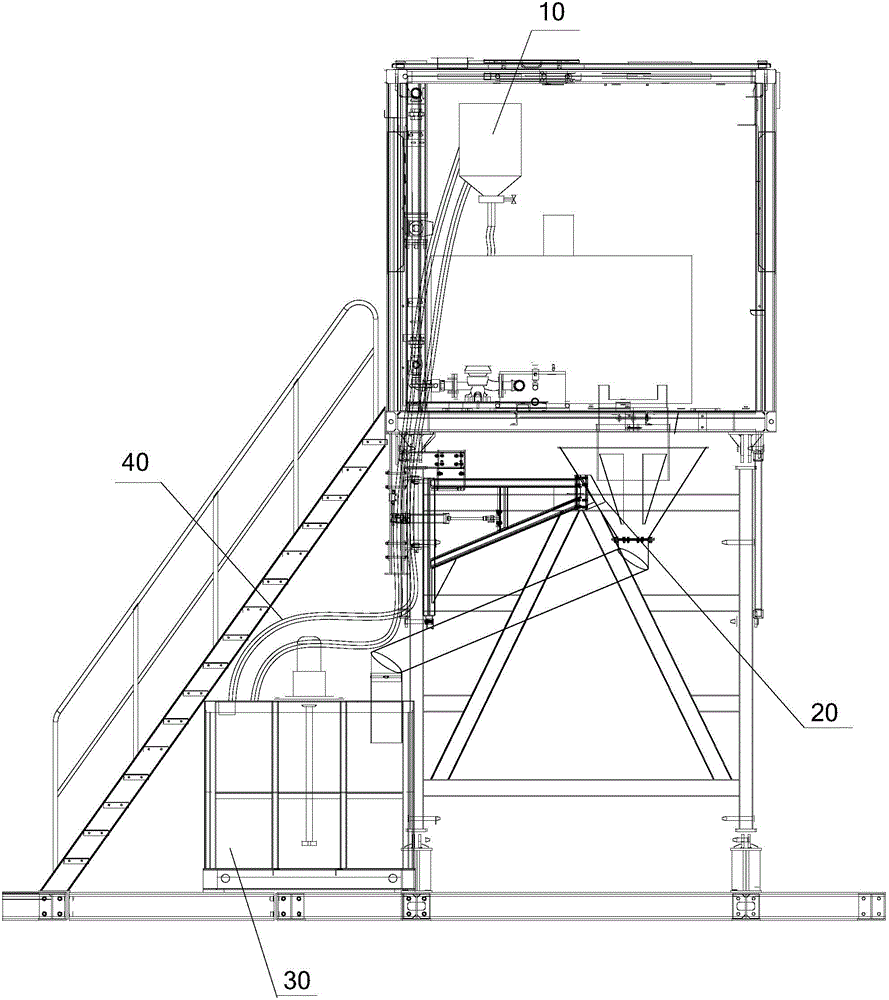

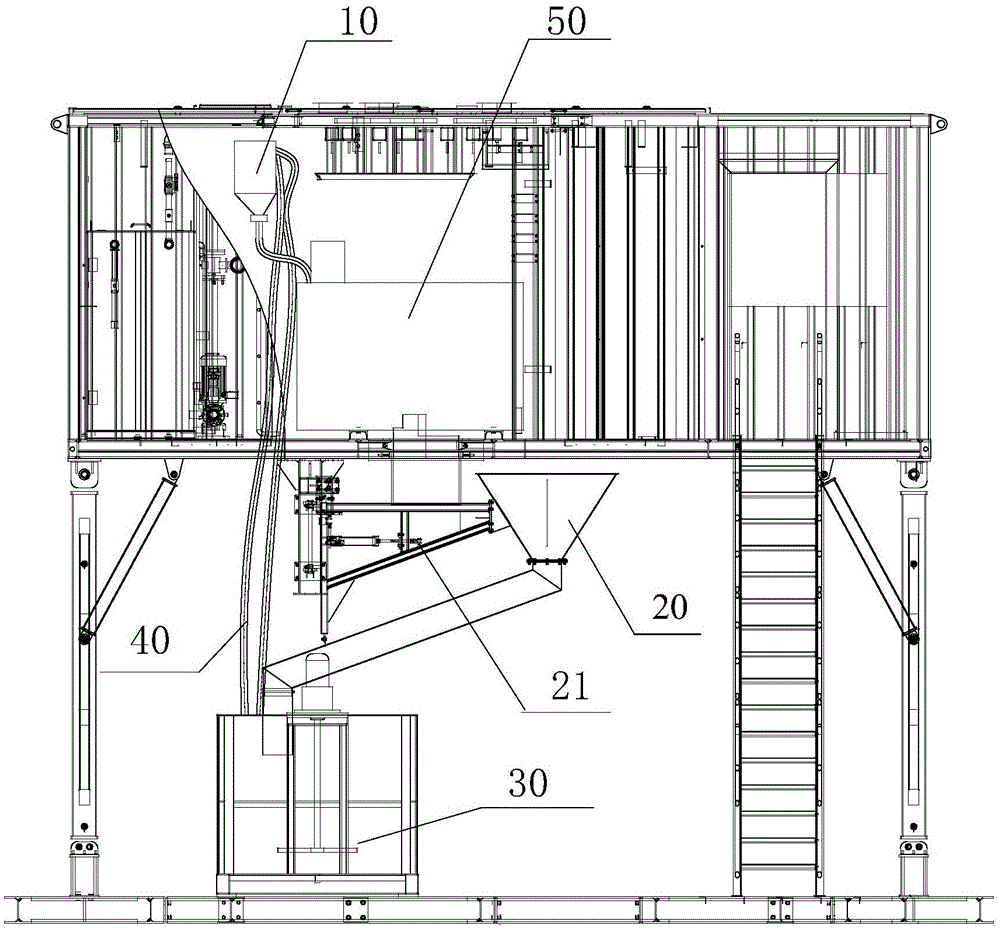

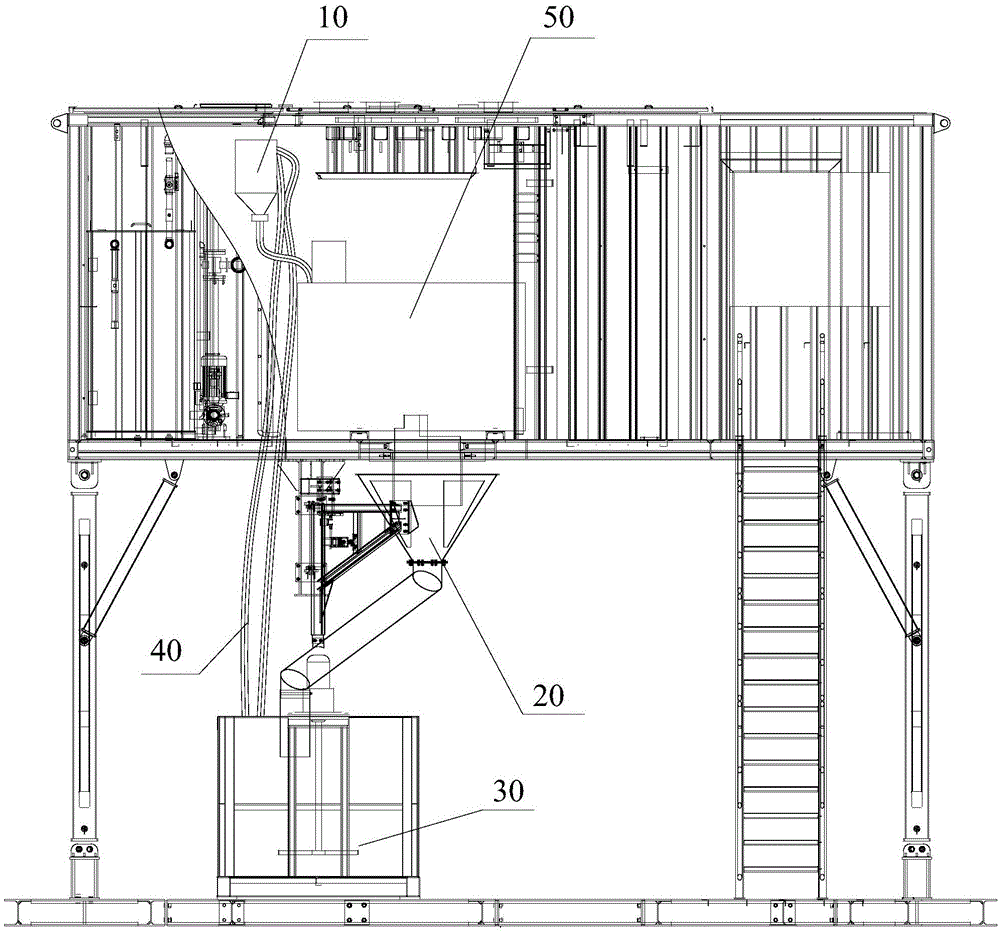

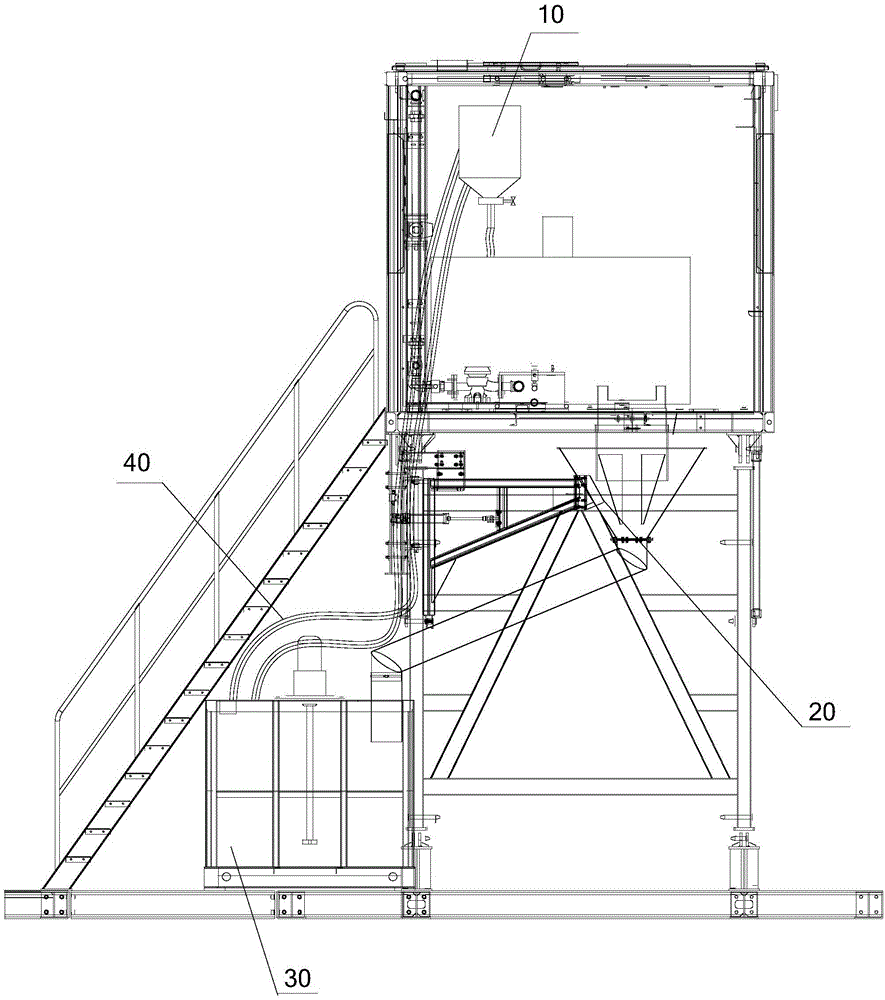

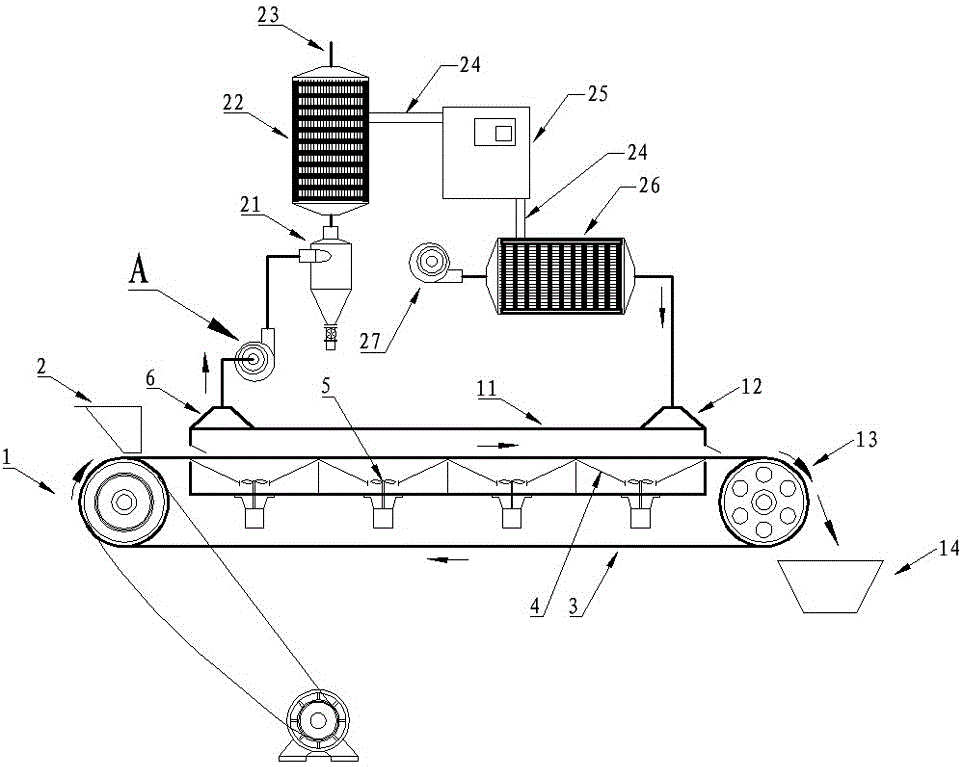

Wastewater recycling system and mixing station

ActiveCN103601259AAchieve recyclingEasy to assemble and disassembleWater/sewage treatmentMixing operation plantWastewaterSewage

The invention discloses a wastewater recycling system and a mixing station. The wastewater recycling system is used for the mixing station. The wastewater recycling system comprises a wastewater metering device, a material guiding device, a wastewater treatment device and a connecting pipe, wherein the wastewater metering device is arranged in a main body of the mixing station and is communicated with a mixing mainframe in the main body; the material guiding device is detachably arranged below the mixing mainframe and is used for exporting the wastewater in the mixing mainframe; a wastewater inlet of the wastewater treatment device is communicated with the material guiding device, and a wastewater outlet is connected with the wastewater metering device through the connecting pipe for drain the treated wastewater to the wastewater metering device; therefore, the wastewater recycling system disclosed by the invention not only is easy and convenient to disassemble and assemble, simple in structural design and relatively low in equipment cost, but also can improve an energy conservation and environmental protection index of site operation of a mobile mortar mixing station.

Owner:SANY AUTOMOBILE MFG CO LTD

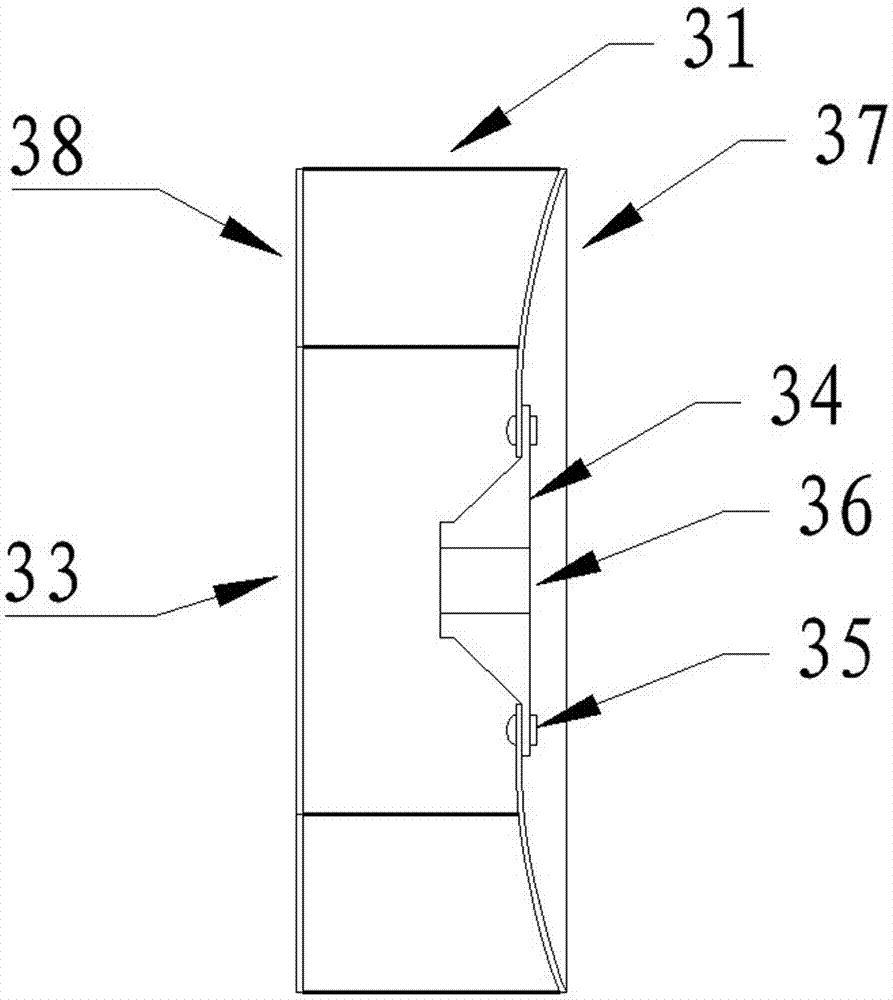

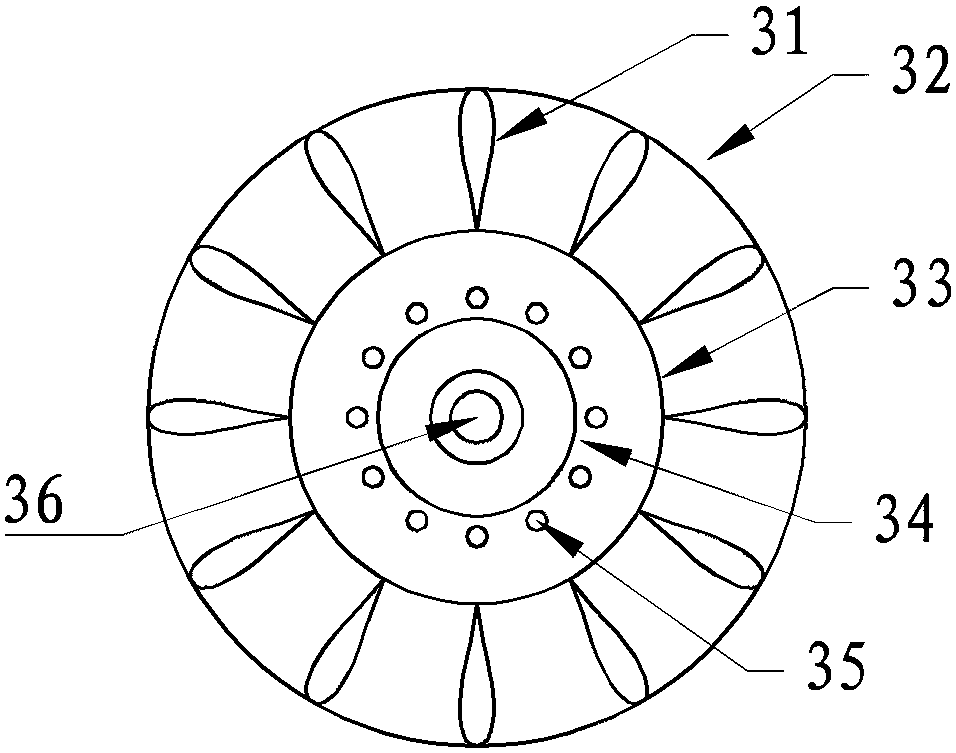

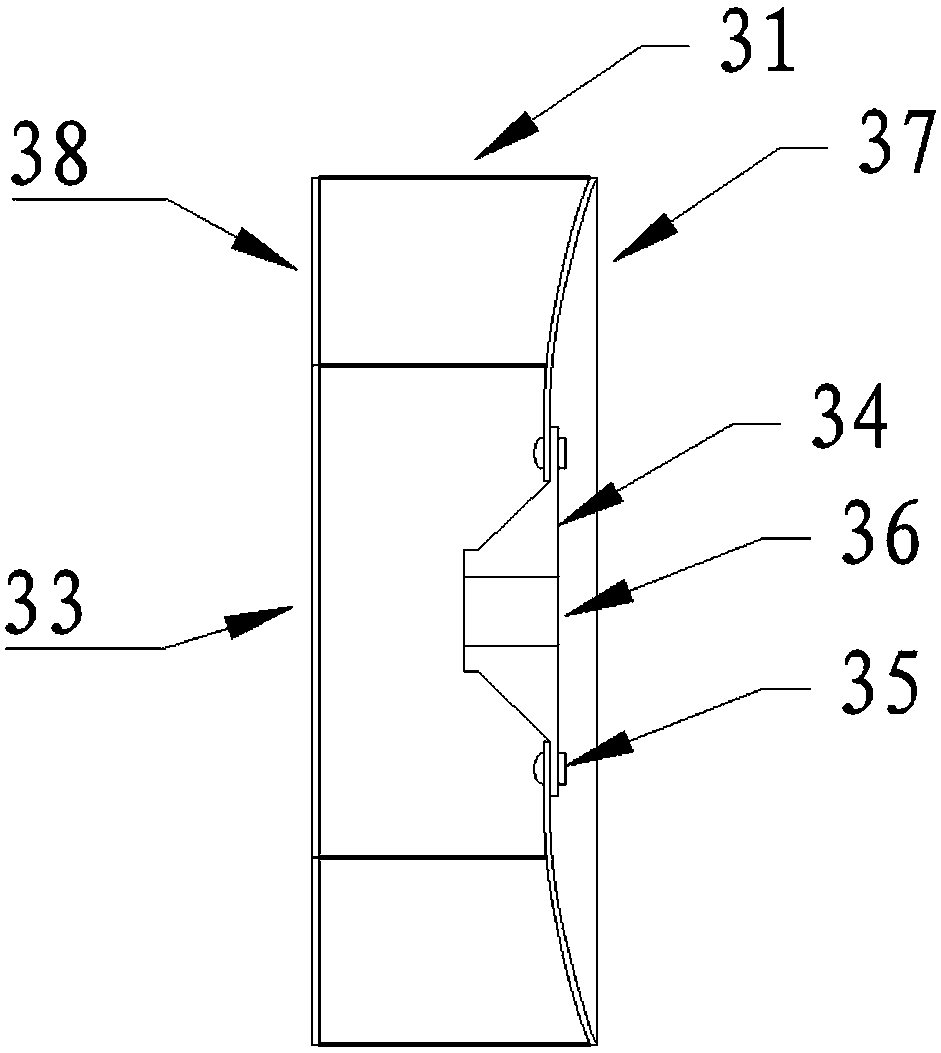

Heat pump tail heat recovery countercurrent dryer

ActiveCN105066643BRealize penetrating countercurrent low temperature dryingRecycling fitDrying solid materials with heatHeat recovery systemsInvoluteAir blower

The invention discloses a heat pump type tail heat recovery counterflow drying machine. A draught hood of the drying machine is connected with an induced draft fan, the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector, and then evacuation is carried out. The evaporator of the heat pump system is connected with a main engine through a refrigerant tube, and the main engine is connected with a condenser through a refrigerant tube. The air outlet end of an air blower is connected with an air inlet hood through the condenser. An impeller of the induced draft fan is provided with a structure with hollow inverted-drop-shaped blades. The contour line of the appearance of the induced draft fan is an involute. The induced draft fan, a heat exchanger and a closed cone hopper below a screen plate steel rip are arranged, an axial fan is arranged in the cone hopper, so that penetrating type counterflow low-temperature drying of materials is achieved, and the heat pump system is especially suitable for recovery of heat of low-temperature tail gas. The blades are of a hollow inverted drop shape, so that dust on the impeller of the induced draft fan is removed in real time, the strength of the impeller of the fan is increased, and stability is improved; and potential safety hazards caused by dust accumulation are effectively eradicated, and wide application prospects are achieved.

Owner:安徽上元家居材料股份有限公司

A heat pump type tail heat recovery penetration countercurrent fluidized dryer

ActiveCN105066653BImprove rigidityImprove carrying capacityDrying solid materials with heatPump componentsHeat penetrationAir blower

The invention discloses a heat pump type tail heat recovery and penetrating counterflow fluidized drying machine. A material seal spiral feeding machine is arranged on the upper portion of a drying tower, and an air-lock valve discharging machine is arranged at the bottom of the drying tower. The upper portion of the drying tower is connected with an inducted draft fan, and the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector, and then evacuation is carried out. The evaporator of the heat pump system is connected with a main engine through a refrigerant pipe, and the main engine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected with the lower portion of the drying tower through the condenser. An impeller of the induced draft fan is provided with a structure with hollow inverted-drop-shaped blades and a dish-shaped back plate. The contour line of the appearance of the induced draft fan is an involute. Screen mesh cone covers, screen mesh cone discs, a blanking tube, a telescopic vibration transmission shaft and a conical plug are arranged, so that penetrating, counterflow, boiling and fluidized drying on materials are achieved ingeniously and perfectly, and a classic boiling counterflow drying mode is thoroughly exceeded; and more energy is achieved, the drying quality is higher, the power consumption of the fan is lower. The heat pump type tail heat recovery and penetrating counterflow fluidized drying machine is especially suitable for recovery of heat of low-temperature tail gas.

Owner:JIANGSU XUEMEI REFRIGERATION EQUIP

Heat pump tail heat recovery penetrating countercurrent fluidized dryer

ActiveCN105020986BAchieve penetrationAchieve countercurrentDrying solid materials with heatHearth type furnacesInvoluteDrop-shaped

The invention discloses a thermal pump type tail heat recycling reverse flowing penetrating fluidized drying machine. According to the thermal pump type tail heat recycling reverse flowing penetrating fluidized drying machine, a material seal screw feeder is arranged on the upper portion of a drying tower, and a closed-air aspirator discharging machine is arranged at the bottom of the drying tower; the upper portion of the drying tower is connected with an induced draft fan, and the induced draft fan is connected with an evaporator of a thermal pump system through a cyclone dust collector, and then carries out evacuation; the evaporator of the thermal pump system is connected with a main machine through a refrigerant pipe, and the main machine is connected with a condenser through a refrigerant pipe; the air outlet end of an air blower is connected with the lower portion of the drying tower through the condenser; an impeller of the induced draft fan is provided with a structure with blades in a hollow reverse drop shape; and the shape contour line of the induced draft fan is an involute. According to the thermal pump type tail heat recycling reverse flowing penetrating fluidized drying machine, through the arrangement of sieve mesh cone covers, sieve mesh cone disks, discharging pipes, a telescopic vibration transmission shaft and cone stoppers, penetration, reverse flowing, boiling and fluidized drying are tactfully and perfectly conducted on materials; the classic boiling reverse flowing drying mode is completely surpassed, the energy saving effect is better, the drying quality is higher, and power consumption of the draught fan is lower; and the thermal pump type tail heat recycle is particularly suitable for recycling heat of tail gas at a low temperature.

Owner:湖北沄禾泽生态农业开发有限公司

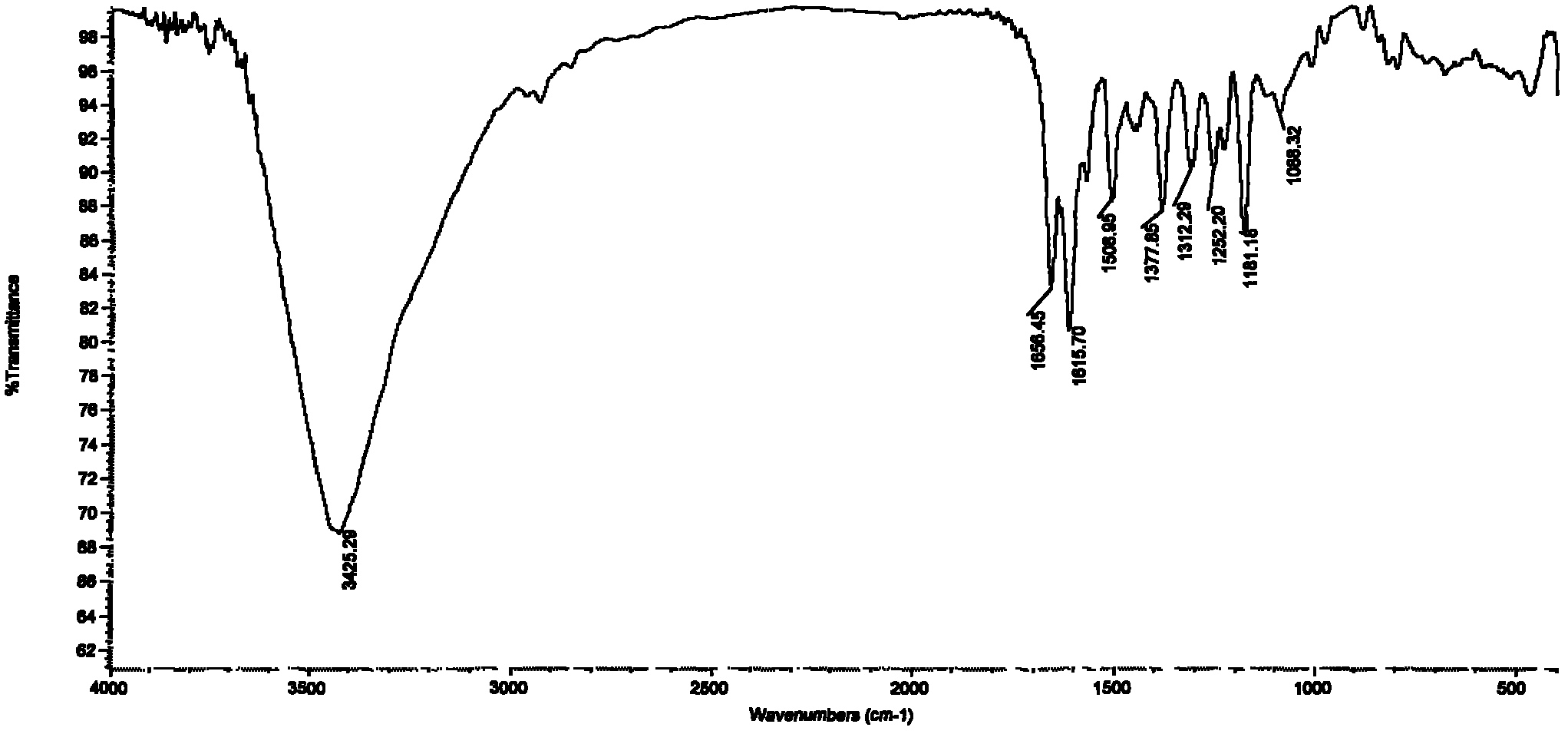

Method for extracting general flavone from sorrel shell waste residues through microwave refluxing

InactiveCN102526137AIncrease profitImprove extraction efficiencyAntibacterial agentsAntipyreticAluminium chlorideFiltration

The invention discloses a method for extracting general flavone from sorrel shell waste residues through microwave refluxing. The method comprises the following specific steps of: 1, removing impurities from naturally-dried sorrel shells, smashing, sieving with a sieve of 40-60 meshes, and putting into a constant-temperature drying oven for drying sorrel shell powder for later use; and 2, uniformly fixing the powder treated in the step 1 with 30-60 percent of ethanol in the weight volume ratio of 1:25-1:50, performing reflux leaching at microwave power for 10-25 minutes, performing suction filtration to obtain a general flavone extracting solution, removing ethanol by rotationally evaporating, and performing vacuum drying to obtain a general flavone solid. The content of general flavone in a concentrated solution is measured with an aluminum chloride colorimetric method. According to measurement, the extraction ratio of general flavone is 95 percent, and the yield is 0.20 percent. The method has the advantages of quickness, high extraction ratio, environmental friendliness and nontoxicity by taking ethanol water as a solvent, simple equipment operation, small solvent using amount, easiness for recovering and suitability for expanded production in plants. The method has wide application prospects in medicines and foods.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

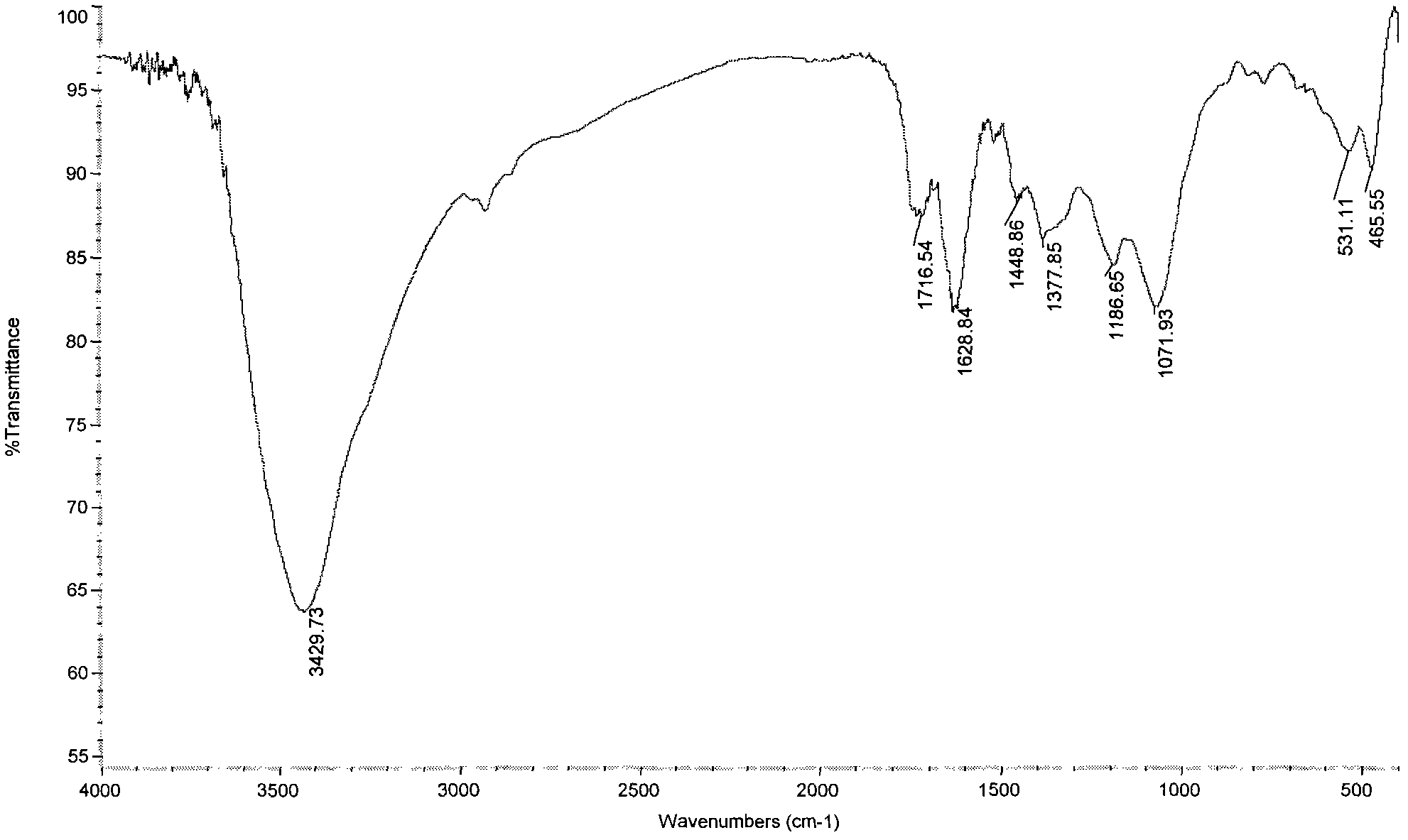

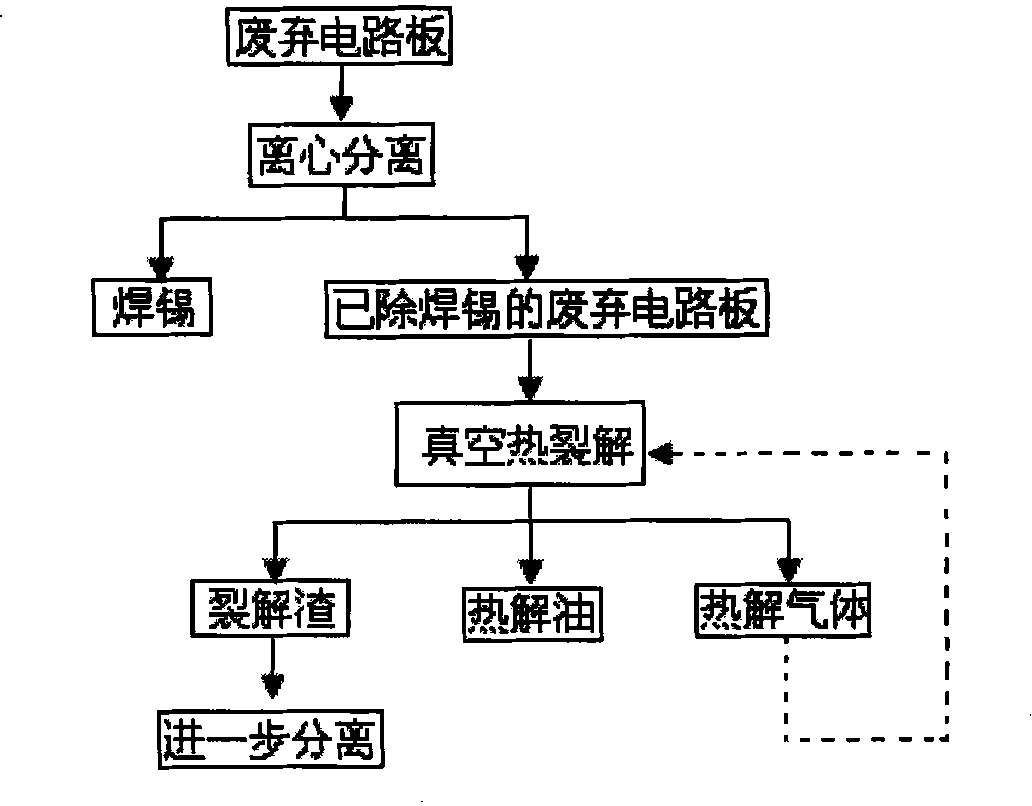

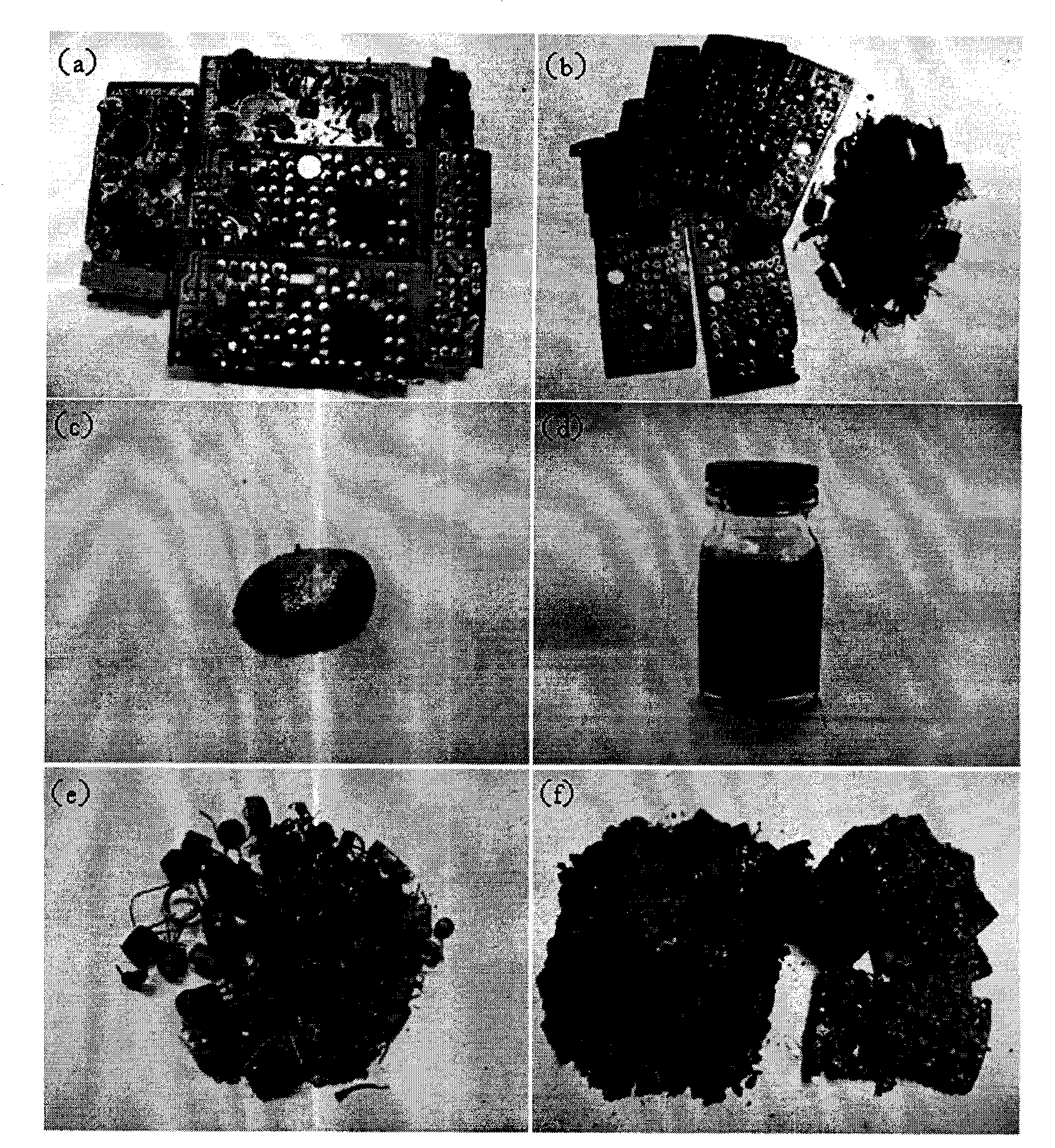

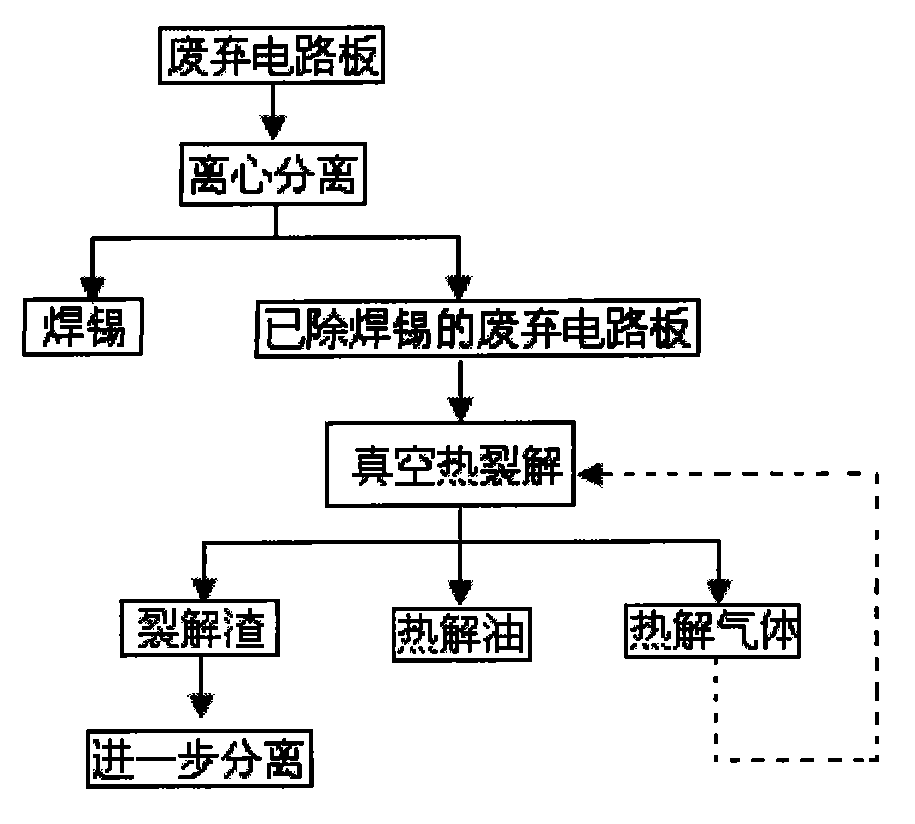

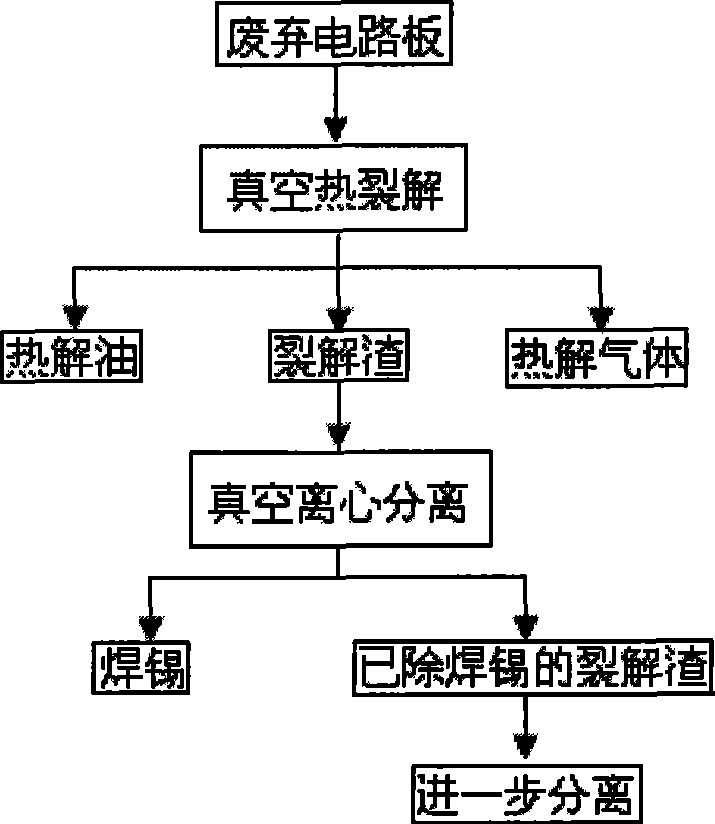

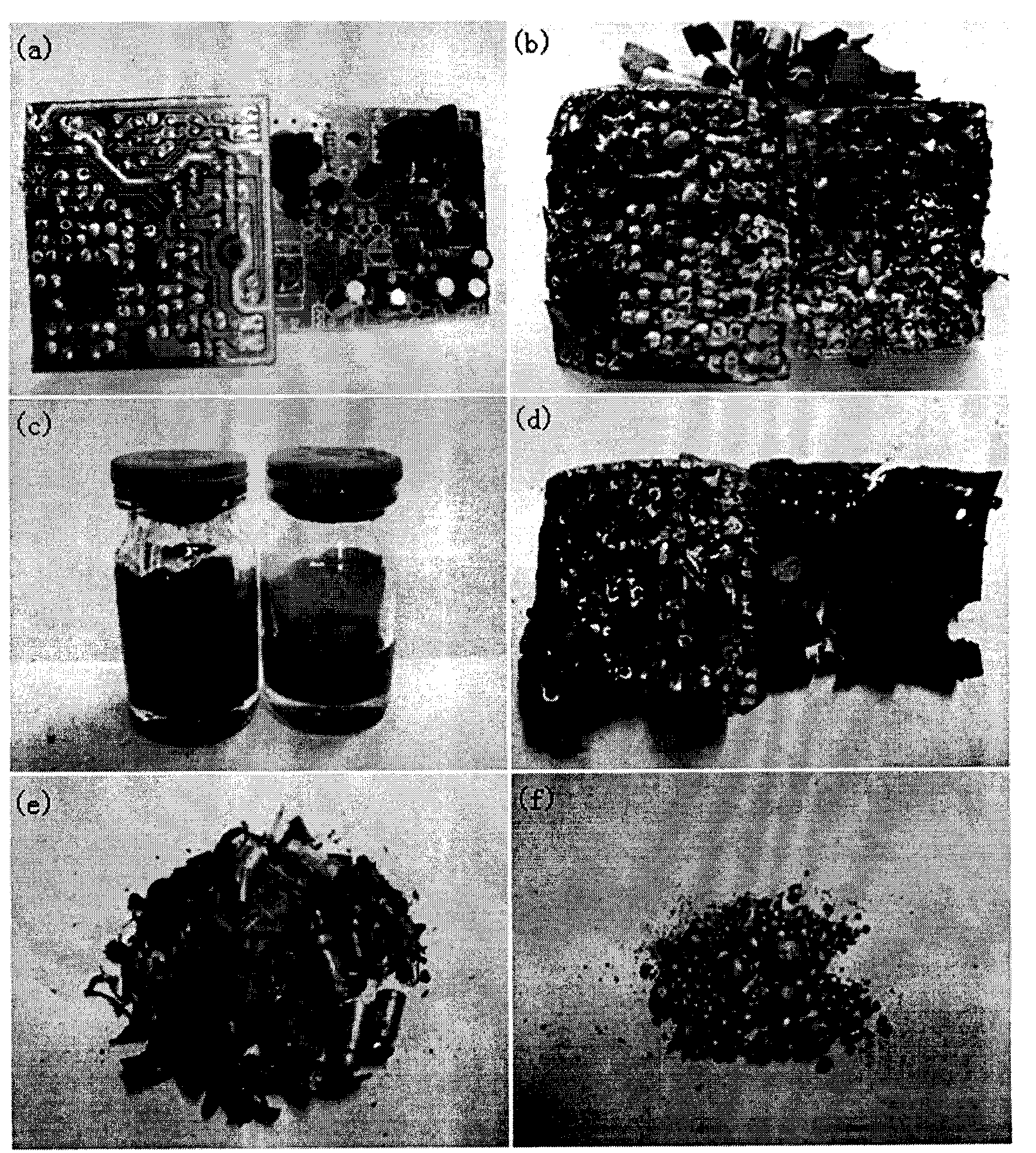

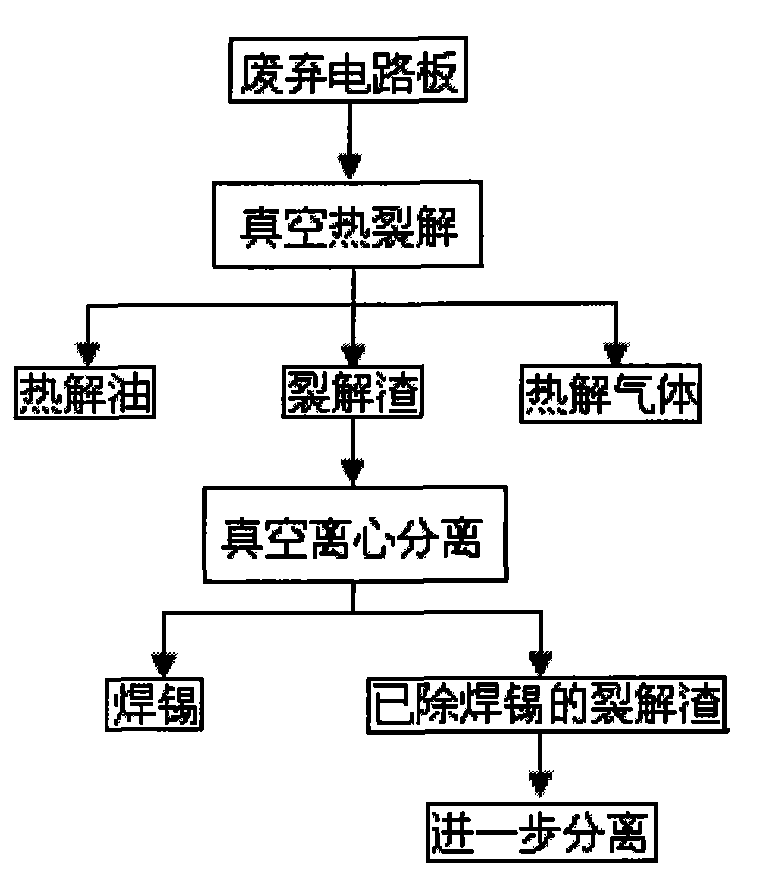

Recovery method of waste circuit board

InactiveCN101423898BEfficient separationOptimizationSolid waste disposalLiquid hydrocarbon mixture productionRecovery methodGlass fiber

The invention provides a method for recovering waste circuit boards. The method comprises the following: 1. a step of heating and centrifugally separating, which is to put the waste circuit boards in an oil bath, heat to melt solder and pass the waste circuit boards with the solder melted through a centrifugal machine so as to efficiently separate the solder from the waste printed circuit boards;2. a step of cracking in vacuum, which is to put waste circuit board substrates with the solder removed, as well as an electron component in a vacuum cracking device, heat for thermal cracking, collect thermal-cracking volatile products and condense the volatile products into fluid oil; and 3. a step of collecting solid matter after vacuum cracking, which is to classify and collect the electron component and the circuit board substrates after thermal cracking, so as to recover precious metals and other valuable metals of the electron component, as well as copper foil, glass fiber and other substances on the circuit board substrates. The method performs treatment by stages according to the structural characteristics of the waste circuit boards, has the advantages of simplicity, no pollution, low cost, high efficiency and high rate of recovering waste resources of the waste circuit boards, and is suitable for industrial application and the large-scale recovery of the waste circuit boards.

Owner:CENT SOUTH UNIV

Sewage recycling system and mixing station

ActiveCN103601259BAchieve recyclingEasy to assemble and disassembleWater/sewage treatmentMixing operation plantWastewaterSewage

The invention discloses a wastewater recycling system and a mixing station. The wastewater recycling system is used for the mixing station. The wastewater recycling system comprises a wastewater metering device, a material guiding device, a wastewater treatment device and a connecting pipe, wherein the wastewater metering device is arranged in a main body of the mixing station and is communicated with a mixing mainframe in the main body; the material guiding device is detachably arranged below the mixing mainframe and is used for exporting the wastewater in the mixing mainframe; a wastewater inlet of the wastewater treatment device is communicated with the material guiding device, and a wastewater outlet is connected with the wastewater metering device through the connecting pipe for drain the treated wastewater to the wastewater metering device; therefore, the wastewater recycling system disclosed by the invention not only is easy and convenient to disassemble and assemble, simple in structural design and relatively low in equipment cost, but also can improve an energy conservation and environmental protection index of site operation of a mobile mortar mixing station.

Owner:SANY AUTOMOBILE MFG CO LTD

Heat pump type tail heat recovery counterflow drying machine

ActiveCN105066643ARealize penetrating countercurrent low temperature dryingRecycling fitDrying solid materials with heatHeat recovery systemsImpellerPulp and paper industry

The invention discloses a heat pump type tail heat recovery counterflow drying machine. A draught hood of the drying machine is connected with an induced draft fan, the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector, and then evacuation is carried out. The evaporator of the heat pump system is connected with a main engine through a refrigerant tube, and the main engine is connected with a condenser through a refrigerant tube. The air outlet end of an air blower is connected with an air inlet hood through the condenser. An impeller of the induced draft fan is provided with a structure with hollow inverted-drop-shaped blades. The contour line of the appearance of the induced draft fan is an involute. The induced draft fan, a heat exchanger and a closed cone hopper below a screen plate steel rip are arranged, an axial fan is arranged in the cone hopper, so that penetrating type counterflow low-temperature drying of materials is achieved, and the heat pump system is especially suitable for recovery of heat of low-temperature tail gas. The blades are of a hollow inverted drop shape, so that dust on the impeller of the induced draft fan is removed in real time, the strength of the impeller of the fan is increased, and stability is improved; and potential safety hazards caused by dust accumulation are effectively eradicated, and wide application prospects are achieved.

Owner:安徽上元家居材料股份有限公司

A heat pump tail heat recovery countercurrent dryer

ActiveCN105180628BImprove rigidityImprove carrying capacityDrying gas arrangementsHeating arrangementInvoluteEngineering

Owner:GUANGDONG NEW ENERGY TECH DEV

Tower penetrating countercurrent fluidized dryer

ActiveCN104990369BAchieve penetrationAchieve countercurrentDrying solid materials with heatHearth type furnacesAir blowerCyclonic spray scrubber

The invention discloses a tower type penetrating reverse flow fluidized direr. A material seal screw feeder is arranged at the upper portion of a drying tower. An air-lock valve discharger is arranged at the bottom of the drying tower. The upper portion of the drying tower is connected with an induced draft fan. The induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector and then is evacuated. The evaporator of the heat pump system is connected with a host through a refrigerant pipe. The host is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected with the lower portion of the drying tower through the condenser. A plurality of layered repeated structures composed of sieve hole conical covers and sieve hole conical discs are arranged inside the drying tower. The sieve hole conical covers, the sieve hole conical discs, a discharging pipe, a stretchable vibration transmission shaft and a conical plug are arranged, so that penetrating, reverse flow, boiling and fluidization drying of materials are ingeniously and perfectly achieved, the classic boiling reverse flow drying mode is completely exceeded, more energy is saved, the drying quality is higher, and electricity consumption of the fans is lower; heat-pump-type tail heat recovery is particularly suitable for heat recovery at the low tail gas temperature.

Owner:泰兴市中全新能源技术有限公司

Natural gas high-efficiency liquefaction recovery method and device

ActiveCN105387683BEasy to useLow investment costSolidificationLiquefactionRecovery methodBoiling point

The invention relates to a natural gas high-efficiency liquefaction recovery method and device. This method utilizes the differences in boiling point, freezing point, and saturation temperature and pressure between liquid nitrogen and natural gas to pass natural gas directly into a low-temperature container filled with liquid nitrogen, and in the same low-temperature container, the natural gas and liquid nitrogen are directly mixed and liquefied into LNG, control the saturation pressure of the liquid in the cryogenic container, so that the natural gas does not freeze and freeze, and can effectively separate LNG from liquid nitrogen. The biggest advantage of the invention is that the equipment investment cost is low, and it does not affect the normal use of LNG. It can be widely used in the liquefaction of micro and small gas sources, and is especially suitable for BOG recovery of LNG gas filling.

Owner:WUXI CHINA RESOURCES GAS

Thermal pump type tail heat recycling reverse flowing penetrating fluidized drying machine

ActiveCN105020986AAchieve penetrationAchieve countercurrentDrying solid materials with heatHearth type furnacesAir blowerDrop-shaped

The invention discloses a thermal pump type tail heat recycling reverse flowing penetrating fluidized drying machine. According to the thermal pump type tail heat recycling reverse flowing penetrating fluidized drying machine, a material seal screw feeder is arranged on the upper portion of a drying tower, and a closed-air aspirator discharging machine is arranged at the bottom of the drying tower; the upper portion of the drying tower is connected with an induced draft fan, and the induced draft fan is connected with an evaporator of a thermal pump system through a cyclone dust collector, and then carries out evacuation; the evaporator of the thermal pump system is connected with a main machine through a refrigerant pipe, and the main machine is connected with a condenser through a refrigerant pipe; the air outlet end of an air blower is connected with the lower portion of the drying tower through the condenser; an impeller of the induced draft fan is provided with a structure with blades in a hollow reverse drop shape; and the shape contour line of the induced draft fan is an involute. According to the thermal pump type tail heat recycling reverse flowing penetrating fluidized drying machine, through the arrangement of sieve mesh cone covers, sieve mesh cone disks, discharging pipes, a telescopic vibration transmission shaft and cone stoppers, penetration, reverse flowing, boiling and fluidized drying are tactfully and perfectly conducted on materials; the classic boiling reverse flowing drying mode is completely surpassed, the energy saving effect is better, the drying quality is higher, and power consumption of the draught fan is lower; and the thermal pump type tail heat recycle is particularly suitable for recycling heat of tail gas at a low temperature.

Owner:湖北沄禾泽生态农业开发有限公司

Heat pump tail heat recovery penetrating countercurrent dryer

InactiveCN105066636BRealize penetrating countercurrent dryingRecycling fitDrying gas arrangementsDrying machines with progressive movementsImpellerCounter flow

The invention discloses a heat pump type tail heat recovery penetration counter flow dryer. A draught hood and an air inlet cover are arranged at the two ends of a box of the dryer respectively, the draught hood is connected with an induced draft fan, and the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector and then emptied. The evaporator of the heat pump system is connected with a main machine through a refrigerant pipe, and the main machine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected with the air inlet cover through the condenser. A plurality of vertically-arranged flexible separation plates are arranged in the box of the dryer and divide an upper case body and a lower case body into a plurality of units. Through the induced draft fan, the flexible separation plates and axial fans, penetration type counter flow drying is ingeniously achieved, and work efficiency is improved. Heat pump type tail heat recovery is suitable for heat recovery of low-temperature tail gas, and is particularly efficient and convenient. Through the structure that blades are in a hollow inverted drop shape, dust on impellers is cleaned away in real time, the impeller strength of the fan is increased, stability is increased, safety accidents caused by dust accumulation are effectively eradicated, and the application prospect is wide.

Owner:贵州九鼎新能源科技开发集团有限公司

Recovery method of waste circuit board value resource

InactiveCN101417284BAvoid pollutionIncrease oil production rateSolid waste disposalLiquid hydrocarbon mixture productionRecovery methodGlass fiber

The invention disclose a recovery method of valuable resource of an abandoned circuit board, which comprises the following steps of: (1) vacuum cracking: the abandoned circuit board provided with an electronic component is placed inside a vacuum cracking device for thermal cracking and volatile products after thermal cracking are collected and condensed to be fluid oil; (2) heating vacuum centrifugation: solid-state products after cracking are placed inside a vacuum centrifugation machinery and heated so as to lead soldering tin to be separated from cracking dregs efficiently; and (3) the collection of the cracking dregs obtained from the step (2): noble metal and other valuable metals are collected respectively and substances of copper foil, glass fibers, carbon residue and the like are recovered discretely. The invention carries out treatment in phases according to the structural characteristics of the abandoned circuit board, optimizes the treatment procedures and conditions of theabandoned circuit board and is simple in method, and leads the recovery of the abandoned circuit board to have lower cost, higher efficiency and higher recovery rate of the abandoned resource, thus being more in accordance with the demands of industrialization and applicable to large-scale recovery of the abandoned circuit board.

Owner:CENT SOUTH UNIV

A method for extracting copper from waste circuit boards by using moderately thermophilic bacteria

ActiveCN104328283BEfficient separationReduce processingProcess efficiency improvementRaffinateCulture mediums

The invention relates to a method for extracting copper in waste printed circuit boards by virtue of moderately thermophilic bacteria. The method comprises the following steps of carrying out shaker hydraulic sorting on the artificially dismounted and pulverized waste printed circuit boards to obtain metal and waste residues; putting the waste residues into an improved 9K culture medium, adjusting the pH value to 2 and leaching with a mixed strain of leptospirillum ferriphilum, acidithiobacillus caldus, sulfobacillus thermosulfidooxidans and thermoacidiferriphile as a leaching strain to obtain a copper-enriched solution and leaching residues; filtering the copper-enriched solution with a hollow fiber membrane system to obtain the strain and a copper-containing filtrate and putting the strain again into the leaching system for repeatedly using; and extracting the copper-containing filtrate with hydroxy oxime and a hydroxy oxime complex Lix984 as extraction agents to obtain a copper-loaded organic phase and a raffinate, carrying out back extraction on the copper-loaded organic phase with a 10-30% sulfuric acid solution to obtain a back extract and a blank organic phase and carrying out electrodeposition on the back extract to obtain cathode copper and an electrodeposited barren liquid. By the method disclosed by the invention, the environment-friendly, economic and full-value recovery of the waste printed circuit boards is achieved and the method has the advantages of short flow, low investment, high efficiency and low treatment cost and is suitable for the recovery of all types of the waste printed circuit boards.

Owner:CENT SOUTH UNIV

A kind of preparation method of palbociclib intermediate

ActiveCN112898299BMild reaction conditionsSimple post-processingOrganic chemistryAcetic anhydrideKetone

The invention discloses a preparation method of a palbociclib intermediate, which uses 5-bromo-2,4-dichloropyrimidine and cyclopentylamine, uses dichloromethane and other solvents and water as solvents, and uses inorganic bases as acid-binding Preparation of 5-bromo-2-chloro-N-cyclopentaline-4 amine, then DIEA is used as an acid-binding agent, DMF is a solvent, and TBAB is a phase transfer catalyst. In the presence of water, a small amount of palladium is used to catalyze, Through normal hexane reflux dehydration, further dehydration ring closure of acetic anhydride obtains 2-chloro-8-cyclopentyl-5-picoline [2,3-D] pyrimidin-7 (8H)-one, the obtained compound is in acetonitrile In reaction with NBS, 6-bromo-2-chloro-8-cyclopentyl-5-methylpyrido[2,3-D]pyrimidin-7(8H)-one is obtained. The method has the advantages of mild reaction, simple and convenient operation, reusable solvent, less environmental pollution, high yield, low cost and high product quality, and is suitable for industrialized production.

Owner:SHANDONG BOYUAN PHARM CO LTD

A heat pump type tail heat recovery penetrating countercurrent dryer

ActiveCN105135849BImprove rigidityImprove carrying capacityDrying gas arrangementsDrying machines with progressive movementsImpellerEngineering

The invention discloses a heat pump type tail heat recycling through counterflow drying machine. An air draft hood and an air inlet hood are respectively arranged at the two ends of a drying machine box body. The air draft hood is connected with an induced draft fan. The induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust remover and is then emptied. The evaporator of the heat pump system is connected with a main machine through a cold medium pipe, and the main machine is connected with a condenser through the cold medium pipe. The air outlet end of an air blower is connected with the air inlet hood through the condenser. A plurality of soft baffles vertically distributed are arranged in the drying machine box body so as to divide an upper box body and a lower box body into a plurality of units. Through type counterflow drying is skillfully realized through the induced draft fan, the soft baffles and an axial fan, so that the work efficiency is improved. Heat pump type tail heat recycling is suitable for recycling low-temperature heat from exhaust gas and is particularly efficient and convenient. Blades are in the shape of a hollow reverse water droplet, and a back plate adopts a patelliform structure, so that dust on the impeller is cleared in real time, the impeller strength of the fan is increased, the stability is enhanced, and safety accidents caused by dust accumulation are effectively avoided. The application prospect is wide.

Owner:重庆和创简一科技有限公司

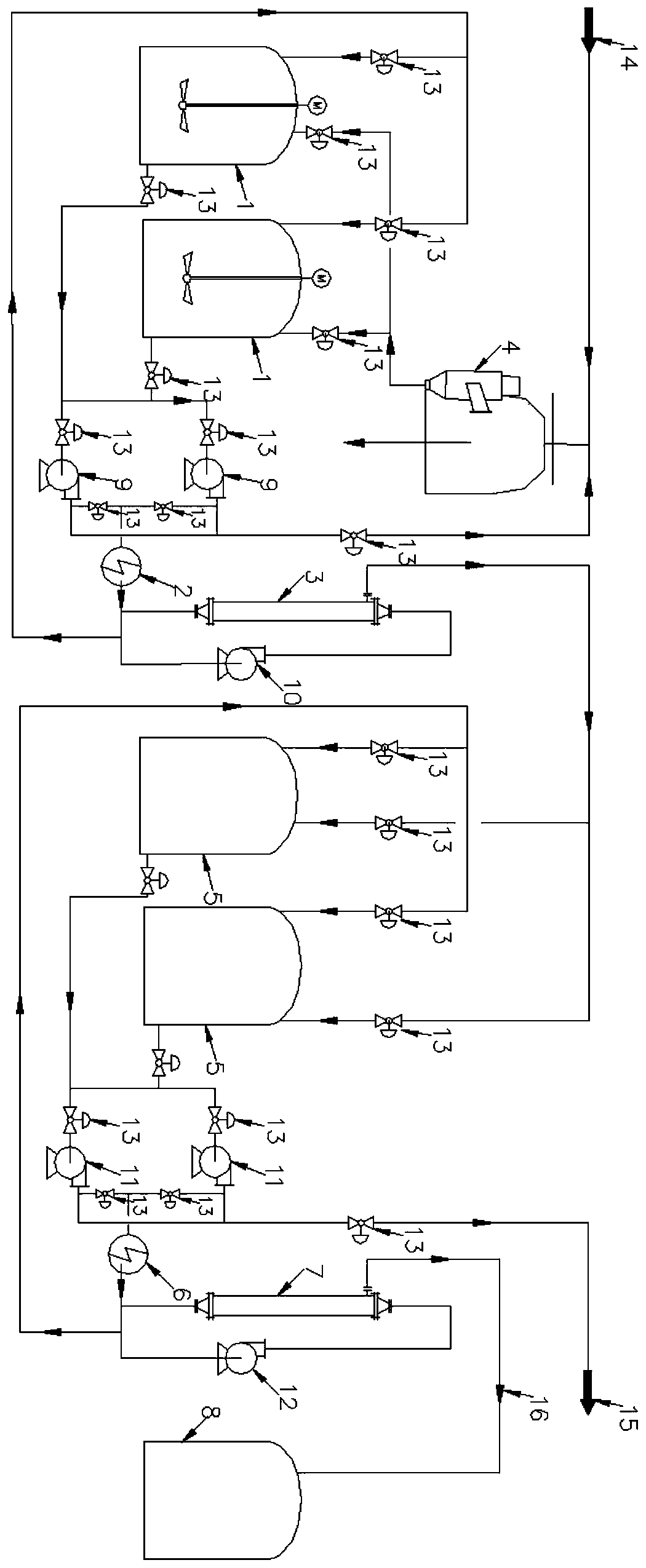

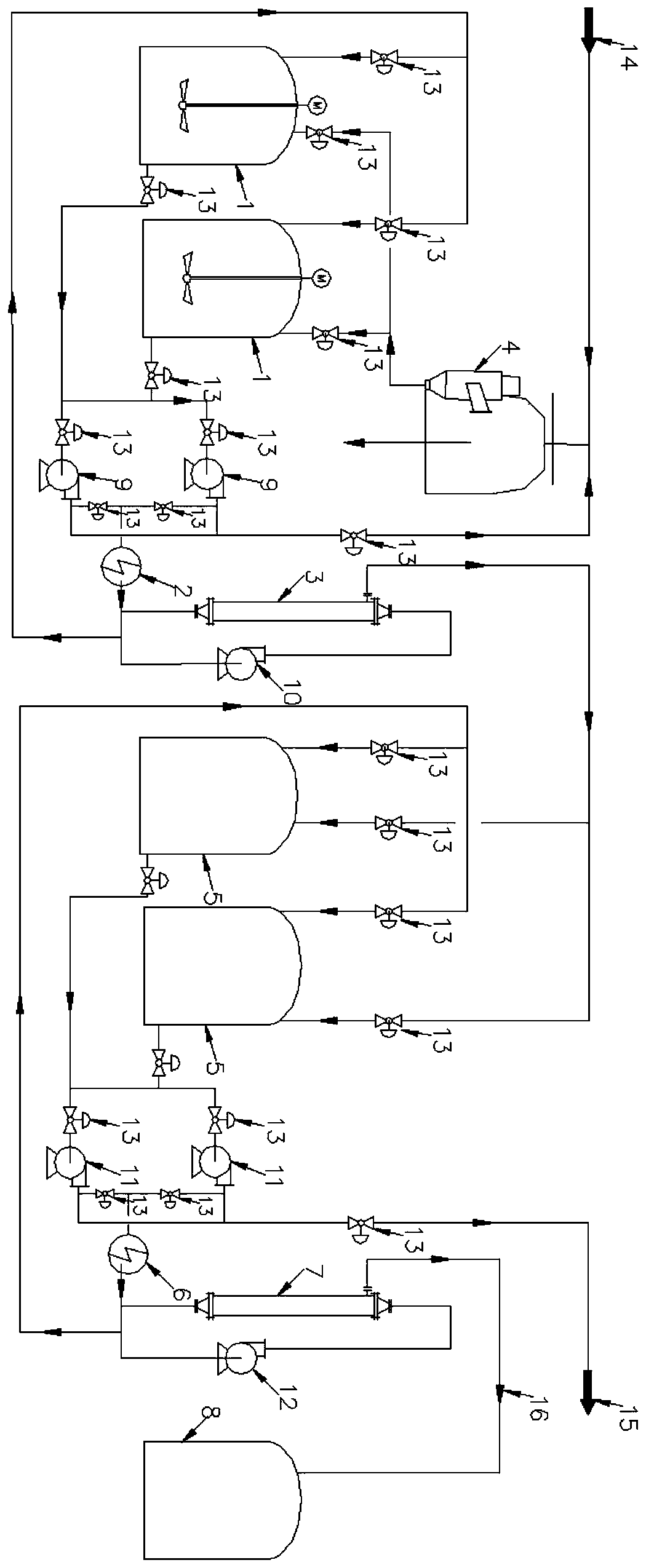

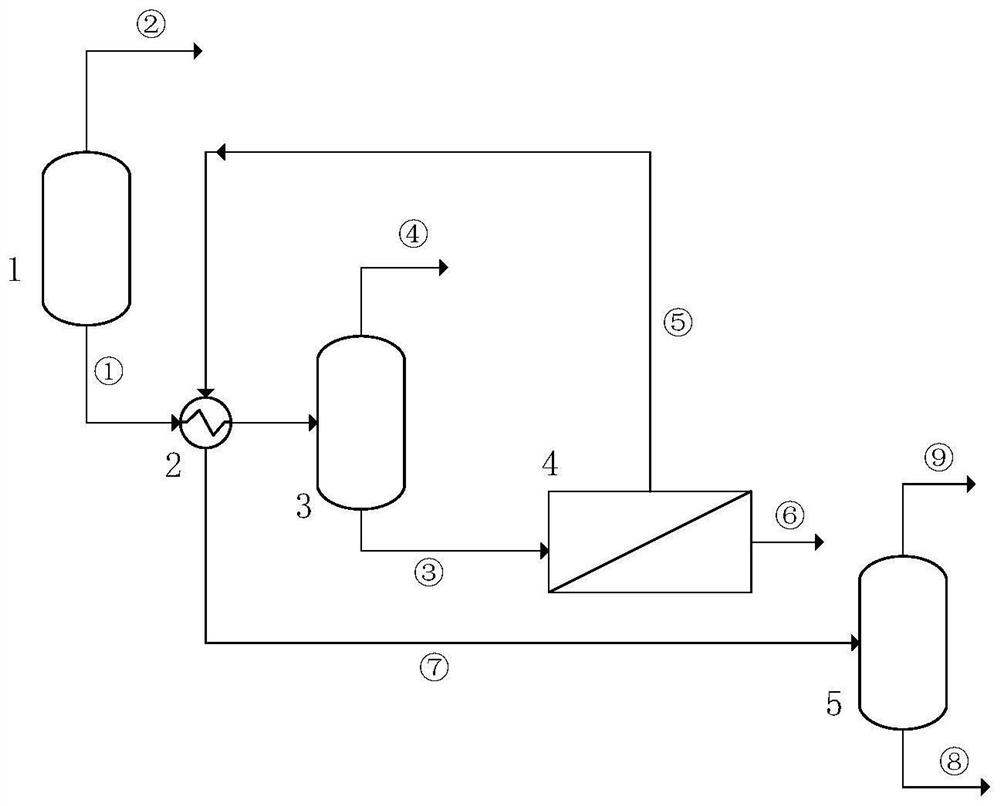

Filtrate recovery system and method

InactiveCN111170485AReduce processingReduce processing costsWater treatment parameter controlWater contaminantsProcess engineeringControl valves

The invention relates to a filtrate recovery system and a method. The filtrate recovery system comprises the following components which are sequentially arranged at the downstream of a separator: at least two first-stage filtrate switching tanks arranged in parallel, afirst-stage cooler, a ceramic membrane device, at least two second-stage filtrate switching tanks arranged in parallel, a second-stage cooler, a nanofiltration membrane deviceand arecycled water tank; a waste liquid outlet of the separator is connected with thefirst-stage filtrate switching tanks through a pipeline with a controlvalve;liquid outlets of the first-stage filtrate switching tanks are connected with the first-stage cooler; an outlet of the first-stage cooler is connected with the ceramic membrane device, a clearliquid outlet of the ceramic membrane device is connected with the second-stage filtrate switching tanks,liquid outlets of the second-stage filtrate switching tanks are connected with the second-stagecooler, an outlet of the second-stage cooler is connected with the nanofiltration membrane device, and a clear liquid outlet of the nanofiltration membrane device is communicated with the recycled water tank. By utilizing the switching tanks, the concentration of the filtrate is controlled to change from low to high in one cycle, themembraneflux is integrally improved, and the recovery of productparticles in the filtrate and the recovery and reuse of the filtrate are realized.

Owner:浙江海钛新材料科技股份有限公司

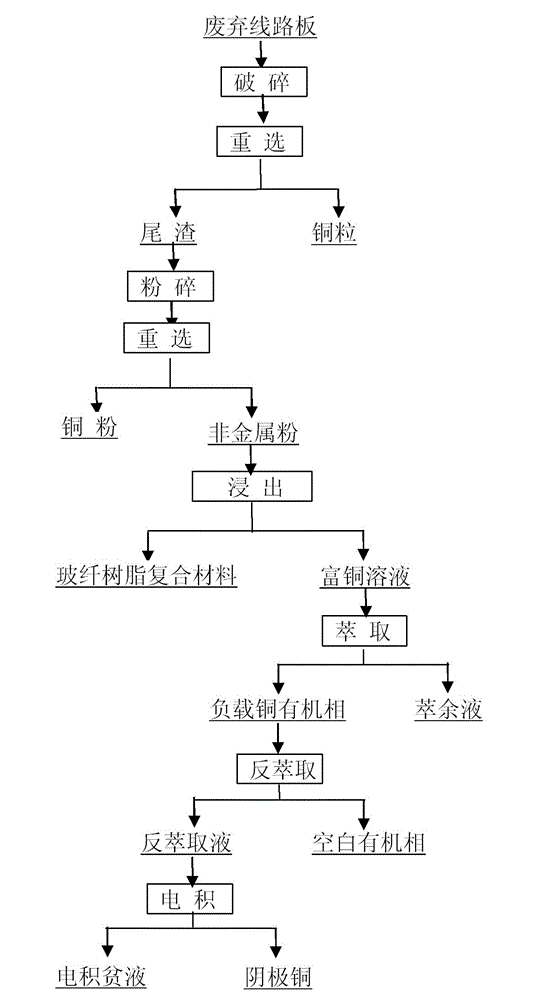

Recovery method for waste circuit board

InactiveCN102218437BComponent greenComponent economySolid waste disposalPlastic recyclingRecovery methodIron(II) oxide

The invention discloses a recovery method for a waste circuit board, which is characterized in that: the waste circuit board is cracked and reselected to obtain shot copper and tailings; the tailings are cracked and reselected to obtain copper powder and nonmetallic powder; an H2SO4 liquid is added into the nonmetallic powder so that a pH value is 1.5-3.5; acidithiobacillus ferrooxidans is used as a leaching strain under a temperature of 20-35 DEG C for leaching to obtain a copper-rich liquid and fiberglass resin composite material; an extracting agent with a volume ratio of hydroxyl aldoxime extracting agent to hydroxyl ketoxime extracting agent to kerosene being 5-20:5-20:60-90 to extract the copper-rich liquid is adopted to obtain loaded copper organic phase and raffinate; a 10-30 percent sulphuric acid liquid is used for re-extracting the loaded copper organic phase to obtain a re-extracting liquid and blank organic phase; and then electrodeposition is implemented on the re-extracting liquid to obtain cathode copper and electrodeposition barren liquor. The recovery method for the waste circuit board realizes green, economic and full-value recovery of the waste circuit board, has the advantages of short flow, less investment, high efficiency and low processing cost, and is suitable for recycling various waste circuit boards.

Owner:广东省资源综合利用研究所

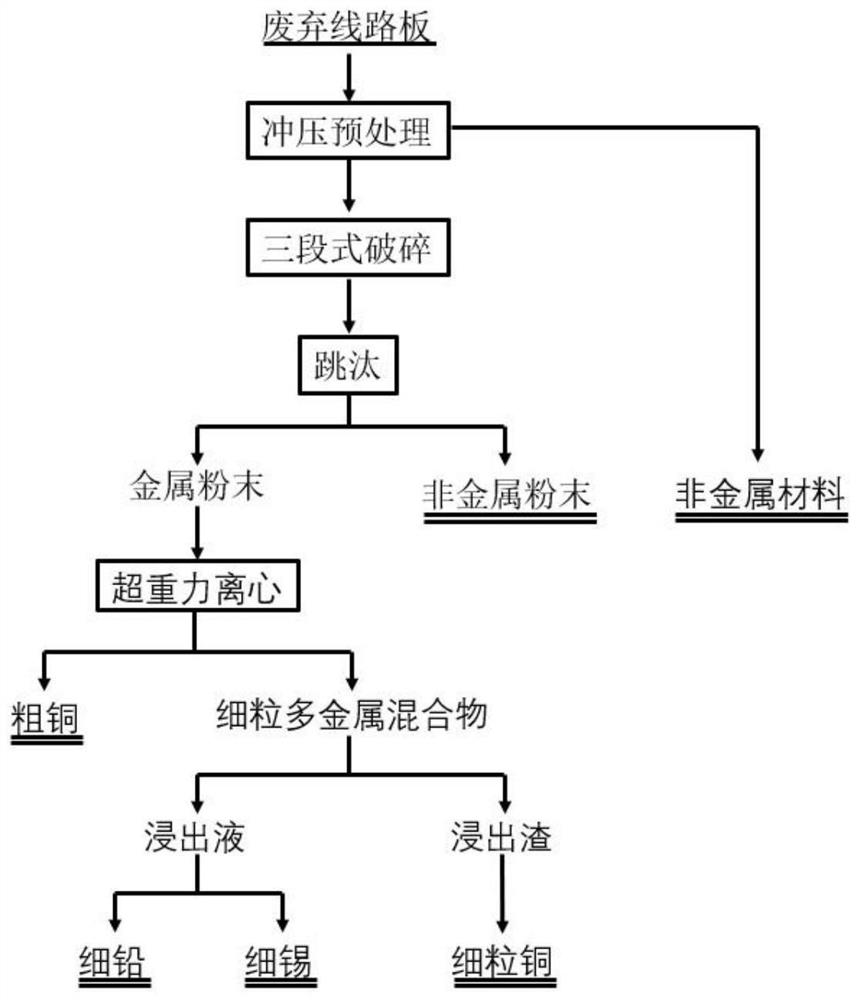

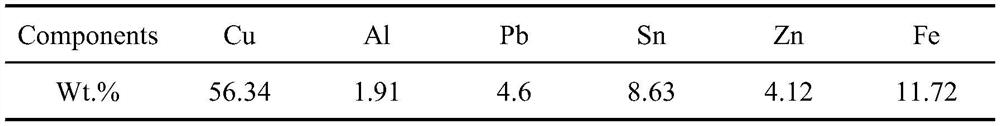

A comprehensive recycling process for waste circuit board resources

ActiveCN111663045BAchieve separationReduce the burden onSolid waste disposalCentrifugesPregnant leach solutionSlag

A comprehensive recycling process for waste circuit board resources, comprising the following steps: (1) performing stamping pretreatment on waste circuit boards that have disassembled electronic components, so that multilayer composite materials are initially dissociated and non-metallic materials are recovered; (2) After three-stage crushing of the remaining waste circuit boards, jigging separation is carried out to obtain non-metallic powder and metal powder; (3) separation of metal powder to obtain crude copper and fine-grained polymetallic mixture; (4) fine-grained polymetallic mixture Alkali leaching, solid-liquid separation to obtain lead and tin-containing leaching solution and copper-containing leaching slag, adding sodium sulfide precipitant to the lead and tin-containing leaching solution, solid-liquid separation to obtain lead-containing precipitation and tin-containing solution, and the tin-containing solution is spun After the galvanic deposition recovers tin, it returns to the alkaline leaching process, and the copper-containing leaching slag recovers fine-grained copper. The invention realizes full resource recovery of waste circuit boards, has the advantages of high recovery efficiency, no pollution, simple operation, etc., and is suitable for large-scale recovery of waste circuit boards in industry.

Owner:CENT SOUTH UNIV

Soft partition board type through counter-flow drier

InactiveCN105004170ARealize penetrating countercurrent dryingRecycling fitDrying gas arrangementsDrying machines with progressive movementsCounter flowEngineering

The invention discloses a soft partition board type through counter-flow drier. An air suction hood and an air inlet hood are arranged at two ends of a casing of the drier respectively, the air suction hood is connected with an induced draft fan, and the induced draft fan is emptied after being connected with an evaporator of a heat pump system through a cyclone dust collector; the evaporator of the heat pump system is connected with a main unit through a refrigerant pipe, and the main unit is connected with a condenser through a refrigerant pipe; an air outlet end of an air blower is connected with the air inlet cover through the condenser; multiple soft partition boards vertically arranged in the casing of the drier divide an upper casing body and a lower casing body into a plurality of units respectively; the soft partition boards press materials softly and block air currents completely, and material conveying is not influenced; axial flow fans are arranged in the units, the upper fans face downward and the lower fans face upward. Through counter-flow drying of materials is ingeniously realized through the induced draft fan, the soft partition boards and the axial flow fans, the drying efficiency is improved, the drying speed is increased, and the energy consumption is also reduced; heat pump type tail gas heat recovery is suitable for heat recovery of tail gas with a lower temperature efficiently and conveniently.

Owner:JISHOU UNIVERSITY

Method for extracting general flavone from sorrel shell waste residues through microwave refluxing

InactiveCN102526137BIncrease profitImprove extraction efficiencyAntibacterial agentsAntipyreticAluminium chlorideFiltration

The invention discloses a method for extracting general flavone from sorrel shell waste residues through microwave refluxing. The method comprises the following specific steps of: 1, removing impurities from naturally-dried sorrel shells, smashing, sieving with a sieve of 40-60 meshes, and putting into a constant-temperature drying oven for drying sorrel shell powder for later use; and 2, uniformly fixing the powder treated in the step 1 with 30-60 percent of ethanol in the weight volume ratio of 1:25-1:50, performing reflux leaching at microwave power for 10-25 minutes, performing suction filtration to obtain a general flavone extracting solution, removing ethanol by rotationally evaporating, and performing vacuum drying to obtain a general flavone solid. The content of general flavone in a concentrated solution is measured with an aluminum chloride colorimetric method. According to measurement, the extraction ratio of general flavone is 95 percent, and the yield is 0.20 percent. The method has the advantages of quickness, high extraction ratio, environmental friendliness and nontoxicity by taking ethanol water as a solvent, simple equipment operation, small solvent using amount, easiness for recovering and suitability for expanded production in plants. The method has wide application prospects in medicines and foods.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

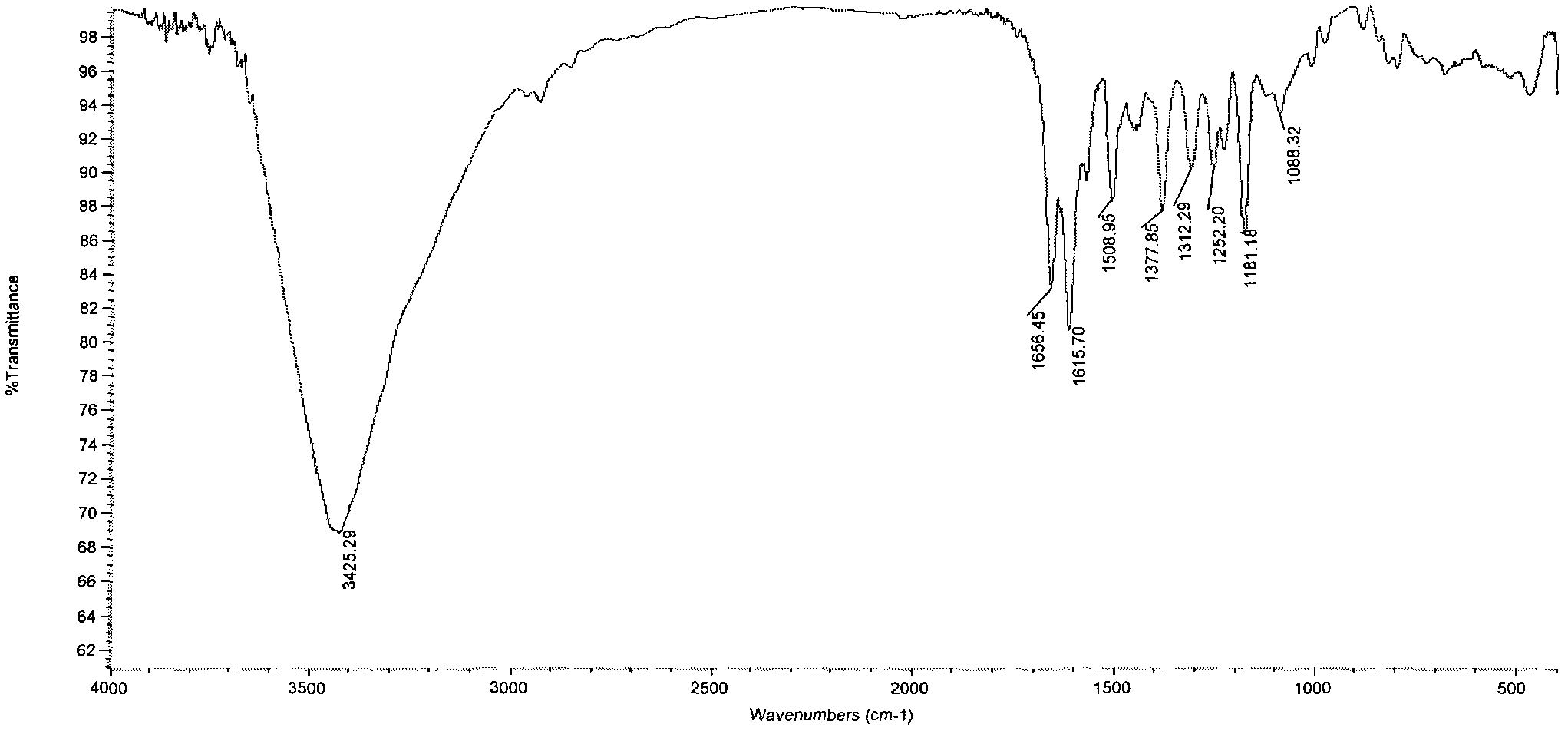

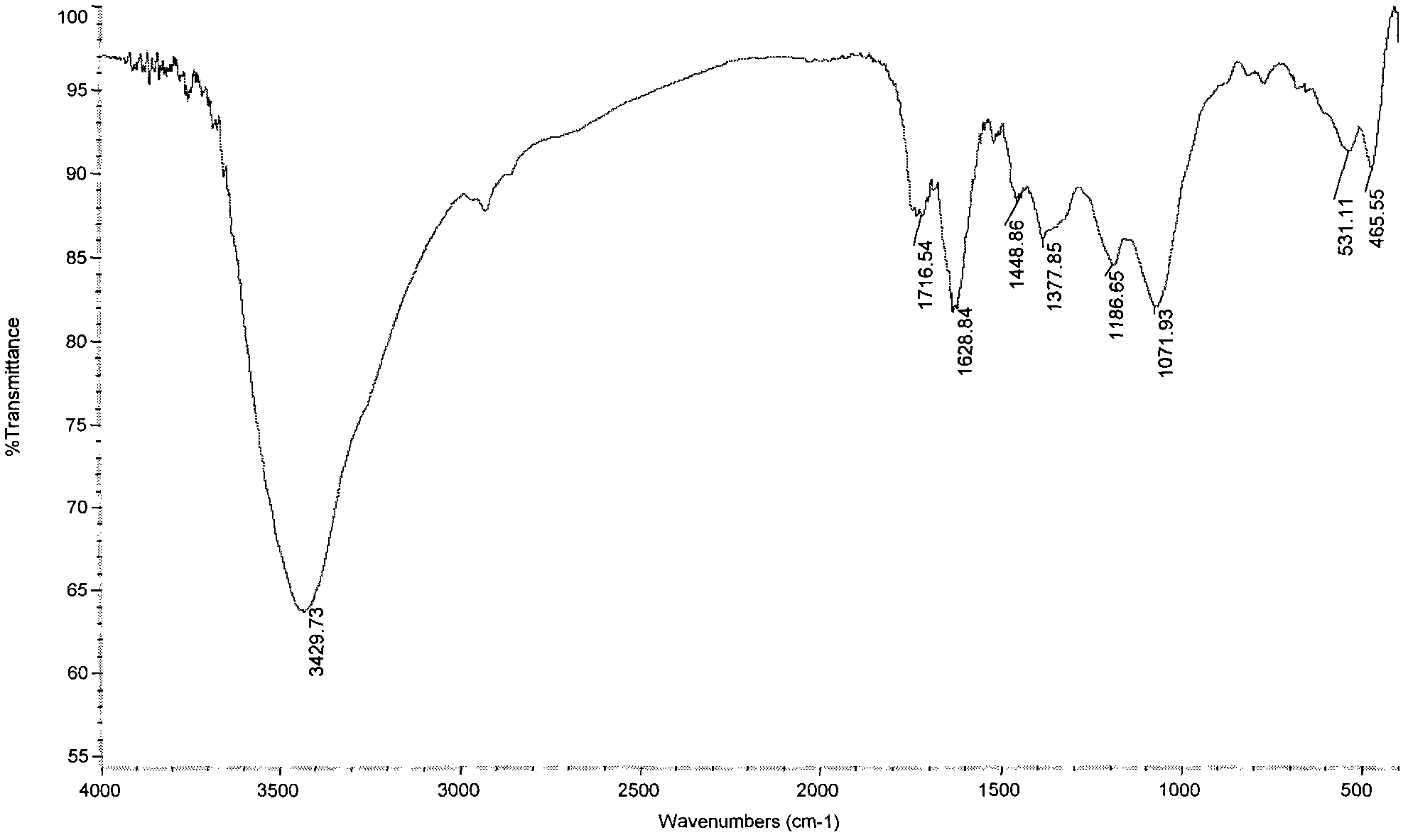

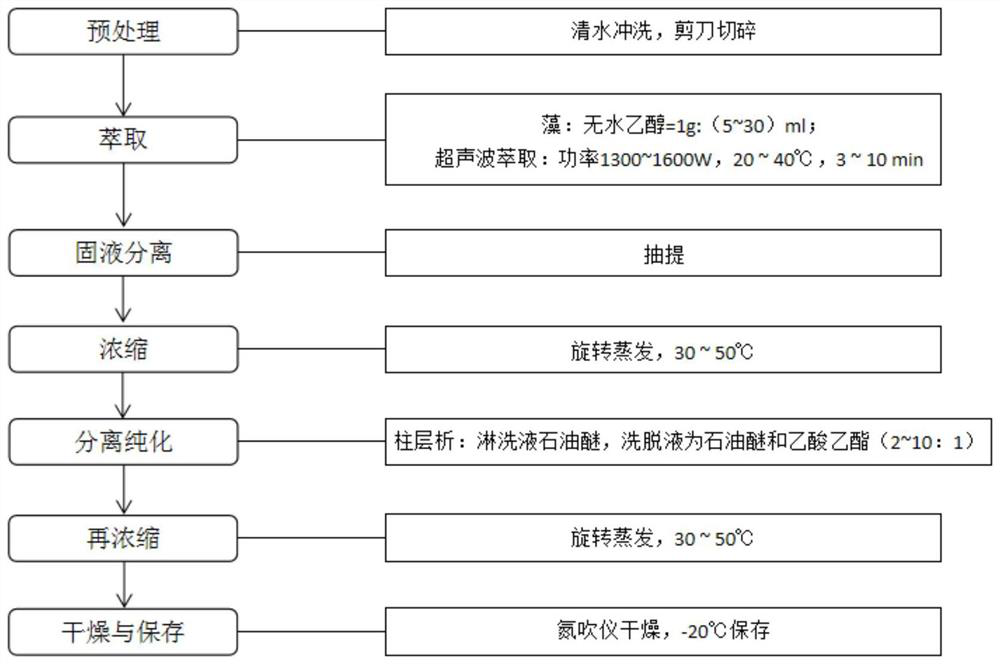

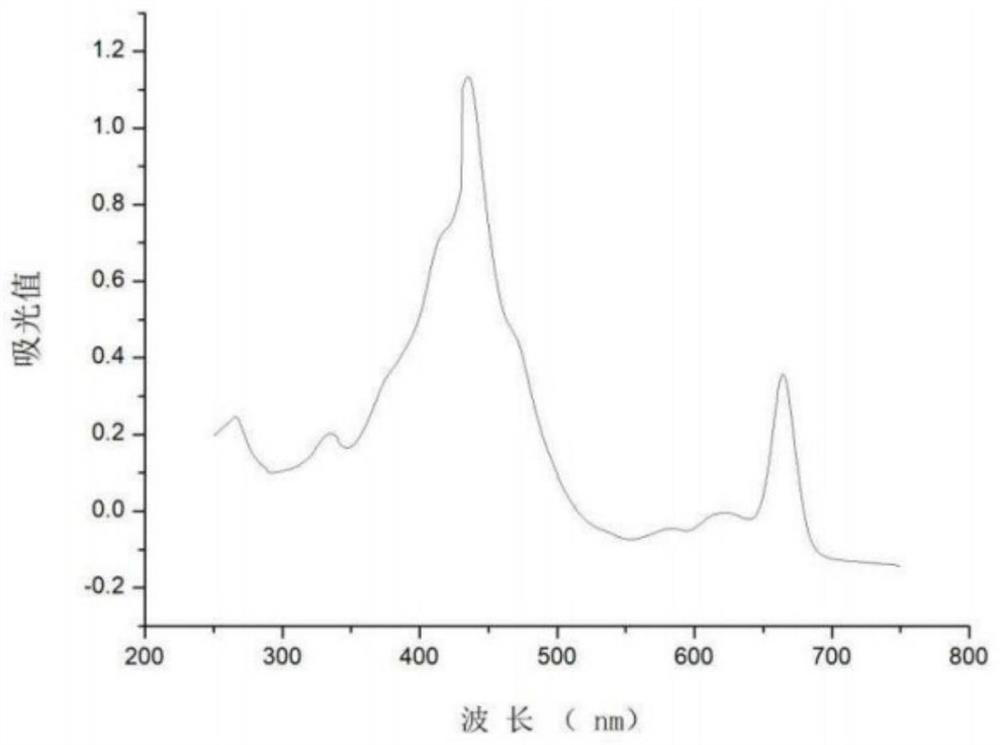

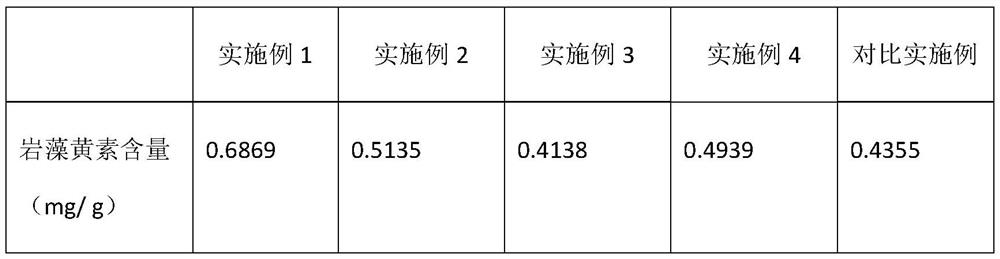

Method for extracting fucoxanthin from gulfweed

PendingCN112679451AImprove the extraction effectHigh purityOrganic chemistryNatural dyesBiotechnologyFucoxanthin

The invention discloses a method for extracting fucoxanthin from gulfweed, and belongs to the field of fucoxanthin extraction processes, and the method comprises the following steps: A1, pretreatment; A2, extraction; A3, solid-liquid separation; A4, concentrating; A5, separation and purification; and A6, reconcentration. The method for extracting fucoxanthin from sargassum is simple in operation process, low in cost and suitable for large-scale production, and the extraction effect can be guaranteed.

Owner:FUJIAN NORMAL UNIV

Preparation method of preferential water permeable membrane and morpholine wastewater treatment and morpholine substance recovery method

ActiveCN112479459ASmall footprintReduce energy consumptionWater treatment parameter controlOrganic chemistryMorpholineEngineering

The invention provides a morpholine wastewater treatment and morpholine substance recovery method. The wastewater can come from a morpholine production process or a morpholine byproduct process. The method mainly comprises the steps of (1) rectifying morpholine wastewater under normal pressure to remove light components, cooling a heavy component I at the bottom of a tower, feeding the cooled heavy component I into a reduced pressure rectifying tower for rectification, extracting wastewater with extremely low COD content from the top of the tower, and extracting a heavy component II rich in morpholine substances from the bottom of the tower; (2) feeding the heavy component II into a membrane assembly provided with a preferential water permeable membrane for separation, and obtaining a morpholine substance-containing heavy component III of which the water content is lower than 0.5% on the interception side; (3) feeding the heavy component III into a morpholine refining tower for rectification, and extracting high-purity and low-chroma morpholine substances from the top of the tower. The method provided by the invention is simple in process flow, does not involve common solvents required by extraction or azeotropic distillation, and is low in energy consumption and environment-friendly, and morpholine obtained by separation is high in purity and low in chromaticity.

Owner:WANHUA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com