A comprehensive recycling process for waste circuit board resources

A waste circuit board and process technology, which is applied in the field of high-efficiency and comprehensive recycling process of waste circuit boards, can solve the problems of cumbersome steps, long process and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

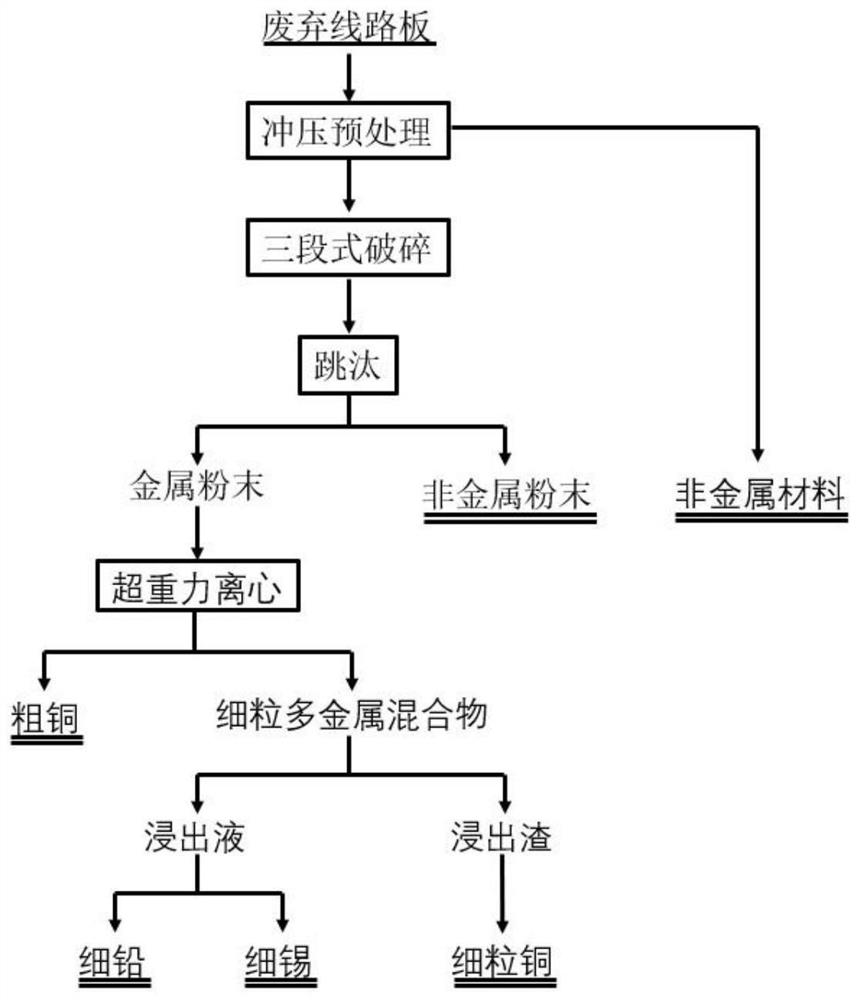

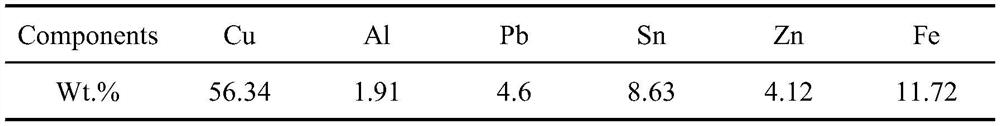

[0040] For waste circuit boards (the mass fraction of each component is shown in Table 1), carry out comprehensive recycling, including the following steps:

[0041] (1) Place the discarded circuit boards that have disassembled electronic components on a hydraulic punching machine for punching pretreatment, using a quantitative pump with a flow rate of 34.5 / min, a stroke of 180mm, and a punching time of 15n / min, and most of the low metal of copper and tin have been stripped The recovery rate of the non-metal part of the content is 16.7%;

[0042] (2) The remaining waste circuit boards are firstly crushed by a twin-shaft shearing crusher, and then screened. Materials with a particle size greater than 20mm continue to be returned to coarse crushing. Materials with a particle size of less than 0.6mm are collected for later use; materials with a particle size of 0.6-20mm Enter the hammer crusher for crushing, and then sieve. The material with a particle size greater than 1mm will ...

Embodiment 2

[0051] For waste circuit boards (the mass fraction of each component is shown in Table 1), carry out comprehensive recycling, including the following steps:

[0052] (1) Place the discarded circuit boards that have disassembled electronic components on a hydraulic punching machine for punching pretreatment. A quantitative pump with a flow rate of 49.5L / min is used, the stroke is 250mm, and the punching time is 20n / min. Most of the copper and tin have been stripped. The recovery rate of non-metallic materials with metal content is 19.2%;

[0053] (2) The remaining waste circuit boards are firstly crushed by a twin-shaft shearing crusher, and then screened. Materials with a particle size greater than 25mm continue to be returned to coarse crushing. Materials with a particle size of less than 0.6mm are collected for later use; materials with a particle size of 0.6-25mm Enter the hammer crusher for crushing, and then sieve, the material with a particle size greater than 2mm will c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com