Filtrate recovery system and method

A waste liquid recovery and filtrate technology, which is applied in the direction of chemical instruments and methods, filtration treatment, water treatment parameter control, etc., can solve the problems that cannot be directly discharged, cannot be directly recycled, and the treatment cost is high, so as to reduce the cost of sewage treatment, The effect of reducing the amount of sewage treatment and increasing the product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

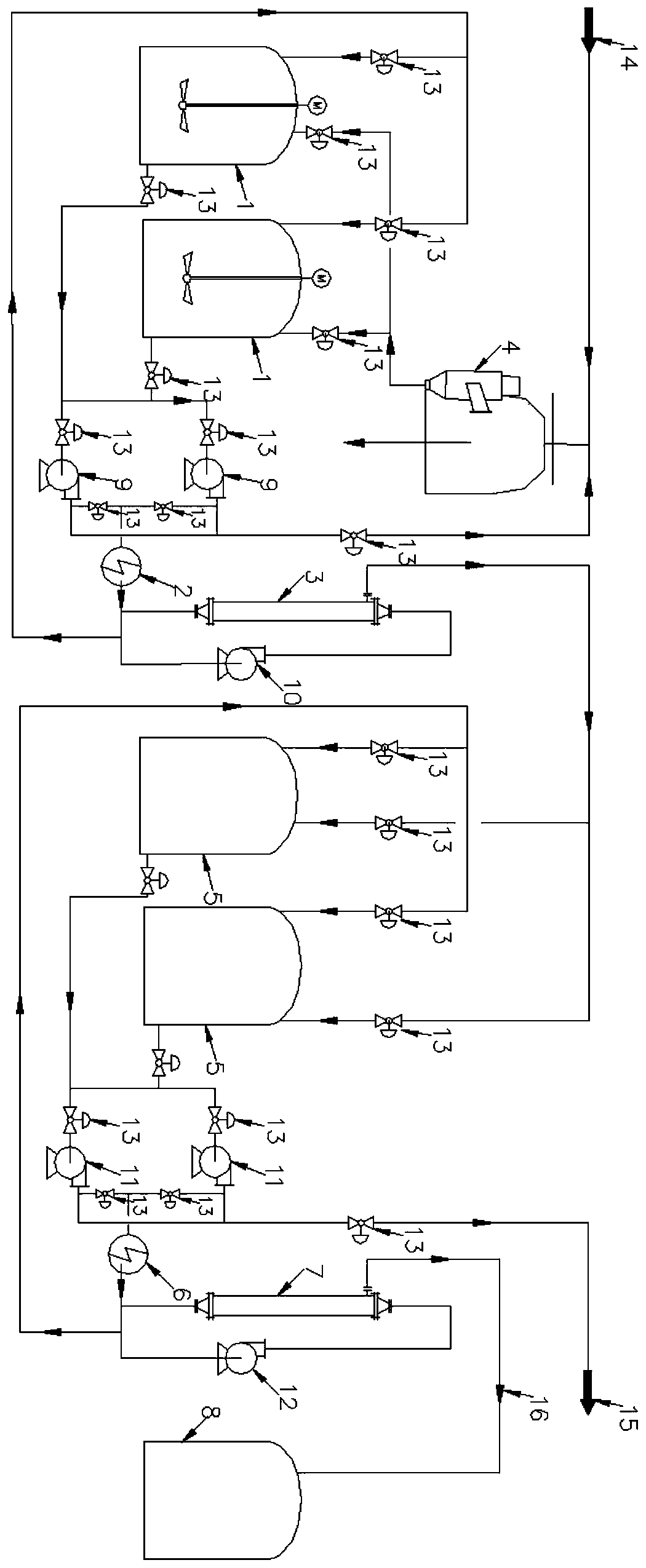

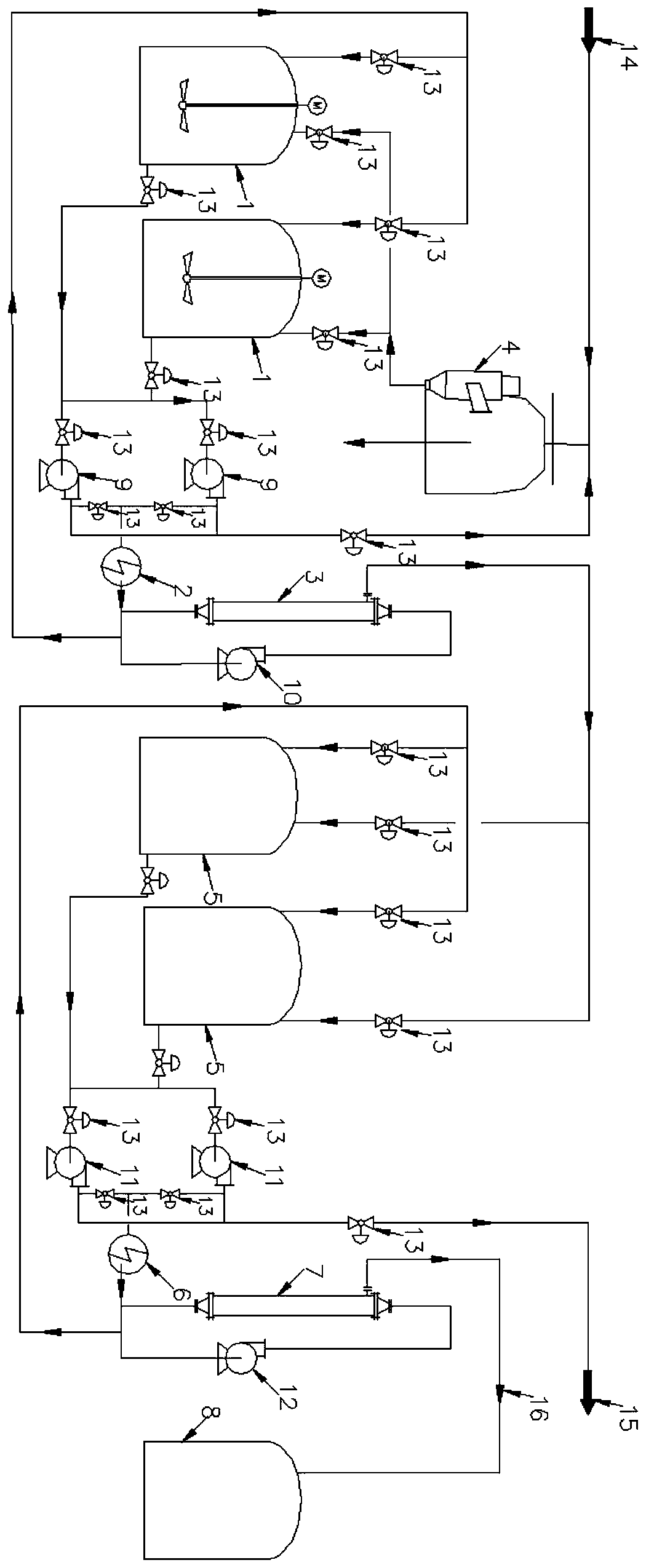

[0019] like figure 1 As shown, a waste liquid recovery system is based on a separator 4 for pre-separation of the production mother liquor. The system includes the following components sequentially arranged downstream of the separator: at least 2 primary filtrate switching tanks 1 arranged in parallel, primary cooling 2, ceramic membrane device 3, at least 2 secondary filtrate switching tanks 5, secondary cooler 6, nanofiltration membrane device 7 and recovery water tank 8, at least 2 sets in parallel, the waste liquid outlet of separator 4 is switched with primary filtrate Tank 1 is connected through a pipeline with a control valve 13, the liquid outlet of the primary filtrate switching tank 1 is connected to the primary cooler 2 through a pipeline with a control valve 13 and a primary delivery pump 9, and the outlet of the primary cooler 2 passes through The pipeline with the primary circulation pump 10 is connected to the ceramic membrane device 3, and the clear liquid outl...

Embodiment 2

[0033] A standard formula condition is used to produce microsphere expansion agent, the filtrate separated by 2000 mesh filter cloth is used (centrifugation is more difficult), and the COD in the separated mother liquor is 14890mg / L;

[0034] Take 20L of the filtrate and store it in a steel tank. The steel tank is cooled by a jacket and pumped to a ceramic membrane device for separation. The initial pump outlet pressure is 0.26MPa, the ceramic outlet pressure is 0.18MPa, and the membrane flux is 16.5L / h. When the pump outlet pressure is 0.28MPa, the ceramic outlet pressure is 0.19MPa, and the membrane flux is 13.8L / h, the dense phase is 1.4L, and the clear liquid is 17.3L;

[0035] Dry 1.4L of dense phase, and the weight of the solid is 0.12kg;

[0036] The 17.3L clear liquid obtained by separating the ceramic membrane is stored in the steel tank, the steel tank is cooled by a jacket, and is separated by pumping to the nanofiltration membrane device. The initial pump outlet pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com