Recovery method of waste circuit board value resource

A waste circuit board and recycling method technology, applied in electronic waste recycling, recycling technology, solid waste removal and other directions, can solve the problems of incomplete solder recycling, low recycling efficiency, strict temperature requirements, etc. The effect of conditions, low recovery cost, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

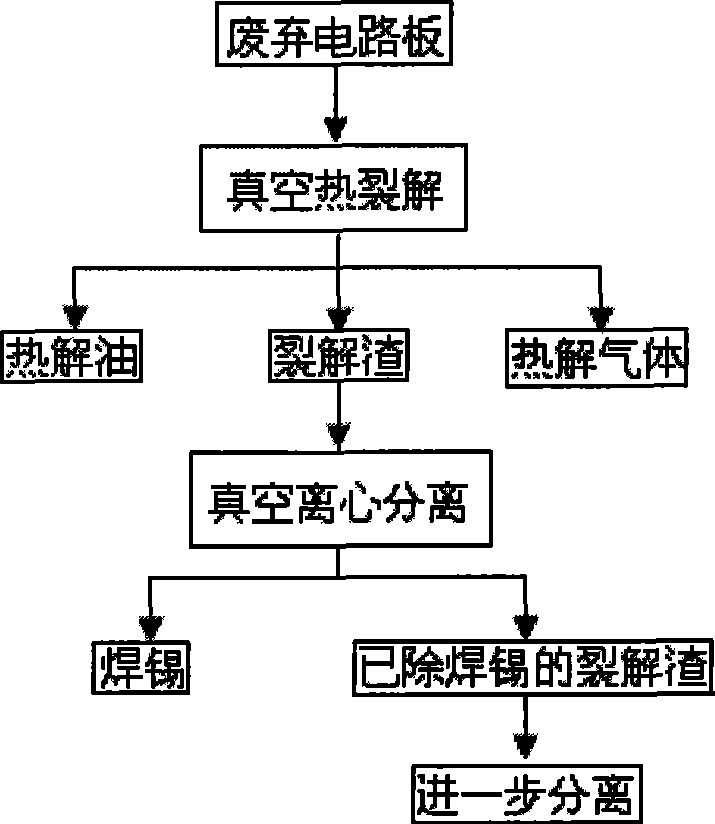

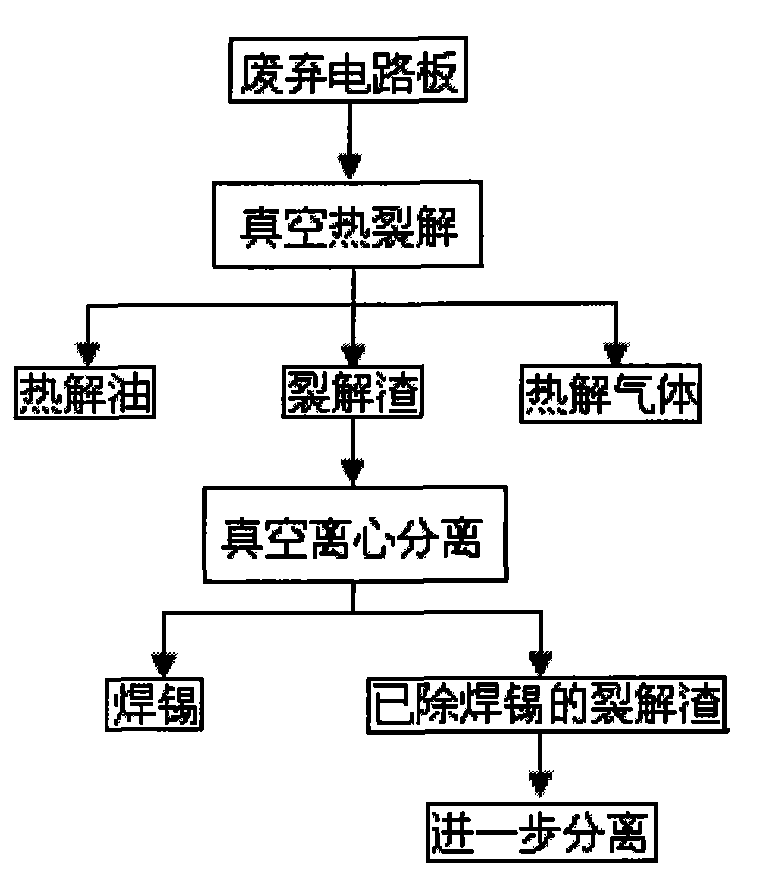

Method used

Image

Examples

Embodiment 1

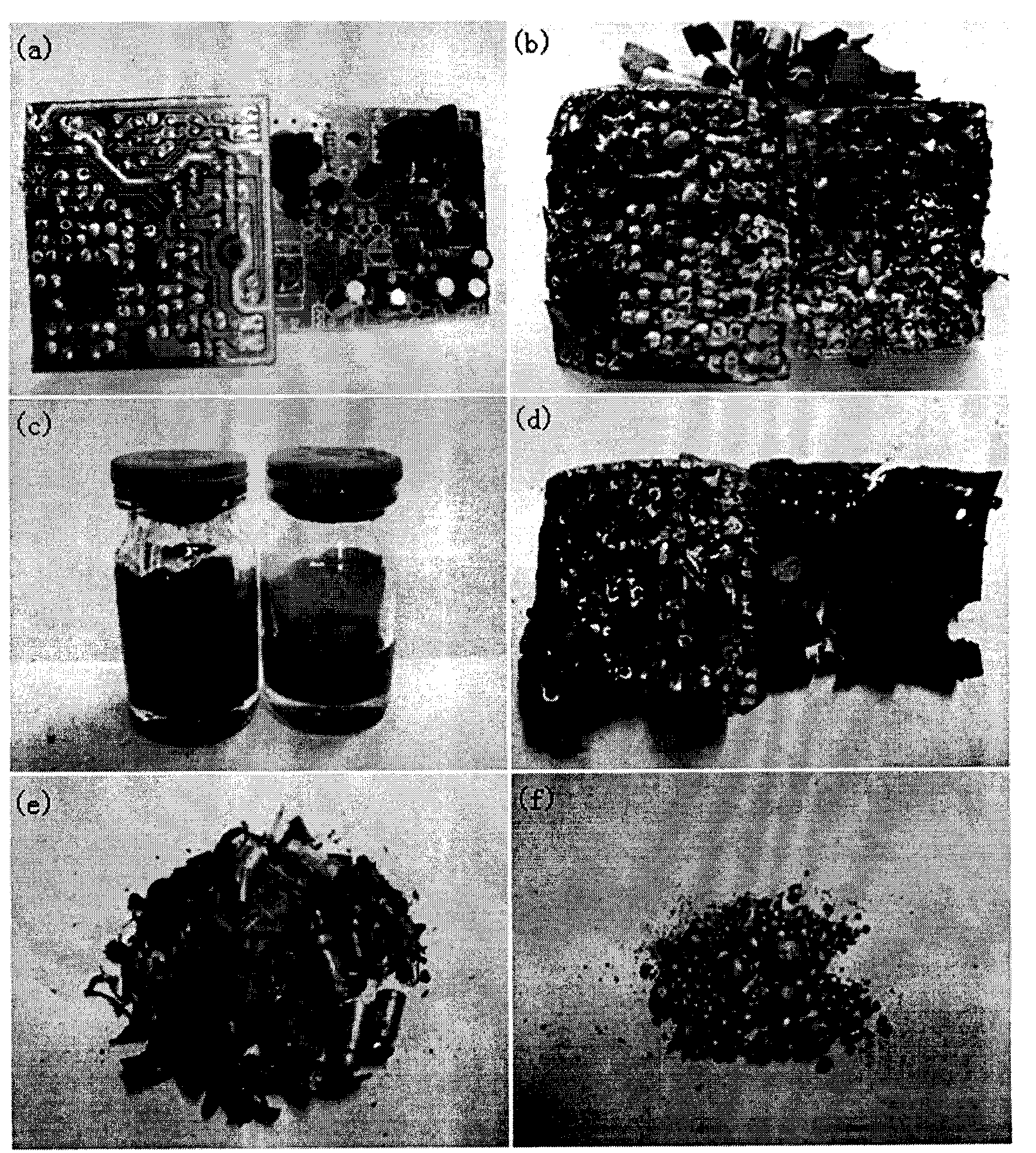

[0045] Put the waste circuit boards into the vacuum pyrolysis device and vacuumize. The following experimental conditions were set: the final temperature of cracking was 500°C, the holding time of the final temperature was 20min, and the condensation temperature was -20°C. Heat the vacuum pyrolysis device, collect the obtained liquid oil and the solid product of waste circuit board cracking; then put the solid product of waste circuit board cracking into a vacuum centrifuge, raise the temperature to 250°C, and rotate for 10 minutes after the temperature is constant. The rotation speed was 600 rpm.

[0046] in conclusion:

[0047] ①In the vacuum pyrolysis step, the oil yield was 21.26%.

[0048] ② During the solder recovery step, a large number of electronic components fall off, and only a few electronic components are attached to the circuit board; a large amount of solder falls off, and a small amount of solder remains on the cracked substrate.

Embodiment 2

[0050] Put the waste circuit boards into the vacuum pyrolysis device and vacuumize. The following experimental conditions were set: final cracking temperature of 550°C, final temperature holding time of 30min, and condensation temperature of -30°C. Heat the vacuum pyrolysis device, collect the obtained liquid oil and the solid product of waste circuit board cracking; then put the solid product of waste circuit board cracking into a vacuum centrifuge, raise the temperature to 350°C, and rotate for 10 minutes after the temperature is constant. The rotation speed was 800 rpm.

[0051] in conclusion:

[0052] ①In the vacuum pyrolysis step, the oil yield was 22.12%.

[0053] ②In the process of recycling solder, a large number of electronic components fall off, and only a very small number of electronic components are attached to the circuit board; a large amount of solder falls off, and a very small amount of solder remains on the cracked substrate.

Embodiment 3

[0055] Put the waste circuit boards into the vacuum pyrolysis device and vacuumize. The following experimental conditions were set: final cracking temperature 600°C, final temperature holding time 40min, condensation temperature -40°C. Heat the vacuum pyrolysis device, collect the obtained liquid oil and the solid product of waste circuit board cracking; then put the solid product of waste circuit board cracking into a vacuum centrifuge, raise the temperature to 350°C, and rotate for 10 minutes after the temperature is constant. The rotation speed was 1000 rpm.

[0056] in conclusion:

[0057] ①In the vacuum pyrolysis step, the oil yield is 22.58%.

[0058] ②In the solder recovery step, the electronic components are completely removed, and no electronic components are attached to the circuit board; the solder is completely removed, and no solder remains on the substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com