Method and device for efficiently liquefying and recovering natural gas

A recovery method and technology for natural gas, applied in the field of low-temperature storage and transportation of natural gas, can solve the problems of complicated operation and huge heat exchanger area, and achieve the effect of continuous recovery and low equipment investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the examples, but the present examples do not constitute any limitation to the present invention.

[0029] In this embodiment, the BOG recovery of the LNG storage tank of the LNG filling station is used for illustration.

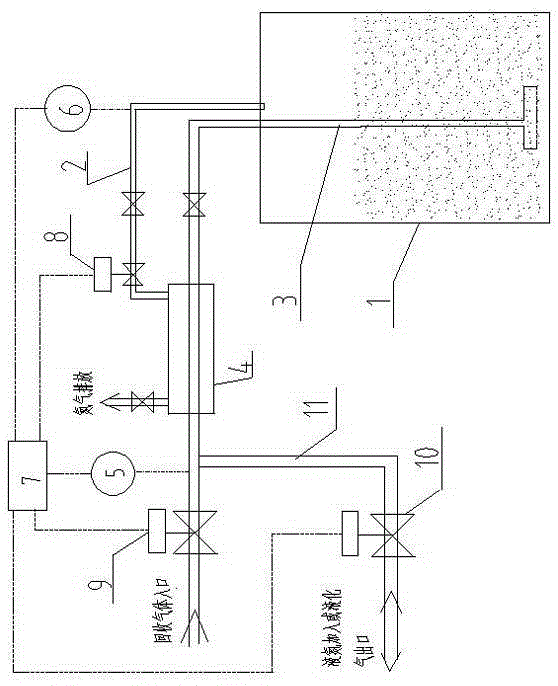

[0030] see figure 1 , the cryogenic container in this embodiment is a special 450L cryogenic gas cylinder 1, which is filled with liquid nitrogen of about 0.3mpa with a volume of 90% before being put in; Above, the natural gas inlet end of the tube side of the natural gas precooling heat exchanger 4 is equipped with an inlet valve 9 and an inlet pressure detection instrument 5; the natural gas input pipeline 3 is introduced into the low-temperature gas cylinder 1, and the outlet end of the natural gas extends to the low-temperature gas cylinder. The bottom layer of liquid nitrogen in bottle 1;

[0031] A nitrogen exhaust pipe 2 is connected between the shell side of the natura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com