Floating automatic oil recovery device

A floating and buoyant technology, used in general water supply conservation, water conservancy projects, and open-air water surface cleaning, etc., can solve problems such as low work efficiency, low use efficiency, and outdated equipment, and achieve simple structure, reasonable design, and improved use efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

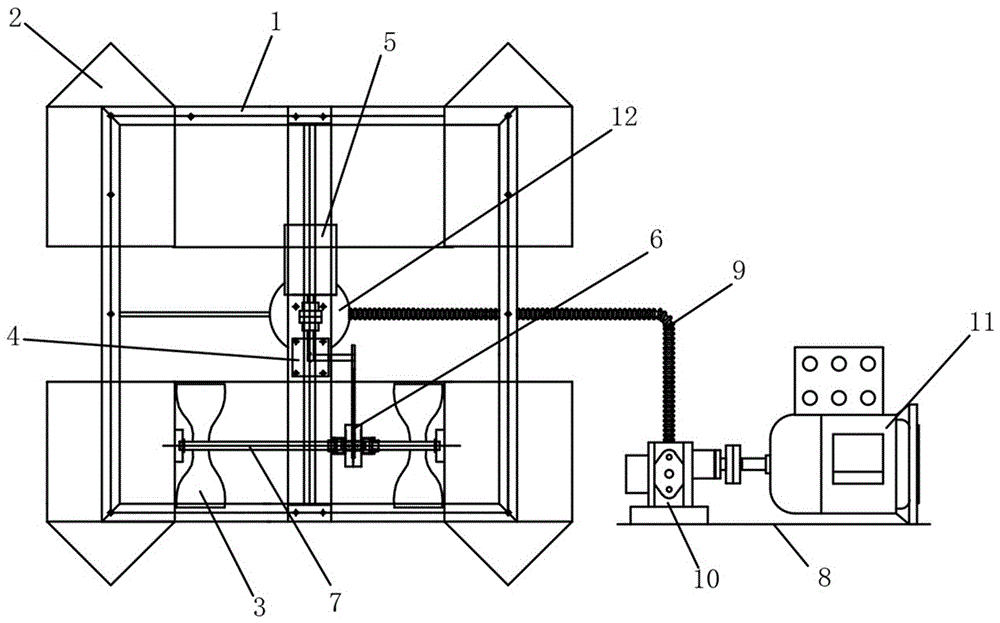

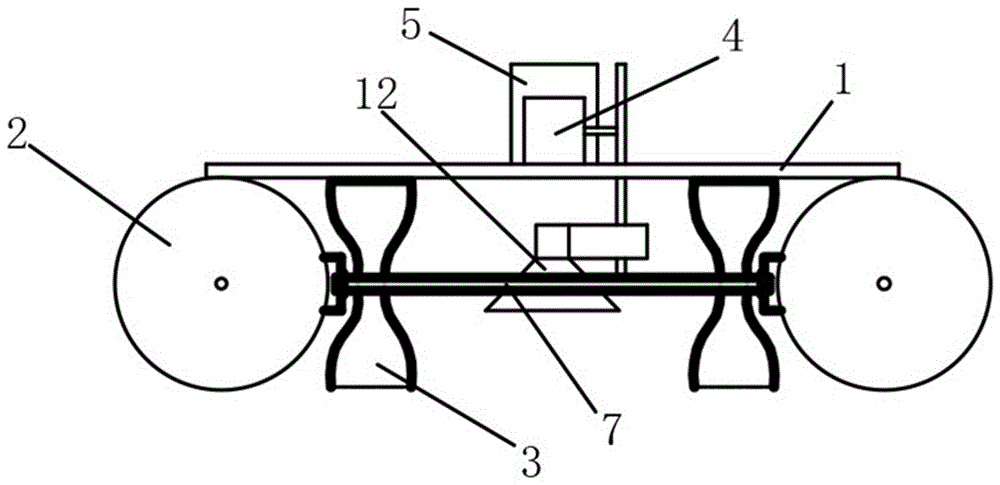

[0032] like figure 1 As shown, the present invention includes a fixed frame body 1, a buoyancy box body 2, an impeller 3, a speed reducer 4, a first drive unit 5, a second drive unit 11, a transmission assembly 6, an oil suction assembly, and a controller; the fixed frame body 1 is provided with a number of buoyancy boxes 3; a shaft 7 is installed on the fixed frame body 1, and two impellers 3 are installed on the shaft rod 7; a first drive is installed on the fixed frame body 1 unit 6; the first drive unit 5 is connected to the reducer 4 installed on the fixed frame body 1; the reducer 4 is connected and matched with the impeller 3 through the transmission assembly 6, and drives the impeller 3 to rotate around the shaft; the transmission The assembly 6 includes a gear set and a transmission link; the oil suction assembly includes an underframe 8, an oil delivery pipe 9, an oil suction pump 10, a second drive unit 11, and an oil suction nozzle 12; the oil suction pump 10 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com