Method for extracting fucoxanthin from gulfweed

A technology of fucoxanthin and sargassum, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of unsuitability for large-scale production and high cost of enzymatic hydrolysis, and achieve the goal of being suitable for large-scale industrial production and operation High efficiency and volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

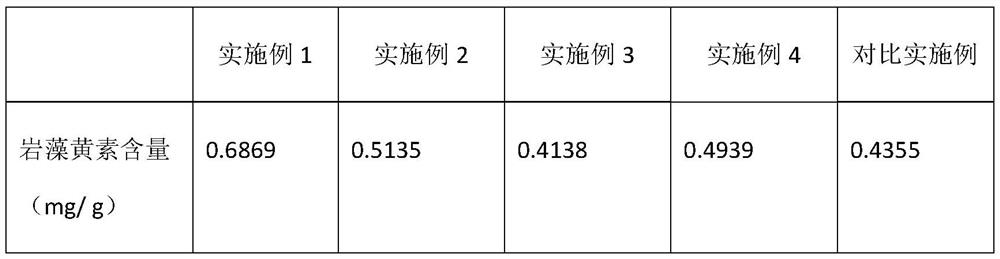

Embodiment 1

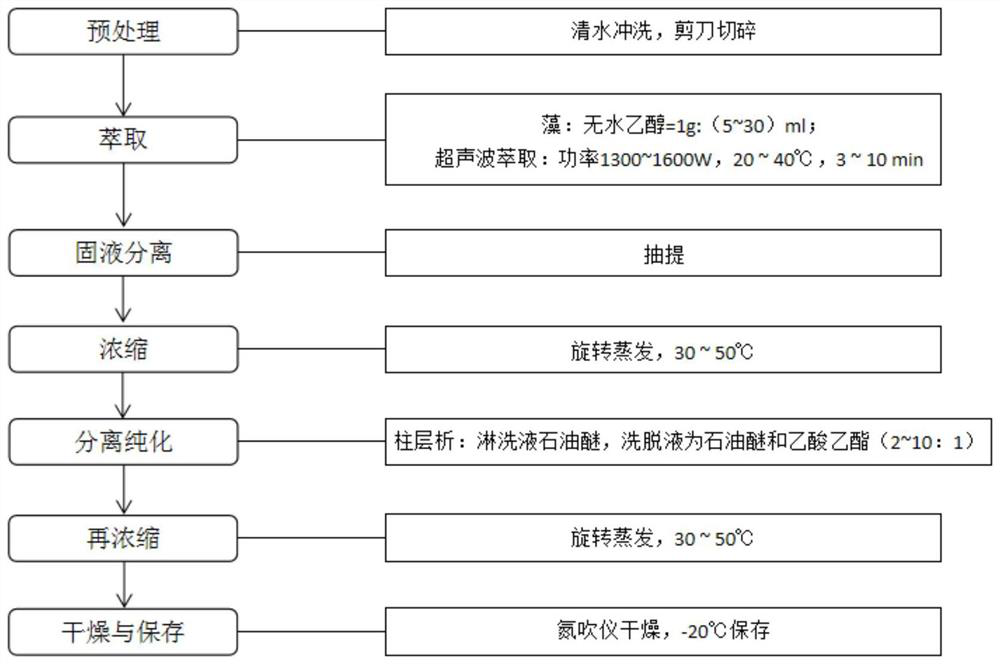

[0031] A method for extracting fucoxanthin from sargassum, comprising the steps of:

[0032] A1. Pretreatment: Rinse the fresh sea wormwood with clean water, wash off the surface sediment particles and mucus, drain the surface water, and cut it into 0.3cm-sized crushed algae;

[0033] A2. Extraction: Weigh the chopped Sargassum algae, add absolute ethanol according to the ratio of material to liquid 1g: 10ml, mix well, put it into an ultrasonic extraction instrument for ultrasonic extraction; the ultrasonic power is set to 1500W, the initial temperature 20°C, extraction time 5min, repeat ultrasonic extraction twice;

[0034] A3, solid-liquid separation: the extract is subjected to solid-liquid separation by suction filtration;

[0035] A4. Concentration: put the separated extract into a rotary evaporator, and evaporate and concentrate the extract at a temperature of 40°C to obtain a crude fucoxanthin extract;

[0036] A5. Separation and purification: The obtained crude fucox...

Embodiment 2

[0041] A method for extracting fucoxanthin from sargassum, comprising the steps of:

[0042] A1. Pretreatment: Rinse the fresh sea millet with water, wash off the surface sediment particles and mucus, drain the surface water, and cut it into 0.5cm-sized crushed algae;

[0043] A2. Extraction: Weigh the chopped Sargassum algae, add absolute ethanol according to the ratio of material to liquid 1g: 30ml, mix well, put it into an ultrasonic extraction instrument for ultrasonic extraction; the ultrasonic power is set to 1600W, the initial temperature 40°C, extraction time 10min, repeat ultrasonic extraction 3 times;

[0044] A3, solid-liquid separation: the extract is subjected to solid-liquid separation by suction filtration;

[0045] A4. Concentration: Put the separated extract into a rotary evaporator, and evaporate and concentrate the extract at a temperature of 50°C to obtain a crude fucoxanthin extract;

[0046] A5. Separation and purification: The obtained crude fucoxanthi...

Embodiment 3

[0051]A method for extracting fucoxanthin from sargassum, comprising the steps of:

[0052] A1. Pretreatment: Rinse the fresh sage algae with clean water, wash off the surface sediment particles and mucus, drain the surface water, and cut it into 0.4cm-sized crushed algae;

[0053] A2. Extraction: Weigh the chopped Sargassum algae, add absolute ethanol according to the ratio of material to liquid 1g: 20ml, mix well, put it into an ultrasonic extraction instrument for ultrasonic extraction; the ultrasonic power is set to 1400W, the initial temperature 30°C, extraction time 7min, repeat ultrasonic extraction twice;

[0054] A3, solid-liquid separation: the extract is subjected to solid-liquid separation by suction filtration;

[0055] A4. Concentration: put the separated extract into a rotary evaporator, and evaporate and concentrate the extract at a temperature of 40°C to obtain a crude fucoxanthin extract;

[0056] A5. Separation and purification: The obtained fucoxanthin cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com