Recovery method of waste circuit board

A recycling method and printed circuit board technology, applied in the field of resource recycling and reuse of waste electronic and electrical products, can solve the problems of high energy consumption, easy pollution of the environment, high energy consumption and environmental pollution, and achieve low energy consumption, good quality, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

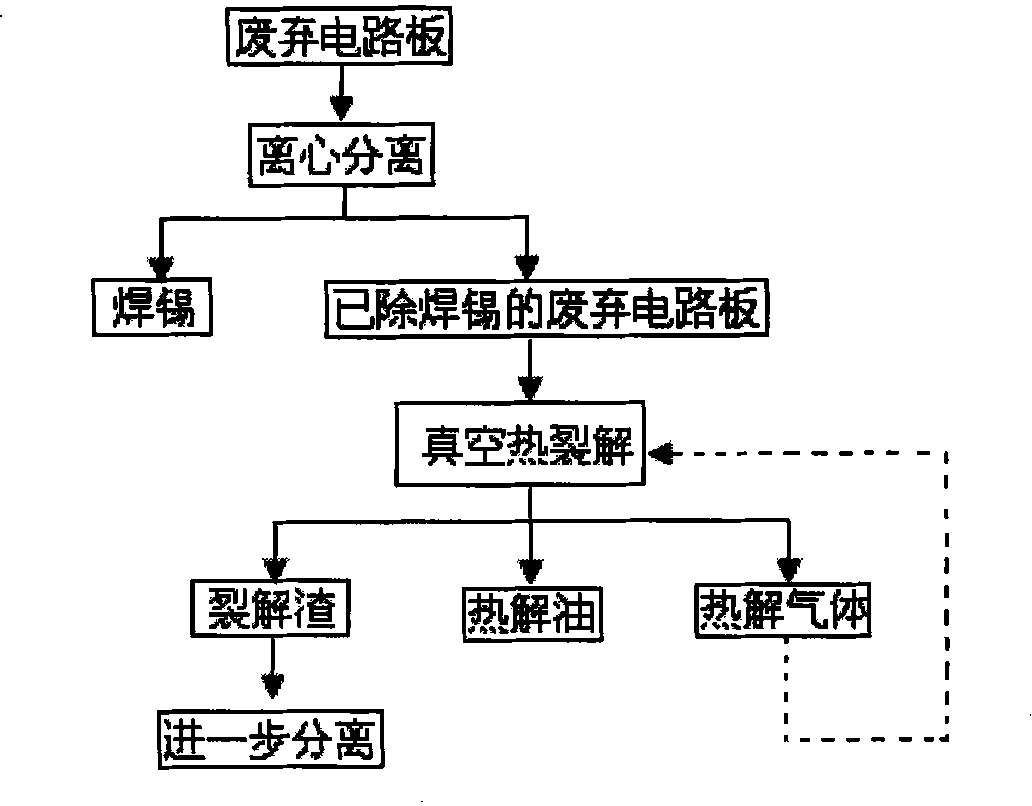

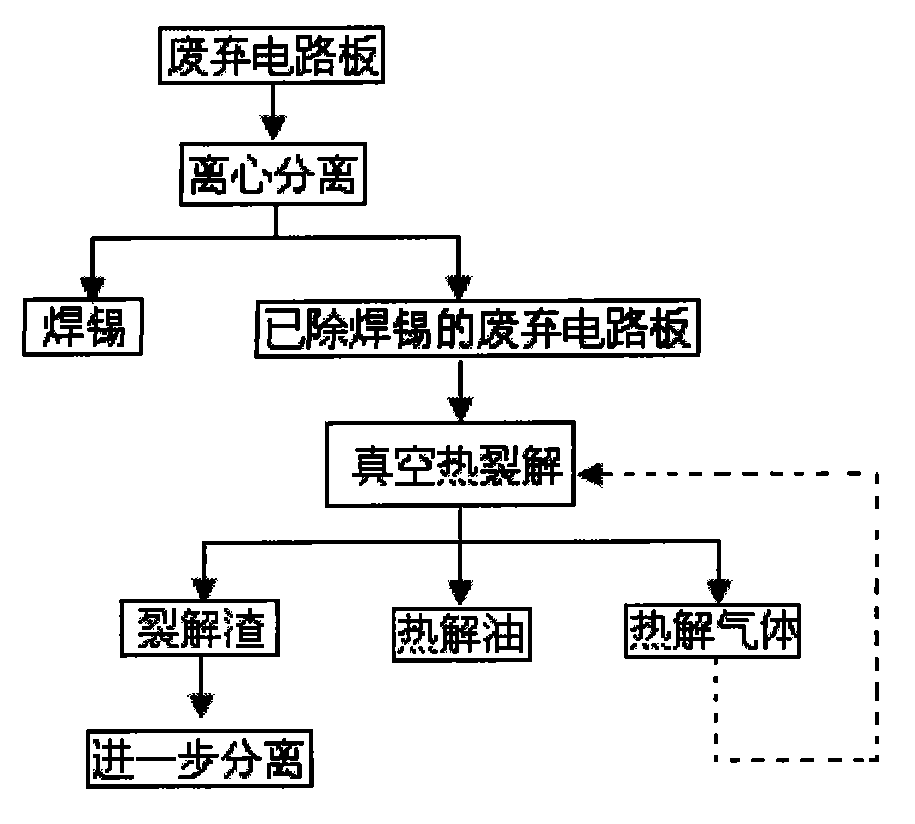

Method used

Image

Examples

Embodiment 1

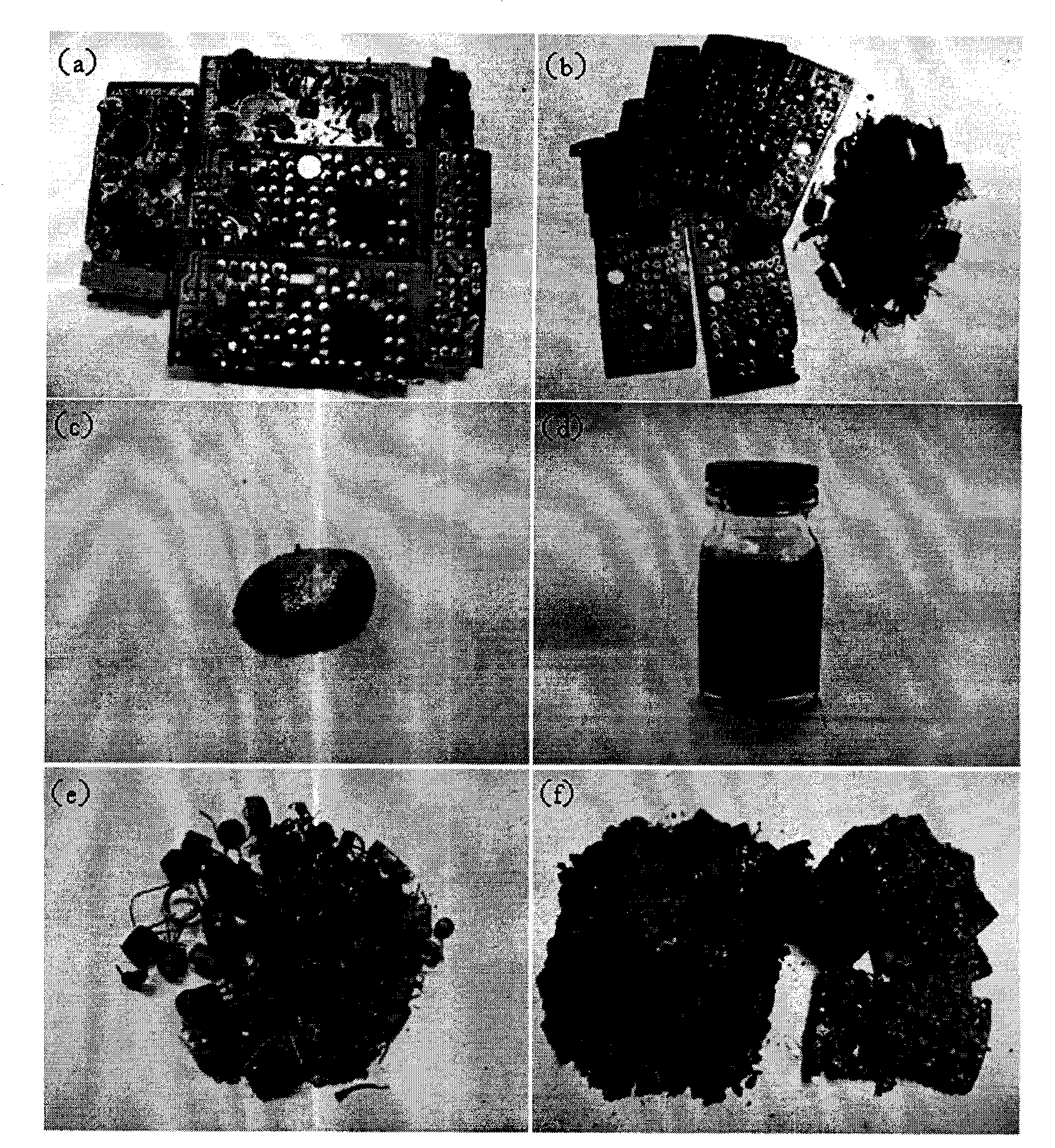

[0037] 1. Put the discarded circuit boards with electronic components in an oil bath at 220°C to 300°C and heat until the solder melts. Then, put the discarded circuit boards with melted solder in a centrifuge, start the motor to rotate for 6 minutes, and solder It is detached from the circuit board under the centrifugal force generated by the rotation to realize recycling.

[0038] 2. Place the desoldered substrate and electronic components in a vacuum pyrolysis device and heat them to 500°C, hold the final temperature for 20 minutes, collect the gas generated by thermal cracking, and condense into liquid oil in a -20°C condensing device.

[0039] 3. Collect the pyrolysis oil obtained from pyrolysis, the circuit board substrate and electronic components after pyrolysis, so that the next step can be classified and recovered or separated and recovered.

[0040] in conclusion:

[0041] ①In the desoldering step, all electronic components fall off, and no electronic components ar...

Embodiment 2

[0044] 1. Put the discarded circuit boards with electronic components in an oil bath at 220°C to 300°C and heat until the solder melts. Then, put the discarded circuit boards with melted solder in a centrifuge, start the motor to rotate for 8 minutes, and solder It is detached from the circuit board under the centrifugal force generated by the rotation to realize recycling.

[0045] 2. Place the desoldered substrate and electronic components in a vacuum pyrolysis device to heat to 550°C, hold the final temperature for 30 minutes, collect the gas generated by thermal cracking, and condense it into liquid oil in a -30°C condensing device.

[0046] 3. Collect the pyrolysis oil obtained from pyrolysis, the circuit board substrate and electronic components after pyrolysis, so that the next step can be classified and recovered or separated and recovered.

[0047] in conclusion:

[0048] ①In the desoldering step, all electronic components fall off, and no electronic components are a...

Embodiment 3

[0051] 1. Put the discarded circuit boards with electronic components in an oil bath at 220°C to 300°C and heat until the solder melts. Then, put the discarded circuit boards with melted solder in a centrifuge, start the motor to rotate for 10 minutes, and solder It is detached from the circuit board under the centrifugal force generated by the rotation to realize recycling.

[0052] 2. Place the desoldered substrate and electronic components in a vacuum pyrolysis device to heat to 600°C, hold the final temperature for 40 minutes, collect the gas generated by thermal cracking, and condense it into liquid oil in a -40°C condensing device.

[0053] 3. Collect the pyrolysis oil obtained from pyrolysis, the circuit board substrate and electronic components after pyrolysis, so that the next step can be classified and recovered or separated and recovered.

[0054] in conclusion:

[0055] ①In the desoldering step, all electronic components fall off, and no electronic components are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com