Method for extracting general flavone from sorrel shell waste residues through microwave refluxing

A technology of microwave reflux and total flavonoids, which is applied in the direction of pharmaceutical formulations, non-central analgesics, medical preparations containing active ingredients, etc., to achieve the effects of wide application prospects, improved extraction efficiency, and short extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The chestnut hair shell that removes impurity is broken into 40 order powders with crusher. Take the material and adjust the material ratio to 1:25 with 45% ethanol. After soaking for 40 minutes, put it in a microwave oven reflux device, extract it for 10 minutes under a microwave power level of 450W, and remove it for suction filtration to obtain the total flavonoid extraction solution. The filter residue was extracted again, concentrated by rotary evaporation under reduced pressure to obtain crude flavonoids, and the ethanol was recycled. The content of the total flavonoids in the concentrate is determined by aluminum chloride colorimetry, and the extraction rate of the total flavonoids is 85%, the purity is 40%, and the yield is 0.19%.

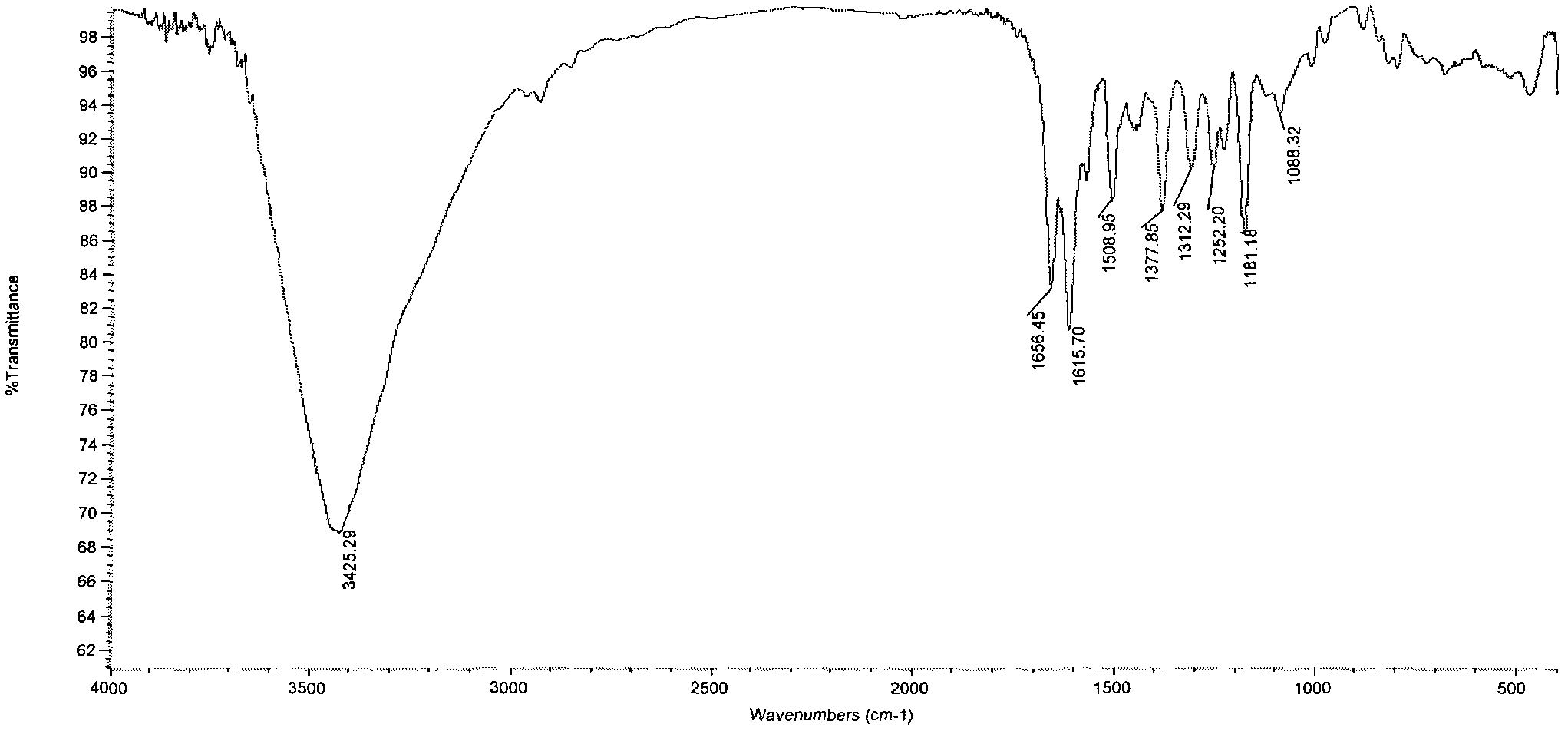

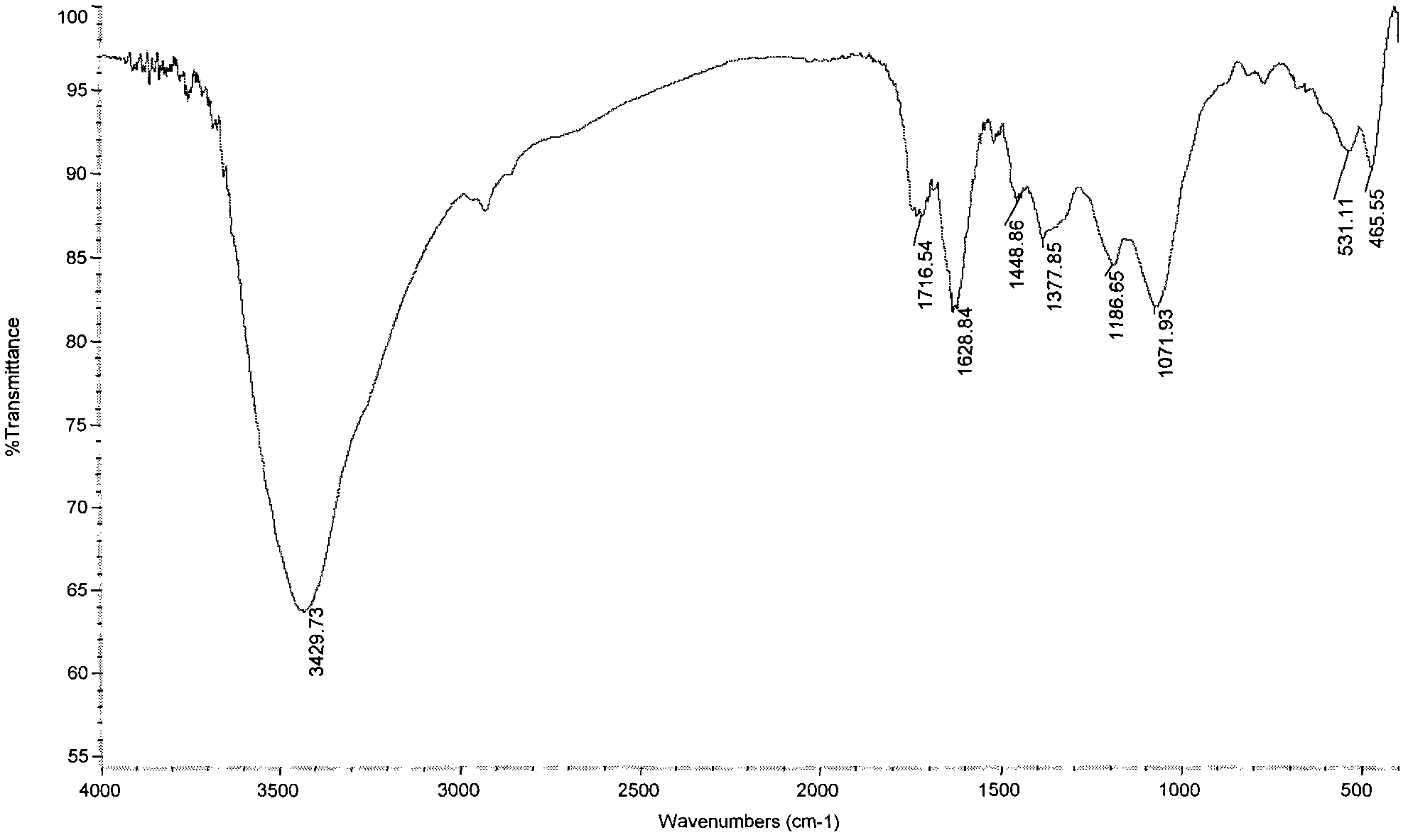

[0025] The extracted flavonoids were separated and purified to scan the IR spectrum of the small sample. Get the graph (see attached figure 1 , 2), analyze and compare, determine that the product contains flavonoids.

[0026] The...

Embodiment 2

[0031] The chestnut hair shell that removes impurity is broken into 60 purpose powder material with crusher. Take the material and adjust the material ratio to 1:40 with 50% ethanol. After soaking for 60 minutes, put it in a microwave oven reflux device, extract it for 18 minutes under a microwave power level of 180w, and remove it for suction filtration to obtain the total flavonoids leaching solution. Extract the filter residue once more, combine the two extracts, concentrate by rotary evaporation under reduced pressure to obtain the total flavonoids of the product, and recycle the ethanol. The content of total flavonoids in the concentrate was determined by aluminum chloride colorimetry. The extraction rate of total flavonoids obtained was 93%, the purity was 45%, and the yield was 0.20%.

Embodiment 3

[0033] The chestnut hair shell that removes impurity is broken into 50 mesh powders with crusher. The material was adjusted to 1:50 with 55% ethanol, soaked for 50 minutes, placed in a microwave oven reflux device, leached for 25 minutes at a microwave power level of 150W, removed and suction filtered to obtain the total flavonoids leaching solution. Extract the filter residue once more, collect all the solutions, concentrate by rotary evaporation under reduced pressure to obtain the total flavonoids of the product, and recycle the ethanol. The content of total flavonoids in the concentrate was determined by aluminum chloride colorimetry. The extraction rate of total flavonoids obtained was 88%, the purity was 42%, and the yield was 0.19%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com