Preparation method of preferential water permeable membrane and morpholine wastewater treatment and morpholine substance recovery method

A technology that prioritizes water permeation and morpholine, and is used in infiltration/dialysis water/sewage treatment, water/sewage treatment, extraction water/sewage treatment, etc. large problems, to achieve the effects of high comprehensive economic benefits, high energy integration, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of the preferential water-permeable membrane is as follows:

[0044] Preparation of polymer coating solution: where N,N-dimethylformamide is used as a solvent. Mix 8% methyl methacrylate, 3% sodium diamino-p-benzenesulfonate, 2% hydroxylated graphene oxide and N,N-dimethylformamide, which account for the total amount of the polymer coating solution, and use The mechanical stirring was carried out at 70° C. to disperse evenly, the stirring speed was 2000 r / min, and the stirring time was 18 hours to obtain a polymer coating liquid. The polymer coating liquid was coated on the polysulfone membrane twice by spraying, and the coating thickness was 3 μm. Place the coated film in a constant-temperature vacuum oven and dry it at 80°C for 48 hours to obtain a preferentially water-permeable film.

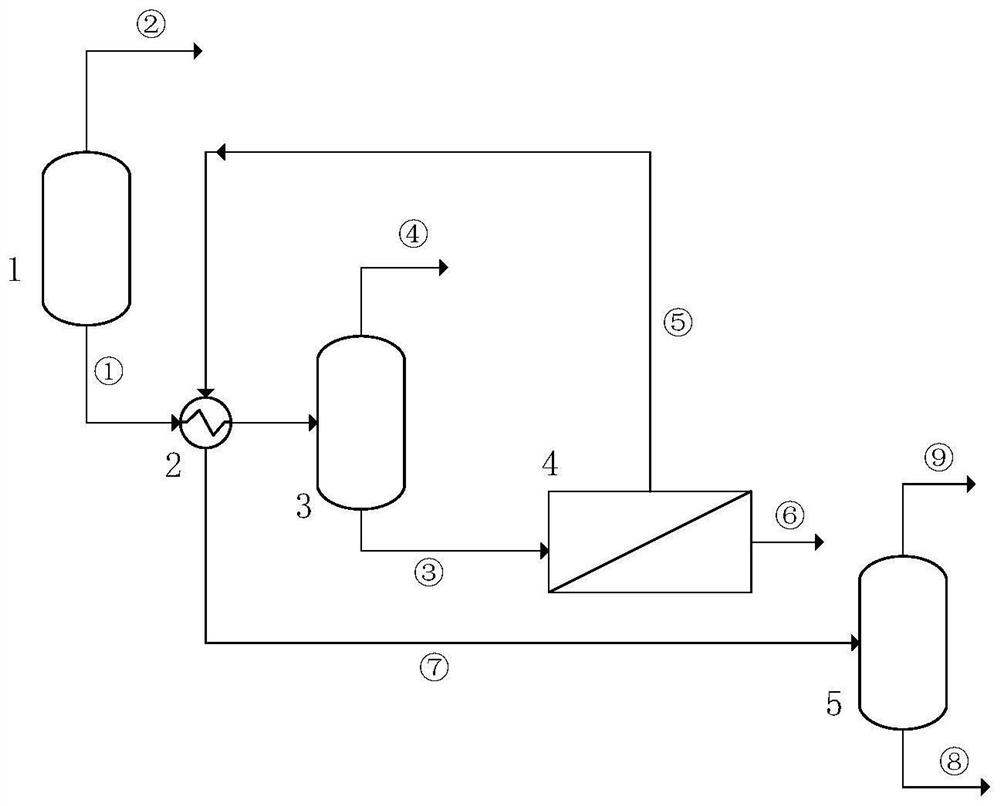

[0045] The content of morpholines in the process wastewater is 15wt%, and the COD is 300000mg / L, which is recovered by the following process, such as figure 1...

Embodiment 2

[0050] The preparation method of the preferential water-permeable membrane is as follows:

[0051] Mix 6% of methyl acrylate, 2% of sodium p-aminobenzenesulfonate, 2% of hydroxylated graphene oxide, and solvent acetone in the total amount of the polymer coating solution, and disperse evenly at 60°C using mechanical stirring. The rotational speed was 1000 r / min, and the stirring time was 24 hours to obtain a polymer coating liquid. The polymer coating liquid was coated on the polyacrylonitrile film four times by scraping, and the coating thickness was 8 μm. Place the coated film in a constant-temperature vacuum oven and dry it at 80°C for 48 hours to obtain a preferentially water-permeable film.

[0052] The content of morpholines in the process wastewater is 25wt%, and the COD is 500000mg / L. The morpholines are reclaimed by the following process, as figure 1 Shown:

[0053] (1) The morpholine wastewater is subjected to atmospheric distillation to remove light components, th...

Embodiment 3

[0057] The preparation method of the preferential water-permeable membrane is as follows: the total amount of polymer coating liquid 8% ethyl methacrylate, 4% sodium lignosulfonate sodium sulfonate, 3% hydroxylated graphene oxide and ethanol are mixed, use Ultrasound was dispersed evenly at 80°C to obtain a polymer coating solution, which was sprayed onto the polyacrylonitrile film three times with a coating thickness of 5 μm, and the coated film Place it in a constant-temperature vacuum oven, keep the temperature at 100°C and dry for 72 hours to obtain a preferential water-permeable membrane.

[0058] The content of morpholines in the process wastewater is 5wt%, and the COD is 50000mg / L. The morpholines are reclaimed by the following process, as figure 1 Shown:

[0059] (1) The morpholine wastewater is subjected to atmospheric distillation to remove light components, the operating pressure is atmospheric pressure, the temperature at the bottom of the tower is 115°C, the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com