Method for extracting copper in waste printed circuit boards by virtue of moderately thermophilic bacteria

A waste circuit board, moderate heat-loving technology, applied in the direction of process efficiency improvement, etc., can solve the problems of large investment in mechanical equipment, large energy consumption, difficult metal separation, etc., to achieve low processing cost, high efficiency, and small investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

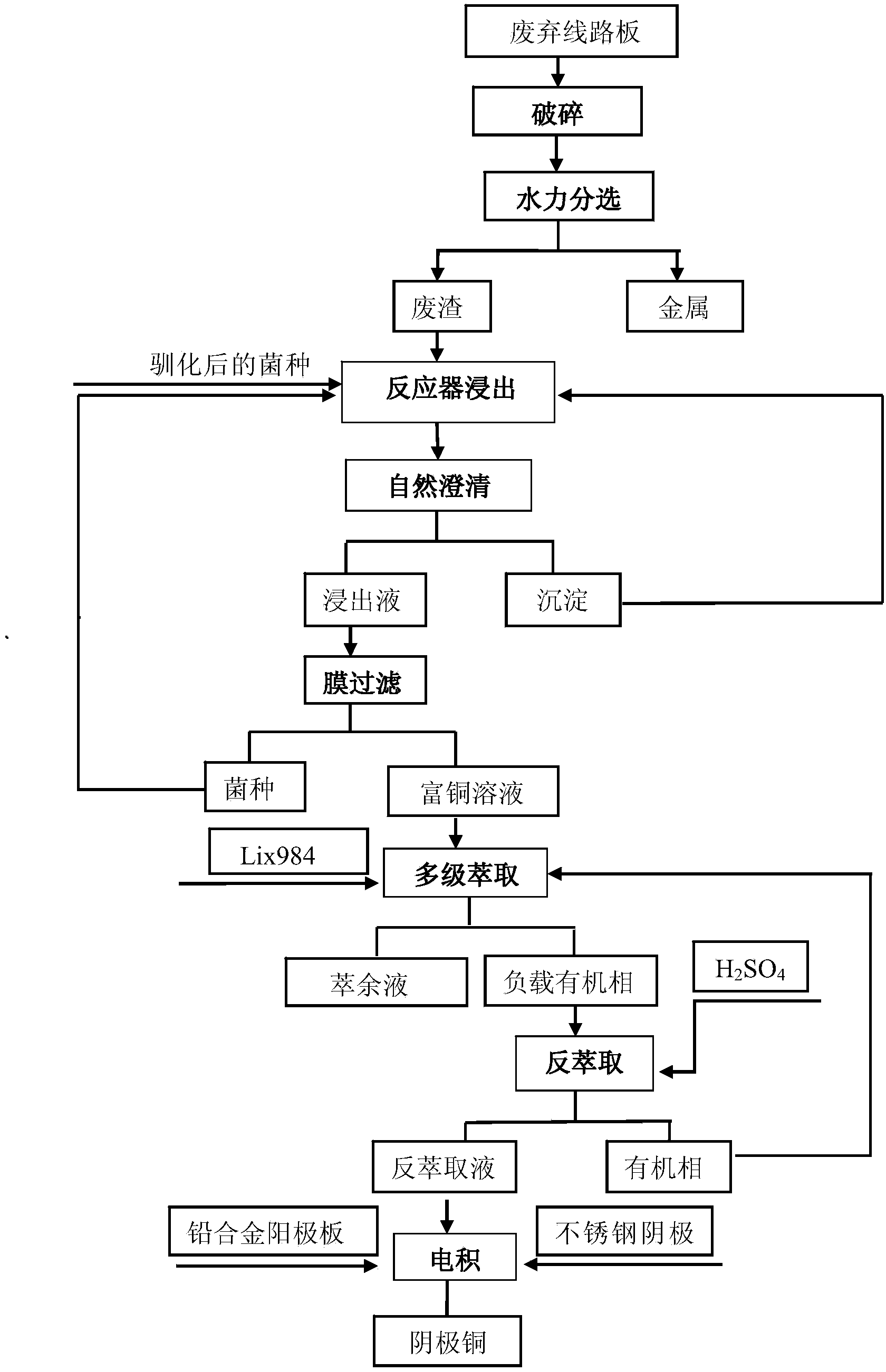

Image

Examples

Embodiment 1

[0026] The domestication process of the mixed strains of the present invention is specifically as follows: firstly cultivate various strains separately, centrifuge and collect the strains after reaching the late logarithmic period of growth, count them under a microscope, and when the concentration of each pure strain is 2×10 8 ~8×10 8When each / mL, mix the four kinds of pure bacteria in equal volumes, and then insert the mixed bacteria solution into the improved 9K medium according to the volume percentage of 10-15%, and add 16g / L FeSO 4 ·7H 2 O and 8g / L elemental sulfur are used as energy substances, the circuit board waste residue concentration is 1% (100g / L), the stirring speed is 45r / min, the ventilation rate is 8L / min, and the evaporation of water in the reactor is supplemented by adding distilled water. When the microbial concentration reaches 2×10 9 When the individual / mL is more than the second acclimatization, specifically, under the same culture conditions, insert ...

Embodiment 2

[0028] 10kg of waste circuit boards with a Cu content of 11.46% were crushed to less than 1.0mm, and 1.98kg of metal with a copper content of 49.46% and 8.02kg of non-metal powder waste residue with a copper content of 0.82% were obtained by hydraulic separation; at 45°C, inoculation of 10% was carried out Example 1 The domesticated bacterial solution (adjust the pH to 2), the circuit board waste residue concentration is 8%, the stirring speed is 48r / min, and the ventilation rate is 8L / min. Under the condition of leaching for 18-22d, a copper-rich solution and a Cu content of 0.04 are obtained. % glass fiber resin composite material 7.96kg, copper leaching rate reached 93%. The copper-rich solution is filtered by an external pressure hollow fiber membrane system, and the obtained strains are put into the stirring and leaching device for reuse. The copper-containing filtrate uses LIX984: kerosene volume ratio = 10:90 as the extraction agent, and the phase ratio is 1. Two-stage ...

Embodiment 3

[0030] 10kg of discarded circuit boards with a Cu content of 12.00% were crushed to below 1.0mm, and 2.07kg of metal with a copper content of 50.03% and 7.93kg of non-metallic powder with a copper content of 1.32% were obtained through hydraulic separation; at 45°C, inoculated with 12% 1 The domesticated bacterial solution (adjust the pH to 2), stirred and leached for 18 to 22 days under the conditions of circuit board waste residue concentration of 12%, stirring speed of 45r / min, and air flow of 10L / min, to obtain copper-rich solution and Cu content The 0.06% glass fiber resin composite material is 7.84kg, and the copper leaching rate reaches 93%. The copper-rich solution is filtered by an external pressure hollow fiber membrane system, and the obtained strains are put into the stirring and leaching device for reuse. The copper-containing filtrate uses LIX984: kerosene volume ratio = 20:80 extractant, the phase ratio is 1, and carries out 4-stage countercurrent cascade extrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tolerance concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com