Natural gas high-efficiency liquefaction recovery method and device

A recovery method and technology of natural gas, which is applied in the field of low-temperature storage and transportation of natural gas, can solve problems such as complex operation and huge heat exchanger area, and achieve continuous recovery and low equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the examples, but the present examples do not constitute any limitation to the present invention.

[0029] In this embodiment, the BOG recovery of the LNG storage tank of the LNG filling station is used for illustration.

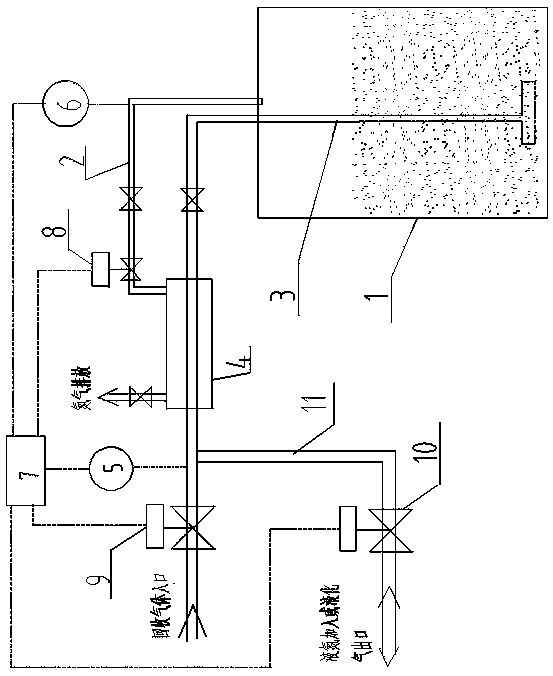

[0030] see figure 1 , the cryogenic container in this embodiment is a special 450L cryogenic gas cylinder 1, which is filled with liquid nitrogen of about 0.3mpa with a volume of 90% before being put in; Above, the natural gas inlet end of the tube side of the natural gas precooling heat exchanger 4 is equipped with an inlet valve 9 and an inlet pressure detection instrument 5; the natural gas input pipeline 3 is introduced into the low-temperature gas cylinder 1, and the outlet end of the natural gas extends to the low-temperature gas cylinder. The bottom layer of liquid nitrogen in bottle 1;

[0031] A nitrogen exhaust pipe 2 is connected between the shell side of the natura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com