Recovery method for waste circuit board

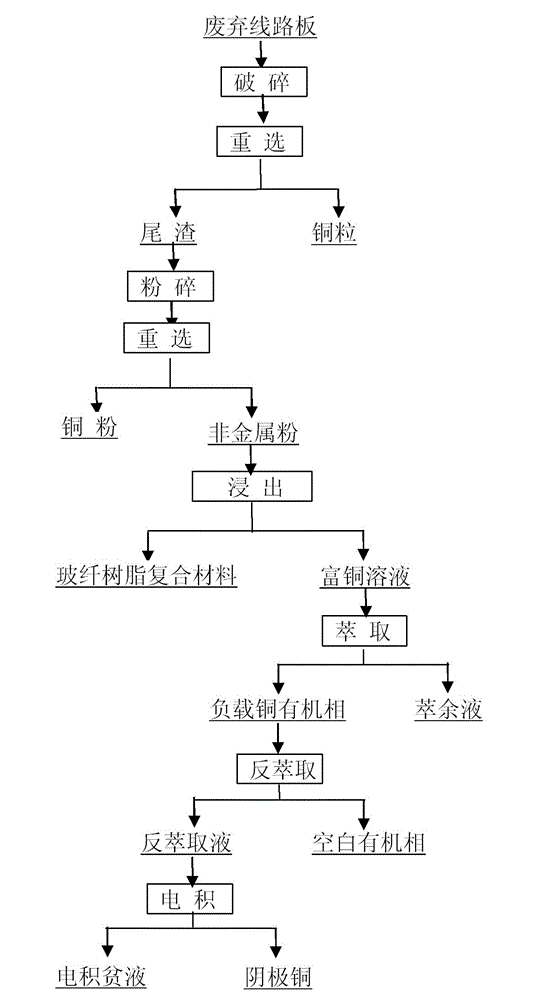

A technology of waste circuit boards and recycling methods, applied in the direction of electronic waste recycling, plastic recycling, recycling technology, etc., can solve the problems of incomplete separation, non-metallic materials cannot be fully recycled and reused, and achieve low processing costs and small investment , the effect of reducing the amount of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: 10kg of discarded circuit boards with a Cu content of 19.34% were broken to less than 2.0mm, and shaker sorted to obtain 1.95kg of copper particles with a Cu content of 95.49% and 8.05kg of tailings with a Cu content of 0.93%; crush the tailings to 0.1mm Next, 0.09 kg of copper powder with a copper content of 53.11% and 7.96 kg of non-metallic powder with a Cu content of 0.34% were obtained by shaking table separation; at 25°C, an acidic aqueous solution with a pH value of 1.5 containing Acidophilus ferrooxidans was used , the non-metallic powder was leached for 48h under the condition of liquid-solid ratio of 3 / 1, and 7.91kg of copper-rich solution and glass fiber resin composite material with Cu content of 0.05% were obtained. Using LIX860:LIX63:kerosene volume ratio=10:10:80 extraction agent, the phase ratio is 1, carry out 2-stage countercurrent cascade extraction, the extraction time of each stage is 20min, extract the copper-rich solution to obtain the c...

Embodiment 2

[0015] Example 2: 10 kg of waste circuit boards with a Cu content of 19.34% were broken to below 2.0 mm, and shaker sorting obtained 2.01 kg of copper particles with a Cu content of 93.54% and 7.99 kg of tailings with a Cu content of 0.71%; crushed tailings to 0.1 mm Next, 0.08 kg of metallic copper powder with a copper content of 49.52% and 7.91 kg of non-metallic powder with a Cu content of 0.2% were obtained by shaking table separation; The non-metallic powder was leached for 36 hours under the condition that the leaching liquid-solid ratio was 5 / 1, and 7.82 kg of copper-rich solution and glass fiber resin composite material with Cu content of 0.06% were obtained. Using LIX860N:LIX84:kerosene volume ratio = 5:5:90 extractant, phase ratio is 1, 4-stage countercurrent cascade extraction is carried out, the extraction time of each stage is 10min, and the copper-rich solution is extracted to obtain the copper-loaded organic phase and raffinate ; Under the condition that the rat...

Embodiment 3

[0016] Example 3: 10 kg of discarded circuit boards with a Cu content of 21.25% were broken to below 2.0 mm, and shaker sorting obtained 2.18 kg of copper particles with a Cu content of 93.11% and 7.82 kg of tailings with a Cu content of 1.17%; crushed tailings to 0.1 mm Next, 0.103 kg of metallic copper powder with a copper content of 58.56% and 7.71 kg of non-metallic powder with a Cu content of 0.4% were obtained by shaking table separation; The non-metallic powder was leached for 24 hours under the condition that the leaching liquid-solid ratio was 6 / 1, and 7.66 kg of copper-rich solution and glass fiber resin composite material with Cu content of 0.07% were obtained. Using LIX860:LIX64:kerosene volume ratio=15:15:70 extractant, with a ratio of 1, carry out 6-stage countercurrent cascade extraction, the extraction time of each stage is 5min, and extract the copper-rich solution to obtain the copper-loaded organic phase and raffinate ; Under the condition that the ratio is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com