Filter for filtering molten metal and manufacturing method thereof

A molten metal and filter technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of easy moisture absorption, affecting product use, low strength, etc., to increase high temperature resistance, enhance mechanical properties, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

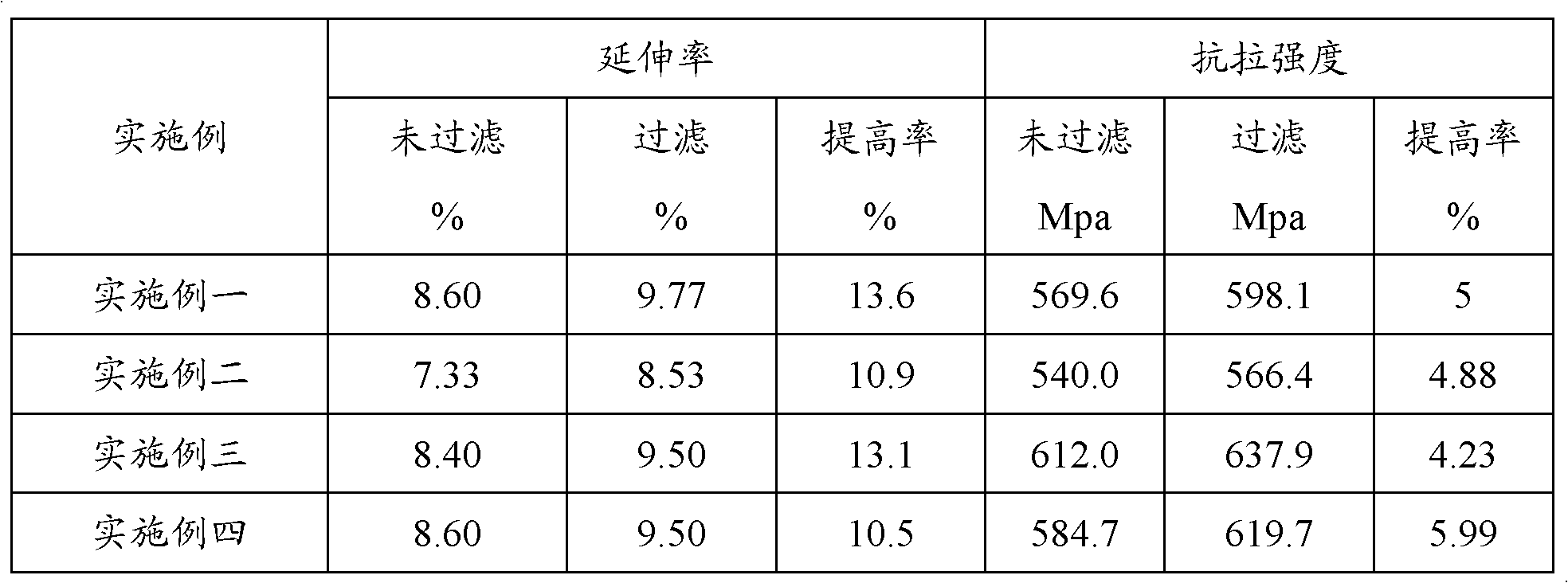

Examples

Embodiment 1

[0060] Add water to 45wt% corundum powder, 50wt% carbon, 2wt% aluminum silica gel, 1.5wt% dispersant and 1.5wt% active agent to make a slurry. Wherein the weight ratio of the total weight of corundum powder, carbon, aluminum silica gel, dispersant and active agent to water is: 100%: 12%.

[0061] This slurry was used to coat the cut polyurethane foam. The foam coated with slurry is dried and then sprayed with diluted slurry, then dried, and then sintered at 950°C.

Embodiment 2

[0063] Add water to 29% spinel powder, 56% carbon, 12% silica sol, 2.5% dispersant and 0.5% active agent to form a slurry. Wherein the weight ratio of the total weight of spinel powder, carbon, silica sol, dispersant and active agent to water is: 100%: 18%.

[0064] The slurry is made by mixing powder and water with a high-efficiency mixer, and the slurry is used to coat polyurethane foam. The coated foam is dried and then coated with diluted slurry once, then dried, and sintered at 1100°C.

Embodiment 3

[0066] Add water to 30% mullite powder, 47% carbon, 20% high softening point pitch, 2% polyvinyl alcohol, 2% dispersant and 1.0% active agent. Wherein the weight ratio of the total weight of mullite powder carbon, high softening point pitch, polyvinyl alcohol, dispersant and active agent to water is: 100%: 20%.

[0067] The slurry is made by mixing mullite powder, carbon, high softening point pitch, polyvinyl alcohol and water with a high-efficiency mixer. The mixed slurry was used to coat the polyurethane foam. The coated polyurethane foam is dried and then sprayed once with diluted slurry, then dried, and then sintered at 1150°C in an oxygen-free atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com