Environmentally friendly sintering coating of low-adhesion phase metal ceramic

A cermet, low-bonding technology, applied in the direction of coating, etc., can solve the problems of high cost of ingredients and not being considered as coating, and achieve the effect of improving the mechanical properties of cermets, simple components, and economical price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of sintered coating of environment-friendly low binder phase cermet, its preparation process is as follows,

[0024] ① Taking materials according to mass ratio, high-purity natural flake graphite (fixed carbon content ≥ 90%) 20g, polyethylene glycol (PEG-4000) 2.5g, Tween-80 6.5g, deionized water 71g;

[0025] ② Taking materials according to mass ratio, high-purity natural flake graphite (fixed carbon content ≥ 90%) 22g, polyethylene glycol (PEG-4000) 2.5g, Tween-80 6.5g, deionized water 69g;

[0026] 3. Taking materials by mass ratio, high-purity natural flake graphite (fixed carbon content ≥ 90%) 24g, polyethylene glycol (PEG-4000) 2.5g, Tween-80 6.5g, deionized water 67g;

[0027] 4. Taking materials by mass ratio, high-purity natural flake graphite (fixed carbon content ≥ 90%) 26g, polyethylene glycol (PEG-4000) 2.5g, Tween-80 6.5g, deionized water 65g;

[0028] 5. Taking materials by mass ratio, high-purity natural flake graphite (fixed carbon content ≥ 90%...

Embodiment 2

[0032] A kind of sintered paint of environment-friendly low binder phase cermet, the composition (mass ratio) of its sintered cermet is shown in the following table,

[0033] The mass ratio of the components of the cermet

[0034]

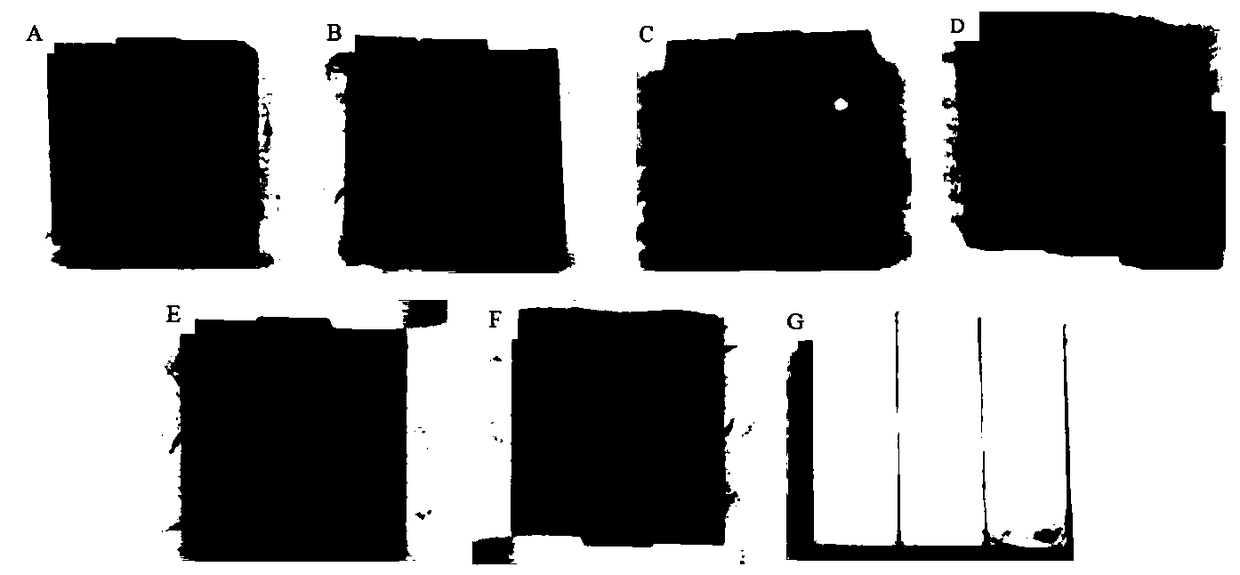

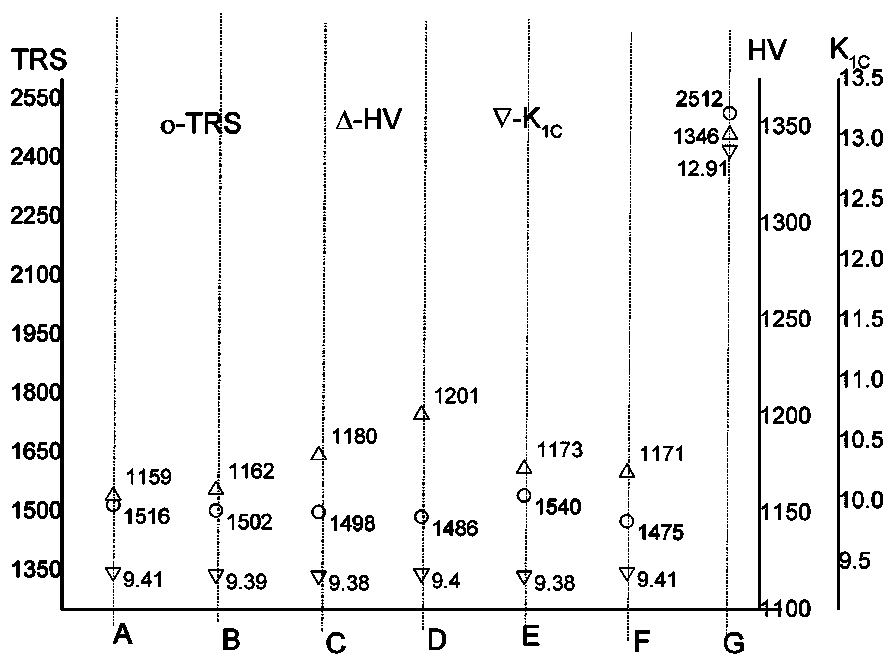

[0035] ①Take the above-mentioned paints (A, B, C, D, E, F), and brush them evenly on six different burning boats with a fine brush, and wait for them to dry, then take a piece of folded graphite paper and place them Take 21 samples of the above-mentioned Ni-Co-24 cermets on the unpainted burning boat (denoted as G), and place each group of 3 samples on six different burning boats with paint. And covered with graphite paper on the burning boat, vacuum sintering is carried out in the sintering furnace, the liquidus temperature of the sintering is 1490 ℃, the sintering time is 1h, and the vacuum degree is controlled at 10 0 -10 1 Between Pa, the surface quality of the sample after sintering is as follows figure 1 As shown, the performance of the...

Embodiment 3

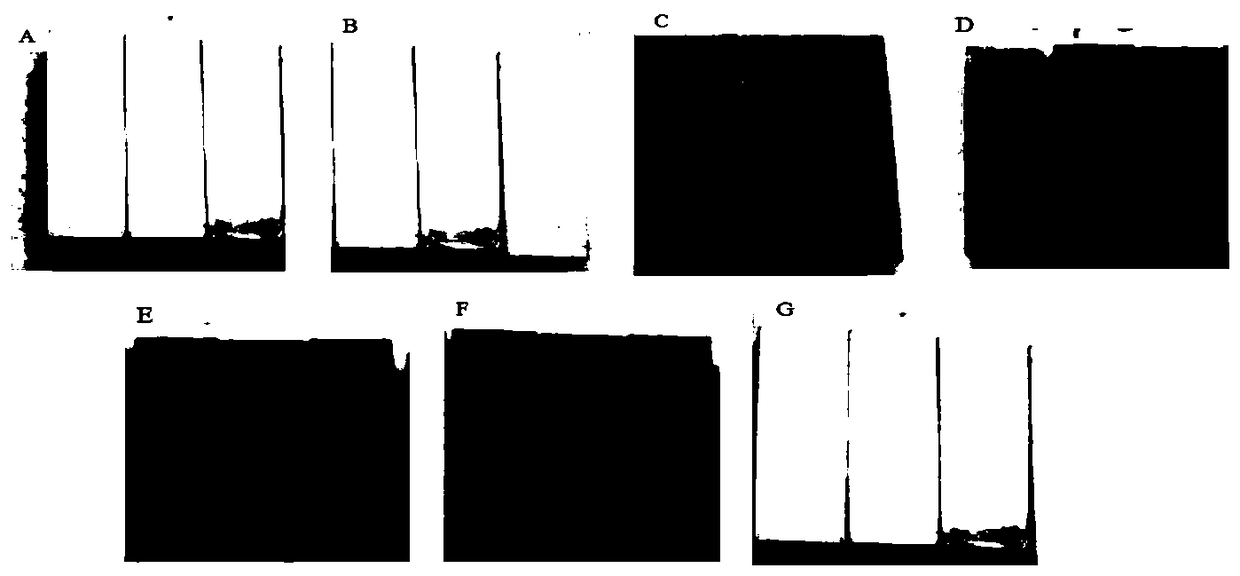

[0044] Prepare sintered coatings with different dispersants for sintering, and the preparation method is as follows:

[0045] ① Taking materials according to mass ratio, high-purity natural flake graphite (fixed carbon content ≥ 90%) 25g, sodium silicate 2.5g, Tween-80 6.5g, deionized water 69g;

[0046] ② Taking materials according to mass ratio, high-purity natural flake graphite (fixed carbon content ≥ 90%) 25g, sodium hexametaphosphate 2.5g, Tween-80 6.5g, deionized water 69g;

[0047] ③ Taking materials by mass ratio, high-purity natural flake graphite (fixed carbon content ≥ 90%) 25g, sodium pyrophosphate 2.5g, Tween-806.5g, deionized water 69g;

[0048] 4. Taking materials by mass ratio, high-purity natural flake graphite (fixed carbon content ≥ 90%) 25g, sodium humate 2.5g, Tween-806.5g, deionized water 69g;

[0049] Place in four ball milling jars, use a glass rod to stir the graphite adhering to the wall of the ball milling jar to a suspended state, then weigh 500 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com