A Tail Heat Utilizing Inertial Dust Capture Hot Air Penetration Counterflow Dryer

A dryer, inertial technology, applied in dryers, drying, components of pumping devices for elastic fluids, etc., can solve problems such as difficulty in disassembly, prevent fatigue fractures, facilitate lightweight, and enhance The effect of axial elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Now in conjunction with accompanying drawing, the present invention is described in further detail.

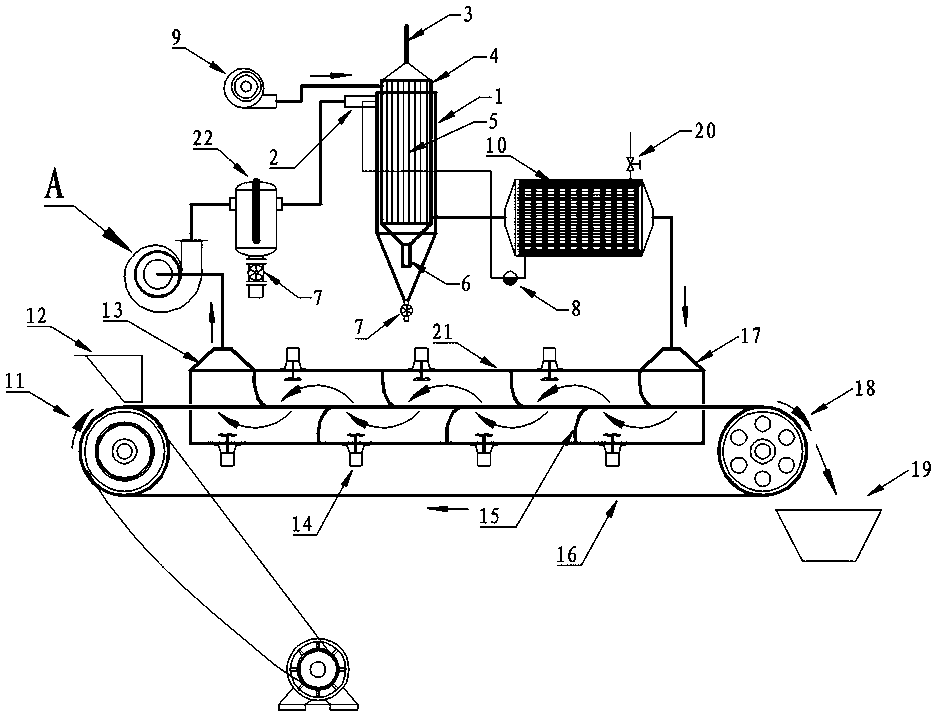

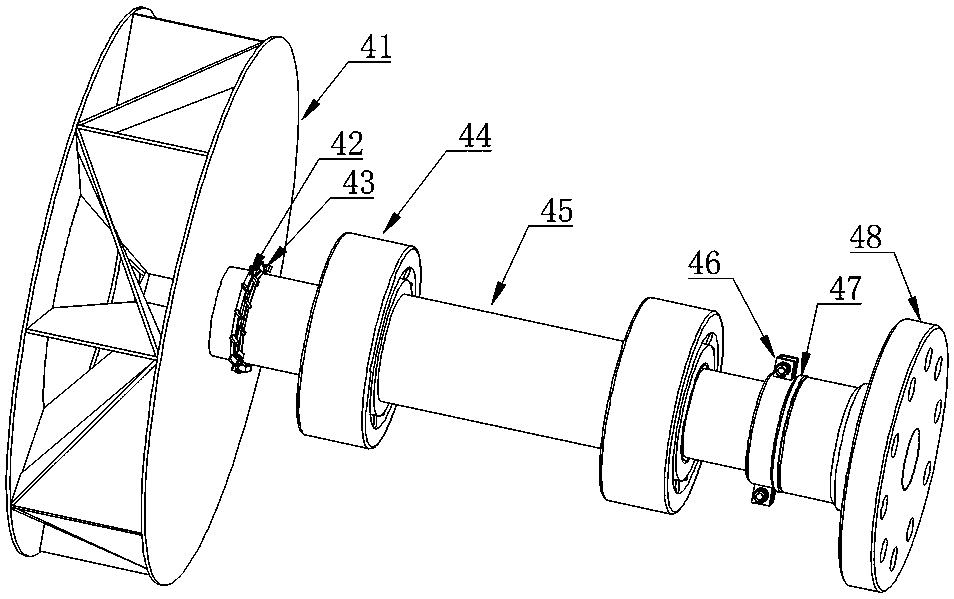

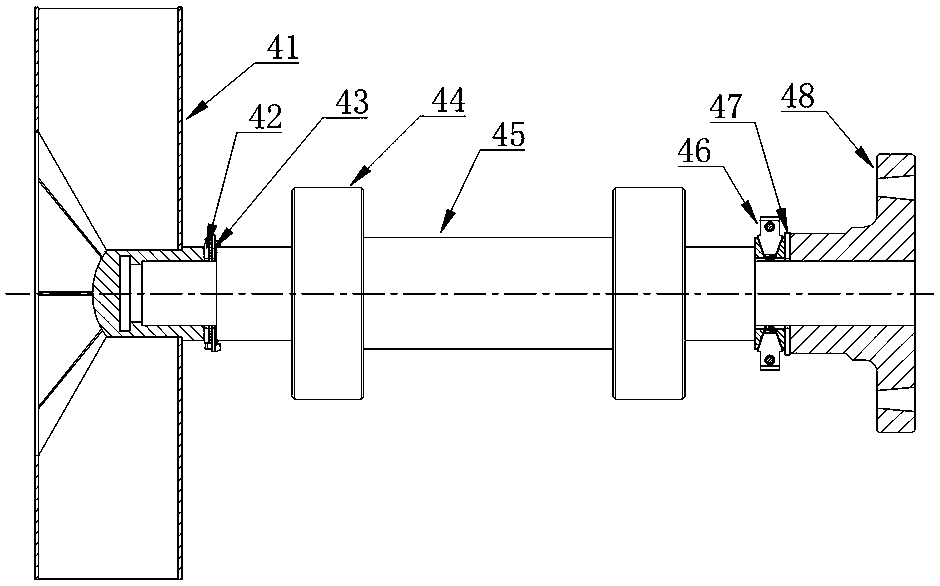

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 The shown tail heat utilizes the inertial dust-catching hot air penetrating countercurrent dryer, which includes a dryer box 21 and an induced draft fan A. The two ends of the dryer box 21 are respectively equipped with an exhaust hood 13 and an air inlet hood 17, and the exhaust hood 13 Connect the induced draft fan A, and the induced draft fan A is tangentially connected to the cyclone dust removal tail heat high-efficiency recovery device formed by the superposition of the tube and tube heat exchanger 4 and the cyclone dust collector 1 through the inertial dust collector 22, and then empties; the tube and tube heat exchange The air inlet end of the shell side of the device 4 is connected to the blower 9, and the air outlet end is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com