Bag filter-type manganese processing rotary kiln system with highly demountable induced draft fan

A technology of bag dust removal and rotary kiln, which is applied to parts of pumping devices for elastic fluids, rotary drum furnaces, mechanical equipment, etc., can solve problems such as difficult disassembly, achieve rapid centrifugal separation, reliable use, and promote material turning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Now in conjunction with accompanying drawing, the present invention is described in further detail.

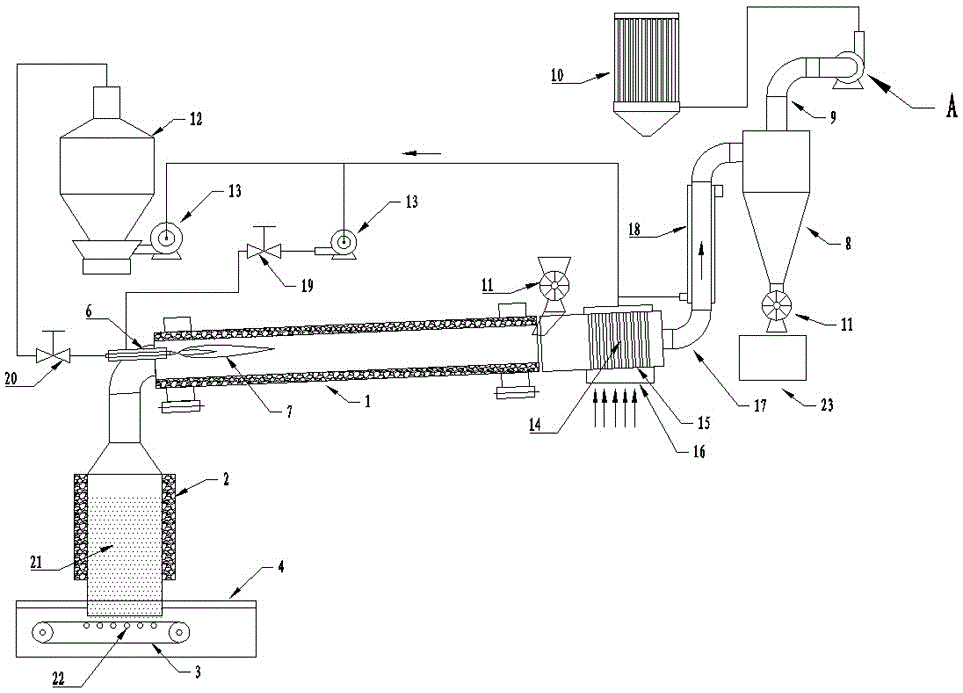

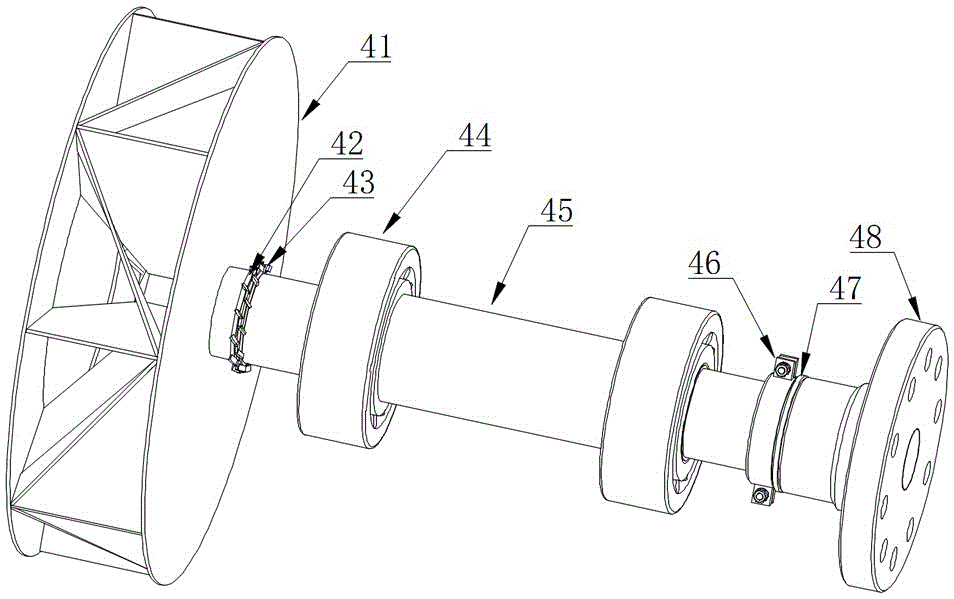

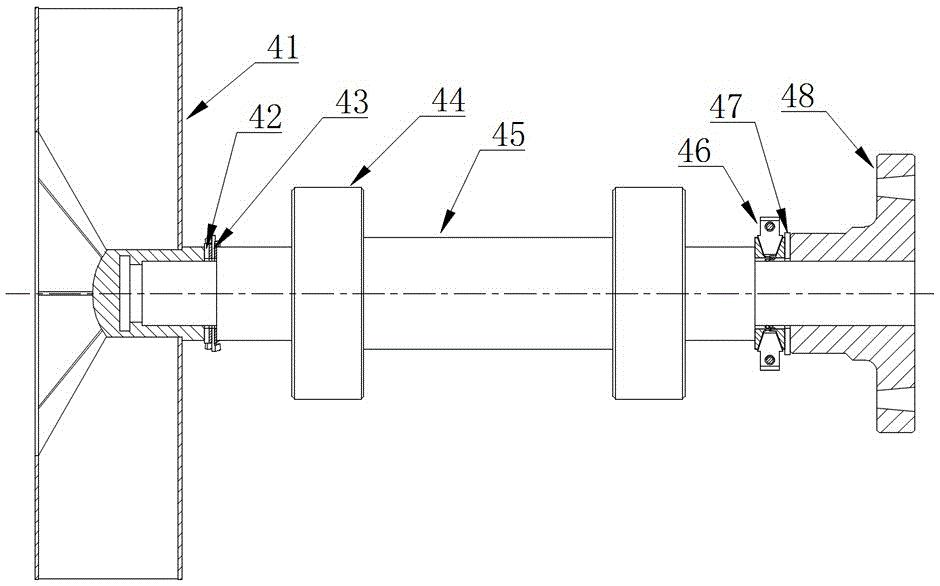

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 The bag dust removal type manganese processing rotary kiln system shown is easy to dismantle, including rotary kiln 1, which is arranged obliquely, with built-in burner 6, and burner 6 is connected to air control valve 19 and gas control valve 20; the high end of the rotary kiln There is an air locker 11 for feeding, and it is connected to the cyclone dust collector 8 through the wing segment 15 and the air pipe 17. The cyclone dust collector 8 is connected to the induced draft fan A, and the exhaust port of the induced draft fan A is connected to the bag filter 10. Below the cyclone dust collector 8 Connect the air locker, and there is a dust collection bucket 23 under the air locker; fins 14 are arranged inside the fin section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com