Heat supply system of biomass boiler

A technology for biomass boilers and heating systems, which is applied in the directions of induced draft, combustion method, fluid heater, etc., can solve problems such as difficulty in disassembly, and achieve the effect of improving disassembly and assembly technology, achieving remarkable effects and enhancing bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail with reference to the accompanying drawings.

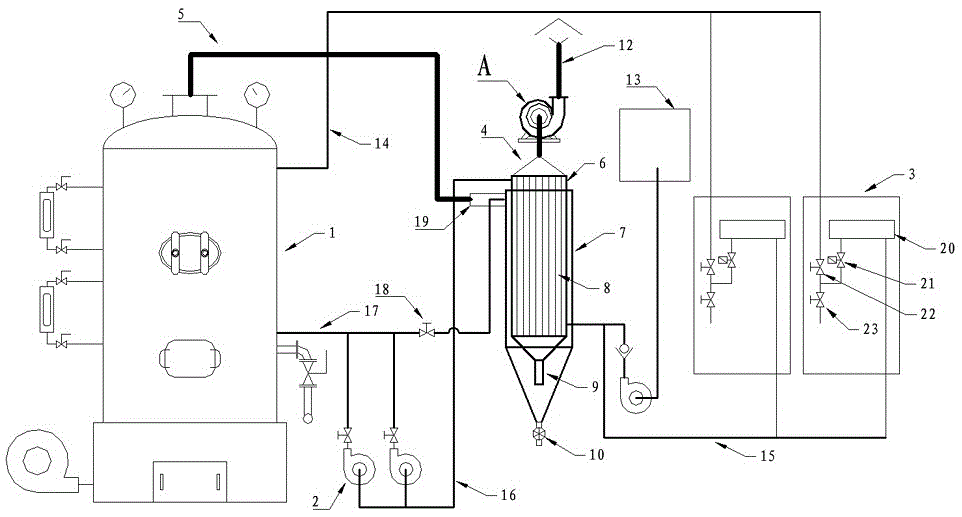

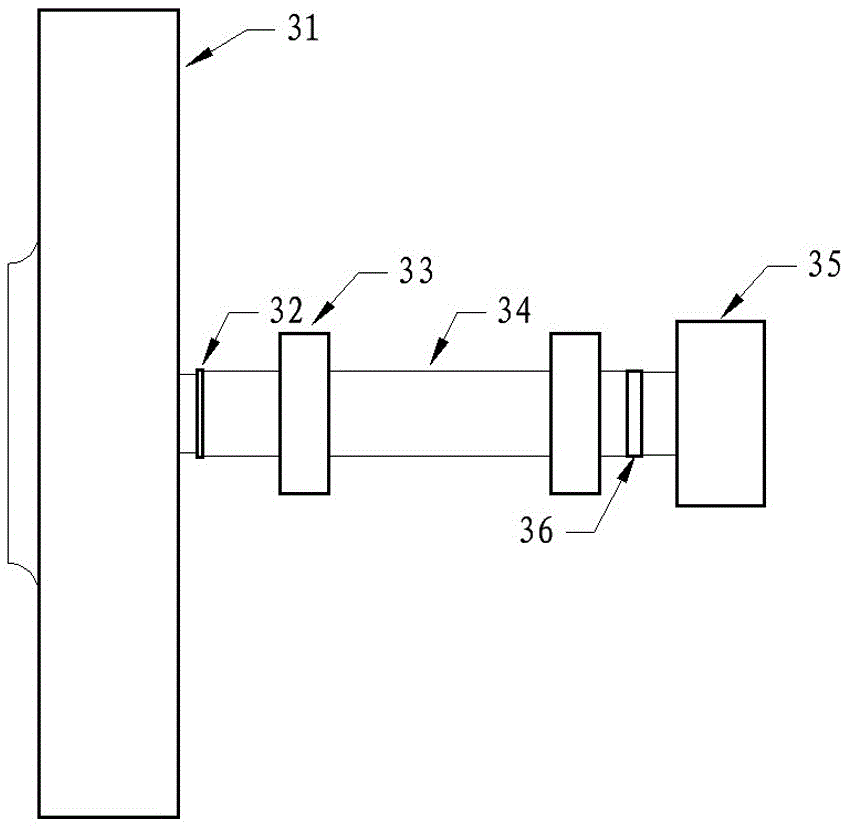

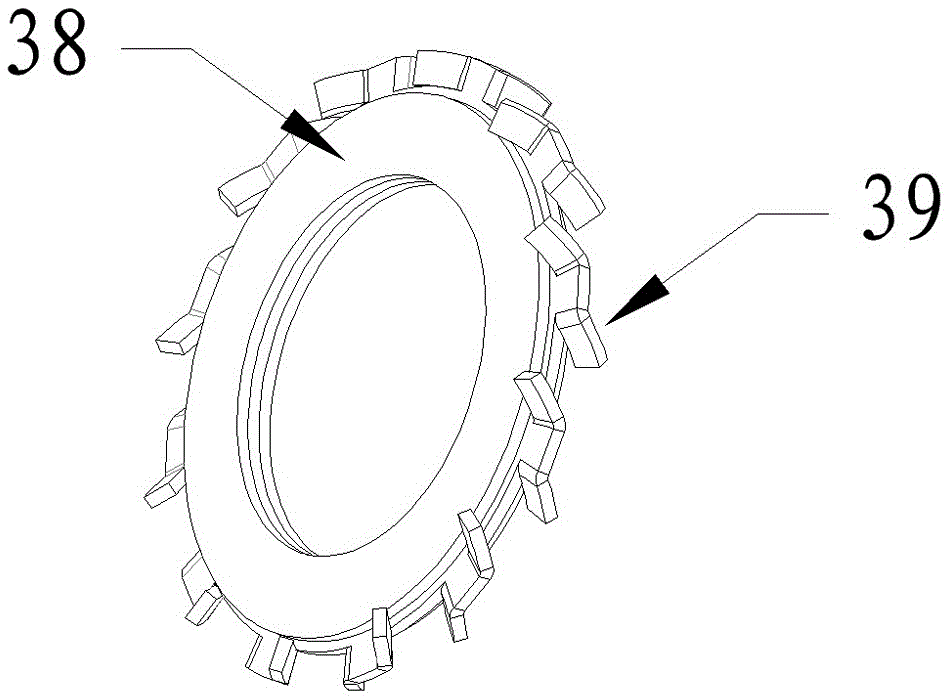

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 The biomass boiler heating system shown includes a biomass hot water boiler body 1, a high-level soft pool 13 provides water to the boiler, a hot water outlet pipe 14 is provided on the boiler body to connect to room 3, and the high temperature exhaust pipe 5 of the boiler body is connected to an induced draft fan A The room 3 is equipped with valves 22, 23 to control the use of hot water bathing, and an electromagnetic valve 21 is added to link the fan coil 20 to work, and the fan coil 20 is connected to the return pipe 15 for confluence and return; the induced draft fan A includes a fan impeller 31, The bearing 33, the fan shaft 34 and the coupling 35, the coupling 35 and the fan shaft 34, and the fan impeller 31 and the fan shaft 34 are all assembled with threads. The thread directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com