Piano string locking peg facilitating string replacement and tuning

A technology for strings and pianos, applied in the field of piano string locking devices, which can solve problems such as easy rusting of pegs, increased difficulty in disassembly, and tightness of easy-to-break connection parts, etc., to achieve novel and practical structure, and string tuning operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

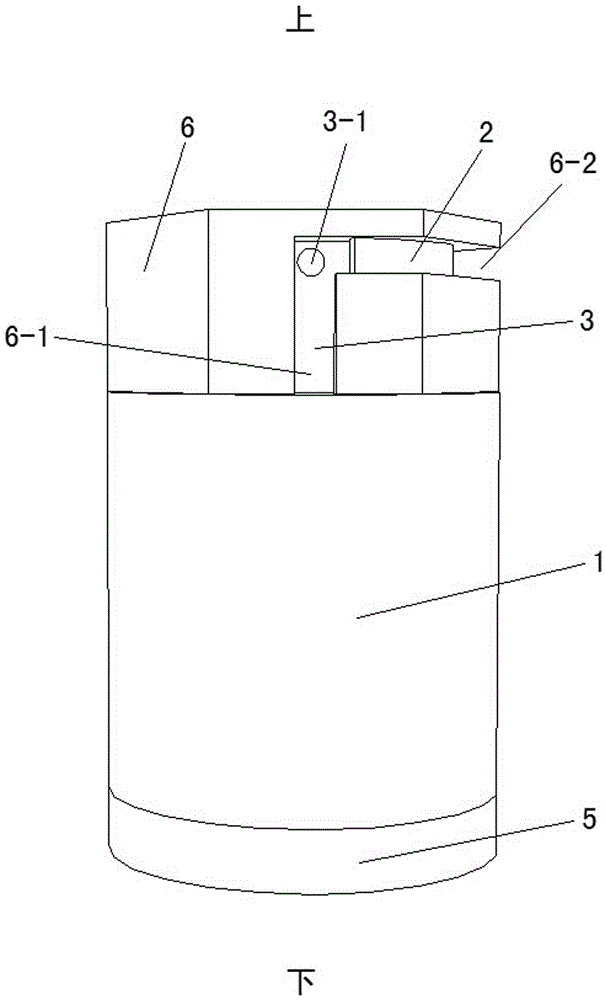

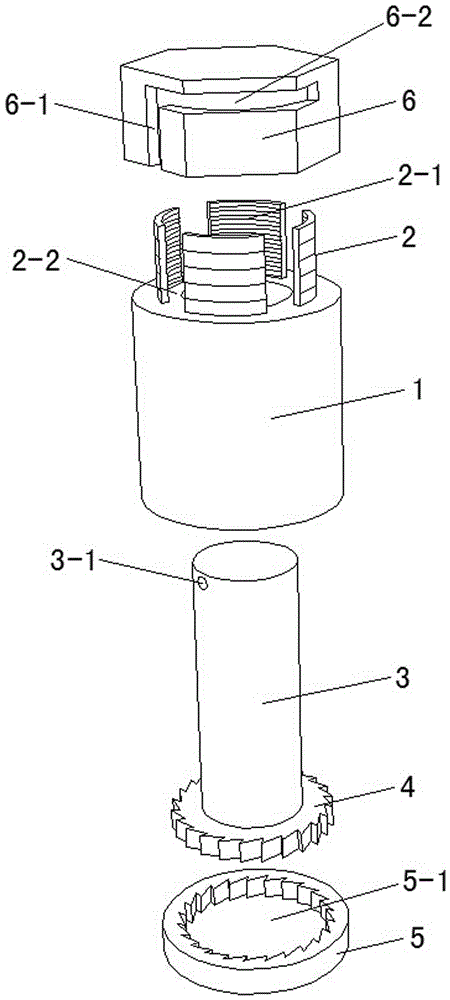

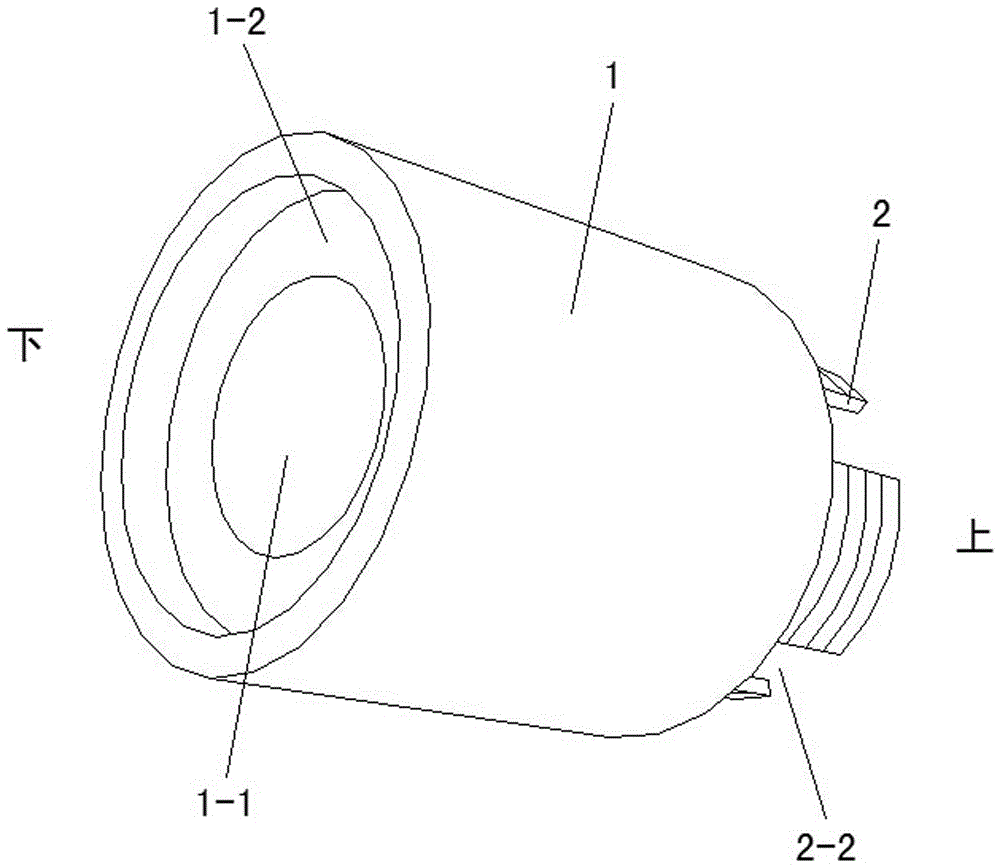

[0013] Specific implementation mode one: as Figure 1~Figure 4 As shown, the present invention discloses a piano string locking nail that is convenient for string changing and tuning, including a cylinder body 1, a fastening cylinder 2, a rotating rod 3, a positioning wheel 4, a chassis 5 and a fastening cap 6, the The cylinder body 1 and the rotating rod 3 are both cylindrical in shape, and the cylinder body 1 is coaxially provided with a small cylindrical inner cavity 1-1 and a large cylindrical inner cavity 1-2, and the small cylindrical inner cavity 1-2 is coaxially arranged. 1 is connected with the upper end surface of the barrel body 1, the large cylindrical inner cavity 1-2 is connected with the lower end surface of the barrel body 1, and the lower end of the rotating rod 3 is inserted into the small cylindrical inner cavity 1-1 of the barrel body 1 and In the inner cavity 1-2 of the large cylinder, the upper end of the rotating rod 3 is located outside the cylinder bod...

specific Embodiment approach 2

[0014] Specific implementation mode two: as figure 2 As shown, this embodiment is a further description of specific embodiment 1. The inner wall of the fastening cylinder 2 is provided with anti-skid lines 2-1, and the wall of the fastening cylinder 2 is provided with a plurality of axially penetrating gaps 3-2. -2, the plurality of gaps 3 2-2 divides the fastening cylinder 2 into a plurality of arc-shaped sheet members. The shrinkage performance and anti-skid ability of the fastening cylinder 2 are increased, so that the strings are fastened more firmly.

specific Embodiment approach 3

[0015] Specific implementation mode three: as figure 2 As shown, this implementation mode is a further description of the second specific implementation mode, and the number of the plurality of gaps 3 2-2 is 3-6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com