Welding and assembling platform of nuclear power station reactor cavity water gate

A platform and level technology, applied in the field of welding and assembling platforms for large stainless steel sluice gates, can solve the problems of increasing manufacturing costs and difficulties, and achieve the effects of preventing displacement, convenient assembly and positioning, and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

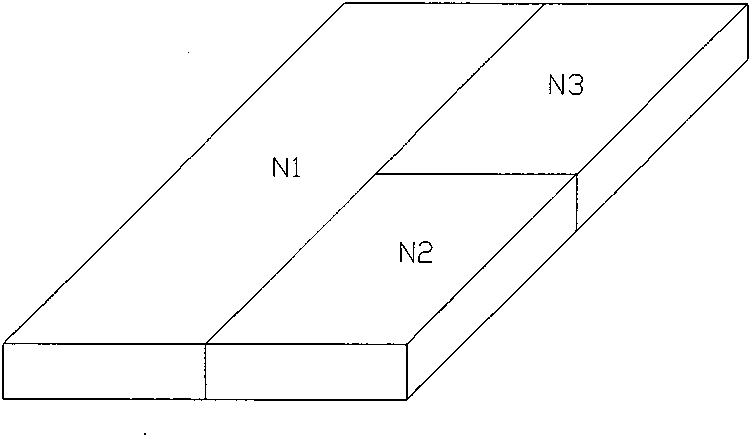

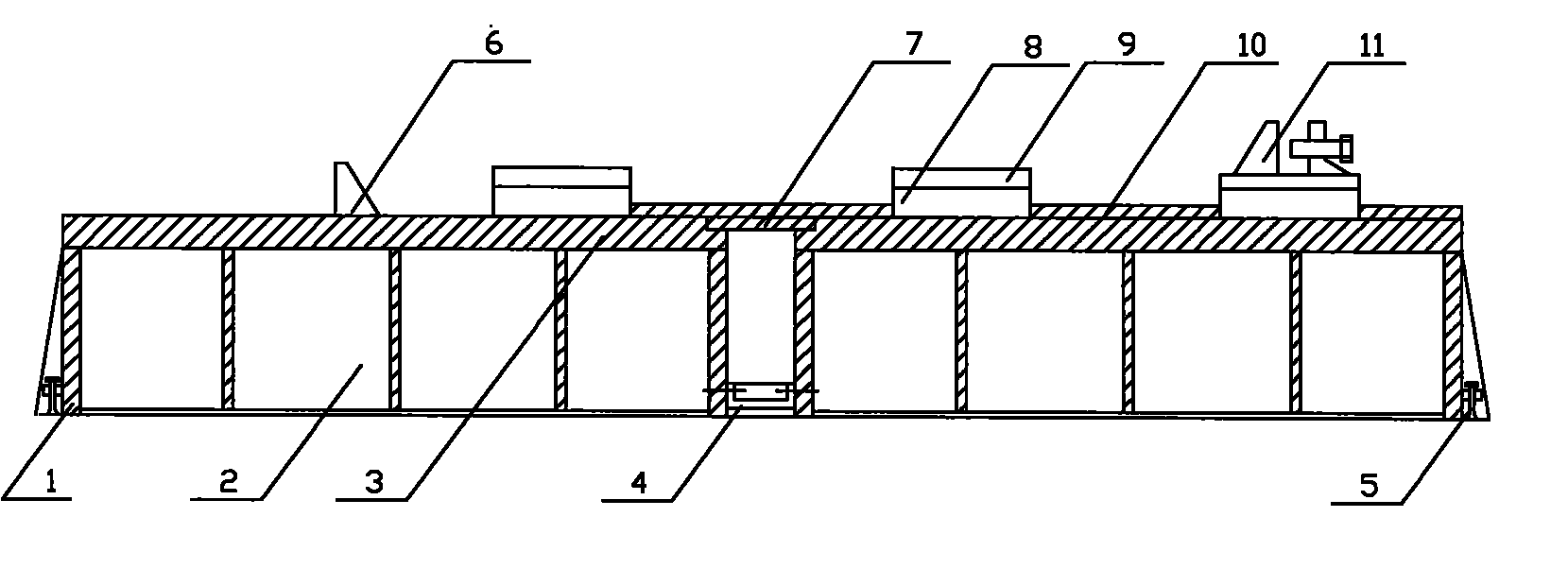

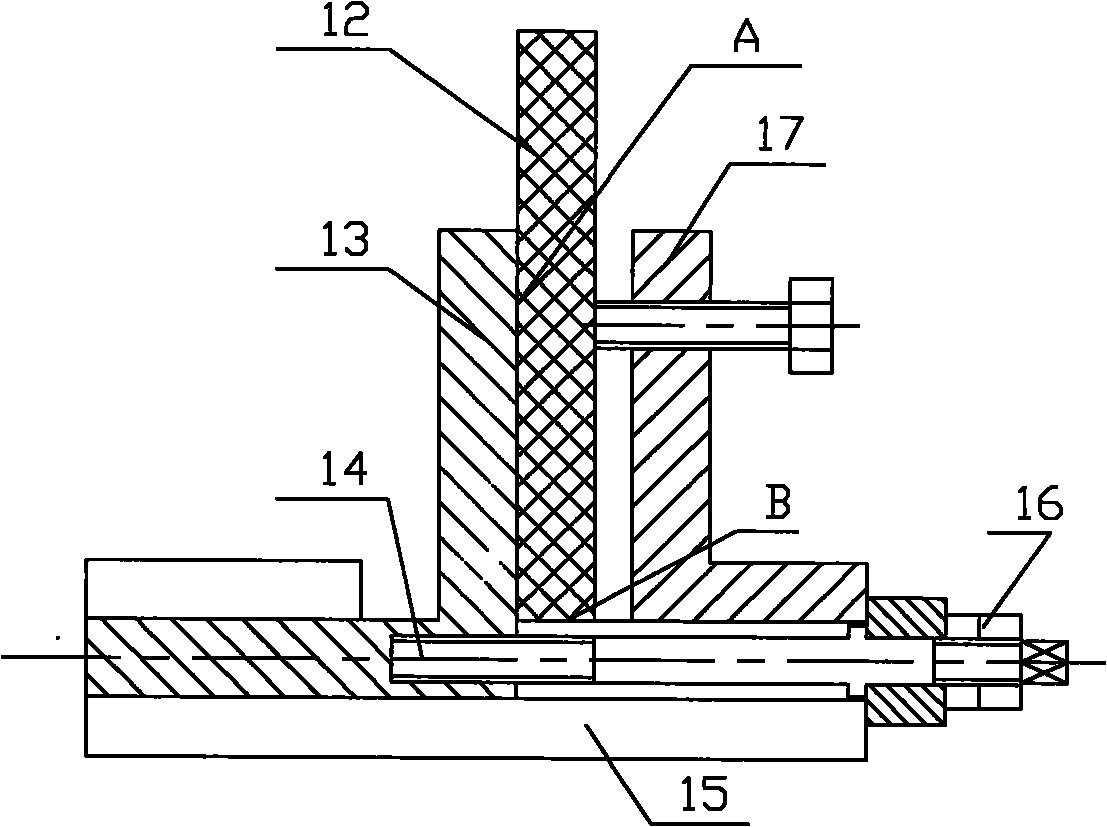

[0011] combine figure 1 , figure 2 , a welding and assembling platform of the present invention includes several small platforms that can be spliced. 1. The support rib 2 and the panel 3, the frame plate 1 is arranged around the lower part of the panel 3, and the lower part of the panel 3 is also supported by the support rib 2, and the connecting device 4 includes a connecting block and a connecting bolt. The surroundings of the small platform frame plate 1 are provided with adjusting legs 5 for adjusting the level of the small platform. A steel plate 7 is arranged at the gap between adjacent small platforms. A stainless steel thin plate 10 is arranged above the panel 3 of the small platform. Several horizontal contour blocks are arranged above the welding assembly platform, and the horizontal contour blocks are composed of a basic horizontal block 8 and a contour block 9 , and the contour block 9 is arranged above the basic horizontal block 8 . The supporting ribs 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com