Compression plate connecting structure of dust-connecting bucket component

A technology of connecting structure and compression plate, applied in the direction of suction filter, etc., can solve the problems of unsmooth airflow, affecting the direction of wind flow, and difficulty in aligning the combined orientation of the assembly gear shaft and the connecting shaft, so as to achieve smooth flow and reduce airflow noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the drawings and examples. The same symbols are used for the same components in the present invention as in the prior art.

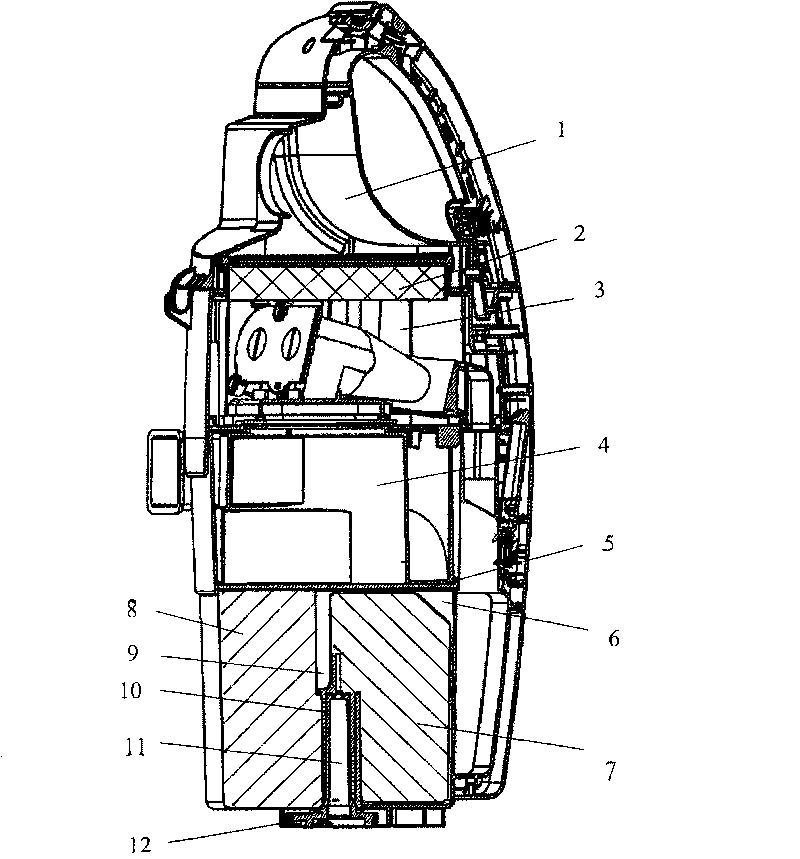

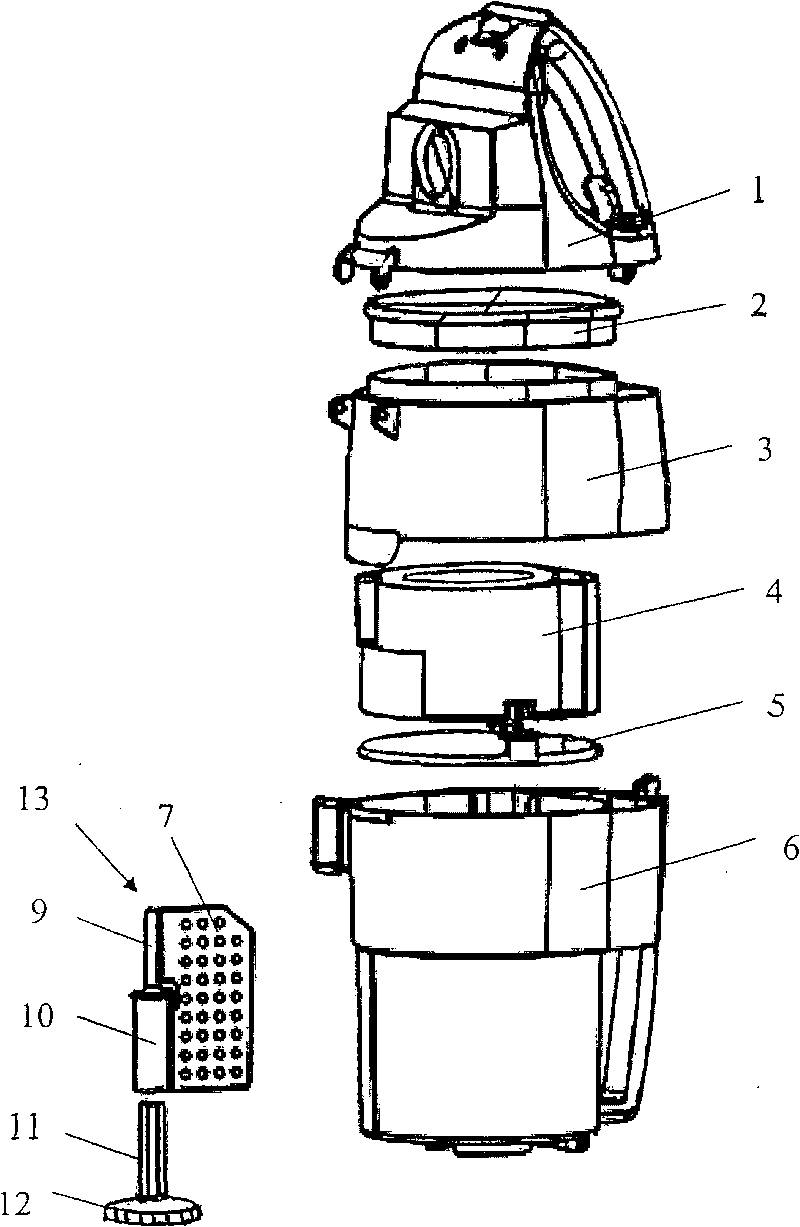

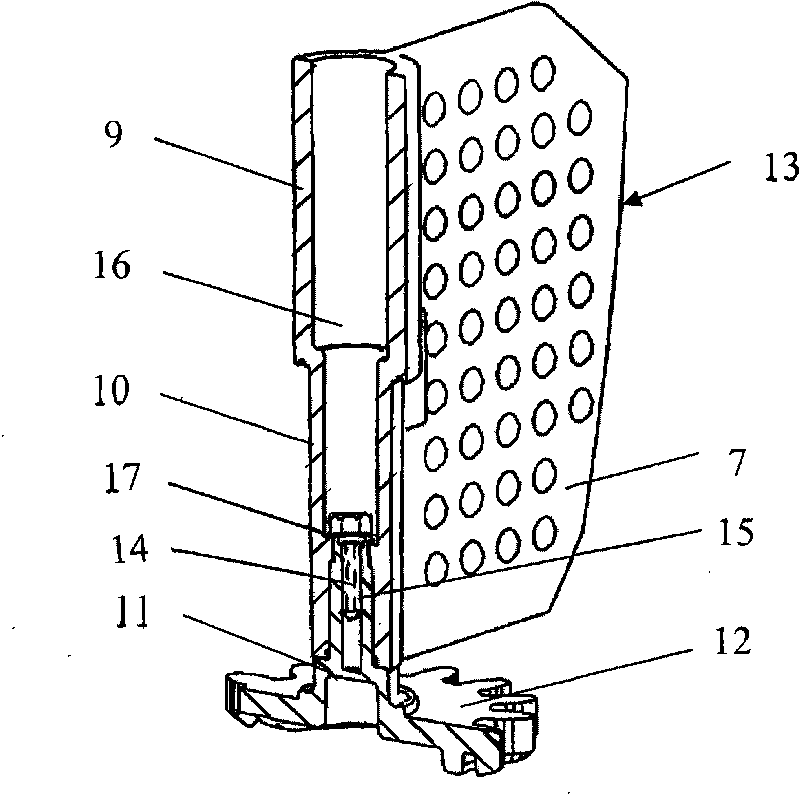

[0039] The compression plate connecting structure of the dust collecting bucket assembly of the present invention, such as Figure 4 , Figure 5 , Image 6 as shown, Figure 4 It is a three-dimensional view of the compression plate connection structure of the present invention; Figure 5 It is a partial sectional view of the connection structure of the compression plate of the present invention; Image 6 It is a three-dimensional view of the compression plate of the present invention; Figure 7 It is a three-dimensional view of the gear shaft and the gear of the present invention.

[0040] The compression plate connection structure 19 of the dust collection barrel assembly of the present invention is composed of a compression plate 7 and a column 20 affixed to one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com