LED (Light Emitting Diode) lamp

A technology of LED lamps and LED lamp beads, which is applied in the direction of lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of damaging LED light sources, inability to form vertical convection up and down, and unattractive shape of the lampshade, etc. Beautiful, smooth flow, best heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

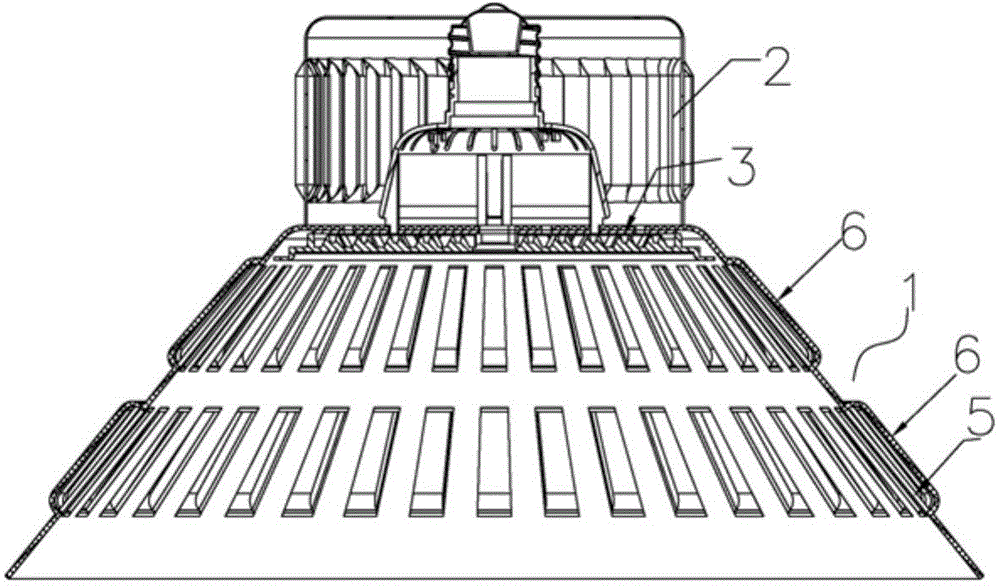

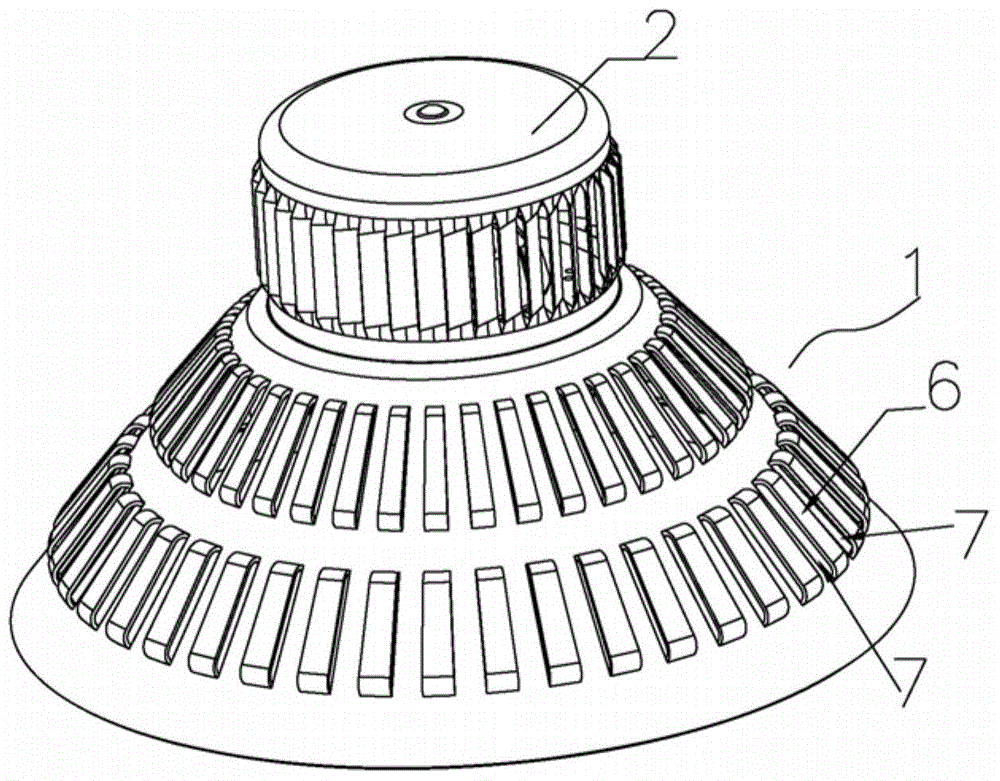

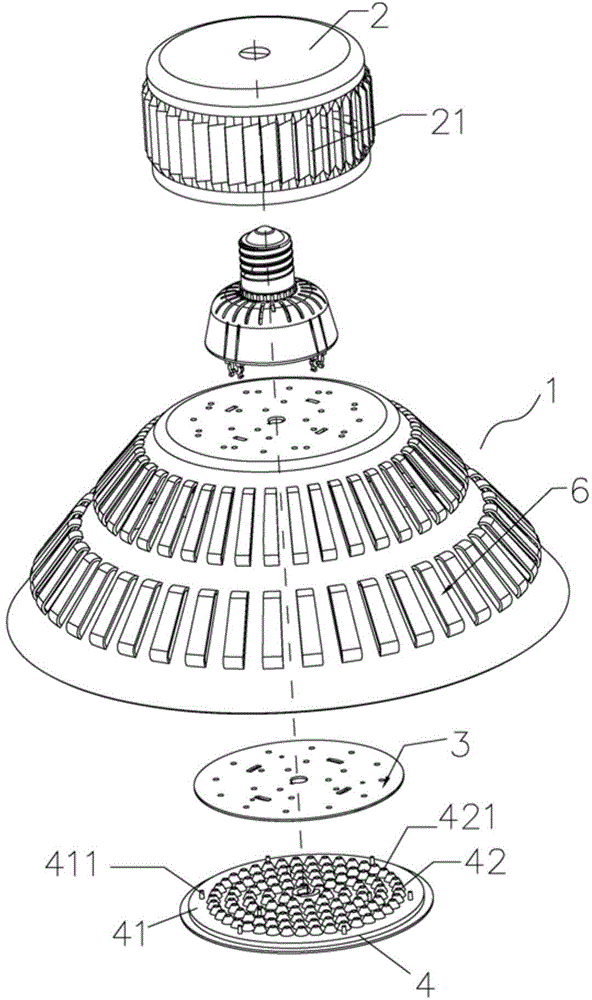

[0030] Such as figure 1 As shown, an LED lamp includes a lampshade 1 , a power supply box 2 and an LED lighting assembly. The LED lighting assembly includes an aluminum substrate 3 , LED lamp beads (not shown in the figure) and a lens 4 . The lampshade 1 is in the shape of a truncated cone with a lower opening, and the lampshade 1 has elongated cooling holes 5 distributed uniformly in a circle. Holes 5 form a cooling hole group;

[0031] It also includes a dust-proof diversion cover 6, the shape of the dust-proof diversion cover 6 is adapted to the shape of the heat dissipation hole 5; the upper end of the dust-proof diversion cover 6 is connected to the upper end of the heat dissipation hole 5, and the lower end is connected to the heat dissipation hole The lower end of 5 is connected, the circumferential surface of the dust-proof guide cover 6 is adapted to the circumferential surface of the lampshade 1, and two guide gaps 7 are formed on both sides between the dust-proof g...

Embodiment 2

[0040] Such as Figure 5 As shown, the whole of the lampshade 1 is in the shape of a lower opening, the four sides of the lampshade are isosceles trapezoidal, and the upper and lower bottom surfaces are rounded rectangles;

[0041] The elongated heat dissipation holes 5 are evenly distributed and arranged on the side of the lampshade in a rectangular shape, and the length direction of the heat dissipation holes 5 is along the bus bar of the lampshade 1, and the heat dissipation holes 5 distributed uniformly in a rectangle form a heat dissipation hole group;

[0042] The power supply box 2 is in the shape of a square with a lower opening. The peripheral surface of the power supply box 2 is provided with strip-shaped flow guide and heat dissipation holes 21 .

Embodiment 3

[0044] Such as Image 6 As shown, there are four lampshades 1, and two adjacent lampshades 1 are arranged up and down along the axial direction of the lampshade;

[0045] The lampshade 1 of the lower part is embedded in the lampshade 1 of the upper part, the top plate of the lampshade 1 of the lower part is attached to the top plate of the lampshade 1 of the upper part and the diameter of the top plate of the lampshade 1 of the lower part is smaller than the diameter of the top plate of the lampshade 1 of the upper part, and the upper and lower lampshades 1 Radiation gap 8 is arranged between the circumferential wall plates.

[0046] The lower end of the upper lampshade 1 is located above the lower end of the lower lampshade 1 .

[0047] The heat dissipation method of LED lamps is as follows: when the LED lamp beads work, a large amount of heat is generated, which is transmitted to the cylindrical lampshade 1 with the lower opening through the aluminum substrate. The dust-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com