Automatic guide trolley

A technology for automatically guiding trolleys and car bodies. It is used in motor vehicles, transportation and packaging. It can solve the problems of high fatigue and easy damage of elastic parts, and achieve the effect of precise movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

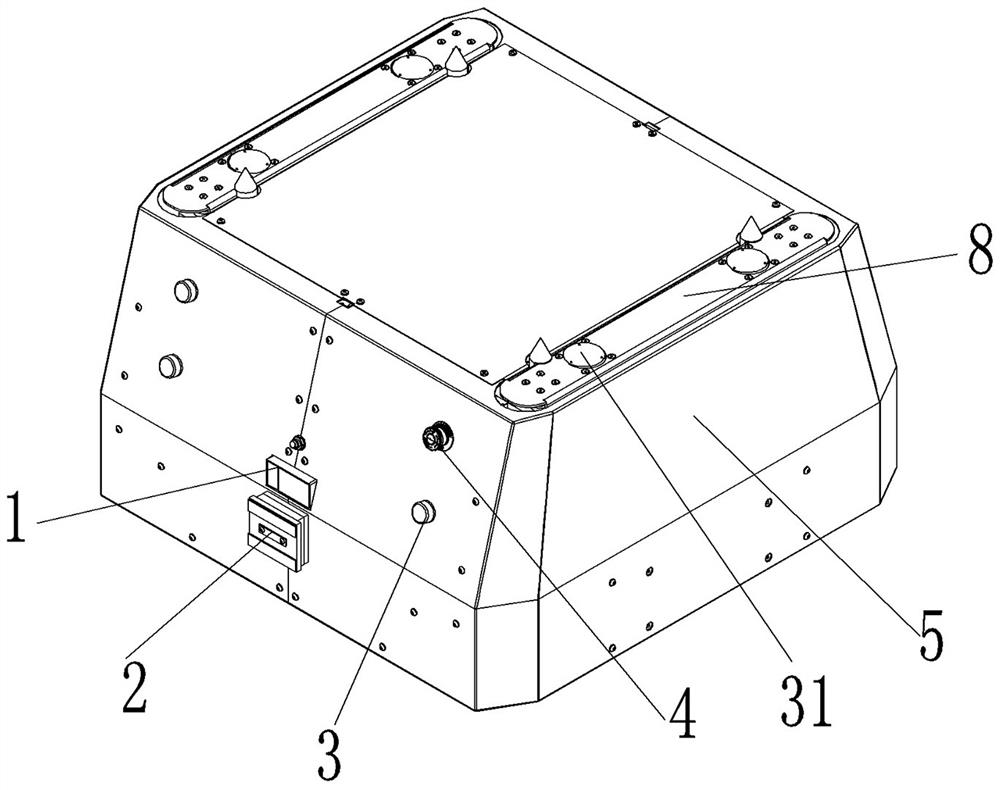

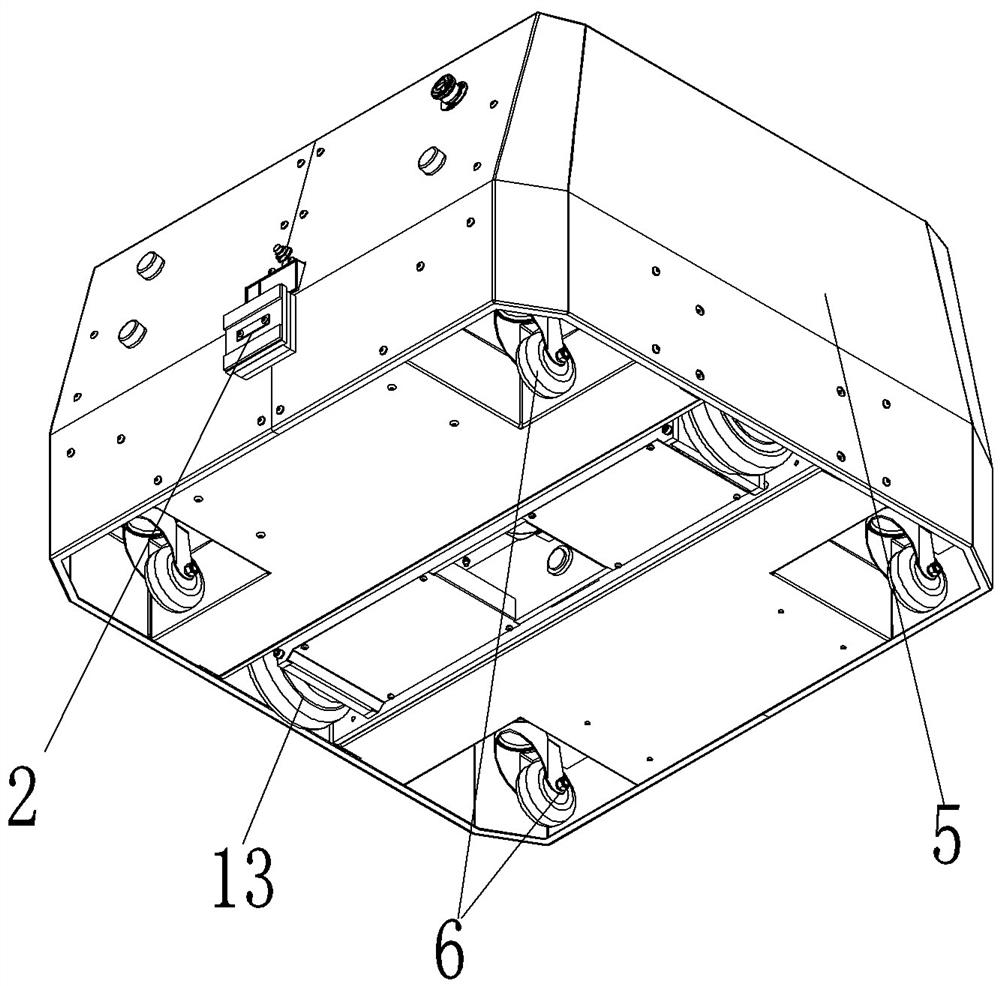

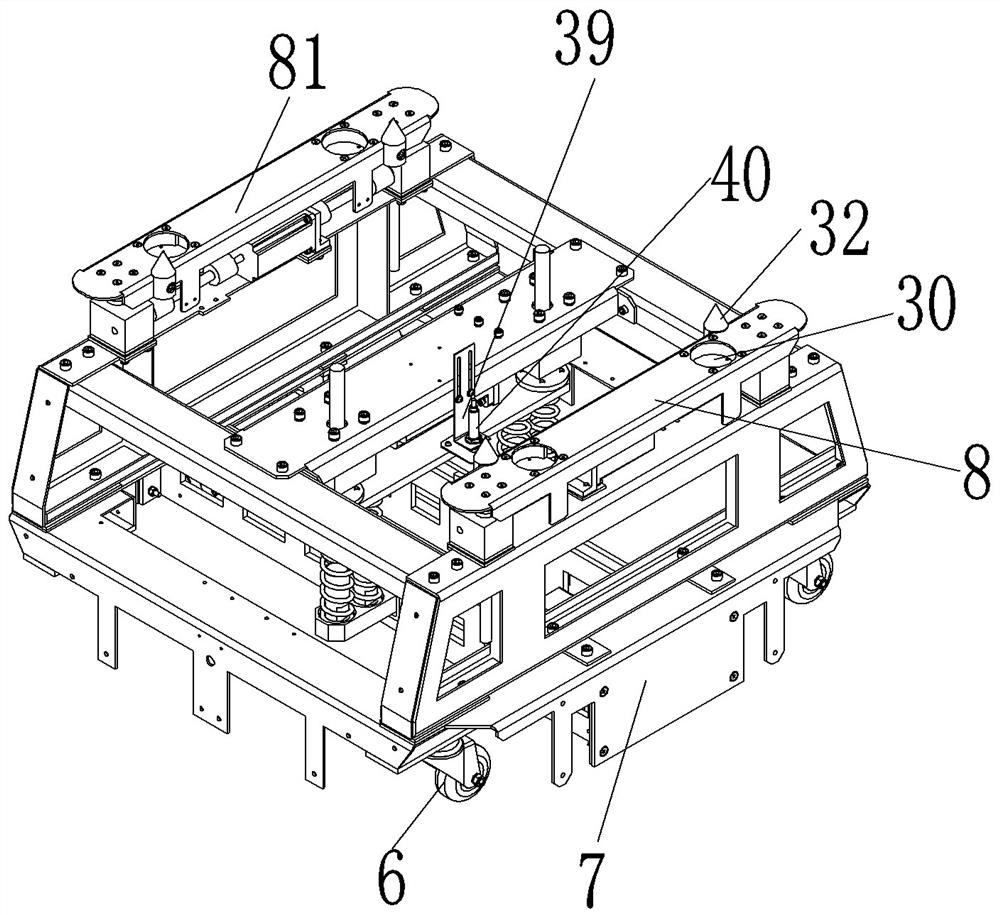

[0053] like Figure 1 to Figure 10 As shown, the automatic guided vehicle includes a car body 7, a casing 5 is arranged outside the car body 7, and traveling wheels are installed on the lower part of the car body 7 to realize the movement of the car body.

[0054] The top of the car body 7 is provided with a lifting platform 8 for lifting up to carry items to be transported. Specifically, the output part of the lifting platform is two strip-shaped supports 81. There are elongated holes for the passage of the strip supports 81 . Moreover, to facilitate positioning and assembly, a tapered positioning post 32 is provided on the bar-shaped support 81 for positioning and assembling with the corresponding tray.

[0055] In addition, an installation slot 30 is provided on the strip support member 81 , and a load cell 31 is provided in the installation slot 30 to weigh the item to be transported when lifting the heavy object.

[0056] An obstacle avoidance sensor switch 1, a chargin...

Embodiment 1

[0078] The wheel bracket in Embodiment 1 includes a driving wheel mounting frame and a support member, and both of them can rotate relative to each other, which makes the driving wheel mounting frame not only float up and down, but also rotate and adjust around the circular sleeve. The difference between the automatic guided vehicle provided in this embodiment and Embodiment 1 is that in this embodiment, the wheel bracket is a frame structure, the driving wheel is directly installed on the wheel bracket, and the wheel bracket can only move up and down along the car body. Floating, cannot be adjusted by rotation.

specific Embodiment 3

[0080] Compared with Embodiment 1, the difference between this embodiment and Embodiment 1 is that the lifting drive mechanism in this embodiment adopts an electric push rod mechanism instead of the screw elevator in Embodiment 1, but attention should be paid to the support of the electric push rod mechanism. strength.

[0081] In addition, in this embodiment, the support includes a front support shaft and a rear support shaft arranged at intervals along the front-to-back direction. In other embodiments, only one support may be provided. At this time, the front and rear ends of the support are respectively Hinged on the front and rear side plates of the drive wheel installation frame, the support plate can be located between the front and rear side plates, or only one support plate can be provided. At this time, a rectangular hole is arranged on the support plate, and the front and rear ends of the support The part in between is a rectangular shaft section, and the rectangular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com